In today's realities, an open-type expansion tank for heating has long and irrevocably lost the competition of a more modern and efficient closed tank.

Nevertheless, obsolete equipment is actively used. And in a number of situations it even has some advantages over technologically advanced membrane tanks.

In this material we will analyze its purpose and design features, and also get acquainted with the operating principle and rules for calculating this type of tank.

Purpose of the tank

From a basic physics course, many remember that solids are subject to expansion when heated.

In turn, the liquid and gas increase in volume. Water cannot be compressed like gas. If water is heated in a closed container, the pressure will increase, since there is no space for expansion. As a result, the container will simply burst. These processes are observed in a closed heating circuit with a liquid container. The expansion of water by temperature is estimated by a nonlinear indicator. It indicates how many times the liquid expands per heating per degree. On the Internet you can find many visual experiments demonstrating this principle.

Experience in demonstrating thermal expansion of liquid

You can consider this experience with an example. On the left side there is a container into which one liter of water is poured. Water is filled up to the overflow hole. Temperature reading +4 degrees Celsius. The liquid at a given temperature can be considered the zero reference point. Also in the illustration you can see a vessel with divisions. It is located under the overflow hole.

On the right side of the illustration you can see the same vessel, but in a heated state. The temperature of the liquid increases. Accordingly, the density of the liquid decreases. The mass of the medium does not change. At the same time, the volume of liquid increases. When the water reaches a temperature of +90 degrees Celsius, the measuring vessel is filled. It produces a little more than 30 ml of liquid. This amount is called excess volume.

Many will say that 30 milliliters of water is not a critical volume. However, it is important to understand that if there is initially more water, then as its volume expands, there will also be more excess water. For example, if one hundred liters of water expands, then there will be an excess of 3.5 liters, and this is already significant.

An increase in the volume of the liquid medium during heating in the thermal circuit of a country house

The water in a home's heating system can heat up to 70 degrees Celsius. As temperature increases, water expands. Without including an expansion tank in the heating system, the pressure will increase significantly. Accordingly, excess water needs to go somewhere. As a rule, leaks occur from weakly protected places in the circuit. Usually the water comes out of a section of the pipeline or from a heating pipe.

To prevent undesirable consequences, a safety valve is installed. It serves to drain excess hot water. However, it will not be possible to adjust the heating operation in the house to the required level due to one factor. After the liquid cools, its volume remains the same, and since the hot water is drained, an air mass takes its place. As a result, air pockets form, and this is one of the main troubles of all heating circuits. These plugs can become an obstacle to the flow of fluid in the pipeline.

An air lock in a country house heating radiator prevents heat from being distributed throughout the radiator

Air locks can be eliminated by deflating the air mass from the batteries. Installing a safety valve will require constant addition of water to the system, which is inconvenient and not cost-effective. It takes a long time to heat the newly received water. It is much faster to heat the water that enters the boiler from the heating system pipeline.

By installing an expansion tank, you can achieve normal functioning of the heating system in your home. We are talking about a bright orange tank connected to the heating system by a tube. The vessel is designed to compensate for excess pressure in the heating system of the house.

Purpose of the expansion tank for boilers

At the moment of heating, the volume of any body increases.

This is due to the physical properties of the substance. Liquid bodies, and in pipes and heating radiators these are coolants, increase by about 0.3% when heated for every 10 °C.

Since the liquid cannot be compressed, its excess appears, which must be directed somewhere. For this, an expansion tank is installed.

This device receives excess liquid from the heating pipes and makes up for the lack of coolant when it cools and, as a result, contracts.

Important! In the absence of an expansion tank, during heating of the coolant, pressure increases, which leads to rupture of pipes and radiators. The expansion tank ensures safe operation of all components of the heating system

The expansion tank ensures the safe operation of all components of the heating system.

Its service life depends on its correct installation. Thus, the reservoir is needed in order to:

- temporarily remove excess coolant from the heating system when it is heated;

- remove excess liquid from the tank when the maximum level is exceeded;

- make up for the lack of coolant in the pipes when cooling;

- maintain the pressure of the heating system by adjusting the volume of coolant;

- accumulate and release into the atmosphere air and vapors from a liquid that appear when it is heated.

Various types of containers

There are various designs of expansion tanks. They vary in size and shape. You can determine which vessel is needed by calculating its data. Also, when choosing a unit, you should take into account the type of heating system installed in the house. The form factor of the tanks is represented by a tablet, as well as a cylindrical shape.

Expansion tank in the form of a tablet

The different appearance depends on the method of use. The customer can purchase:

- Open type tank;

- Closed tank with built-in membrane.

