Over thousands of years of history, humanity has learned to extract oil and gas, invented electricity, uses wind and solar energy, but still burns wood in furnaces. Firewood, sawdust, old wood, waste from wood processing enterprises - all this can be used if you make a wood-burning gas generator with your own hands.

Many craftsmen successfully use this device for the home and even for the car. If you are interested in this topic, or have an idea to make a generator yourself, we will tell you how to implement it in practice.

In our material we will talk about the principle of operation of a wood-burning gas generator, the advantages and disadvantages of such a system, as well as how to assemble such a device yourself.

Fuel prices are constantly rising

The high cost of gasoline and diesel, as well as rising gas prices, are forcing us to switch to more economical types of fuel.

The principle of operation here is simple. The engine does not run on gasoline, diesel fuel or regular gas (methane, propane), but on gas released when wood burns.

Devices that allow the production of such gas are called gas generators.

In addition to the domestic sphere, they are very popular and have long been used in industry.

As for manufacturing methods, they differ. In this article we will look at the most popular of them.

Schematic diagram of the operation of the gas generator.

Advantages and disadvantages

A gas generator machine for the production of flue gas, operating on wood, is characterized by the following number of advantages:

- High efficiency. Under accompanying conditions, the value can reach 95%.

- Up to 25 hours of burning per load of firewood.

Large sawdust gas generator for electricity generation Source d-system.ru

Method No. 1

In the classic version, the gas generator is made from the following elements:

1. Housings.

This part of the structure is the main gas generator. The main components of the boiler are usually installed inside.

The body can be assembled from steel sheets or angles. All that is required is to first mark them according to drawings and templates.

2. Bunkers.

This container is designed to contain alternative fuel, namely firewood, pallets or charcoal.

You can make a bunker from sheet metal, after which it is fixed in the casing of the device.

For compactness, space for the bunker is allocated directly in the housing. The only requirement is that the two nodes be separated using mild steel plates.

3. Combustion chambers.

This structural element is located at the bottom of the bunker. The main task of the unit is to create high temperature, so heat-resistant steel should be used as the material for manufacturing.

The hopper lid must be sealed to prevent oxygen from entering.

4. The neck part of the combustion chamber.

A special area where resins are cracked.

This part of the camera must be separated from the main part of the body using special asbestos gaskets.

5. Air distributor boxes.

A part that is located outside the main body. In this case, the air distributor fitting must be cut in with the help of a check valve.

The purpose of the unit is to ensure the normal supply of oxygen inside the combustion chamber.

At the same time, flammable gases are retained in it (chamber).

6. Filter elements and pipe.

The purpose of these elements is to combine the neck of the chamber in which the fuel is burned with another chamber where the olefins are burned.

7. Grate.

A product that will perform the function of separating doors, beams and coals in the combustion chamber.

By the way, the door helps ensure normal access to the inside of the case.

After preparing all the elements, the gas-generating installation itself is assembled.

Below is the general layout of the device using the example of the UralZIS-352 gas generator.

The sequence of actions is as follows:

- prepare all the nodes mentioned above;

- assemble the body;

- install a bunker equipped with a combustion chamber in the main body. At the same time, the gas generator must be supplemented with a blower and grate;

- combine the neck part of the chamber, where the fuel burns, with the olefin combustion chamber (this is done using a pipe). For greater reliability, the cooling system must be installed in the pipe (it is installed outside the main body);

- Mount the air distributor box on top of the housing. At the same time, prepare the introduction of olefins into the chamber (use a check valve for this);

- install the door (entrance to the bunker) on reliable hinges, and also make special hatches into the combustion chambers;

- Complete the finished structure with a chimney and an air compressor.

At the final stage, it is worth attaching a water “jacket” with an air outlet and air supply fitting mounted on it to the boiler body.

It is in this “jacket” that the coolant will circulate.

The shirt can be placed in two places. This may be the olefin combustion chamber or the double-walled housing itself.

Gas generator operation diagram.

Sample of a gas generator based on a VAZ car.

How does a gas generator work?

