How to determine the required expander volume?

The volume of the expander must exceed the value of the required volume, which represents the maximum amount of coolant entering the tank as a result of its heating.

First of all, the total volume of coolant in the system is determined. By summing the internal volume of pipes and cavities of all system elements (boiler, heating radiators, shut-off valves), we obtain the total volume. The amount of liquid in pipelines can be calculated depending on the size of the pipe, using the data in Table 1. The volume of equipment cavities is indicated in the documentation (passport or manufacturer’s catalog) for the product.

Table 1 - Determination of the volume of coolant in 1 linear meter of pipeline.

Next, knowing the total amount of liquid, determine the required volume of the expander using the data in Table 2. This value is selected depending on the pressure in the system. If the previously calculated value is between two tabular ones, the required tank volume is determined by the larger of the values.

Table 2 - Determination of the required volume of the expansion tank.

The data in Table 2 is valid if water is used as a coolant. For liquids with a coefficient of thermal expansion different from water, the tabulated value of the total volume is multiplied by a correction factor equal to the ratio of the density of water and the liquid used.

The main advantages of closed expansion machines

Depending on the power of the boiler, as well as on the volume of liquid used, the volume of the membrane heating tank differs slightly. It is recommended to install such equipment in country houses, since they have numerous positive qualities when compared with open tanks.

The coolant does not come into contact with air, as a result of which the liquid does not evaporate; for the same reason, pipes and radiators are not oxidized by air, which helps to increase their service life.

In closed tanks, the likelihood of liquid spilling out is zero, so you don’t have to worry about finishing the walls and floors. Installation can be carried out anywhere in the cottage; there is no chance of air pockets, which in open devices arise as a result of increased pressure at the top point of the heating system.

There is also no need to recharge the heating system with coolant. Conclusion - operating a membrane expansion tank is very easy.

Closed tanks mean efficiency, safety and reliability.

Design and principle of operation

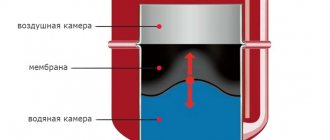

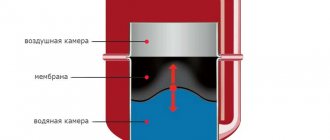

A membrane tank is a hermetically sealed metal container divided into two compartments (chambers) by an elastic membrane. One such chamber is a pneumatic chamber, which contains gas or air under pressure. The coolant enters the second chamber, the hydraulic chamber.

The device operates as follows:

- the air pressure, which is in a state of equilibrium, in the pneumatic chamber compensates for the fluid pressure in the heating system, the volume of the coolant and the hydraulic chamber is reduced to a minimum;

- when the fluid pressure increases in the system, including during heating, the pressure also increases in the hydraulic chamber, where excess coolant flows;

- due to the elasticity of the membrane, the volume of the pneumatic chamber decreases, which is accompanied by an increase in gas pressure;

- when the pressure in the pneumatic chamber increases, the increase in pressure in the hydraulic chamber is compensated, and the system returns to a state of equilibrium.

When the coolant pressure in the system decreases, the opposite occurs. Gas (air), compressed in the pneumatic chamber, expands and displaces liquid from the hydraulic chamber into the system until the pressure difference is restored. The design eliminates the possibility of contact between the coolant and air, reducing the likelihood of rust not only in the tank, but also in other parts of the heating system - piping, boiler. Sealed expansion tanks are equipped with safety valves that allow you to limit the maximum pressure in the heating system to an acceptable level. This characterizes the tank as a protection device for the heating system.

Using a tank in a closed system

Expansion tank

A practical location is suitable for installing a closed tank. The only important point is that the tank cannot be installed immediately behind the circular pump, because such placement will cause excessive pressure drops in the heating system.

The expansion tanks under consideration operate according to an extremely simple scheme: the coolant is heated, resulting in an increase in its volume, then the excess coolant fills the space in the installed membrane tank. This helps prevent pressure in the system from increasing above the permissible level.

To make the functions and procedure for using the tank more clear, you should consider these points using the example of the most popular unit - a double-circuit boiler running on gas. Closed systems are equipped with additional tanks in situations where the usual capacity of a gas heating boiler is not enough to normalize the pressure.

Expansion tank

The physical properties of water are such that as its temperature increases, it increases in size. To compensate for the excess generated during the heating process, gas units are equipped with stationary tanks. If the expansion of water begins to lead to an increase in the pressure level in the heating pipes, a special valve opens and a certain amount of coolant enters the tank you have installed. When the temperature drops, the liquid leaves the tank and goes into the batteries. That is, the heating radiators always maintain the same amount of water required for uniform and high-quality heating.

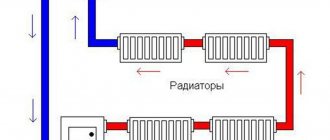

Visual heating connection diagram

The standard volume of a stationary expansion tank included in a double-circuit gas boiler is about 8 liters. For normal operating conditions, this capacity is more than enough. But if it is necessary to provide heating for large areas, it is necessary to install an appropriate number of batteries, which leads to an increase in the volume of coolant, i.e. water. And in such situations, the volume of the stationary expansion tank may be too small.

Calculation of tank volume

If the tank volume is insufficient, there is a high probability of an emergency release of liquid from the heating boiler, which is absolutely unacceptable. As a result of an emergency release, the pressure level in the system may decrease so much that the unit simply cannot start operating in automatic mode. And if the owner does not add the missing liquid in a timely manner, the system may defrost or even fail completely.