Closed tanks without a built-in membrane are also available. However, experts recommend refraining from using this type of tank in home heating systems. Unfortunately, the design features of this product require careful refinement. The movable partition in such tanks is replaced by an air mass. Thus, air will be allowed to enter the internal heating system of the house, and the presence of air in the circuit is unacceptable. In such a tank, the water level will increase all the time until it reaches a critical point.

Open tank

Installed in the heating system of the house. The system is not isolated from the atmosphere, although it has a closed design. The system is not sealed. Accordingly, conditions for the occurrence of excess pressure will not arise.

Open heating system in a country house

Installation of an open tank

The expansion vessel for an open heating system is mounted at the highest point of the heating circuit. You cannot install the tank at another point, since the rule of communicating vessels will apply, as a result of which water will pour out of the tank. The location of the open tank at the top of the heating system serves as a proven method of removing air from the circuit. It is worth noting that there is air in the circuit, one way or another. It can be dissolved in water, and also be formed as a result of a chemical reaction between water and the material from which pipes and heating radiators are made. If you do not pay due attention to removing air from the system, one or more pipes may simply fail. An open tank serves to remove gas bubbles from the water in the heating system of the house. Simply put, this tank serves to remove air.

An open expansion tank for the heat-carrying fluid on the supply pipe of the heating system

It is also possible to install an expansion tank on the return path of water movement in the heating system. However, even in this case, it must be installed at the highest point of the highway section. It is necessary to install a vertical pipe directed to the tank installation point. The tank will not remove gas from the system if it is mounted on the return path of the heating system. Because of this, during the installation of the entire heating system, valves are installed on the heating radiators. They are also mounted at the very top of the supply pipeline.

Expansion tank for heating with your own hands: its capacity and installation | Heat monster

In our life, everyone dreams of a house built with their own hands. Its construction is associated with various problems.

Figure 1. Heating system of a house on the water.

An important place among them is occupied by the problem of improving an effective heating system with your own hands.

Only in a warm home can you create cozy and comfortable living conditions. There are several options to help solve this problem.

Traditional heating options

Figure 2. Diagram of a heated hydraulic floor.

Very often the house is equipped with traditional heating. The options are as follows: connect to the water supply and sewerage system, if such an opportunity exists, and create individual heating. To connect to the centralized system, you need to complete some documents and obtain the necessary permissions. Independent heating systems have a number of completely solvable problems that require investments of money, a little calculation and a lot of work.

Traditional heating equipment requires some preparation work. More often, a system of convective circulation of a coolant is used, which in most cases is considered to be simple water. There is no need for auxiliary pumps here. Cooled water flows from the batteries into the boiler and displaces hot water, which enters the heating batteries. This kind of circulation happens all the time. To do this, the temperature difference between hot and cooled water should be approximately 25 degrees.

A similar result can be achieved by placing the heating boiler in the basement of the house. If this does not work, then the boiler is placed on the lower floor no higher than the radiators. This system is called a two-pipe system, since hot and cooled water is supplied through a wide variety of pipes.

Heating system installation

Figure 3. Do-it-yourself heat supply for a personal home.

It makes sense to start installing a heating system by drawing up a diagram that should indicate detailed piping and heating devices, all the calculations that are necessary for this regarding the amount of materials. An example of a similar diagram is in Figure 1. Heating appliances are usually placed under the windows.

Care must be taken to place the pipes in such a way as to avoid unnecessary bends and turns, leading to a decrease in the operating efficiency of the heating system. It is necessary to mark the maximum point of the system on the diagram. An expansion tank for heating is installed here.

Laying pipes is not particularly difficult. The pipe from the boiler is led to the heating device. The heating device itself is installed and attached. Then comes the laying of the pipe to the next battery. The procedure is repeated a couple of times. It would be a good idea to equip each heating device with a tap, thanks to which it will be possible to get rid of possible air pockets during operation of the heating system.

Layout diagram of hydraulic heated floor heating elements.

The circuit is closed in the same boiler where the wiring originated. It is recommended to equip the boiler with a water purification filter, and sometimes with a pump to move water through a closed circuit. In the heating system, you need to plan the installation of drainage systems and filling it with water. It would be a good idea to do the first start-up of the system in the presence of a qualified technician.

Instead of installing classic heating devices, you can equip a warm heated floor by laying metal-plastic or polypropylene pipes under the floor covering. Hot water will circulate through the pipes and transfer its own heat to the room. Heated floor diagram in Figure 2.

In general, it would be a good idea to arrange heat supply with the involvement of a person skilled in these matters, so that later you do not encounter unnecessary problems during operation. Traditional heating is approximately 20 percent more affordable than stove heating. The return line lies close to the floor, sometimes under it. Hot water supply pipes are located above heating appliances, in most cases under the ceiling. It would be a good idea to insulate sections of pipes located under the floor or in the attic to prevent them from freezing during the winter.

