One of the most common problems in functioning heating systems is airing, which leads to uneven heating of radiators or underfloor heating pipes. To combat this negative phenomenon, air vents for heating systems operating in different modes are widely used.

Using an air vent installed at the inlet of the heat exchange devices, air is released from the heating circuits. There are various types of air vents on the market, in order to understand the wide range of models and choose the right device for an individual heating system, you should know the operating principle, existing types and design features of manufactured air vents.

Rice. 1 Air vents

The influence of air on the heating system

The functioning of the heating system is based on the circulation of heated water with the release of part of the heat into the radiators to heat the room. If air enters the internal part of the system (the process is called airing), a disruption in the circulation of the coolant occurs. The system responds to airing as follows:

- When the coolant circulates, noises are clearly audible, which not only creates discomfort for residents, but is also a symptom of pipeline vibration, as well as backlash in connections. In some cases, vibrations result in the destruction of welded joints with obvious unpleasant consequences.

- Air pockets form in the circuits. This happens especially often in non-residential premises where there is no regular temperature control. The result of traffic jams is defrosting the system.

- Deterioration of circulation or its complete cessation. Under conditions of slow circulation, the efficiency of the system decreases and fuel consumption increases.

- The development of corrosion processes as a consequence of air penetration into internal metal parts. The result of corrosion is a reduction in the operating life of equipment.

How does a steam air vent (thermostatic steam trap) work?

The operating principle of a thermostatic steam trap is based on the temperature difference between steam and condensate. A capsule with a disk filled with a special composition that expands when heated is responsible for opening/closing the diverter valve. Below it is a saddle that acts as a locking mechanism. In a cold state, there is a gap between the disk and the seat through which air, non-condensable gases and the condensate formed escape. As soon as the steam-condensate system warms up, the disk lowers onto the seat and prevents steam from escaping.

Main types

Air bubbles contained in the coolant begin to accumulate in certain areas of the heating system and in the radiators. The bubble that appears continues to be replenished with new portions of air and forms a plug that blocks the movement of the coolant in this place. As a result, nearby heating radiators cool down. To remove air, 2 types of bleed valves are used:

- automatic air release valve;

- Mayevsky manual crane.

Mayevsky manual crane

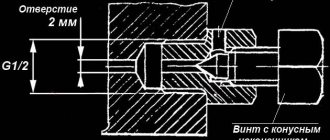

The design of the Mayevsky valve is very simple to understand. At the ends of the housing with an external threaded connection ½″ or ¾″ there is a hole with a diameter of 2 mm. This section is covered with a screw with a cone-shaped tip. There is a small hole on the side of the faucet that is designed to release air.

The modernized air release valve has a rotating plastic sleeve, inside of which there is a channel for exhaust. Convenience is that the position of the reset hole can be adjusted by turning the plastic sleeve. A mechanical valve for bleeding air from the heating system works according to the following principle:

- When the heating is running, the shut-off screw is screwed in and the cone securely closes the hole.

- If it is necessary to get rid of the air lock, the screw is unscrewed several turns. Under the pressure of the water in the thermal system, the plug comes out through the hole, then passes into the drain channel and moves outward along it.

- First, clean air comes out, then along with the coolant. The screw is tightened when clean water begins to come out of the channel.

In this video you will learn the pros and cons of the air valve (air vent):

Automatic air vent

It is easy to understand that this valve operates without human intervention. The device has the form of a vertical brass barrel with a G ½″ threaded connection, where a plastic float is located, which is connected to a spring-loaded valve to remove the air lock. The operating principle of an automatic air valve for heating is as follows:

- When the heating system is running, the chamber in the housing is filled with water, which lifts the float upward. The spring-loaded valve is in the closed position.

- Taking into account the accumulation of air in the upper part of the valve, the water level decreases and the float lowers.

- When the level drops to its maximum, the mass of the float will completely compress the spring, thereby opening the valve. As a result, air begins to escape.

