Domestic brick stoves for coal remain worthy competitors to solid fuel boilers in a situation where in winter it is necessary to heat a small and medium-sized home, and main gas is not supplied. If in some respects coal stoves are inferior to steel and cast iron heat generators, then in other respects they have no equal. Therefore, the demand for the construction of brick kilns remains consistently high.

Using coal instead of firewood is an inexpensive and efficient option for heating your home.

Advantages of brick heat source

Installing a solid fuel boiler is easier and cheaper than building a brick heating stove in the middle of the house. On the other hand, for the unit to operate, it is necessary to install a water heating system, and the stove can do without it.

Despite the high cost and complexity of construction, many homeowners still prefer brick ovens. The reasons are significant:

Features of placing the stove in the house.

- Durability. When coal is burned in the firebox of any heater, a fairly high temperature arises, which over time destroys steel products. While even ordinary ceramic bricks will last for decades.

- Cast iron boiler heat exchangers run the risk of cracking due to temperature changes, while brickwork can easily withstand temperature shock.

- Heat capacity. A brick stove on coal accumulates a large amount of heat during operation, and the boiler for this requires a buffer tank, which costs a lot of money.

- The accumulated heat is released into the room for a long time after the coal in the combustion chamber has died out.

- The stove produces healthy, pleasant heat transmitted through infrared radiation and convection.

Since coal stoves still cannot do without the firewood required for kindling and heating, an indescribable atmosphere is created in the house, saturated with the natural smells of nature. There are 2 types of such heat sources:

Properties of a natural fuel stove

As already mentioned, the combustion temperature of coal is quite high. With sufficient air supply to the firebox, it reaches 1000-1100 °C, so not every material can withstand such conditions for a long time.

For comparison: dry wood under identical circumstances can produce no more than 700 °C in the firebox, and even then very rarely. In addition, coal fuel is much higher in calories than firewood.

That is, when burning 1 kg of anthracite, almost 2 times more thermal energy is generated than from the same amount of wood, as shown in the table:

| Type of fuel | Calorific value | |

| MJ/kg | kW/kg | |

| Wood with a moisture content of 25% | 10,1 | 2,8 |

| Stone coals | 21,5 | 5,9 |

| Brown coals | 15,5 | 4,3 |

Previously, in old houses, heating stoves or slabs were made only of solid red brick. When constantly burning high-calorie coals, the masonry gradually began to crumble due to exposure to high temperatures, so the owners lined the inside of the firebox with thick steel soles from railway tracks to protect the walls.

At the moment, the problem of burning coal is solved much easier - with the help of fireclay bricks. The design of the furnace provides for lining the fuel chamber with fireclay stone grade ША, ШБ or ШВ to a thickness of a quarter or half a brick. This material can easily maintain temperatures of 1400 °C and short-term temperatures of up to 1650 °C.

There is another point: due to the higher calorie content than wood, a larger amount of heat is released, part of which goes with the combustion products into the chimney.

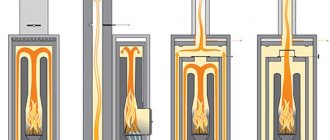

To avoid this, a more developed smoke circulation network is provided in the coal furnace, where flue gases have time to transfer heat to the brick walls, and not immediately fly out into the chimney.

Otherwise, this is an ordinary brick stove with all the advantages and disadvantages.

Principle of fuel combustion

Alternative types of fuel can be used to operate a solid fuel boiler.

Coal briquettes. The fuel is produced by pressing small fractions of coal and coal dust. They use minerals or coal tar as a binder. The advantages of this type of fuel are ease of installation and kindling, high calorific values and excellent flammability.

Pressed peat or wooden eurobriquettes. Fuel briquettes made from peat have a small area, but are capable of smoldering for a long time, maintaining the active combustion phase.

Pellets. This is biofuel made in the form of granules. Peat, wood and agricultural waste are used for production. This is an environmentally friendly and energy-efficient material, which is preferable to use in boilers whose design is adapted to pellets.

We suggest you read: Where can you dig a well?

Types of fuel for a pyrolysis furnace.

A long-burning coal stove works somewhat differently than standard solid fuel boilers, in which the logs themselves are burned first and only then the natural gases themselves.

Coal-fired home stoves operate according to the following principle: it is the top layer that is most susceptible to heating, the lower temperature is observed in the outlet channel. The efficiency of such a heating unit primarily lies in the fact that the combustion chamber is large enough and can accommodate a large amount of coal.