Pipes can be used steel or metal-plastic. Is the diameter suitable for risers? or 1 inch. Half-inch pipes are suitable for wiring. Horizontal pipes are laid with a slope of 0.1 degrees in the direction of the movement of hot water.

Expansion tank

Diagram of the expansion tank.

In any heating system filled with water, it is impossible to do without an expansion tank. When water is heated, it increases in volume. The tank is designed to compensate for excess water. An industrial gas boiler is equipped with such a membrane type tank.

In most cases, its capacity is 6-8 liters. For heating a large house, this may be very little. In order for the heat supply to work uninterruptedly, it is necessary to install an additional expansion tank. Otherwise, an emergency spillover from the system may occur. This leads to its complete stop.

It is better to install an additional expansion tank of a fairly significant volume - 10-30 liters. It can be purchased ready-made, welded from sheet metal, or a container of appropriate volume can be adapted. To install it into a working system, you need to turn off the boiler and drain the water. To avoid these difficulties, it is better to install an expansion tank when the heating system is being installed.

It is placed in the place of the system where the pressure is minimal. In other words, the return line is considered such a place. In a private home, it is often installed in the attic. There he doesn’t bother anyone and doesn’t take up living space. The remaining water formed as soon as the temperature increases will flow into this container, the system will operate smoothly. Through the same tank you can fill the system at the beginning of the heating period. Installation diagram of the expansion tank in Figure 3.

The expansion tank can be closed or open. Open ones are used in systems with convective circulation of the coolant, closed ones – in systems equipped with pumps. Open tanks are placed at the highest point of the system, very often in the attic of a personal home. A closed tank can be placed in any place, very often somewhere in the corner of the house on the floor. Such a tank is attached to the return branch of the system with pipes with a diameter of at least 20 mm.

The absence of an expansion tank can lead to a significant increase in pressure in the system due to an increase in the volume of heated water, which will cause pipe rupture. And this leads to high costs for repairs.

Traditional heating installation.

For an open system, a common method is to install a variety of ready-made and home-made containers as an expansion tank. This design is very simple. It is easy to add water to such a tank, which evaporates a little during heating operation.

The expansion tank is calculated according to the rule: its capacity should be equal to 10 percent of the capacity of the entire heating system. How to determine the capacity of the entire system? The most common way is to take readings from the water meter when the system is filling. There is no point in presenting more accurate mathematical methods of calculation, since they are incredibly complex.

When using antifreeze as a coolant instead of water, it is necessary to make an expansion tank twice as large in volume. You can use a fuel tank from a truck or a stainless steel tank from a washing machine. You can weld it from steel sheets 2-4 mm thick, from a metal barrel or a large-diameter round. The main riser of the system is connected to the bottom of the tank or to its side.

A traditional heating system makes it possible to provide comfort in the home. However, without an expansion tank, it can quickly fail. Building such a tank is not a problem. It can be created from sheet metal. Even correct calculations are not required for this. Many people successfully use suitable containers in the form of automobile fuel tanks and other capacious vessels. Their installation significantly increases the operating life of the heating system.

Most Requested Blog Posts in Seven Days

Types of tanks

The design features of an open vessel are quite simple; it has a certain volume. A cap with a loose structure is placed on top of the tank. It protects the water from foreign objects getting into it. Since the tank is not sealed, the pressure level in it is identical to atmospheric pressure. The vessel can also be equipped with a number of pipes depending on its design.

Open type expansion tanks

The customer can choose the volume of the open tank. No action is required to use them. The product is made of stainless steel, which prevents the formation of rust. It is also possible to manufacture a custom-made tank according to individual client conditions. In manufacturing, galvanized or stainless steel sheets are used.

At the moment, several possible open layout expansion tank schemes have been successfully tested and are operating. The most elementary design is a vessel with a pipe embedded in the lower part. The pipe is used to connect to the heating system of the home.

A simple diagram of an open tank for coolant expansion

This scheme eliminates the circulation of water through the vessel. Using this container, the water in the heating system is located up to the middle division in the tank. If the volume of water in the heating system changes, it will also change in the expansion tank.

It is necessary to constantly monitor the liquid level in the expansion vessel. Since water is constantly evaporating, it is necessary to maintain its level in the heating circuit by adding water to the tank. If you do not replenish the water supply, air will take its place, and this is unacceptable in a home heating system.

You can estimate the amount of liquid in the tank using a pipe connected to a transparent hose.

Expansion tank with transparent hose to control water level

Often, an open-type expansion tank is placed in the attic. This is a good solution, because the vessel is not conspicuous. When located in the attic, you can simply go into this room and inspect the container. There is no need to stand on a ladder and check the tank in an awkward position.

You should also pay attention to another way to control the expansion tank.