- Due to excessive pressure in the thermal system, the coolant will displace the air from the valve, water will take this place and bring the float back into working condition.

According to their design, automatic valves for venting air from the heating system can be with an angular or straight connection. Some manufacturers make the discharge hole from above, others - to the side. For the consumer, these differences do not play a significant role, but for an experienced plumber they can tell a lot. As practice has shown, equipment with side discharge is more reliable in operation than valves with top outlet.

The design of automatic valves is constantly being improved. Leading manufacturers provide these elements with various functions:

- Protection against water hammer using a special plate (installed at the entrance to the chamber).

- Installing a mini-valve into the radiator plug.

- Possibility to unscrew the air vent for repairs without emptying the heating system. This is achieved thanks to the presence of an automatic shut-off spring-loaded valve installed on the inlet fitting. If the plumber unscrews the element, the spring is aligned and the sealing washer blocks the passage.

Automatic air vent – operating principle, overview:

Finding a suitable installation location in the system

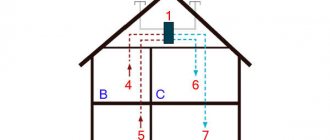

Taking into account the operating principle of an automatic heating air vent, it is usually used in the following areas:

- The highest point of the heating circuit (tops on vertical risers, etc.). This is where the internal air of the system usually accumulates.

- End areas of dead-end pipeline lines.

- Boiler piping safety group. Boilers using solid fuels especially need this. In this case, an automatic air bleeder is included in the set of instruments, which also contains a pressure gauge and an emergency valve. Thanks to the air vent, air is released as the coolant fills the water jacket of the boiler. In addition, the device increases the rate of water drainage when the heat generator is disconnected from the general system.

- Together with a circulation pump, which allows you to optimize its operation. This option is used only for those models of pumping equipment whose design provides for the possibility of installing an air vent. If the coolant is pumped with air, there will be a noticeable deterioration in the quality of the pump, even to the point of stopping it. All this leads to rapid wear of the impeller and bearings. Using a bleeder, you can also remove steam from the coolant if it overheats.

- Areas of the heating circuit where there is constant airing of the system. One of the reasons for such phenomena is an incorrectly calculated angle of inclination of the pipe.

- Heating appliances.

Ball

Sewage flooding is especially likely in high-rise buildings, where several apartments are located on one vertical pipe. Even one plastic bag may be enough to clog the riser, and then yes, not finding its way, will rush back, splashing out of all the drain holes. This situation is especially likely in old houses, where the pipes are covered on the inside with thick crusts of deposits.

The risk of backflow of waste water is especially high in apartments on the ground floor. Often at night in such apartments it is necessary to plug the drains with rags, plugs and other improvised plugs. But if valves are installed on the first floors, water can break through on the second floor. Up to the third floors, the pressure is usually not enough, and if it is strong enough, it will simply destroy the blockage and the water will go into the pipe.

So, it’s worth installing a check valve if:

- Your apartment is located on the first or second floor.

- You live in an individual home: a cottage, a dacha, a private house.

- The house was built a long time ago and there has been no major repair of the sewer system or replacement of risers.

- According to neighbors, there are frequent cases of sewer blockages in the house.

In this case, the small costs of purchasing and installing protective devices will pay off handsomely, allowing you not to worry about sudden costs and hassle.

If your home has a common riser valve installed, it can reduce the risk of flooding. But in problem apartments it is better to install separate valves on each drain to be completely sure.

Device

In 2022, there are many options for such a unit. They differ in materials, sizes and shapes, locking methods and many other parameters. But all types of valves have the same purpose - to cut off sewer water in the pipe that rushes sharply in the opposite direction.

Almost any design has the following elements:

- The pipes through which drained water enters and leaves the valve.

- A handle that closes the valve forcibly. It can be used when cutting off drains at night, or when trying to unclog a sewer system.

- A removable cover that allows you to inspect the condition of the valve and, if necessary, clean its parts from contamination.