Wall-mounted steel model, equipped with a small fuel chamber

The oven is presented in a red tint and is equipped with a temperature and pressure control sensor

Solid fuel stove with a closed round combustion chamber

Do-it-yourself coal stoves also require a special place, and ideally a room in which the coal will be stored. It is important that the selected space has a suitable temperature and low humidity levels. It is also not recommended to store coal for more than one year, since over time, anthracite begins to cake in the fuel.

The disadvantages of a coal stove for the home include the fact that during operation, the space easily and quickly becomes dirty, objects and furniture get dirty. That is why, to install this heating unit yourself, it is recommended to find a separate room or fence off this area and equip it with easy-to-clean surfaces.

Coal stoves have their own exceptional advantages, thanks to which many people choose them:

- Coal stoves, when installed in a separate room and connected to a water circuit, do not pollute the space and can efficiently heat both a one-story house and a two-story cottage;

- Purchased or homemade long-burning coal stoves are characterized by high efficiency, heat capacity, and good efficiency. Also, such models are quite economical in terms of fuel consumption;

- Since the device has a well-thought-out structure, residual combustion products settle and are produced on the inner surface in minimal quantities, which makes cleaning quite rare;

- If the model has the ability to operate automatically, you can adjust the fuel supply without doing it yourself for several days. If you add a bunker to the unit, loading can be carried out automatically within 10-15 days;

- Additional functionality makes the care and use of the unit even simpler and more convenient.

Three-tier stove equipped with a combustion chamber and ash pan

What does the long-burning model consist of?

Despite the many advantages, the following difficulties may arise when using long-burning coal stoves:

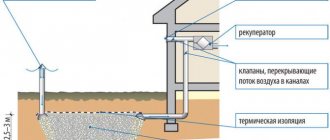

- A long-burning coal stove for a home requires equipment for a separate small room. With high-quality ventilation and sealing;

- Since the combustion temperature of coal in furnaces is quite low, after prolonged use quite complex, serious blockages of the system can arise, which can only be dealt with by cleaning;

- High-quality hearths have a fairly high cost.

How to build a stove?

First you need to understand what requirements are put forward for a heating stove for coal:

- the heater must warm up evenly and quickly, intensively transferring heat to the air in the rooms;

- the outer walls of the brickwork facing the rooms can warm up to a maximum of 90 °C;

- fuel combustion must be efficient;

- the stove should be located in the house in such a way that its walls heat several rooms;

- when constructing the body of the stove and chimney, it is important to comply with all fire safety rules;

- It is not allowed to use flammable materials during construction;

- the masonry must be smooth, without cracking;

- The heater should be finished in accordance with the interior of the home.

When the requirements are known and worked out in relation to your home, you should select a stove design that is suitable in size and lay a solid foundation for it.

Laying the foundation

A coal stove is a massive and quite heavy structure, and therefore the foundation for it must be made reliable. Its dimensions in plan are taken to be 5 cm larger in each direction from the dimensions of the future structure.

An important condition: the foundation of a brick heating or cooking device should not be connected to the base of the building itself, but should be at least 10 cm away from it.

Work on laying the foundation is carried out in the following sequence:

After laying the foundation, you can begin building the stove according to the procedures.

Firewood

Firewood is another popular type of fuel for boilers. Only dried wood is suitable for burning. Under-dried firewood in the firebox begins to release moisture, which accumulates on the internal surfaces of the firebox and chimney. In combination with smoke and carbon monoxide, tar is formed - it reduces the operational properties of the boiler and reduces the permeability of exhaust gases.

Firewood selection

For melting, hardwood with a long burning life and slow heat transfer is optimal. Preference should be given to deciduous trees over coniferous ones. During the combustion process, conifers emit a large amount of resinous substances and quickly pollute the combustion chamber and heat exchanger.

According to the degree of hardness, wood species are divided into 3 categories:

- hard - white acacia, ash, beech, oak, maple, yew, hazel, pear;

- medium hard - walnut, alder, sycamore, birch, cherry, cherry, cedar;

- soft - poplar, aspen.

- At the first stage, it is necessary to warm up the heating device well. This will prevent smoke from leaking into the room. Sheets of paper are placed at the bottom of the fuel chamber, on them are flammable birch bark, chips and splinters, and on top are small logs (up to 15 cm in diameter). The space between the chips can be filled with paper for faster ignition.