To understand what benefits a gas generator can have in a household, you need to understand its operating principle, and then its structure. Then it will be possible to estimate the costs of its production, and most importantly, what kind of result will be obtained.

So, a pyrolysis gas generator is a complex of components and assemblies designed to separate a mixture of combustible gases from solid fuel for the purpose of its use in internal combustion engines.

For reference. The designs of generators differ from each other depending on the type of solid fuel burned; we will consider the most relevant of them - wood-burning.

If wood is burned in a closed space, limiting the supply of oxygen, then the output can be a mixture of combustible gases. Here is their list:

- carbon monoxide (carbon monoxide CO);

- hydrogen (H2);

- methane (CH4);

- other unsaturated hydrocarbons (CnHm).

Note. The mixture also contains non-flammable ballast gases: carbon dioxide (carbon dioxide), oxygen, nitrogen and water vapor.

An effective wood gas generator must not only produce a combustible mixture, but also make it suitable for use. Therefore, the entire cycle of obtaining fuel for internal combustion engines can be safely called a technological process consisting of the following stages:

- gasification: wood does not even burn, but smolders when the amount of oxygen supplied is 33-35% of that required for complete combustion;

- primary rough cleaning: volatile particles of combustion products produced by wood gas generators after the first stage are separated using a dry vortex filter - a cyclone;

- secondary rough cleaning: carried out in a scrubber - purifier, where a flow of fuel is passed through water;

- cooling: combustion products with temperatures up to 700 ºС pass through it in an air or water heat exchanger;

- fine cleaning;

- sending to the consumer: this can be pumping fuel by a compressor into the distribution tank or supplying it to the mixer, and then directly to the internal combustion engine.

You can consider the design and operating principle of an industrial gas generator in the technological diagram presented below:

The full gas production cycle is quite complex, since it includes several different installations. The most basic one is a gas generator, which is a metal column of cylindrical or rectangular shape, narrowing downward. The column has pipes for air and gas outlet, as well as an access hatch to the ash pit. The unit is equipped with a lid on top for loading fuel; the chimney is not connected to the body; it is simply missing. The combustion and pyrolysis process taking place inside the column is well reflected by the gas generator diagram:

Without going into the intricacies of the chemical reactions taking place inside the column, we note that the mixture of gases described above is obtained at the exit from it. Only it is contaminated with particles and combustion byproducts and has a high temperature. Having studied the drawings of gas generators of any design, you will notice that all other equipment is designed to bring gas back to normal. Air is forced into the combustion zone by a traction or blowing machine (in simple words - a fan).

It must be said that a homemade wood-burning gas generator is made by home craftsmen with a less complex design and the technology for releasing gas in it is somewhat simplified, which will be discussed below.

Method No. 2

When creating a gas generator for a car, the main emphasis is not only on the reliability and efficiency of the device, but also on its compactness.

Abroad, the cooling filter, cyclone and housing part are made of stainless steel, which allows the use of metal that is half as thick.

Naturally, this design turns out to be much easier. In our conditions, to reduce the cost of construction, old propane cylinders or fire extinguishers are used.

Liquefied propane cylinders are often used to make external containers.

The internal part is made from the receiver of a truck, for example, KAMAZ or ZIL.

Particular attention should be paid to the grate - it is made of thin metal, and the pipes are made of ordinary pipes (the main thing is to choose the right diameter).

The upper part of the cylinder is used to make a cover with fasteners. As a last resort, the part can be made of sheet steel.

The lid is sealed using a special cord treated with graphite impregnation and made of heat-resistant asbestos.

To make a coarse filter, you can use an old fire extinguisher or do it even simpler - take a piece of pipe.

At the bottom there should be a cone-shaped nozzle necessary for unloading ash.

At the top, the end must be tightly closed with a lid (as a rule, it is welded).

An outlet pipe is installed in the cover itself, and on the side there is another fitting for supplying combustion products.

The gases released by the gas generator have a high temperature, so they require high-quality cooling.

There are two reasons for this:

- firstly, gases heated to high temperatures have a minimum density, which makes the process of burning them in internal combustion engine cylinders almost impossible;

- secondly, there is a risk of a spontaneous outbreak if the gas comes into contact with hot engine elements.