- Locking mechanism. A ball valve is a rubber ball, but membranes, flaps and other devices can also be used.

The valve will not work if the “input” and “output” are reversed. Typically, the direction of movement of the drains in the valve is shown by an arrow marked on the body. Take this into account during installation!

Main types

First of all, valves vary in diameter. In the standards for sewer installation, left over from Soviet times, a diameter of 110 mm is established for risers, and all other pipes have a diameter of 50 mm. Today, non-standard options have appeared, for example, with a diameter of 75 mm, but they are significantly less widespread.

Various materials are used to make shut-off devices. They can be either metal (bronze, brass, stainless or carbon steel) or polymer (PVC, polyethylene). Each option has its own advantages and disadvantages:

- Metal products are significantly more expensive. They are durable, but require attention to their condition and periodic maintenance.

- Plastic valves are cheaper. They practically do not corrode. But the mechanical strength of such structures is less.

The design of check (or fan) valves also differs. Here are the most common options:

- The ball valve has a very simple design: a rubber ball is loosely located in the pipe, the diameter of which is slightly larger than the overall diameter of the pipe. When the liquid moves in the forward direction, the ball moves into a special chamber, and when it moves in the opposite direction, the ball, picked up by water, tightly plugs the neck of the pipe. Thanks to such a simple design, there is simply nothing to break in this device.

- Wafer device. The most compact option. This valve is convenient for installation in confined spaces. But if it fails, you will have to disassemble part of the system in order to repair or replace the faulty unit.

- Lift and rotary valves have spring-loaded flaps in their design. Such devices are relatively large, heavy and not cheap. The advantage is the ability to easily disassemble for cleaning, adjustment and minor repairs.

The choice of a specific type of device depends on the budget allocated for repairs, installation location, type of pipe and existing conditions.

How to properly install an air valve for sewerage, read the article: here

How the device works

An air valve (or several) is installed in the heating system, in places where air bubbles are most likely to accumulate. This prevents the formation of a large traffic jam and the heating operates uninterruptedly.

Mayevsky crane

Such devices are named after the name of their developer. The Mayevsky tap has a thread and dimensions for a pipe with a diameter of 15 mm or 20 mm. It's structured simply:

- There are 2 through holes made in the body of the valve body, which in the open position of the Mayevsky tap communicate with the heating system.

- These holes are closed by a threaded screw with a conical tip.

- Air is released through a small (2 mm) hole directed upward.

In order to bleed air from the system, unscrew the screw 1.5-2 turns. The air escapes with a whistle as the communications are under pressure. The end of the air plug exit is characterized by a drop in pressure and the appearance of water.

On the market you can find several varieties of the Mayevsky tap, which are identical in design, but differ in the way they regulate the shut-off screw. There are:

- with a convenient handle for unscrewing by hand;

- with a regular head for a flat screwdriver;

- with a square head for a special key.

For an adult, the principle of unscrewing the locking screw does not matter. However, in a house where there are children, it is safer to use devices that should be unscrewed with a special tool. By unscrewing a regular tap with a comfortable handle, a child can be scalded by boiling water.

Automatic crane

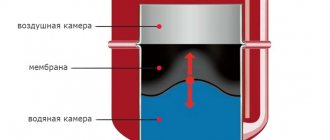

The automatic air release valve is designed on the principle of a float chamber, the design includes:

- vertical housing with a diameter of 15 mm;

- float inside the housing;

- a spring valve with a cover, which is connected and adjusted by a float.

The automatic air valve for the heating system operates without human intervention. In normal condition, when there is no air in the system, the float is pressed by the pressure of the liquid filler to the valve cover. The lid is tightly closed.

As air accumulates in the valve body, the float moves down. As soon as it drops to a critical level, the spring valve opens and bleeds air out. Under the pressure of the carrier in the system, the space is again filled with liquid. The float rises, closing the spring valve cover.