An additional tank can be installed in any part of the circuit

To avoid such adverse consequences, the system must be equipped with an additional expansion tank. When the main tank is completely filled, the coolant will begin to flow into an additionally installed container, which will prevent an emergency release of water from the boiler. The volume of coolant and pressure in the heating system will be maintained at a constant level.

Before installation, the tank must be adjusted. The whole setup boils down to turning it upside down and removing the plastic plug from it. There is a nipple under the plug. An ordinary pump is connected to this nipple and the air is bleed from the container. Next, the container needs to be pumped with air until the pressure level in it rises to 1.1 kPa. In the heating system, the pressure should be 0.1-0.2 kPa higher than that for the installed expansion tank. Only after such adjustment can the container be placed in the designated place.

How to check and pump up the expansion tank

Before connecting and filling the tank with coolant, it is necessary to check the pressure in the air chamber of the tank for compliance with the pressure in the heating network. To do this, a plastic plug is unscrewed or removed from the side of the air compartment, and under it there is a regular spool, familiar to you from car cameras. You measure the pressure with a pressure gauge and adjust it to your system by pumping it up with a pump or releasing it by pressing the spool rod.

For example, the design pressure in the network after filling should be 1.3 Bar. Then in the air compartment of the expansion tank you need to make 1 Bar, that is, 0.2 Bar less. The trick is to keep the rubber “bulb” of the tank pressed against the water side. Otherwise, when cooling, the compressed coolant will begin to draw air through automatic air vents, which is unacceptable. After setting up, open the tap, fill the entire system with coolant and calmly start the boiler.

Note. Some manufacturers indicate on the packaging of their products the factory pressure in the air compartment. Using it, you can choose a suitable tank and not bother with pumping.

Where is the expansion tank installed for heating?

The location of the tank depends on the type of heating system and the purpose of the tank itself. The question is not why an expansion tank is needed, but where it should compensate for the expansion of water. That is, in the heating network of a private house there may be not one such vessel, but several. Here is a list of functions that are assigned to tanks installed in different places:

- compensation of thermal expansion of water in open heating systems;

- the same for closed systems;

- serve as an addition to the standard expansion tank of a gas boiler;

- handle the increasing volume of water in the hot water supply network.

An open-type reservoir, where the coolant is in contact with atmospheric air, is the hallmark of an open heating system. In this case, the installation of the expansion tank is carried out at the highest point of the heating network of a private house. Often such systems are made gravity-flow with increased pipeline diameters and a large amount of coolant. The capacity of the tank should be appropriate and be about 10% of the total volume of water. Where else if not in the attic to put such a large tank?

For reference. In old one-story houses you can often see small expansion tanks for an open heating system installed in the kitchen next to the floor-standing gas boiler. This is also correct; a container located under the ceiling is easier to control. True, it doesn't look too good in the interior. To put it mildly.

Alternative homemade tanks

Closed-type heating systems are distinguished by the fact that the membrane expansion tank for water can be placed anywhere. But still, the optimal installation option is in the boiler room, next to the rest of the equipment. Another place where it is sometimes necessary to install a closed expansion tank for heating is the kitchen in a small house, since the heat source itself is located there.

About additional capacities

Following new trends, many manufacturers equip their heat generators with built-in reservoirs that absorb the volume of coolant that increases when heated. These vessels cannot fit all existing heating schemes, and sometimes their capacity is not enough. To ensure that the coolant pressure during heating is within normal limits, in accordance with the calculation, an additional expansion tank is installed for the wall-mounted boiler.

For example, you converted an open gravity system into a closed one without replacing the mains. The new heating unit was selected according to the heat load. Whatever capacity it contains, it will not be enough for that amount of water. Another example is underfloor heating in all rooms of a two- or three-story building plus a radiator network. Here, the volume of coolant will also be impressive; a small tank will not cope with its increase and the pressure can increase significantly. That is why a second expansion tank for the boiler is needed.

Note. The second tank to help the boiler is also a closed membrane container, located in the furnace room.

When the hot water supply to the house is provided by an indirect heating boiler, the question also arises - where to go with the water that expands when heated. One option is to install a relief valve, as is done on electric water heaters. But the indirect heating boiler is much larger in size and it will lose too much hot water through the valve. What better way to select and install an expansion tank for a boiler.

For reference. Buffer tanks (heat accumulators) from some manufacturers also provide the ability to connect a compensating tank. Moreover, experts recommend installing it even on large-capacity electric boilers, as shown in the video:

Plastic tank

Here you just take a plastic container. A 10-40 liter canister or a regular 10 or 12 liter bucket can serve as a tank. A more preferable option would be a rectangular base.

For it you should purchase a threaded fitting with a thread for two bends and a rubber washer according to the diameter of the fitting, as well as two nuts for the diameter and pitch of the thread of the bends.

Then one of the ends of the fitting is heated over an open fire with a blowtorch, gas cutter or gas stove, and with this heated fitting, the bottom of the canister, bucket or some other container intended for the expansion tank is burned. After this, you should cut off the top of the product and burn three holes using a nail heated over an open fire. These holes are made in a triangle and serve to attach the tank to the wall.

Now you should equip the bottom of the product with a fitting. For this purpose, a nut is screwed onto the drive, and it itself is inserted into the hole. From the inside of the tank container, put a rubber sealing washer on the thread of the outlet and screw on the second nut, tightening it tightly. The purpose of this second nut is to tightly fix the rubber to the bottom part with emphasis on the second nut located on the outside.

The last stage of work is to mount the container higher, somewhere under the ceiling. For this, dowels or self-tapping screws are used. They are inserted into holes pre-burnt with a hot nail or drilled in plastic. This mounting method is suitable for mounting a 5-liter container, but for its 10-liter sample, you will need to build a shelf.