- When the firebox is about half full, you should set fire to the paper and open the ash pan valve for better draft. Close the main chamber door.

- When the chamber and chimney warm up and the preparatory filling begins to burn out, the firebox can be filled with large firewood. You can lay out the logs in a row or in the form of a well, leaving gaps between them for air penetration.

- As the firewood burns out, you will need to make a new stack without waiting for the previous one to die out.

Long-burning boilers greatly simplify the work. Fuel is added to them once every 6 hours due to automatic regulation of draft and combustion process. Such devices should be melted in accordance with the attached instructions.

Recommendations for masonry

To lay a stove where you plan to burn coal, you will need 2 types of mortar - clay-sand and fireproof. With the help of the first, the body of the furnace is built from solid ceramic bricks, and the second is used for the internal masonry of fireclay stones. The thickness of the seams also differs: for ordinary masonry it is a maximum of 5 mm, for fireproof masonry - 3 mm.

To prepare both types of mortar, it is recommended to purchase ready-made construction mixtures that are commercially available. Only experienced stove makers can make a good solution from natural clay. You also need to prepare masonry and measuring tools, and then start building the stove:

The stove solution does not harden, but dries, for which it needs to be given 2-3 days. Afterwards, all that remains is to lay out the chimney, observing the rules for passing through the floors and roof, and at the end make a test firebox. You can fill the stove with coal only after it has completely warmed up, making sure that there are no cracks or crevices.

This site uses Akismet to reduce spam. Find out how your comment data is processed.

Often a coal stove is chosen for installation in a country house or bathhouse. Its heat output is one and a half to two times higher than that of a wood stove due to the fact that coal burns at a higher temperature.

This stove has a simple design, reliable operation, and is also economical due to the low cost of fuel.

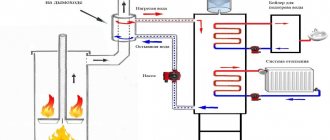

Coal stove diagram for home

The design of a brick coal stove is almost no different from the design of a conventional wood stove.

It consists of, located in a certain sequence: foundation, ash pit, combustion chamber, vault, chimney.

The main difference between a coal stove is a reinforced firebox and an increased volume of the ash pan (when burning coal, a larger amount of ash is produced than when burning wood).

A larger area grate is also required (ideally it replaces the bottom of the firebox).

The coal in the combustion chamber of the furnace burns out from below, so the walls of the compartment are made inclined - this design helps the upper layers of coal to sink as they burn out. The dimensions of the standard device are 110x900cm , the height without a chimney is about a meter.

For the bath

The sauna device is characterized by the presence of a heater - a container for stones. Together with it, the height of the stove will be 1.6 m , length 1.1 m , width 90 cm . The heater is made open and located in the upper part of the stove. Because of this, the chimney is located not above the combustion chamber, but to the side.

More compact metal stoves are often installed in the bathhouse. The dimensions of a standard metal coal stove are 50x80 cm and height 80 cm . It is recommended to make the wall thickness at least 8-10 mm.

How much coal will be needed for the heating season?

Experts advise using anthracite for home heating. If desired, you can either buy it in a bag or order several tons at once. In this case, the seller usually takes care of the delivery of fuel to the storage facility. To calculate the amount of coal needed for one heating season, we will take a bucket as a unit of measurement, because This is what most homeowners use in their households.

A standard metal bucket holds approximately 18 kg of anthracite. For 1 day to heat a spacious house with an area of 200 sq.m. use:

- at the very beginning of the season - 1 bucket (late September - early November),

- during the frost period (from November to February) it takes about 10 buckets,

- at the end of the season - 1-2 buckets (in March-April).

If we calculate the total amount of coal used per season, we get 580 buckets, which is 10,440 kg. Before the start of the heating season, you need to order at least 10 tons of fuel. Multiply this amount by the current cost and get the amount you need to save for home heating per year. If the area of the house is less than 200 sq.m. the quantity will be less. If the stove is used in the summer as a cooking stove - large.

Coal is considered to be a “dirty fuel”. This opinion is not entirely correct. Anthracite burns relatively cleanly, although it cannot be compared with gas or liquid fuels

Stoves are made of brick, cast iron and steel. Brick structures are more heat-intensive, while metal structures are lighter and more convenient to install. Which material to choose is up to each homeowner to choose. The main thing is that the stove is installed in accordance with fire safety standards, and its performance is sufficient for high-quality heating of the house.