When there is no coolant in the communications, the float lies at the bottom of the valve. As the system fills, air comes out of the tap in a continuous stream until the coolant reaches the float.

The following configurations of automatic air valves for heating are distinguished:

- with vertical air discharge;

- with side air discharge (through a special jet);

- with bottom connection;

- with corner connection.

For an amateur, the design features of an automatic crane do not matter. However, for a professional there is a difference in choosing between devices.

It is believed that:

- a device with a jet and a side hole is more reliable in operation than an automatic valve with vertical air discharge;

- a bottom-mounted valve traps air bubbles more effectively than a side-mounted valve.

If the design of the Mayevsky crane has not undergone changes for many years, the design of automatic valves is constantly being improved and supplemented.

Manufacturers offer automatic valves with additional devices:

- with a membrane to protect against water hammer;

- with a shut-off valve for easy dismantling of the device during the heating season;

- mini valves.

Automatic heating air valves require frequent inspection and cleaning. The undoubted advantages of these devices include the ability to install them in hard-to-reach places.

Installation recommendations

Regardless of the type of automatic air intake for heating, you need to ensure that the exhaust cap faces up during installation. Bleed valves in systems are usually installed after ball valves or shut-off valves. An exception to the rule is the boiler safety group: secondary intermediate fittings are not used in this case.

Thanks to the shut-off check valve, it becomes possible to carry out maintenance or replacement of the air vent without emptying the entire heating system. Therefore, having such a device is very convenient. Only wrenches are suitable for installing an automatic bleeder: they, unlike adjustable ones, allow you to measure the effort required to screw the fastener. During installation work, it is not recommended to hold the device by the body to avoid damage. For these purposes, the design provides a hexagon at the bottom of the cylindrical chamber.

Installation of an automatic air vent

Before installation, a comprehensive check of the device is performed. The housing must be free from dirt, rust and scale, if any. Next you need to do the following:

- The most convenient area for placing the air vent is calculated. It is advisable to think it over at the design stage of the heating system. The installation point must be as high as possible, must collect air and gases from all circuits and at the same time be accessible for maintenance.

- Using a shut-off channel or other connecting fittings (if necessary), tighten the automatic air vent valve so that the sealing material ensures a tight joint. If a corner or radiator device is used, then the working part of the housing with the chamber and float must be facing upward for unhindered air release.

- The air vent can only be tightened with an open-end wrench - it is not advisable to use lever wrenches.

- The tightness of the connection is checked, after which the cap at the top of the device body is unscrewed. Next, you can fill the branch with coolant.

Causes of air

The logical question is: how does air get into the heating system if it is completely sealed?

There can be many reasons for this phenomenon:

- High blood pressure. Water contains not only magnesium and calcium, but also oxygen. The volume of oxygen depends on the pressure level in the system. As pressure increases, the concentration of oxygen in water increases.

- Violation of requirements for pipe slopes during installation work.

- Incorrect filling of the pipeline, leading to air congestion. Water should be supplied slowly while air is pumped out of the batteries, right? otherwise, the formation of bubbles is inevitable, which causes airing of the heating system. The general rule is: the more branches a system has, the slower its filling should occur.

- Diffusion. This phenomenon is a process during which the ability of molecules of one substance to penetrate between the molecules of another is realized. In the described case, we mean the penetration of oxygen molecules between the molecules of polypropylene or polyethylene. To prevent diffusion, special coatings are applied to the pipe material.

- Insufficient connection density between system elements.

- Faulty or missing air vents.

- Carrying out repair work during which depressurization occurred.

- Corrosive processes leading to violation of the tightness of equipment.

The above factors do not exhaust the reasons that cause air in the heating system, but they are the most common.

Design and operating principle

The automatic air valve for heating systems has a simple and reliable design. The hollow metal body is equipped with a connecting pipe, which is located at the bottom or side, depending on the version of the product. In the inner chamber of the device there is a float made of polymer resin. The float is connected by a lever rod to a needle valve that closes the hole in the upper part of the air vent cover.