Reservoir with a pipe for overflow and control of the minimum liquid level

First, two pipes are installed in the tank. Using one of them, you can determine the maximum filling of the container. It is cut into the upper part of the tank, and it acts as an overflow. A hose is placed on the nozzle. An overflow is also installed, excess water from which goes into the ground.

The lower pipe is designed to connect to a pipe that goes to one of the living rooms. A ball valve is inserted into this pipe where it is convenient for the client. Using this pipe you can determine the minimum water level in the tank. If water does not come out of the tap, then the liquid needs to be added. A sufficient water level can be seen by how water flows out of the upper pipe.

Advantages and disadvantages of an open heating system

This scheme is still used to heat private houses and cottages. Hot water from the boiler, according to the laws of thermodynamics, without a pump, rises up the riser, and then spreads along the supply lines located with a slope of 0.5 cm/m. At the same time, it fills the radiators. The liquid then flows by gravity back into the boiler or boiler to be reheated.

Main elements of an open heating system:

- Boiler

- in an open circuit, gas and solid fuel boilers of single- and double-circuit types are used. - Radiators

- the pressure in an open heating system is low, so any battery model is connected to it. Aluminum heaters work efficiently, heat up quickly and release heat intensively. You can install bimetallic radiators with an aluminum body and a steel water-conducting part. Traditional cast iron options also serve reliably. - Pipes

- in modern houses, models with a diameter of 25–50 mm made of heat-resistant polymer are used. Pipes of the maximum size are installed at the outlet of the boiler, and minimum size at the outlet. This allows you to maintain the required pressure and proper fluid circulation. - An open-type expansion tank -

you can buy it in a specialized store, order it online, or make it yourself. - Shut-off valves

- installed on the riser and collectors for emergency shut-off of water. - Control taps and automatic thermal heads

are additionally mounted on batteries to adjust the temperature. - For Mayevsky's wounds

there are air vents necessary for releasing air and preventing air locks. Installed on radiator housings.

Advantages of an open system:

- Energy independence

- this circuit works without a pump, so it is not afraid of power outages. If there is a power outage, the water and pipes will not cool down. - Budget-friendly

- no pumping equipment is required for operation; you can weld the tank yourself, buy it inexpensively, or adapt an ordinary canister. - Easy to use

- owners only need to monitor the condition of its elements and add water.

Flaws:

- The complexity of calculations and installation - when installing collectors, it is important to maintain the required angle - even small errors will lead to stagnation of water and poor heating of the batteries.

- Impossibility of use in buildings with irregular occupancy - non-freezing liquid cannot be poured into such a heating system. When it comes into contact with air in the tank, it evaporates and loses its properties.

- Difficult to operate in houses with a large area and number of floors - for such buildings, a closed heating system is preferable, which is able to warm up a building of any size.

However, despite the disadvantages, an open heating circuit is appropriate in small houses with permanent residence. Therefore, she does not lose her popularity.

Required capacity volume

There are no specific rules for how much liquid should be in an open type expansion tank. You can calculate the volume of increased liquid if you know the necessary parameters:

- Parameter of liquid expansion with increasing temperature;

- The volume of the entire heating network in the home;

- Heating system temperature.

The temperature expansion parameter of a liquid at different pressure levels and different temperatures can be seen in the table below:

Coefficient of thermal expansion of water at different pressures and temperatures

We can consider the situation using a simple example.

When water in a volume of one hundred liters increased by three and a half liters at a temperature of +90 degrees Celsius, the percentage increase in liquid occurred by 3.5%. It seems that a 5 liter capacity will be enough, but this is misleading. Calculation data shows that the expansion tank must be at least ¼ full. Thus, no air mass entered the heating system. It is also necessary to take into account the volume that will compensate for the expanding water mass, as well as the empty space above the overflow pipe. Qualified craftsmen install such a container, the volume of which will be 10% of the total water mass in the heating system of the house.

Closed type expansion tank

This type of tank is in steady demand among end consumers due to its small size. It can be installed anywhere in the heating system. If you study the design of heating systems, such vessels are mounted on the return line, near the pump. Placing the expansion tank in this way will be the most correct decision.

Location of the tank in a closed version

Unlike open tanks, a closed tank is a sealed container. That is why the pressure in the heating system can only increase to a certain point. In this regard, it is necessary to install a number of additional units that will ensure the normal functioning of the entire heating system.

These devices include:

- Safety valve. It is programmed to trigger when the pressure indicator approaches critical;

- An automatic device capable of independently releasing air that appears in it from the heating system;

- Pressure gauge. It is a device for monitoring pressure levels.

Safety group for a closed heating network

All of the above devices are required to be installed in a closed heating system. Only in this case is the circuit allowed to operate with all the required safety standards.