We invite you to familiarize yourself with: Homemade metal stoves for baths drawings

Making a device yourself

Carrying out brickwork is quite a difficult job if you lack experience. Therefore, before starting construction, it is better to seek advice from a master. When making a stove yourself, it is important to carefully follow all the steps and not change the selected project design.

Project selection, drawings

The choice of oven model is primarily influenced by the desired power of the device. The efficiency of the heater depends on the size of the combustion chamber. Typically, coal combustion has a heat output of about 500 kcal/hour . Therefore, a device of standard dimensions 110cmx90cm is suitable for heating a room up to 35 square meters. m .

Photo 1. Drawing of a metal coal stove. The device is small in size, it will fit even in small rooms.

Photo 2. Drawing of a coal stove made of metal. Arrows also indicate all parts of the device.

Materials and tools

To build a coal stove, you will need fireclay bricks that can withstand heating up to 1400-1650 degrees without cracking. To prepare masonry mortar, fatty clay is used mixed with water and sand. To lay out the external walls you will need solid red brick.

Doors, hinges, and grate are purchased at a hardware store.

The work will also require tools: hammers, a trowel, usually a mortar shovel, a hacksaw, a grinder, a building level, plumb lines, and a tape measure.

Stages of work

When choosing a place to build a stove, factors such as the location of the chimney and the size of the room (in a large area it is better to install the equipment in the center).

The walls and ceiling in the selected area are sheathed with fire-resistant material.

It is better to immediately think about the place where the coal will be stored - in order to avoid fire hazards, it should not be placed in close proximity to the stove . It is also necessary to take into account that coal is very dusty and dirty.

A massive brick oven is installed only on a concrete foundation , which is not connected to the main one. Therefore, its location is better than

The operating principle of wood and coal stoves

Technologies do not stand still. And gradually a new trend is gaining popularity. These are so-called long-burning furnaces. This design increases the combustion time of firewood by 2 times, and coal by 3 times.

The operating principle of such a furnace is based on forced air supply and fuel combustion in the upper chamber. The fuel is pressed down with a special weight, which sinks lower and lower as it burns. The air is pumped using a fan.

This principle is fundamentally different from the classical one, when combustion occurs due to the supply of air from below, through the blower.

The stove can use any solid fuel: brown coal, anthracite, briquettes, sawdust, firewood, etc. The fuel supply process can be automated. In this mode, the oven can operate for up to several weeks. As in the classic version, there is an ash chamber located below. It is separated from the combustion chamber by a grate.

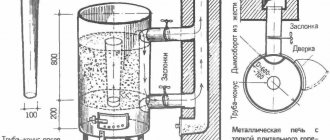

Homemade potbelly stove

Recently, many designers have been offering exclusive versions of potbelly stoves or fireplace stoves that are installed in country houses. For residents of prestigious cottages, they are not only an additional source of heat, but also a beautiful accessory for the interior design of the room. Such individual stoves fill the room with warmth and special comfort. Firewood crackling in a stove or fireplace looks very beautiful and romantic when a winter blizzard is raging outside the window.

The most popular, primitive and effective long-burning stove for temporary heating is the well-known potbelly stove. Its simple design is based on the “symbiosis” of a Russian stove and fireplace. With one load of fuel, it is capable of maintaining a comfortable indoor temperature for 4 hours. The potbelly stove can be installed in any space where a chimney can be removed.

Today, anyone who has the skills to perform plumbing work can make a potbelly stove with their own hands from all kinds of available materials. This oven:

- Does not depend on electricity or gas.

- Easy to maintain and operate.

- Allows you to control the combustion process.

- Takes up little space.

- Compact and economical.

- May have a hole for installing utensils to cook food or heat water.

Among the disadvantages of such a furnace, it should be noted the low efficiency, high speed of exhaust gases and rapid cooling. Therefore, to maintain the temperature in the room, it must be heated constantly.

Our craftsmen make potbelly stoves with a welding machine on hand and used:

- large cans;

- metal corners;

- wide pipes;

- gas cylinders;

- metal boxes;

- large fire extinguishers;

- old barrels;

- steel sheets;

- chimney pipes;

- metal gratings.