When removing the plug using a manual valve, you need to control the process in order to shut off the device in time - the air will be completely released when a trickle of coolant flows through the vent. Installing an automatic air vent eliminates the hassle of servicing the heating system.

The operating principle of the device is based on the use of gravity - a hollow float is lighter than water, but heavier than air. In the normal state, the air extractor is filled with coolant, due to which the float is in the upper position, pressing the needle valve. Over time, the coolant is displaced from the internal chamber of the device by accumulating gas.

As a result, the float falls down under the influence of gravity, opening the valve slightly. The accumulated air under the pressure of the liquid in the heating system comes out through the hole in the drain body, and the chamber is again filled with coolant, which raises the float, automatically closing the valve.

Float ventilators serve to remove air pockets and also help speed up the draining of coolant from the system during maintenance or repair work. Due to a decrease in the coolant level in the circuit, the valves automatically open, and the air entering through them causes the liquid to drain faster.

Reasons for airing the system

Air in the heating circuit negatively affects the function and durability of the system. Oxygen reacts with steel and causes corrosion. Air locks interfere with the normal movement of the coolant, blocking the heating of the upper part of the radiators or entire heating devices. The presence of air bubbles in the coolant leads to premature wear of the moving parts of circulation pumps.

Air-filled heating system

There are several reasons for the formation of air jams

:

- Using water from a water supply system as a coolant that has not undergone special treatment to remove dissolved air. When heated, gases leave the liquid medium and accumulate at the upper points of the pipeline and batteries.

- Excessively fast filling of the system with coolant or its supply is not from the lowest point. In such a situation, the liquid does not have time to displace air from all corners of the installed system.

- Loss of system tightness due to installation errors or damage to elements.

- The use of polymer pipes that do not have a barrier coating, which prevents the penetration of oxygen molecules into the coolant.

- Errors when developing a project or arranging a system (incorrectly chosen angle of inclination of pipes, etc.).

- Air entering the system during repairs that require dismantling circuit elements.

What is an air valve?

The air valve for heating is a sealed cone-shaped or cylindrical body made of brass. Inside it is a hollow float made of Teflon or polypropylene. This float is connected by a lever to the drain valve, which is equipped with a locking plug. This plug prevents coolant leakage if the device breaks down.

Now, once and for all, without any registrations or SMS, you can download 1xBet for Android for free by clicking on the active link and continue to enjoy the game and place bets on your favorite team in a convenient mobile application.

Air vents for heating systems come in three types:

- Direct devices of traditional type. They are mounted only vertically.

- Corner type devices that are installed at right angles. They are mounted on radiators instead of Mayevsky taps or in the event that a direct type of air vent cannot be installed.

- Special models for installation on radiators.

According to the principle of operation, the air vent can be manual (Maevsky tap) or automatic. The last variety is the float-type devices described above.

Operating principle of manual valve

Let's figure out how a manual air bleeder for a heating system works. To understand the structure of this type, you need to look at the drawing of the Mayevsky crane. At the end of the brass body with external thread there is a hole with a diameter of 2 mm. It is covered by a screw with a cone tip. On the side of the same body there is a hole of a smaller diameter, which is used to bleed air.

The operating principle of a manual air vent is as follows:

- In operating mode of the heating circuit, the shut-off screw is tightly tightened. The outlet is hermetically sealed with a cone.

- To release the air lock, the screw is unscrewed a couple of turns. As a result of coolant pressure, air begins to escape through a small hole, then enters the outlet channel and is discharged outside.

- Moreover, at first only air comes out of the hole, then an admixture of water appears. The tap must be closed when only a stream of water flows from the hole.

Because there are no moving parts to clog, rust, or wear out, a manual air vent is a reliable, trouble-free device. This valve is installed only on radiators.

Manual type valves are divided into the following types according to the method of unscrewing:

- a metal or plastic handle is used for opening;

- More often you can find a slot for a screwdriver with a flat working blade;

- To unscrew it with a special key, there is a screw with a tetrahedral tip.