What does the system consist of and how does it work?

In order for heat to flow from the boiler room to the heating devices, a mediator is used in the water system - liquid. This type of coolant moves through a pipeline and heats rooms in the house, all of which can have different areas. This factor makes such a heating system popular.

The coolant can move naturally; circulation is based on the principles of thermodynamics. Due to the different densities of cold and heated water and the slope of the pipeline, water moves through the system.

One of the important elements of the heating system is the open expansion tank; excess heated liquid enters here. It is this element that stabilizes the coolant pressure. The main condition is that the tank should be located at the highest point of the heating system.

Open heating operates according to the following scheme:

- The boiler heats water and supplies it to heating devices in every room of the house.

- On the way back, excess liquid goes into an open-type expansion tank, its temperature drops, and the water returns to the boiler.

Single-pipe heating systems involve the use of one line for supply and return. Two-pipe systems have independent supply and return pipes. When deciding to install a dependent heating system yourself, it is better to choose a single-pipe scheme; it is simpler, more accessible and has a basic design.

Single-pipe heat supply consists of the following elements:

- Heating boiler.

- Batteries or radiators.

- Expansion tank.

- Pipes.

A simplified scheme involves using pipes with a cross-section of 80-100 mm instead of radiators, but it should be borne in mind that such a system is less efficient in operation.

Installing a membrane expansion tank

Unlike an open one, a membrane accumulator can be installed directly at the heating point, next to the boiler, for ease of maintenance. Usually it is placed in a straight section in front of the circulation pump, preferably so that water (or other coolant) enters the compensator from above. It must be equipped with a pressure gauge, a safety valve and connected to the return line.

Even less successful countries such as Austria and Germany have widespread solar thermal systems than Italy. Other sun-kissed countries such as Israel, Greece and Spain have long understood the economic and environmental benefits that flow from the use of this technology and use it with diffusion up to 40 times that can be found in Italy. this delay is due to the lack of adequate awareness of the economic and environmental benefits associated with the use of these plants and the high technological maturity they have achieved.

Hydraulic accumulators with a volume of up to 30 liters are mounted on the wall, larger ones are installed on the floor. When mounting on a wall, the tank should be securely fastened, since its weight increases sharply when filled with water.

Several membrane tanks in a heating point

The technology that converts solar energy into thermal energy has achieved remarkable levels of reliability and convenience in recent years. It is estimated that in the production of sanitary hot water these savings can reach 90%, while in solutions integrated with the heating system they can reach 40% of the total energy requirement of the entire building. The key element of the system that allows us to capture the sun's energy is the Solar Collector. This, through the photothermal effect, transforms solar radiation into heat, unlike a photovoltaic panel which converts it into electrical current instead.

System components

Open-type heating in a private house requires the installation of a boiler that runs on solid fuel or fuel oil. The fact is that this type of heating is characterized by the periodic formation of air pockets, which can cause an accident when using electric and gas boilers.

You can calculate the power of a heating boiler using a standard scheme, according to which heating 10 m2 of room area requires 1 kW of energy plus 10-30%, depending on the quality of the thermal insulation.

You should not use polymers as a material for the expansion tank; steel would be the best option in this case. The volume of the tank depends on the area of the heated room; for example, in the heating system of a small building one floor high, an expansion tank of 8-15 liters can be used.

As for the pipes for the heating system circuit with a circulation pump, in this case the following materials can be used:

- Steel. This pipeline is characterized by high thermal conductivity and resistance to high pressure. However, installation has some difficulties and requires the use of welding equipment.

- Polypropylene. This system is characterized by easy installation, durability and tightness; it can withstand temperature fluctuations. Polypropylene pipes have been characterized by flawless operation for a quarter of a century.

- Metal-plastic. Pipes made of this material are resistant to corrosion; deposits do not form on their internal walls, which would impede the natural movement of the coolant. However, the cost of such a system is quite high, and its service life is only 15 years.

- Copper. A copper pipeline is considered the most expensive, but it can withstand high temperatures, up to +500 degrees, and is characterized by maximum heat transfer.

Operating principle of the device

The expansion tank is part of the simplest heating systems that work according to the laws of physics. When liquid moves through pipes and radiators by gravity, the energy for this is provided by the pressure difference.

In order not to disrupt the natural heat exchange and water circulation, the expansion tank should be installed at the highest point of the entire heating system, while the boiler should be the lowest. We talked in more detail about installing and connecting the tank in this article.

Otherwise, the presence of a tank will not give the desired effect. This will not protect against increased pressure, water hammer and subsequent breakdowns.

An important advantage of open expansion tanks is their availability. For example, a tank can be made even from scrap materials, which are sufficient in summer cottages and in the utility rooms of private houses. Any metal or plastic container of the required size can become an expansion container, as evidenced by the photo

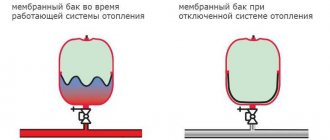

When the coolant is cold, the tank itself does not take any part in the operation of the heating system.

Everything changes when the liquid heats up to significant temperatures and creates excess pressure in pipes and radiators, since in such situations its excess is actively created and squeezed into the expansion tank. Where it remains until the coolant cools down, after which it again flows by gravity into the pipes and radiators, the boiler.

The described procedure is performed cyclically, that is, throughout the entire period of operation of the tank.

Due to the fact that the heating system is open, like the tank itself, compensation for the effects of expansion cannot be carried out without human intervention.

The reason is that the coolant, being in direct contact with the air, evaporates, and the more it heats up, the more active this procedure occurs.