Detailed drawings are not needed to make a potbelly stove. The main thing is to get the most efficient design possible. Let's look at the main components that make up a homemade stove.

Advantages and disadvantages

This solution has obvious advantages:

- the oven can operate offline for up to 10 days;

- the operating time on one load of fuel increases by 2 times for firewood, and by 3 times for coal;

- low requirements for fuel quality;

- simplicity of design and installation;

- the ability to add additional options.

But practice has shown that there are also disadvantages:

- it is impossible to add fuel until the previous fuel is completely burned;

- you need a dry place to store fuel;

- coal produces a lot of dust and soot;

- high fire hazard if the requirements of SNiP 2.04.05-91 are not followed;

- The ash pan must be cleaned after each firebox, and the chimney before each heating season;

- environmental pollution.

You can make the stove yourself or purchase a factory-made analogue. The purchased option is preferable. Such a furnace will allow you to automate the process as much as possible. But it’s not cheap either.

To save money, you can make a similar design yourself. It will not be equipped with modern automation, but for a summer residence this is often not necessary.

The best material for the stove is heat-resistant alloy steel. Sometimes, when making it yourself, they use old gas cylinders. They are made of St3 steel with a high carbon content. Fire-resistant bricks are also widely used.

A long-burning stove using coal and wood can heat one room, or maybe an entire cottage. It all depends on the power. In the latter case, the furnace is used to heat the coolant - water, which enters the heating system.

How to heat so that coal burns as long as possible

The correct firing of a long-lasting coal boiler largely depends on the presence of control automation and, of course, the quality of the coal itself.

What coal is better to use

Manually operated boilers can operate on coal of any fraction. But it must be taken into account that the temperature of the gases in the chimney during long-term combustion is much lower than during direct combustion: the use of raw fuel can lead to the accumulation of excess moisture in the pipe and the formation of condensation - a black viscous liquid with a tar smell. Therefore, the relative humidity of coal (like any other solid fuel) should be no more than 15–20%.

Reference. Equipment with an automatic fuel supply function is more sensitive to the fraction, since it was originally developed for the 5–25 mm standard. In addition, it should be heated with low-caking (type 31 or 32) and low-ash (up to 15%) coal to avoid the appearance of excess “garbage” and a decrease in efficiency.

Correct firebox

The combustion of a long-burning boiler is carried out according to the following scheme:

- Fuel loading - the distributor is raised to its original position so that it is just above the loading door, and all the coal is immediately poured.

- Kindling - dry wood chips and paper are placed on top of the coal, after which they are ignited and burn with the top door open and the air duct closed.

- Combustion - when the temperature in the heat exchanger reaches 50-60 °C, the door closes tightly, then the telescopic air duct regulator opens.

- Temperature adjustment - the boiler automatically enters the optimal mode, but if necessary, the temperature is adjusted by the air duct damper.

Upon completion of the full combustion cycle, it is necessary to remove sintered pieces of coal from the loading chamber, clean the ash pan and fill in a new batch of fuel.

Which stove is better to choose for your home?

Criterias of choice

When choosing a specific stove, pay attention to the following characteristics:

- power

- operating time on one fuel fill

- coefficient of performance (efficiency).

- The worse the room is insulated, the more heat will escape outside. Accordingly, in order to save money, it makes sense to take care of reliable thermal insulation in advance.

- When purchasing a factory model, all data will be indicated in the product passport. If you decide to make the oven yourself, then you will have to do the calculations yourself. Divide the area to be heated by 10 and take 20% as a reserve. This will give you the power you need.

- The next parameter is the operating time on one fuel load. Modern models can work autonomously for up to 48 hours. The longer the operating time on one tab, the more efficiently the fuel is used. And the less often you need to add it.

- There are models that use a hopper to automatically add fuel. Such a stove can operate autonomously for up to 10 days.

- The operating time of a stove for a summer cottage using wood and coal on one stack should be at least 12 hours. You won't enjoy waking up at night to add fuel. The efficiency of factory models is 75-90%. For homemade analogues – 75-80%. Factory boilers are beyond competition here. The only negative is their cost.