Operating principle of automatic valve

The automatic air collector for the heating system works without human intervention. It is essentially a vertical brass cylinder with threads and a plastic float inside. The float is connected by means of a lever to the air release valve pressed by a spring. This valve is built into the lid.

The operating principle of an automatic air vent in a heating system is as follows:

- When the heating system is operating, the internal chamber of the device is filled with water, which presses the float up. As a result, the air valve is pressed by a spring and tightly closed.

- When air accumulates in the upper part of the chamber, the level of the coolant decreases, which causes the float to lower.

- When the liquid level drops to a critical value under the weight of the float, the spring compresses and opens the valve. As a result, the air begins to bleed out.

- Due to the increased coolant pressure in the system, all air is displaced from the chamber of the device. The liquid takes the place of the displaced air and causes the float to rise, which pushes the valve up and tightly closes the hole.

While the network is being filled with coolant, air pockets are constantly being bled off, since the float lies at the bottom of the container. When water fills the chamber, a spring mechanism raises the valve. As a result, the bleeding process stops. However, some oxygen remains in the housing under the cover, but this in no way affects the operation of the heating circuit.

Automatic devices come with angular and direct connection. The latter type discharges vertically, and the first - to the side. The corner version is valued for its reliability, but collects air bubbles worse.

Where are the air release valves located?

In any water heating system there are places where the installation of air vents is mandatory. If we talk about Mayevsky’s taps, then they need to be installed on all batteries in order to bleed off the collected air. The exact location is in the plug of the upper corner, distant from the point of connection of the supply line to the device. An air bubble forms there.

If the boiler is equipped with a built-in air vent, then there is no need to install it on the supply

The automatic air valve must be installed strictly vertically at the following points in the heating network:

- in the safety group of a boiler connected to a closed type system;

- on both underfloor heating collectors;

- if the highest point is a pipeline and not a radiator, then a float air vent cuts into it;

- into a buffer tank and an indirect heating boiler, if provided for by the design;

- on the heated towel rail coil;

- into the common distribution comb of a complex and branched system (to both collectors);

- to the hydraulic circuit separator (hydraulic arrow).

In addition to the indicated points, air vents are installed in problem areas of the heating network, where, due to difficult installation conditions, pipes form U-shaped loops turned upward. For example, a highway goes around a doorway or flight of stairs at the top, and then goes down again. In such compensators, air pockets form with a 100% probability, so an air vent is needed, preferably an automatic one.

When the highest point of the network is a pipe or compensator, a valve is mounted on it

Advice. Never cut the Mayevsky valve directly into the pipeline, since the bubbles will pass by it along with the coolant flow and the valve will be useless. For proper operation, a manual “bleeder” needs a chamber to collect air (the “automatic” has its own). Make a vertical pipe into the main line, which will serve as an air collector, and install a faucet on top.

If, when filling the heating network with water, you do not want to run between the radiators with a screwdriver, install automatic corner air vents instead of Mayevsky valves. This option is also suitable for residents of centrally heated apartments: air pockets often occur in cast iron radiators, and there is no way to remove them from there.

Another tip. To prevent the corner air vent flask from sticking out in plain sight and clinging to the curtains, take a mini-model of the valve built into the radiator cap.

Types of automatic air vents

Automatic air vents are available in the following types:

The straight lines that we met in the very first pictures, I’ll show them again:

Angular ones, which are often installed on radiators instead of the Mayevsky tap:

Radiator plugs having the same thread as radiator plugs:

As you know, Mayevsky valves are designed to bleed air from the system through the radiator. This bleeding is performed manually as an air plug forms in the radiator, which is easy to determine by touching the radiator with your hand... Installing a radiator air vent frees you from such work, since the air will be removed automatically.

However, no matter what the air vent looks like, they work on the same principle.