Expansion tank for heating with your own hands

The expansion tank is considered one of the most important components of the heating system. This design looks like a container partially filled with air. You can do the installation of the expansion tank yourself, but you need to understand that this is a very important job that requires a good and competent approach. The installation sequence will vary according to the type of heating system present.

Expansion tank for heating with your own hands

Using a tank in a closed system

For closed heating systems, the necessary closed tanks are intended. By their design, they look like a tightly closed capsule, which consists of two sections separated by rubber membrane fabric. This is actually why experts sometimes call such a device a membrane expansion tank.

The actual location is suitable for installing a closed tank. The only decisive point is that the tank cannot be placed immediately behind the circulation pump, because a similar arrangement will cause excessive pressure changes in the heating system.

The expansion tanks under consideration operate according to a very simple scheme: the coolant heats up, due to this its volume increases, then the remaining coolant fills the space in the installed membrane tank. This makes it possible to prevent an increase in pressure in the system above the possible level.

To make the functions and procedure for using the tank more clear, it is necessary to consider these points using the example of the most common unit - a double-circuit gas-powered unit. Closed systems are equipped with additional tanks in situations where the ordinary capacity of a gas heating boiler is not enough to normalize the pressure.

The physical properties of water are such that as its temperature increases, it increases in size. To compensate for the excess generated during the heating process, gas-fired units are equipped with stationary tanks. If the expansion of water begins to lead to an increase in the pressure level in the heating pipes, a specialized valve opens and a certain amount of coolant enters the tank you have installed. When the temperature drops, the liquid leaves the tank and goes to the batteries. In other words, the same amount of water is maintained in the heating batteries all the time, which is necessary for uniform and good heating.

Visual diagram of heating connection

The usual volume of a stationary expansion tank included in the double-circuit system is about 8 liters. For normal operating conditions, this capacity is quite sufficient. But if you need to equip heating rooms with an increased area, it is necessary to install a suitable number of batteries, which leads to an increase in the volume of the coolant, i.e. water. And in similar situations, the volume of a stationary expansion tank may be very small.

Volumetric calculation of the tank

If the volume of the tank is insufficient, an emergency release of liquid from the heating boiler will most likely occur, which is considered completely unacceptable. As a result of an emergency release, the pressure level in the system may decrease so much that the device simply will not be able to start working in automatic mode. And if the owner does not add the missing liquid in time, the system may defrost or even break down completely.

An additional tank can be installed in one of the parts of the circuit

To avoid similar unpleasant consequences, the system must be equipped with an additional expansion tank. When the key tank is completely filled, the coolant will begin to flow into an additionally installed container, which will make it possible to prevent an emergency release of water from the boiler. The volume of coolant and pressure in the heating system will be maintained at a systematic level.

Before installation, the tank is first configured. The whole setup comes down to turning it upside down and removing the plastic plug from it. There is a nipple under the plug. A conventional pump is connected to this nipple and air is released from the container. Next, the container must be pumped with air until the pressure level in it rises to 1.1 kPa. In the heating system, the pressure should be 0.1-0.2 kPa higher than that for the installed expansion tank. Only after such adjustment the container can be placed in the place allocated for it.

Expansion tank in an open system

Expansion tank in an open system

Open systems operate on the principle of convective circulation, in which the coolant is in systematic contact with open air. In this case, contact is made specifically through the installed expansion tank.

Central heating systems are equipped with tanks with a conventional top spill. Such a device has the form of a sealed container equipped with a relief valve and a water intake tap. It is impossible to install air vents in such a situation, because the total amount of air for a personal home is too large and it simply cannot be vented through a similar faucet within the allowable time.

An open tank looks like a regular container with an open top. In most cases, it is equipped with a lid, designed primarily to save from various debris. Sometimes it is necessary to add water to such a tank to compensate for the volume of evaporated liquid.

Where is the expansion tank located?

Where is the expansion tank installed?

The expansion tank is considered to be a completely unpretentious unit that can be installed, as already mentioned, in almost any accessible place. In open systems and in the case of central heating, everything is very simple: the container is placed on the upper side of such a heating system. This is the best and best option. The filling slope and the distribution slope must be such that the air is forced into the tank itself.

If it is not possible to equip a slope along the entire length of the heat supply, the pocket, which is designed to accumulate air, must be equipped with an additional expansion tank. It is placed on the same level as the key unit. If the pocket volume is insufficient, you can really get by with conventional air vents.

The expansion tank is primarily installed in a closed heating system, because Without this capacity, the air in the batteries and pipes will help them corrode faster. In the case of a closed system, it is not at all necessary to select a good location on the upper side of the circuit for installation; almost any location will do.

Very often the expansion tank is prepared in front of the pump along a straight length of pipe. Here, there is actually a laminar flow of the liquid, as a result of which constant pressure drops in the tank will not be allowed.