During the ignition process, it is important to ensure normal gas movement along the path - this work is performed by the fan.

After the engine starts, the working composition moves due to vacuum, so there is no need for a fan.

Standard heating radiators can be used as a cooler. The main thing is to position them correctly and ensure maximum contact with air masses.

In some cases, installation of bimetallic radiators is allowed.

Gas fuel must be cleaned before being supplied to the engine - this is ensured using special filters.

We must not forget about another important element - the mixer. With its help, the volume of the supplied gas-air mixture is regulated. The adjustment is made using the damper.

Advantages

It should be noted that the operation of these units is fully automated and does not require constant user participation. In particular, regular refueling of fuel is not necessary; it comes from the main line (cylinder) as needed. In addition, gas generators use the cheapest fuel - natural or liquefied gas (LPG). At the same time, they use it very economically, even in long-term battery mode. If we talk about the cost of these units, then it is not much higher than the prices of similar devices that consume gasoline or diesel.

Considering the fact that the engine of a gas generator will last many times longer, since gas does not cause corrosion of metal elements. Also, parts in the cylinder-piston group are subject to less wear, and the oil needs to be changed much less frequently, due to the reduced exposure to gas. What gas you use can be determined by knowing what gas supply source your gas stove is connected to. If the gas stove is connected to a gas cylinder, then you are using liquefied propane-butane gas.

If the gas stove is connected to the in-house gas pipeline (which in turn is connected to the street gas pipeline), then you are using natural gas, which is called methane. Gas power plants are considered comfortable and easy-to-use equipment, since they are equipped with special casings to protect them from moisture, precipitation and corrosion. They are also equipped with a specific protective base, which allows the units to be installed on any surface.

Gas generators are in no way inferior to diesel and gasoline ones, but, on the contrary, have a number of advantages, such as:

- Greater fuel economy. The use of LPG significantly reduces costs. Savings of up to 40% compared to gasoline. From calculations we found that due to savings on fuel, gas equipment pays for itself within a year. Gas consumption is indicated in the description.

- Fuel efficiency. LPG engines have greater performance and require less maintenance compared to traditional gasoline engines.

- Increasing the service life. Using LPG places less stress on the engine, which prevents excessive wear and mechanical problems.

- Low emissions into the atmosphere. LPG produces fewer exhaust emissions than gasoline, including CO², NO and SO, making it virtually environmentally friendly and a better choice for you.

- Reduced noise level. You will not only breathe clean air, but also experience less discomfort due to the low noise level.

Method No. 3

To implement the following method, you need to prepare a 4.25-inch (14 centimeters in length) stainless steel tube and a five-gallon tank. You can use an old fire extinguisher instead of a pipe.

Next, the algorithm of actions is as follows:

- a special hole is cut in the drum for installing the prepared pipe;

- the flange is cut out. To do this, use a small piece of 1/8 inch steel. It is necessary to secure the flame tube in the drum;

- Using aluminum angles and bolts, the flame tube is secured to the flange.

As a gasket, you can use a silicone gasket, with which you can effectively seal all existing cracks and seams;

a door is cut into the tank of such a size that your hands can get into it to remove old ashes. Then a small door is made (from another tank). The door can be fixed using special fasteners;

- You can use the grill part from a steamer as a grate for the bottom of the tube. The main requirement is that it be made of stainless steel;

- the grate broiler is suspended slightly below the bottom of the flame tube by means of chains;

- all elements are installed on the base, namely the grille, flange, flame pipe. To seal the joints, as mentioned above, high-temperature grease should be used;

- A fan is used to circulate gas.

Other diagrams that can help you in making a gas generator.

Another sample.

Model overview

You can buy a wood-burning electric generator from specialized companies. It is convenient to contact them and get comprehensive information on the websites of these companies:

We bring to your attention several models of such generator stoves designed for domestic needs.

Portable models

They are represented by wood chippers and grills equipped with an electrical converting element. This stove is good for heating food on a hike; you can use it to warm a mug of tea, fry a small piece of meat, and charge your gadgets at the same time. They are not designed for more.