What to do if the air vent does not work

Air vent malfunctions often occur when air is not released from the system. This happens because the drain hole becomes clogged with scale. From time to time it needs to be freed from scale and rust.

To do this, unscrew it, first closing it off from the environment with shut-off valves and draining the water from the repair section of the pipeline

Next, the valve is removed, disassembled, and the needle is carefully cleaned. After cleaning is completed, seal the housing parts and reinstall them

In order to prevent clogging of the automatic vent, experts recommend installing a Valtek filter to purify network water. For dismountable structures, there is often a leak through the seal between the body and the head.

It is almost impossible to replace it, since such seals are not sold in the retail chain, so if such a problem occurs, it is better to use fum tape or silicone sealant. The cause of the leak may be a misalignment of the float; it is easy to fix it yourself.

Thus, we can summarize that the air vent is a mandatory element of any heating system, both central and individual, its installation is in accordance with the current rules. Automatic air vents are used to continuously remove air pockets without operator intervention.

Purpose and types of air vents

Air vents are used to remove accumulated air from the heating system. They are divided into manual ones, opened by service personnel, and automatic ones, which do not require human intervention. The simplest device is a faucet. A more complex device is an air collector. Modern devices - automatic air valve for heating. Special devices are used in individual elements of the heating system. The most common is the “Maevsky tap”.

Manual air vents

When filling the heating system, the coolant, coming under pressure, must displace all the gas. To do this, at the highest point of the system, a valve is installed to bleed air from the heating system. In order for filling to occur in a relatively short time, the capacity of the crane must ensure a free exit. Therefore, taps with a diameter of at least 15 mm, and sometimes more, are installed. After the system is filled, the tap is closed.

In the first days of heating operation, gases are very actively released from the coolant and accumulate. Therefore, maintenance personnel daily, and sometimes 2 times a day, bypass all the air bleed valves and release it. This requires a lot of mechanics and time.

To reduce labor costs, they began to install small tanks for collecting air, which were called air collectors. Now the bypass could be performed much less frequently, but it was still required.

In modern houses, apartment-by-apartment heating distribution with a lower piping arrangement is increasingly being used. The use of such a heating system provides a number of advantages: savings in materials during installation, apartment-by-apartment heat metering, apartment-by-apartment temperature control, up to complete shutdown, and improves the design of the room. But some problems also arise. When filling such a heating system, the air in the batteries cannot be forced out of it. Since the heating device is located above the pipeline.

Schemes of a single-pipe heating system in a private house Single-pipe heating system of a private house with bottom wiring: diagram Comfort in the house is not only a beautiful environment, correctly selected interior items, but also warmth, especially in the winter cold. Heating must be provided constantly, which creates a comfortable…

Therefore, to bleed air, all modern heating devices are equipped with an air vent valve for removing gases, small in size, its name is “Mayevsky tap”. By the name of the inventor of this crane. These taps can only be opened and closed manually. The principle of the device is simple. A screw is screwed into the plug, pointed at the end into a cone. With two or three revolutions, the cone moves away from the hole and slowly releases air. When water drops appear, the screw is screwed back in and closes the hole.

Automatic air vents

Nowadays, all production processes are being automated to reduce costs and improve quality. And instead of air collectors, they came up with an automatic air vent valve. Which will independently bleed air from the heating system.

The device of an automatic air valve for heating resembles a float in a car carburetor. When air accumulates, the float lowers. A needle attached to the float axis opens a hole through which gases escape. Water filling the float chamber raises the float and the needle closes the hole. Some automatic air valves are more complex, but the principle is the same. To check the operation of the valve, many are equipped with a button with a rod, which can be used to manually lower the float and check for the presence of air. At the same time, tear off the tip of the needle from the seat of the hole if sticking occurs due to the deposition of salts present in the water.

Features of choosing air vents

Not everyone knows where to start choosing an automatic air vent. In order for the product to serve for a long time and without failure, it is recommended to buy products of European or domestic production, but not cheap Chinese counterfeits. Buying a cheap automatic graduate can cause the following adverse consequences:

- Passing not only air, but also coolant through the valve. In this case, a puddle of water will be detected under the radiators or in the places where the air vents are installed.