Tank Installation Process Guide

Fastening the expansion tank

Fastening the expansion tank

The initial stage is preparatory work. According to the general scheme, first of all, to install the tank, it is necessary to turn off the heating boiler from the electrical network, close the water supply to the boiler, and then drain the liquid from the heating devices. Additionally, you can open the so-called. air vents, as a result of which faster and more efficient water drainage will be guaranteed.

Prepare your expansion tank for installation and subsequent use. If, for example, polypropylene pipes are supposed to be used to connect system components, prepare a specialized soldering machine to secure them together. You will also need standard parts such as corners, couplings, etc. As for connectors, it is most optimal to use “American” connectors. Such a connector will make it possible to remove the container in the future for maintenance and repair work without unnecessary difficulties.

American connector with internal thread

The American connector consists of 2 important elements. The first part of such a fitting must be secured to the threads on the expansion tank. The second part is attached to the first. A polypropylene pipe is soldered to the second part. Before screwing the fitting to the expansion tank, wrap a threaded sealant around the fastening joint (in most cases, flax is used) and additionally apply a little specialized sealing paste. Screw on the first part of the American fitting using a regular gas wrench.

The second stage is laying PP pipes. Make sure that all water has been drained from the system and proceed to install the pipes. Where the tee will be installed, the pipe is cut using specialized scissors. Solder the tee and a pipe to it. Next you need to solder the stop valve. Thanks to it, in the future it will be possible to repair the tank without the need to remove water from the system. Solder the polypropylene pipes so that the last of them can subsequently be connected to the expansion tank.

Installation of PP pipes

Stage 3 – connecting the expansion tank. You need to screw the American to the container. Then you can safely proceed to placing the tank in the location chosen for it. It is more advisable to install the tank in a corner, on a flat floor, in a similar place so that in the future the tank can be easily accessed for repair work, etc.

The fourth stage is checking and replacing filters and cassettes. Before you put the coolant into the pipes, rinse the cleaning filter thoroughly with water. Remove it in advance. At the same time, replace the pipe filter cartridge. It is placed directly after the pump.

The fifth stage is preparation and launch of the system. Once all the parts are in place and the required connections are made, we begin preparing the tank for use. Restore water supply. Let the batteries fill with liquid until the pressure level in them increases to approximately 1.3 kPa. Next you need to bleed the air from the pipes, close the air vents and start the heating equipment to warm up the rooms.

Tips on bleeding air and ideal pressure values have been given before. If the pressure level rises above 1.1 kPa (and this value was actually set when setting up the tank), unnecessary water will flow into the tank. When the pressure level decreases, the coolant will flow into the batteries. As a result, normal operation of the heating system will be ensured.

Likewise, there is nothing very difficult about installing an element called an expansion tank. Follow the instructions in everything, do not forget about the basic recommendations and everything will be fine. Good luck!

Video - Expansion tank for heating with your own hands

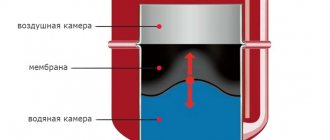

Features of operation of a closed container

The hermetically sealed container consists of two internal cavities. The cavities are delimited by a pliable partition. One of the cavities is intended for liquid circulating in the heating system. The second cavity is allocated for air, which is under the required pressure.

The external design of closed containers looks like a red cylinder. This is the standard form of tank design. They can be located not only vertically, but also horizontally. The tank body is stamped in production and has a prefabricated design. To prevent corrosion, the inside of the tank is treated with anti-corrosive.

Approximate design of most banks for expansion of coolant

The color for a closed expansion tank for installation in a heating system is always red. Thus, it is impossible to confuse it with a container that is installed in the water supply system. This equipment is called a hydraulic accumulator. They are made blue, although structurally they are no different from heating system tanks. It is important to understand that these tanks should not be misused as they are designed, tested and designed to operate at a specific temperature only. In addition, the partitions are made of rubber. It is also important to know that the pressure level in the water supply tank is different from the pressure in the heating tank. The plumbing and heating system operate at different pressure levels.

Hydraulic accumulators and a tank for expanding coolant fluid

The expansion heating tank is designed with a ready-made threaded pipe. The equipment necessary for the correct operation of the heating system at home is connected to the pipe.