Review of the best models

The following table contains the 10 most popular models of factory-made solid fuel boilers. This is a long-burning wood-coal stove using wood, coal, and pellets.

| Model | Characteristics (power, room area, dimensions) | Material | Weight, kg | Price, rubles |

| Dobrokhot 6P |

| Steel | 70 | 12 800 |

| Zota Master |

| Steel | 103 | 24 890 |

| Siberia KVO 10 TPE |

| Steel | 85 | 16 842 |

| Magnum KDG 15 TE |

| Steel | 160 | 36 921 |

| Cooper OK-15 |

| Steel | 98 | 21 563 |

| FACI – 26 with fuel bunker |

| Steel | 350 | 158 000 |

| KST-20 with automation |

| Steel | – | 40 000 |

| Cooper PRO-22 |

| Steel | 115 | 26 751 |

| UmTech TTX-15 |

| Steel | 340 | — |

| Partner 16 |

| Steel | 83 | 21 960 |

Features of operation

If you heat the stove incorrectly, you can lose up to 70% of the heat. Below are the basic rules that must be followed.

Wood burning

Proper preparation of materials

But that's not all. In air, the humidity of firewood is 25 - 30%. The optimal value is no more than 12%. Therefore, before firing, they are dried indoors. If you place the firewood 1–1.5 m in front of the stove, it will dry out in 48 hours.

To do this, use a special tub in which logs are placed (see Fig. No. 1 below). Such firewood will have the optimal humidity and give off the heat indicated in the reference books. Keeping firewood closer than 1 m from the front surface of the stove is prohibited due to fire safety rules. The design of the stove may include a special place for drying firewood - a firewood shed.

Rice. No. 1 Tub for drying firewood

Cleaning the firebox, ash pan and inspecting the stove

You need to clean the stove from ash before firing it. This will eliminate the possibility of fire due to unextinguished sparks. First, the firebox is completely cleared of ash. All remains are swept into the ash pan. Then it is cleaned using a scoop. Ash should not be thrown away. This is an excellent mineral fertilizer.

It is necessary to wipe the doors, view and gate. Dust is the most common cause of chimney fires. When burned, it turns into bitumen. And it forms a dense soot that is very difficult to remove.

Another important step is checking traction

If the draft is insufficient, all the smoke will enter the room and it will be difficult to bring the stove to operating mode.

How to check traction? Very simple. They take a candle. Close the combustion door tightly. The blower is opened slightly. And they bring a burning candle to her. The flame should tilt towards the stove and burn evenly.

What to do if there is no traction? This means that either a vapor lock has formed in the oven or an air lock in the chimney.

You need to completely open the blower, view and gate. And prepare kindling from newspapers, oiled rags or sawdust. The kindling is slowly burned in the stove until the smoke breaks through the plug.

If all else fails, inspect the deflector. It may be damaged or clogged.

Refueling and lighting the stove

To fire the stove, a mandatory tool will be tongs. Without them, it will be difficult to straighten burning logs or coal. And if the wood, when burned, settles unevenly, then a lot of heat is wasted.

How to refuel the oven correctly? First, kindling is placed in the middle of the future bookmark. It is best to use an oiled rag. Just don't let it drip. Also use several sheets of newspaper or thin dry wood chips.

How to properly stack firewood is shown in Fig. 2.

Rice. No. 2 Options for stacking firewood in the stove

Classic is option number 1 . Firewood is stacked in the same way as in a woodpile. Option No. 2 is used if the firewood is too large or not dry enough. There should be free space in the middle, and the gaps between the logs should be 2-3 times smaller than their width. And method No. 3 is suitable for a small firebox.

Preparatory stage of lighting the stove

If you are planning to light a stove that has not been used for a long time, you should carry out a number of preparatory measures. This procedure must be carried out in order to ensure trouble-free operation of the stove, as well as to avoid unpleasant situations that sometimes lead to fires or harm to human health and life.

• Inspect for cracks. Their presence can facilitate the penetration of smoke and even carbon monoxide into the room. If any are found, minor repairs should be immediately carried out using a mixture of clay and sand. • Clean soot from all flues and chimneys. Wipe off dust from the internal walls with a dry rag so as not to smell a bad aroma when kindling. In general, it is advisable to perform this procedure 2-3 times a month.

• Pay attention to the doors, especially their fit and the functionality of the locking mechanisms, to avoid the appearance of smoke. • Select fuel of the appropriate quality, suitable specifically for your type of stove

• Properly equip solid fuel storage areas.