- The product is jammed, so it will not work.

- Rapid deterioration.

Although automatic type safety valves have a shorter service life than manual ones, they must serve without fail for at least 10 years. Manual products have a service life of over 15 years, so instead of buying a cheap machine, it is better to give preference to a manual device. This will allow you to win not only in terms of savings, but there will also be no problems with air bleeding.

To choose good quality Mayevsky uranium, you need to pay attention to the following criteria:

- The presence of a handle allows you to conveniently open the valve for bleeding air. The disadvantage of faucets with handles is that they can be accessed by children, who are quite capable of opening them. Installation of such outlets with handles is appropriate only in hard-to-reach places; in other cases, it is recommended to install conventional products with a key or a screwdriver.

- To avoid losing the special bleeder key, it should be placed on the wall next to the radiator. This will prevent you from losing the key, and will also allow you to quickly bleed the air.

- Buy products with anodized coating. This spraying allows you to protect the metal from the occurrence of oxidative processes.

- If your budget allows, you can purchase a product that can trap air bubbles. However, such manual air vents do not differ much in cost from automatic air vents.

In order not to make a mistake with your choice, you need to pay attention to the manufacturer. Depending on the brand of plumbing and heating equipment, not only the quality, but also the cost will differ. In addition, if a closed heating system is used, then you need to pay attention to the technical parameters of the devices, in particular, operating pressure.

How to ventilate batteries in a private home

The autonomous heating system of a private house differs significantly from a centralized heating network. The fact is that the owners of their houses turn to specialized enterprises for the installation of a heating system. Professionals use design documentation that provides for the installation of an expansion tank.

Ventilation system for autonomous heating communications of a private house

The tank is installed at a point that is higher than the entire heating system. Containers can be open or closed. In the first case, airing of the system is eliminated by simply adding coolant to the expansion tank. The closed tank is equipped with a release valve.

Closed expansion tank

The system is mounted in such a way that air pockets are squeezed out of the radiators and lifted into the expansion tank.

When the heating temperature of the coolant increases, the air collected in the tank leaves the container through the open valve.

Ventilation of the heating system of a private house.

How to bleed air from old-style batteries

To this day, in the housing stock of Russia there are houses built a long time ago with batteries of the MS-140 model. In those days when these batteries were installed, they were equipped with ordinary water taps or simple bolts embedded in plugs with seals to bleed air.

The plugs are reset by simply opening these devices until a continuous stream of water appears without bubbles. If both devices are missing, remove the plugs by unscrewing the plugs, as described above.

When to bleed air from batteries

Any gas is much lighter than water, and therefore, when it enters the radiator, it begins to accumulate at the top point. If the process continues, the air begins to expand and lower the water level. As a result, 50% of the radiator volume or more may remain without water. The heating device practically stops functioning. Therefore, it is necessary to bleed the air from the batteries in any case.

To know when you need to bleed air from a heating radiator in an apartment in a multi-story building, you need to understand when it most often gets there. This occurs under the following circumstances.

- At the end of the heating season in the summer, heating services carry out preventive measures, during which the coolant is drained from the system, both partially and completely. Before the onset of cold weather, new water is poured into the system. Along with it, gas mixtures enter the radiators.

- Owners of private houses often repair their own autonomous heating system in the summer. As a result of inept actions, air enters the heating system.

- In apartment buildings with cast iron radiators, water is specially drained in the summer. This is done to avoid work on replacing gaskets between the registers. If coolant is left in the system, then old radiators may leak at the junctions of sections due to water cooling and pressure drop. When you have to start the heating system again, a large amount of air will enter it.

- During the summer period, the volume of coolant noticeably decreases in volume. When the shut-off valves are opened, due to negative pressure, the water being poured in absorbs gases and fills all risers with them.