As a result, the user has to regularly monitor the available water level. And top it up as needed.

The specified operation is performed using a bucket or other container with water. This is unpleasant, so the system can be automated by organizing the supply of water from a water supply system, from any one: local or centralized.

You should know that geometric shapes and precise calculations in the case of an open expansion tank are absolutely unimportant. The main condition for effective operation is placement at the highest point of the system and the presence of a sufficient volume of container up to the overflow pipe

In addition, using additional equipment, the described procedure can be made completely autonomous.

But in this case, the most important advantages of all open tanks and heating systems are lost:

- cheapness;

- complete autonomy , that is, independence from the performance, serviceability and presence of any engineering systems in the room.

All processes in an open tank occur according to the natural cycle, without the help of pumps and other equipment.

As a result, in order for the expansion tank to be guaranteed to be useful, the dimensions of the system itself must be moderate, that is, it should not be used for heating cottages and buildings whose area exceeds 100 m².

The optimal location for expansion tanks is warm attics. Since the highest point of the system is guaranteed to be there, and this solution also allows you to hide a structure with low aesthetic properties away from eyes

If this rule is ignored, this can lead to significant financial losses, since a number of alterations will have to be made to ensure the efficiency of the tank and the entire system as a whole.

In addition, height should be limited. Since it is very problematic to achieve the expected result when trying to heat more than a two-story building in this way.

Types of expansion tanks

Now understanding the importance of such equipment, the reader has a new reasonable question: “What type of tank is best to buy for your home?” For a complete answer, you will first need to study the product options that exist on the modern domestic market. Let's get started with the review without delay.

Such devices are becoming more and more common. They can be purchased at large retail chains, for example, “Leroy Merlin” or “Moya Rodnya”

Open type – massively popular, elementary simple

This modification is the most common and accessible not only in our country, but throughout the world. It is so simple that anyone can make such a device at home. Structurally, an open expansion tank can serve as any container that has an inlet hole for the coolant to enter, as well as a cutout in the upper part for evaporation of liquid. Accordingly, as the pressure increases, water penetrates into the expander, partially evaporates, and when the temperature drops, it returns back to the system for further circulation.

Despite its simplicity, it is better to purchase a factory-made model - it is more reliable and easier to use.

Closed type (membrane tank) - ready for serious testing

If the previous option is more suitable for heating with natural water supply into pipes, then the next, more advanced nominee is also suitable for complex tasks. The secret is that the design of the membrane expansion tank includes two chambers, different in composition and properties. The first, external, is filled with either ordinary air or inert gas (depending on the price tag). The second, internal, is a hollow empty space where the coolant ends up over time. Between the cavities there is a membrane made of plastic rubber. Initially, a certain pressure is created in a closed-type apparatus. When water enters the internal cavity of the tank, the membrane partition changes its shape, maintaining normal operation of the system. When cooled, the gas or air from the outer chamber expands and pushes liquid out of the expansion tank. Thanks to this device, a closed expansion tank can compensate for the load created by a circulation pump or other artificial supercharger.

Installation of a membrane expander requires considerable skill and knowledge, and ideally, the services of a specialized specialist

It is also important to note the fact that this type of device has two subtypes. The first, with a membrane in the form of a diaphragm (disc)

It has a more affordable price, but if it breaks, the product cannot be repaired

The first, with a membrane in the form of a diaphragm (disc). It has a more affordable price, but if it breaks, the product cannot be repaired.

Low plasticity indicators negatively affect the available useful internal volume of equipment

And the second, with a membrane in the shape of a “pear” (balloon). It features a simple system for replacing a worn partition and a large internal chamber volume.

This shape also allows you to experiment with different pressure values to find the perfect fit.

Battery type - for the most prudent owners

This unusual invention has not yet gained wide popularity among the residents of our country, but it is worthy of mention. The peculiarity and main function of this “miracle of technology” is the accumulation of coolant in its body and its subsequent transfer at the required moment into the system. Accordingly, the battery expander does not combat excess pressure; it simply improves the heating efficiency in a house or apartment.

The high-tech device is capable of storing water at different temperatures, supplying it to the system according to predetermined “scenarios”

Why is it needed?

Practically, all coolants for heating systems are weakly compressible liquids.

Equipment of this type can be used in homes, sports facilities, small workshops, bathing establishments and in all situations where the main requirement is the production of hot water. Anodized aluminum frame that is not susceptible to weathering. Anti-reflection selective solar crystal improves efficiency by 15%. Titanium coated inserts increase yield by 16%. High density polyurethane foam insulation to keep water hot for long periods of time. Anodized aluminum exterior.

Accordingly, there is a need to use stabilizing devices - membrane expansion tanks for the heating system (), capable of receiving part of the liquid when volume and pressure increase, and returning it to the circulation circuit when these indicators decrease.

To compensate for the coolant volume

Expansion tanks are used in the system when the temperature changes.

Magnesium anode for preserving the kettle from stray currents. Forced circulation systems are more complex systems that, in addition to hot water for sanitary use, can be coupled to building system heating. In this way, higher energy efficiency is achieved and solar energy is exploited to its fullest extent.

The ideal solution combines solar collectors, condensing boilers and a highly efficient heat distribution system, all in a highly insulated building. Most often, a solar collector system is integrated into an existing heating system, providing great savings on fuel consumption and the emission of harmful elements into the atmosphere.

Among them there are 2 types of devices:

- open;

- closed (sealed);

Open expansion tanks

have become widespread, but are gradually giving way to sealed heating systems, since they have a number of disadvantages:

- additional installation costs, since they are installed at the top point of the system to create the required level of excess pressure;

- loss of coolant due to natural evaporation, and, as a result, the need to constantly monitor the liquid level and top it up;

- the danger of the development of corrosion processes in the system due to constant contact of the heated coolant with oxygen in the air.