Another device on the tank is the nipple. It is used to regulate the air pressure in the chamber. As a result, it is always possible to adjust the pressure to the optimal level inside the closed tank. This indicator should be 0.2 bar less than the pressure created by the inflated medium in the heating circuit of the house. Can be seen with an example. The cold heating circuit maintains a pressure of 2 bar. Accordingly, the pressure in the expansion tank should be 1.8 bar. It is important to periodically monitor the pressure reading in the expansion vessel. The same value must be monitored in the heating system network itself. It is necessary to check the indicator before turning on the system

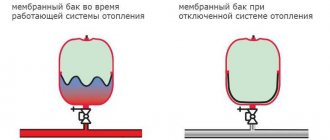

Operation of a tank with a membrane under varying pressure

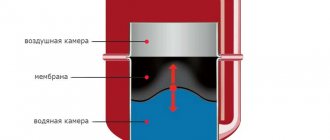

The main and important part of a closed expansion tank is the membrane. Since the membrane is movable, the volume of the two compartments inside the tank will constantly change when the system is running.

Before turning on the heating system, an increased pressure of 1-1.5 atmospheres is created in the air part of the expansion tank. It puts pressure on the pliable septum, and it begins to move in its lower part. At the same time, in the water compartment the volume is set to the minimum value. After the heating system is filled with liquid, the pressure in the heating circuit reaches the operating level. In turn, the compartment with water increases in volume due to the pressure on the membrane, which changes its shape already in the upper part.

As the heating boiler operates, the temperature of the water in the heating system increases. Consequently, there is an increase in the volume of liquid in the heating system of the home. Excess fluid pressure is directed to the water part of the expansion tank, since this is the only place where this pressure can be accommodated. The gas pressure increases due to the fact that one part of the tank increases and another part decreases at the same time.

Operation of the elastic partition in the tank

Over time, the temperature of the water in the heating system decreases. At the same time, the volume of water changes downwards. In the part of the tank where the liquid is located, its quantity decreases. This happens because the pressure in a closed tank is established by the movement of an elastic membrane under the action of the air mass in the upper part of the tank. A flexible partition is installed in such a way as to balance the heating system of the home. That is why any malfunctions in the system are excluded. In case of a critical situation, the safety valve is turned on. It is considered an important component of security sensors. In some cases, the expansion tank is already sold from the factory with this valve.

Tank work. Actuation of the valve on the container during expansion of the heat-carrying liquid

Safety precautions

In addition to maintaining the tank itself, it is important to pay attention to how safely it is used. There are several rules that must be strictly followed:

- if the equipment has visible damage - dents, deformations, etc. - it is prohibited to operate it,

- it is also prohibited to make any changes to the shape of the tank or its design,

- If the equipment needs repairs, then you need to call specialists with the appropriate skills. If it is necessary to replace any parts, you should use only “original” components,

- During operation, constant monitoring of pressure and temperature in the tank is necessary. Exceeding both is unacceptable.

- if it becomes necessary to dismantle parts of the structure that are under pressure, this is done only after disconnecting the expansion tank from the system, draining the water from it and reducing the pressure to atmospheric level,

- The tank capacity, as a rule, is made of materials that are not very resistant to various influences. Therefore, for use in the heating system, you should choose a high-quality coolant - for example, distilled water,

- When installing an open-type tank, it is necessary to select an installation location that will accurately support the weight of the equipment filled with water to the maximum. The floor in this area of the room must be very durable.

If all operating and safety rules are followed, the use of an expansion tank will be extremely beneficial. Based on the information received today, you will certainly be able to independently make the best choice and not get confused in the variety of equipment presented on the modern market.

It is quite possible that this article will be useful not only to you, but also to your friends. Therefore, share it with them on social networks and come back for a portion of new knowledge, of which there is still a lot, very much on this portal. Good luck to you, and see you again!

Instructions for calculating the volume of a closed container

In order to choose the right expansion vessel for your home heating system, it is important to calculate the volume of the closed expansion vessel.

In order to calculate the exact volume of a closed expansion tank, a special formula is derived: V = (Vс * k) / D

Explanation of the formula:

Vc – volume of liquid in the heating circuit;

k – Value indicating the measure of expansion of a liquid as its temperature increases;

D – The value that determines the effective operation of the tank.

If the liquid is antifreeze, then the amount of its expansion is affected by temperature, as well as the amount of glycol contained in the antifreeze. The necessary data can be taken from the relevant reference books.

Below is a table indicating the amount of expansion of antifreeze as its temperature increases:

Expansion coefficient of antifreeze as its temperature increases

There is also a special calculation formula that gives an indicator of the efficiency of the expansion tank: D = (Рм – Рн) / (Рм +1)

It is necessary to decipher the values used in this formula.

- Pm is the highest pressure value in the heating system of a house. As a rule, this value does not exceed three atmospheres. In most cases, the pressure reading is identical to the same reading in an emergency situation when the valve is activated.

Pn - An indicator of the pressure that is created in advance in a half container of water. This can be determined by taking into account the height of the system. Every 500 centimeters is equivalent to half the atmosphere.

Professionals in heating systems recommend installing an expansion tank, guided by formulas for calculating its volume. The resulting value should be equivalent to 1/10 of the total amount of liquid in the home heating system.