During further operation, you should also follow a number of simple rules. Using plastic, construction and household waste for kindling will lead to severe contamination of the stove. It is incorrect to open the vent and the oven door at the same time. It should be heated several times a day for one and a half to two hours to avoid overheating. Dry, medium-sized, dust-free charcoal will provide excellent functionality.

https://www.youtube.com/watch?v=

Avoid storing flammable objects near hot walls. Do not leave the stove unattended while lighting, especially in homes with children.

Tags: heating, stove, coal

« Previous entry

How to make your own stove to heat your home with wood and coal?

What to do if buying a factory model is too expensive? Below are step-by-step instructions for making a stove for wood and coal with your own hands.

Rice. No. 3 Schematic diagram of a homemade boiler

The schematic diagram of such a boiler can be seen in Fig. No. 3 . For manufacturing, heat-resistant steel with a high content of alloying elements is used. Sometimes gas cylinders made of St3 steel with a high carbon content are used.

You can also burn a brick oven with coal. But there are difficulties with constant cleaning. Coal produces a lot of soot.

And the firebox must be made of fireclay bricks. The masonry process itself is also quite labor-intensive and expensive. However, there is a simple option that is quite suitable for a small country house (up to 36 m2).

Setting up a coal and wood stove

Rice. No. 4 Detailed order of a brick oven on coal and wood

Laying instructions

For the future you can download the order here.

Step-by-step diagram for making a brick oven using wood and coal:

- To install the furnace, you will need a concrete foundation with reinforcement. The dimensions of the foundation should be 100 mm larger than the dimensions of the furnace. And the height is 500 – 700 mm. The top of the foundation is at -0.150.

- Lay out the base - the first 2 rows (see Fig. No. 4) with standard dressing of vertical seams. The masonry is carried out using cement-sand mortar. Next, fireclay clay is used as a mineral binder.

- The first row is the bottom of the ash pan. The laying is carried out strictly according to the scheme.

- When laying rows 2 and 3, you must remember to position and secure the blower door with wire.

- The fourth row covers the ash pan and the hole for the blower.

- The grate is laid in the 5th row.

- The firebox door is installed when laying 6-8 rows.

- Carry out the laying according to the diagram. Rows 6–9 form the firebox.

- Row 8 is the arch of the firebox. It is made of ¾ brick. And rows 9-14 overlap it.

- Smoke channels are laid out according to the diagram.

- The valves are located in rows 26 and 29.

- Finish covering the furnace.

- Next, lay out the chimney.

- Drying the oven.

Even a beginner can make such a stove with his own hands. It is enough to have basic masonry skills. No complicated tool is required either. Heat-resistant mortar mixtures for laying stoves can be easily purchased at any construction supermarket.

Let's sum it up

Buying a cooking stove is easier and more convenient. But if you have a limited budget, you will have to make the stove yourself. It's cheaper, but requires certain skills.

The best material for a coal and wood stove is heat-resistant alloy steel. However, in practice, old gas cylinders made of St3 steel or brick are more often used. A large cottage cannot be heated with such a stove. But for a country house with 1 - 2 rooms it is quite suitable.

How to make such a stove with your own hands is discussed above. One of its disadvantages is the need for frequent cleaning. And such a stove will have to be heated 3-4 times a day. But coal will warm up the room much faster. And such a design will cost 2–3 times less than the factory equivalent.

For those for whom the issue of saving is not so pressing, you can purchase a factory boiler. You just need to choose the right power and take into account possible heat losses: window and door openings, etc.

This option has many advantages. One load of fuel will last at least 36 hours. And the unit will have to be cleaned much less often. There is only one drawback - you have to spend a considerable amount of money.

How to calculate coal consumption

Coal consumption in a solid fuel boiler depends on many factors. Costs are affected by:

- Heated area.

- Amount of heat loss.

- Ambient temperature.

Exact costs can only be calculated after the end of the heating season. Moreover, depending on the winter, the average consumption of coal for heating can vary from 8 to 15 tons (for a building of 200 m²).

If you make average calculations based on actual operating experience, you can obtain the following data:

- Costs for September – October will be 1 bucket per day.

- Fuel consumption rates in a coal boiler from November to February will increase to 10 buckets per day.

- In March and April, you will need to burn 1-2 buckets per day.

We suggest you familiarize yourself with: Sauna stove with water tank, DIY wood-burning sauna stove

Calculation of coal consumption for a 20 kW boiler, using the above data, will show that the costs during the heating season will be 580 buckets or 10-10.5 tons.