Sealed expansion tanks do not have such disadvantages

.

Useful tips

It was already mentioned above that the volume of the expansion tank is equal to 10% of the volume of the entire coolant in the heating system of the house. Of course, this is an approximate figure. To accurately determine it, it is necessary to take into account a large number of various coefficients that are included in a complex formula. It will be difficult to make such a calculation on your own, if you are not a specialist. Therefore, take the above ratio as a basis.

By the way, if the safety valve trips very often, you know that you missed the volume. Most likely, you incorrectly calculated the total volume of coolant. In this case, do not rush to replace the installed expansion tank with a new one with a larger volume. You can simply insert another one next to it so that it compensates for the missing liters.

When the question arises of how to install the piping of the expansion tank, there are only two points to consider:

- The coolant must enter it from the top point.

- And leave from the very bottom.

Expansion tanks of open and closed type

This is how you can avoid mixing air with water inside the tank.

Very often, ordinary people ask why the expansion tank is boiling? There are two reasons:

- The diameter of the contour pipe is incorrectly selected. Usually a reduced diameter leads to boiling, so experts advise using pipes of at least 32 mm. But also take into account the fact of correct installation of heating radiators. They should not rupture the pipe system, but crash into it.

- Lack of slope of the contours, which we have already discussed above. Therefore, you will have to redo the heating system or install a circulation pump in it.

A few words about the pump. It was already mentioned above that open-type heating and a circulation pump are not always compatible. If you increase the volume of coolant, then a low-power pump can be inserted into the circuit. And this will solve the problem. By the way, they install it on the return circuit near the boiler. How to increase the volume of coolant? Option one is to increase the diameter of the distribution pipes. You can also increase the sections of heating radiators. In general, everything will need to be calculated and thought through. You shouldn't make hasty decisions.

Installation

The expansion tank can be installed in any part of the heating system, but it is preferable to install it in front of the forced circulation pump. Installation can be performed with either top or bottom connections.

It is recommended to use the top supply, since this scheme prevents air bubbles from accumulating inside the tank.

If during the work it turns out that the designer made a mistake and the accepted volume of the tank is not enough to compensate for the thermal expansion of the liquid, instead of replacing the expansion tank with a larger one, a second tank of smaller dimensions is installed.

If a heating boiler with a built-in expander is installed in the system, installation of a separate tank may not be necessary. Also, when considering various installation options, it should be remembered that in order to reduce heat loss, it is better to choose the mount in which the supply line will have the shortest length.

Types of tanks

Compensation tanks for heating networks differ in shape, design, and internal size.

Open type equipment

They are a rectangular or cylindrical container with an open top, where you can always add water if necessary. Most often, such tanks are made of sheet steel and are thermally insulated. They are installed at the highest level of heating networks with natural circulation.

The design includes the following elements:

- containers of various sizes;

- inlet pipe for supplying coolant;

- outlet pipe for water return;

- control pipe that prevents overflow.

The main disadvantages of open expansion tanks are their large size, tendency to corrosion, the need to add water and constant monitoring.

Closed type device and its functions

Suitable for heating networks where the movement of coolant is provided by pumps. Externally it looks like a closed oval or spherical container with a pipe for connecting to the heating network and a nipple on the reverse side. A membrane is installed inside the tank, dividing the cavity into two chambers: one is filled with gas (air or nitrogen), the other is intended for liquid.

If the circuit is not heated, the tank is empty; when the temperature rises, the excess coolant is directed into the tank, increasing pressure in another chamber. When this parameter reaches the limit level, the valve is activated and excess gas is released. As the liquid cools, it contracts and is pushed back into the circuit. All processes occur automatically.

Photo 1. Closed expansion tank, volume 50 l, steel, without replaceable membrane, .

Closed devices are available in two designs.

With flanged replaceable diaphragm

The main features of expansion devices of this type:

- Water does not come into contact with the walls of the device, remaining inside the membrane cavity - eliminating the risk of corrosion and contamination of the coolant.

- Possibility of replacing the elastic chamber through a bolted flange.

- They have higher maximum pressure values than models with a non-replaceable diaphragm.

- Horizontal and vertical design - convenient to place in boiler rooms of different configurations.

With stationary membrane

The internal space is divided in two by an elastic butyl diaphragm, which is rigidly attached to the walls of the chamber.

Initially, the entire cavity is occupied by gas, so the membrane is pressed against the walls. During heating, the liquid enters the tank, the gas is compressed, and the pressure increases.

80ffce45030ada9c3069748facadb954.jpe

Water comes into direct contact with the inner surface, which creates a risk of corrosion. To prevent the destruction of the metal, a moisture-resistant coating is applied to the inside of the tank walls.

The main advantages of devices with a non-replaceable membrane are their affordable price and variety of design options.

Attention! The main disadvantage is that if the diaphragm fails, the tank will have to be replaced with a new one. Closed expansion equipment is allowed to be installed close to the heating boiler - on the side of the pump inlet pipe

Closed expansion equipment is allowed to be installed close to the heating boiler - on the side of the pump inlet pipe.

Kinds

Heating systems are made with natural and forced circulation of coolant.

In traditional heating designs, open-type expansion tanks are used.

In cases where the coolant is stimulated to move with the help of special circulation pumps, closed-type expansion devices are more often used.

Open type

An open type expansion tank is a regular metal box connected to a pipe from the heating main. It is placed in the highest accessible place of the building (house).

During the heating season, the presence of water in the tank is regularly checked. If necessary, add liquid to the expansion tank.