For example, the BioLite CampStove stove can operate on any wood fuel: twigs, chips, cones. It produces up to 5 W of power and is equipped with USB. To boil a liter of water, just a little wood is enough, and it will take literally 5 minutes. The price of BioLite CampStove is 9,600 rubles.

Indigirka

The Indigirka stove is the most famous model of wood-burning electric generators. This stove heats a room up to 50 m3, weighs 37 kilograms, is made of heat-resistant steel and lasts for decades. Firebox volume – 30 liters. Indigirka's output voltage is 12 volts, maximum output power is 50 W. Of course, the main purpose of the stove is heating; a convenient cast-iron burner allows you to cook food or warm tea. As an electric generator, the stove is able to work within 15 minutes after ignition.

Results

The above are just a few ways to make a gas generator with your own hands. But all of them allow you to get a truly reliable and effective device that provides the following advantages:

- - lower fuel costs (boiler efficiency - from 90%);

- - long combustion process. For firewood it is about 20 hours, and for charcoal it is about 7-8 days. Possibility of using any fuel, be it wood, straw or cake.

- In some cases, whole logs can be placed in the firebox (with the appropriate tank sizes);

- — reliability and ease of operation. Cleaning of the blower or chimney should be done rarely, if at all.

Myths about gas generators

On the Internet there are often many unsubstantiated claims about the operation of such units and conflicting information is given about the use of gas generators. Let's try to dispel all these myths.

The first myth sounds like this: the efficiency of a gas generator unit reaches 95%, which is disproportionately greater than that of solid fuel boilers with an efficiency of 60-70%. Therefore, heating a house with its help is much more profitable. The information is incorrect from the outset; you cannot compare a household gas generator for a home and a solid fuel boiler; these units perform different functions. The task of the first is to produce flammable gas, the second is to heat water.

When talking about generating equipment, its efficiency is the ratio of the amount of product obtained to the volume of gas, which can theoretically be isolated from wood, multiplied by 100%. Boiler efficiency is the ratio of the generated thermal energy of wood to the theoretical calorific value, also multiplied by 100%. In addition, not every biogas plant, let alone a gas generator, can extract 95% of combustible fuel from organic matter.

Conclusion. The essence of the myth is that they are trying to compare mass or volume with units of energy through efficiency, and this is unacceptable.

It is easier and more efficient to heat a house with a conventional pyrolysis boiler, which in the same way releases flammable gases from wood and immediately burns them using the supply of secondary air to an additional combustion chamber.

The second myth is that you can put fuel of any moisture content into the bunker. You can load it, but only the amount of gas released drops by 10-25%, or even more. In this regard, the ideal option is a gas generator that runs on charcoal, which contains almost no moisture. And so the thermal energy of pyrolysis is spent on the evaporation of water, the temperature in the furnace drops, and the process slows down.

Myth three – the cost of heating a building is reduced. This is not difficult to check; just compare the cost of a wood-burning gas generator and a conventional solid fuel boiler, also made by yourself. Plus you need a water heating device that burns wood gases, for example, a convector. Finally, operating this entire system will take a lot of time and effort.

Conclusion. A homemade wood-burning gas generator, made with your own hands, is best used in conjunction with an internal combustion engine. That is why home craftsmen adapt it to generate electricity at home, or even install it on a car.

Precautionary measures

An ordinary furnace cannot be converted into a gas generator. Such manipulations will only lead to smoke in the building. In order to fully use a gas generator device, it is necessary to take into account its disadvantages.

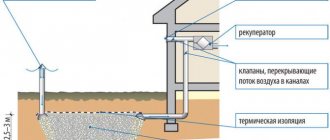

Cold gas is formed at the outlet of such equipment. If the chimney is not properly insulated, condensation occurs. The moisture will flow back into the device. Therefore, experts recommend the use of insulated sandwich structures. They consist of 2 pipes nested inside each other, between which the insulation is located.

In order for the gas generator to operate as efficiently as possible, it is necessary to install an economizer (additional equipment).