For those who find it difficult to obtain accurate calculations on their own using formulas, the website contains a calculator for online calculations. Qualified workers strongly recommend double-checking the received data using calculators on several Internet portals. You should insert the necessary numbers into the free fields, and the system will automatically make the calculations. Then you need to check the resulting numbers one by one on several more sites.

An example of an online calculator for calculating the volume of a tank

Using an automatic calculation system, you can obtain the volume of a container for an expanding liquid. The owner of the house indicates the approximate amount of liquid in the heating circuit, based on the power characteristics of the boiler. According to experts, no matter what result in terms of liquid volume is obtained, it is necessary to purchase a 12-liter closed-type expansion tank for installation.

Equipment selection

To summarize, we can say the following: for an open heating system, take the appropriate type of expansion tank; for a closed one, this rule also applies. In general, you can even make an open tank with your own hands, there is nothing complicated there. The most important thing is to follow the placement rule described above.

Regarding the purchase of closed-type tanks, it is worth immediately warning: in appearance they are very similar to hydraulic accumulators for a water supply system. But these are different types of equipment, they are not interchangeable. Refer to the markings on the product; they indicate the permissible temperatures and pressures. For the expansion tank it is 120 degrees and 3 Bar, and for the hydraulic accumulator it is 70 degrees and 10 Bar.

Another criterion for choosing an expansion tank is its required volume. After all, it is important that the required amount of coolant fits into it. Calculating this indicator is not so simple, although, in principle, there are various online services for carrying out this operation.

But any program can fail, so it is still better to carry out calculations manually. To do this, you need to calculate how much water enters the entire heating system during operation of the latter. That is, you need to consider the following:

- the amount of liquid in the heating boiler tank. This indicator is taken from the technical data sheet of the equipment,

- the amount of coolant in all lines. To do this, you need to find the cross-sectional area of each section of the pipeline (using the formula for the area of a circle), and then multiply the resulting number by the length of the same section,

- the amount of liquid in each radiator connected to the heating system. This indicator is also taken from the technical data sheet of the product.

After all the calculations have been made, the resulting numbers are added up, and then 10% of the amount is calculated. This will be the required volume of the expansion tank.

Nuances of installing an expansion tank

Installers install a closed expansion tank, observing a number of nuances. It is necessary to install the tank so that the threaded pipe is at the bottom of the tank. Located at the bottom, the pipe will effectively remove accumulated gases from the heating circuit of the house.

The correct type of installation is one in which the expansion tank is mounted on the return line of the heating system. It is important that the distance to the boiler is minimal. In this case, the tank must be installed in front of the pump. Thus, its operation will be correct.

Conventional layout of a closed tank

The return line is equipped with a tee. The type of pipes matters when installing a container. Pipeline fittings are installed in the area between the tee and the tank. This way, you don’t have to drain the water from the system when performing scheduled work. The fittings are strengthened so that it is convenient for the home owner. A small piece of pipe is needed, as well as a ball valve. The pipe can be straight or bent. The so-called “American” is also installed to obtain a detachable connection. This will make it easier to remove or service the expansion tank. At the final stage, the pipeline fittings are opened, and all mounted joints and jumpers are checked.

Conventional location of a closed tank

Operating rules

Despite the simplicity of the expansion tank design, this equipment still requires attention. It will reliably perform its functions only if all operating rules are followed. These include the following:

- Every six months the expansion tank should be carefully inspected for damage. These may include various dents, traces of corrosion and smudges. If you discover any of these phenomena, you must immediately understand the causes and eliminate them,

- with the same frequency, it is necessary to check the pressure in the gas compartment with that which is expected in accordance with the design parameters. To carry out this procedure, it is necessary to disconnect the expansion tank from the heating system, drain all the water from it, and then connect the pressure gauge to the nipple-gas cavity. In the event that the pressure is below the required parameter, it should be increased by pumping air using a compressor, connecting the latter to the same nipple,

- It is also necessary to check the condition of the membrane once every six months - if, of course, we are talking about a closed expansion tank. If any defects are detected - for example, the rubber element is deformed, cracked or simply leaks air - the bulb must be replaced with a new one,

- If the expansion tank is used seasonally, that is, with long breaks, then when you stop using it, you must remove all water from the tank and keep the equipment in a dry place. Otherwise, corrosion processes are likely to occur.

Results

Initially, it is necessary to determine the volume of the tank for expansion, and only after that decide what type to purchase, open or closed. Installation of the entire system must be carried out by qualified specialists. Self-connection is not allowed. During the work, the installation team will make sure that all components and assemblies of the system are installed in accordance with safety requirements and correct installation. In addition, the home owner will be provided with a guarantee on materials and work performed. Therefore, if problems arise, the homeowner can seek help from the place where he ordered the project.