Some experts install a float level control system in the expansion tank. When the level drops, the float lowers, which leads to the opening of the feed tap.

The water is automatically added to the required level. Automatic systems are installed only where there is a water supply system in which a pressure exceeding the hydrostatic value Nst is maintained.

- An extremely simple device, easy to make with your own hands.

- It can function for years without causing any complaints from users.

- Corrosion damages the expansion tank first.

- It is necessary to regularly monitor the presence of fluid and top up if necessary. Often in private homes, when installing a heating system, the tank for expansion of the coolant is the last thing that is remembered. I place it near the ceiling, which creates inconvenience when refilling. Forced to use flat bottles to add water.

- It is necessary to lay an additional pipe that will heat only the space near the ceiling.

Important! The coolant tends to evaporate. It needs to be topped up periodically to prevent air pockets from forming inside the heating system.

Closed tank

In such tanks there are two volumes separated from each other by a movable membrane. The lower space contains coolant, and the upper space contains ordinary air.

To create pre-pressure in the system, a valve and fitting are provided on the air part of the tank. By connecting a pump, you can increase the pressure inside the air chamber.

Using a pressure gauge, the set pressure in the heating system Nst is controlled and set.

Installation of such a device is carried out in different parts of the heating system, most often traditionally installed near the boiler on the supply line.

Some users install additional taps and pressure gauges to know the pressure value during operation.

There is no need to constantly monitor the coolant level in the system; after filling it once, you won’t have to worry about it being full for several years.

Non-freezing liquids (high-boiling alcohols) are added to the coolant, which are not afraid of temperature drops below 0 ° C, which is important for country houses that are visited only periodically. There is no metal corrosion, since air does not enter inside. Minus conditional

It is necessary to equip a closed heating system with control devices, as well as a safety valve that will open in the event of a sudden increase in pressure

The minus is conditional. It is necessary to equip a closed heating system with control devices, as well as a safety valve that will open in the event of a sudden increase in pressure.

Attention! A sharp increase in pressure in the coolant is only possible if its circulation stops. This can happen if the circulation pump is damaged or disconnected. There is one more drawback that manufacturers of closed tanks do not want to talk about

The membrane loses its elasticity over time. If the pressure changes inside, damage will occur. That's why collapsible tanks are available on sale. It is easy to replace the membrane in them after a certain time. Typically, such maintenance is done in the summer, in preparation for the new heating season.

There is one more drawback that manufacturers of closed tanks do not want to talk about. The membrane loses its elasticity over time. If the pressure changes inside, damage will occur. That's why collapsible tanks are available on sale. It is easy to replace the membrane in them after a certain time. Typically, such maintenance is done in the summer, in preparation for the new heating season.

Installation of expansion tank

After making calculations, you can begin installing the heating expansion tank

It is important to choose its location correctly in the overall diagram. This directly depends on the type of system - gravity or forced circulation

Despite the fact that the role of the expansion tank in heating will remain unchanged, incorrect installation can lead to malfunctions.

Open design

Installation diagram of an open expansion tank

An open expansion tank is installed at the highest point of the system.

Some experts recommend installing it immediately after the accelerating vertical line. By adding water to the system through the expansion tank, the likelihood of backflow is reduced. Also, in this place in the circuit, the temperature of the coolant is usually the highest and, accordingly, its expansion. You can also connect to the return pipe. But then the operation of the expansion tank in the heating system will be less efficient.

Before installation, we recommend that you familiarize yourself with the general rules and tips:

- Small deviations horizontally and vertically of the structure are allowed. But they should not exceed 2-3°;

- Insulation can be done using basalt wool. She is not afraid of humidity, and most importantly, high temperatures;

- If the pressure inside the heating expansion tank exceeds critically, some of the liquid may fall through the top cover onto the attic floor. It is recommended to provide improved waterproofing of the floor in this area.

A scheduled inspection of the condition of the tank can be done 2 times a month with constant heating operation and always before the first start of the system.

Diaphragm tank

Installation diagram of a membrane expansion tank

Installation of a membrane expansion tank in heating systems is carried out only on the return pipe in front of the circulation pump.

A prerequisite is compliance with the temperature regime in the room. The air heating level should not be less than +5°C. Installation must not be obstructed by foreign objects. The same applies to structural maintenance.

The correct installation of the expansion tank in the heating system is to maintain its level. The structure must stand strictly vertically. Even a slight tilt may cause incorrect operation. For safe servicing, an air valve should be installed on the air chamber to quickly reduce the pressure in it in the event of an emergency.

It must be remembered that the location of the expansion tank in the heating system must not only be technically correct, but also convenient for its maintenance.

The fundamental difference between the operation of an expansion tank in a closed-type heating system is the possibility of its quick dismantling. Therefore, it is recommended to install 2 shut-off valves during installation - one on the inlet pipe to the heating system, and the second on the water chamber of the tank. By blocking them, you can quickly dismantle the container to repair it or install a new one.

The video material presents the design features of expansion tanks and their role in the operation of the heating system:

Characteristics of an open tank

Such tanks are extremely simple - an ordinary bucket, a specially made container from scrap materials, a canister, or something similar can always be used as an expansion tank.

Design features of the container

The main design requirements are:

- availability of sufficient volume;

- lack of tightness.

That is, even the absence of a cover is allowed, although it is desirable - it protects against dirt particles getting into the heating system.

The tank, which is planned to be used as an expansion tank, must be equipped with a pipe to which a pipe from the heating system . This is the only required device.