Classic version

As noted, a wood-fired power plant uses several technologies to produce electricity. The classic one among them is steam power, or simply the steam engine.

Everything is simple here - wood or any other fuel, when burned, heats up the water, as a result of which it turns into a gaseous state - steam.

The resulting steam is supplied to the turbine of the generating set, and due to rotation, the generator generates electricity.

Since the steam engine and generator set are connected in a single closed circuit, after passing through the turbine the steam is cooled, fed back into the boiler, and the whole process is repeated.

This power plant scheme is one of the simplest, but it has a number of significant disadvantages, one of which is the danger of explosion.

After water passes into a gaseous state, the pressure in the circuit increases significantly, and if it is not regulated, there is a high probability of rupture of the pipelines.

And although modern systems use a whole set of valves that regulate pressure, the operation of a steam engine still requires constant monitoring.

In addition, ordinary water used in this engine can cause scale to form on the walls of the pipes, which reduces the efficiency of the station (scale impairs heat transfer and reduces the throughput of the pipes).

But now this problem is solved by using distilled water, liquids, purified impurities that precipitate, or special gases.

But on the other hand, this power plant can perform another function - to heat the room.

Everything is simple here - after performing its function (rotation of the turbine), the steam must be cooled so that it turns into a liquid state again, which requires a cooling system or, simply, a radiator.

And if you place this radiator indoors, then in the end we will receive not only electricity from such a station, but also heat.

Application area

The scope of application of gas cutters is very wide. They are used wherever metal needs to be cut, soldered or welded:

- in procurement areas of machine-building and metalworking plants;

- on construction sites - from country houses to hydroelectric power stations;

- in a car service;

- at shipyards;

- in the defense and aerospace industries;

- when dismantling old metal structures;

- in the production of electronics and radio engineering;

- in jewelry;

- in artistic crafts.

In addition, a gas cutter can become your reliable and productive assistant in your home workshop.

Long-burning wood-fired boilers for the home

Solid fuel thermal installations are not new. They have been used in various variations since time immemorial. While burning fuel in huge quantities did not pose a problem for anyone, they did not lose their relevance. However, in modern conditions, such a wasteful attitude towards resources is inappropriate. Because of this, long-burning wood heating boilers have become widespread. For their operation in operating mode, much less firewood is required than in direct-flow furnaces and boilers.

Sectional view of a long-burning solid fuel boiler

The installation is a furnace with two chambers. One of them is filled with firewood. They smolder slowly from top to bottom with minimal access to oxygen. One portion of firewood is enough for 12–15 hours of boiler operation. As a result of this smoldering, pyrolysis gas is released, which is forced through nozzles into the second chamber. There it undergoes intense combustion. After all, air enters this compartment in sufficient quantities. During combustion, a large amount of heat is released, which heats the liquid inside the circuit.

To increase the efficiency of the heating boiler, you need to take care of home insulation

In addition to being economical, these boilers are highly environmentally friendly, as they are able to break down organic substances from fuel with almost no residue. Therefore, the smoke from such stoves is completely safe for humans.

Helpful advice! To get the maximum benefit from long-burning wood heating boilers, you need to purchase their combined options. Such installations can also operate on ordinary natural gas. Switching between modes is carried out automatically.

The structure of a long-burning solid fuel boiler

Echo CSG-680 – from RUB 60,600.

A successful model, despite some problems with ergonomics. The device is not lightweight, and poor weight distribution “adds” a couple of kilos. From a technical point of view everything is fine:

- a simple and therefore reliable diaphragm carburetor - the gas cutter works in any position;

- automatic ignition timing system compensates for low engine power;

- no problems with belt tension - the tension system is designed for people;

Characteristics of Echo CSG-680

| Characteristic | Meaning |

| Weight, kg. | 11,5 |

| Cutting depth, mm. | 125 |

| Rotation speed, rpm | 4400 |

| Power, hp | 3 |

| Disc diameter, mm. | 355 |

| Diameter of seat, mm. | 20 |

| Noise level, dB | 107 |

| Development/production | Japan |

Peculiarities

A wood-fired power plant is not a new invention, but modern technologies have made it possible to somewhat improve previously developed devices. Moreover, several different technologies are used to generate electricity.