The design of any expansion tank is extremely simple - it is a regular container equipped with one or more inputs/outputs. This allows excess liquid to accumulate and drain. The most technologically advanced tanks are equipped with a water supply and a drain valve, which is needed to transport water to the sewer when there are too large volumes of excess water.

But for comfort and to avoid minor troubles, it is advisable to use the following accessories:

- Overflow hose or pipe - this structural element is necessary in case of overflow of the expansion tank. That is, this structural element, by discharging liquid into the sewer or simply outside the building, eliminates the possibility of its flooding.

- Water supply pipe - it is necessary to replenish the heating system with water. It is quite possible to do without it, but you should understand that this procedure will have to be carried out with a bucket in your hands. Although in the latter case the design will be cheaper.

Since expansion tanks are often installed in attics, care should be taken to insulate them. This will prevent the liquid from freezing and causing the entire system to fail.

Only ordinary water can be used as a coolant. Because modern effective antifreezes evaporate quickly in open tanks. This leads to a significant increase in the cost of the entire heating procedure.

In addition, antifreeze fumes are almost always toxic, which affects the health of residents. We talked more about the types of coolants for the heating system and their features in this material.

Shape and material of manufacture

The shape of the tank is not fundamentally important, so it can be anything:

- round;

- rectangular;

- trapezoidal, etc.

The manufacturing material can be any metal or even plastic, but since the coolant can heat up to significant temperatures, it must be heat-resistant.

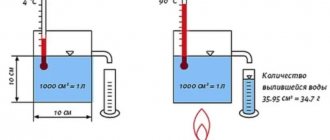

This drawing helps to understand the working principle of the expansion tank. The image on the left shows the coolant in a cold state. The volume provided is more than enough for him. But when heating begins (picture on the right), excess water soon appears. In fact, there is not much excess liquid, but this is quite enough to find a weak point in the system and form a leak or lead to equipment failure

There are various options for open expansion tanks on sale, among which it is easy to choose the most suitable one. Or make a homemade tank from scrap materials, which will act as an expansion tank.

Calculation time - how to determine the required volume of the expansion tank

Having understood the classification and choosing the most suitable option for your purposes, you need to calculate the minimum allowable volume of the tank. For comfortable heating operation, a container containing 10% of the volume of coolant in the system is sufficient. To calculate the amount of all water in pipes and radiators, two variable methods are used:

- measurement of displacement when directly filling the system with water or other coolant;

- calculation of the capacity of all pipes and radiators located in the heating circuit.

For such purposes, you can use canisters or other containers, the volume of which is already known.

To calculate the volume of pipelines, use the table below:

| Pipe internal diameter, mm | Volume of water in 1 linear meter, l |

| 14 | 0,1539 |

| 16 | 0,2011 |

| 18 | 0,2545 |

| 20 | 0,3142 |

| 22 | 0,3801 |

| 24 | 0,4524 |

| 28 | 0,6158 |

| 32 | 0,8042 |

| 36 | 1,0179 |

| 40 | 1,2566 |

| 50 | 1,9635 |

To calculate the volume of heating batteries, you can use the following average values:

| Radiator material | Liquid volume in 1 section, l |

| Cast iron | 1,7 |

| Bimetallic alloy | 0,25 |

| Aluminum | 0,45 |

Having completed all the necessary calculations, you can immediately find 10% of this value. Or use a special formula that will give a more accurate and objective result:

V= VL β / D

- VL – heating system capacity, l;

- β – liquid expansion coefficient;

- D – efficiency of the expansion tank.

To calculate the last indicator in the formula, we perform the following calculation:

D = (PV-PS) / (PV-1),

where PV is the maximum value of operating pressure in the system, bar; PS – pressure in the tank without load, bar.

A special antifreeze, which has its own expansion coefficient, can be used as a heating fluid

Important performance characteristics and compensator volume calculation

When selecting an expansion tank, take into account the maximum operating temperature and pressure. For example, the coolant can heat up to +120° C, and the peak pressure in the heating expansion tank can reach 6-10 bar (the usual average value is 2-4 bar). Therefore, the characteristics of the membrane, its durability, heat resistance, and compliance with sanitary standards are important.

There are three main types. Open plastic manifolds, mainly used for swimming pools where the required temperatures are relatively low and are used for seasonal use only. Flat plate glass collectors, built in endless variations, are by far the most commonly used since then, with the best performance.

Vacuum collectors, although several times with slightly higher efficiency, their price-performance ratio combined with their greater fragility make them marginal and only for special installations. This system does not use actual solar collectors, but instead consists of a dark plastic dome under a sanitary water tank that is heated for a greenhouse effect. However, at a very low cost, it has very low efficiency, coupled with the danger of winter frost, it reduces the seasonality of use.

The volume of the compensator depends on the volume of coolant as a whole in the system. It is not necessary to calculate the volume mathematically accurately; a simplified method is often used: select a tank with a capacity equal to 10% of the total volume of the coolant. And if this volume is unknown, then they proceed from the power of the boiler and the type of heating devices. The ratios are as follows: for heating radiators they take – 11 l/kW, for heated floors – 17.5 l/kW, for wall-floor heaters – 7.5 l/kW.

Its use is limited to the production of hot water and is so called because the circulation between the solar collector and the storage tank is determined by the principle of gravity rather than by a pump. The heat transfer fluid that is heated inside the manifold becomes lighter as it goes into the storage tank where, receiving its heat, it is returned to a large extent, thus creating a natural circulation cycle. For this to happen, it is necessary to place the storage tank on the roof at a slightly higher position than the collectors.

If the capacity of the selected compensator is insufficient, the safety valve will release pressure too often. In this case, it is enough to purchase and connect in parallel another expansion tank.

It is quite difficult to take into account all the nuances, especially since in each house the heating system necessarily has its own characteristics. In order not to make a mistake when choosing and installing a device, it is better to contact a specialized company.

For this reason, theoretically, in many modern homes, many applied restrictions are aesthetic and structural in nature related to weight. It can use all existing solar collectors and is so called because the circulation between the solar collector and the storage tank is determined by a pump. It is not associated with specific positioning protocols, so it meets a wide variety of technical, plant and architectural requirements. It can be built to any size and for any use, from domestic hot water production to heating system integration; from civil use to industrial use.

Features of arranging open heating

Classic open heating equipment

A classic open-type heating system for a private home differs from a closed one in terms of pressure. It is equal to atmospheric. Therefore, to arrange this type of heat supply, significantly fewer components and accurate calculations are required. But this does not mean that an open heating scheme can be drawn up unprofessionally.

To automatically stabilize the coolant pressure in the pipes, the system provides an open expansion tank for open heating. It is the design of this component that distinguishes an open heat supply scheme from a closed one. The coolant can move in two ways:

- Due to thermal expansion of hot water. For this, an accelerating riser is required. According to this scheme, an open heating system with natural circulation is designed;

- Installation of pumping equipment. It allows you to increase the speed of coolant movement. A pump in an open heating system is necessary if the total length of the lines exceeds 25 m.

In addition, it is necessary to reduce the friction of water as it passes through the pipes. To do this, the diameter of the latter must be at least 30 mm. Otherwise, hydraulic resistance will increase, which will reduce natural circulation.

The defining component in the scheme is the boiler for an open heating system

It is important not only to choose the correct design and operating principle of the device, but also to follow all installation rules

Installation of an open type hydraulic tank

An open-type device is used less and less often, as it requires constant user intervention in its operation. An open expansion tank is an unsealed container that serves to generate pressure in the water supply system, accumulate water, and also serves as an expansion chamber.

The tank is connected to: a drain tap, pipes for the recirculation and supply pipes, a control and overflow pipe

The tank is installed above the highest plumbing point, for example, in the attic, water enters the system by gravity. Every meter the device rises increases the pressure in the water supply by 0.1 atmospheres.

To automate the process of providing water, the tank is equipped with a float switch and an automatic relay is installed that will turn the pump on and off.

The container is mounted in a frost-free room, covered with a lid to prevent dust and debris, and the walls are wrapped in mineral wool or other insulation.

This method of organizing water supply requires regular monitoring by the user, otherwise the water may freeze at subzero temperatures (if the room is not heated). The liquid will evaporate, so you will have to constantly add it.

In addition, such a container is bulky and not aesthetically pleasing; it requires an attic space in the house. But the main drawback of the device is that the tank is not designed to work under conditions of high water pressure in the system.

How to make it yourself from plastic containers or stainless steel

You can make an expansion tank yourself. A tank of 10-12 liters is suitable for this (depending on the exact calculations of the coolant volume of the general system).

If you have a ready-made base, for example, a plastic container, you should check its capacity (with regular 3-liter jars), and then attach the missing elements.

Usually the tank is made of stainless steel sheet 2-4 mm thick.

Tools:

- welding machine, electrodes for welding;

- grinder with corresponding circles;

- sheet metal (stainless steel);

- pipes;

- various bolts, a set of fittings;

- rubber gaskets;

- brush, gloves, protective mask;

- Oil paint;

- thermal insulation materials;

- metal file;

- roulette;

- tank diagram with all dimensions.

Marking a sheet of metal

First of all, you need to make markings on the sheet metal. To do this, you can use a cutting card with paper parts, which allows you to use metal with the least waste. When joining two parts on a sheet, you must take into account the thickness of the grinder circle, which can “eat” several millimeters.

Important! All work should be carried out carefully, followed by cleaning the edges

Cutting blanks

The tank body consists of five or six rectangles (depending on the presence of a lid). If desired, you can divide the upper part of the lid into two parts in a way that is convenient, welding one part to the base and attaching the second to the curtains.

Welding a homemade device

The cut pieces must be placed at right angles and welded. The method of fastening can be different - gas is perfect for 2 mm steel sheets, and electric welding works well with 3-4 mm sheets.

It is necessary to make a hole in the bottom of the housing and weld a pipe there through which the coolant will enter the tank. The pipe itself, accordingly, is connected to the circuit of the general heating system.

Insulation

The open heating structure is characterized by the installation of an expansion tank at the highest point of the system. Typically, this is an unheated attic, where in winter the temperature is often sub-zero. Under such conditions, the water in the tank may freeze, damaging the entire system. To avoid this problem, the tank should be insulated with special materials, for example, basalt wool.

This thermal insulation material is resistant to high temperatures, which is a necessary condition, since the water in the tank boils at elevated degrees.

Adding oil

In addition to the main pipe connecting the tank to the system, additional elements are welded into the design of a homemade tank:

- to recharge the system or add coolant (water, oil);

- for emergency drainage of excess coolant into the sewer system.

Important! The drain pipe must be located above the maximum filling level of the tank to avoid liquid overflowing from the top. Through the hole in the lid, water from the tank evaporates and air can enter the system

This leads to overheating of the pipes and poor coolant circulation. To solve this problem, professionals recommend pouring a little oil into the tank. It will cover the surface of the coolant with a thin film, thus creating a protective layer against air penetration

Through the hole in the lid, water from the tank evaporates and air can enter the system. This leads to overheating of the pipes and poor coolant circulation. To solve this problem, professionals recommend pouring a little oil into the tank. It will cover the surface of the coolant with a thin film, thus creating a protective layer against air penetration.