In addition, the concept of “wood-burning” is somewhat inaccurate, since any solid fuel (wood, wood chips, pallets, coal, coke), in general, anything that can burn, is suitable for the operation of such a station.

Let us immediately note that firewood, or rather the process of its combustion, acts only as an energy source that ensures the functioning of the device in which electricity is generated.

The main advantages of such power plants are:

- The ability to use a wide variety of solid fuels and their availability;

- Receive electricity anywhere;

- The use of different technologies makes it possible to obtain electricity with a variety of parameters (sufficient only for regular phone recharging and up to powering industrial equipment);

- It can also act as an alternative if power outages are common, as well as the main source of electricity.

Operating principle of an electric generator

The generators operate on the principle of electromagnetic induction, when current is induced in a closed loop due to its intersection with a rotating magnetic field. The magnetic field is created by windings or permanent magnets.

When the electromotive force from the commutator reaches the closed circuit and the brush nodes, the rotor begins to rotate together with the magnetic flux. This creates tension in the spring-loaded brushes pressed against the plate-type commutators.

Next, the electric current is transmitted to the output terminals, passes into the network, and spreads through the generator.

They use alternating and direct current generators. The alternating current electric generator is small in size, does not generate eddy currents, and at the same time has the ability to operate in extreme temperatures. A device with direct current does not require careful monitoring and has a significant number of resources.

Structurally, the generator includes: brushes with brush holders, a commutator, an armature winding, an armature, a starter, contact rings, a starter winding, a rotor, a housing, a fan, a drive and a frame

The alternating current generator can be either synchronous or asynchronous. The first is with a permanent electric magnet and the number of stator rotations is equal to the rotor, forming a magnetic field. The advantages of such a generator are a consistently high voltage; the disadvantages include current overload due to an excessive load on the regulator, which increases the rotor winding current.

Design of an asynchronous generator: squirrel-cage rotor, stator. When the rotor rotates, the generator induces a current, and the magnetic field produces a sinusoidal voltage.

Making it yourself

Making gasgen with your own hands is a labor-intensive and difficult job . To perform this you will need special materials. Steel is required to produce the housing and fuel tank. For specialized containers - fireproof material. You will also need fireproof gaskets made of any materials, excluding asbestos, as it emits hazardous substances. Pipes will be needed to connect the nodes. To remove any impurities, filters will be needed.

A story about gasgens with your own hands

When making a gasgen with your own hands, it is important to take into account that all parts and components of the gasgen must be breathable.

Flaws

- The main disadvantage can be considered the high cost of a solid fuel gas generator boiler, but you need to remember that operation and maintenance are cheap, and you will be buying a boiler for many years.

- Increased requirements for quality and, especially, fuel moisture.

- To remove burnt substances after pyrolysis, smoke removal is required. This means that the use of solid fuel gas generator boilers is possible only in houses where it is possible to vent the pipe into the atmosphere, without causing inconvenience to neighbors. Therefore, it is hardly applicable in high-rise buildings.

- Some limitation in temperature conditions. To prevent condensation from forming, the temperature of the water coming from the heating system should be about 60 degrees.

- It is impossible to automate the supply of solid fuel to the furnace.

- High requirements for the tightness of solid fuel gas generator boilers. Leakage of flammable gas may cause an explosion or fire.

Power plants for continuous power supply

This category includes expensive models that can work up to 12 hours without interruption. It is useful for “capital” country houses and small industries, where long-term interruptions in power supply are possible, and electricity cannot be limited. If network gas is available, such power plants are the best choice, because the cost of a “gasoline” or “diesel” kilowatt-hour is 5-6 higher, and a gas power plant is serviced less frequently and is cheaper. In this class, it is worth taking a closer look at inverter units - they produce an ideal sine wave in all operating modes. A soundproof casing is also important. It’s one thing to endure 75 dB of rattling for a couple of hours, but quite another to be surrounded by noise for days.