A heating system for a private home can easily be created without connecting to central heating networks.

This option has recently been increasingly used by owners of houses in cottage villages located away from the main centralized lines.

Gas boilers are considered the most effective option for autonomous heating systems, which allow the owner to not monitor their operation too closely.

There are a lot of structural varieties of gas boilers that can provide certain functions.

Let's consider one of the most efficient and productive groups - floor-mounted double-circuit gas boilers.

Double-circuit floor-standing gas boilers

Floor-standing units have no weight restrictions due to installation conditions. This allows you to install more massive and durable parts in them, and use units of greater strength and performance.

Most floor-standing boilers demonstrate much higher performance due to their reliability and ability to experience increased loads without loss of performance.

The general design and operating principle do not differ from the basic design options, the whole difference is concentrated in the area of increasing the power and efficiency of the main components:

- Heat exchanger.

- Gas burner.

- Circulation pump, etc.

In addition, non-volatile models are widely used, which guarantee heating of the house regardless of the state of the electrical networks and their capabilities.

In Russian conditions, a sudden power outage, even for several hours, threatens to freeze the pipelines in the system, which means complete failure of the heating circuit.

Non-volatile boilers completely eliminate this possibility, not requiring anything other than a supply of water and gas.

Main classification

You can find a wide variety of boilers on the heating equipment market. A user who does not understand this topic simply will not understand what the difference is. In fact, gas boilers are classified according to many parameters.

Household heat generators are divided into several types according to:

- Installation method. Wall-mounted and floor-mounted models are now available.

- Method of preparing water. There are single- and double-circuit. The boiler can be built-in or instantaneous.

- Burner type. There are one-, two-stage, atmospheric, supercharged and smooth modulation.

- Kind of traction. It can be natural or forced.

- Heat exchanger material. This element is made of steel, cast iron or copper.

- Dependencies on the power grid. They can be connected to the mains or work autonomously.

- Type of coolant. Some work only on water, but there are models that allow the use of both water and antifreeze.

Each point plays a big role and should be carefully considered, which will allow you to select the optimal model.

Advantages and disadvantages

The advantages of floor-standing gas double-circuit boilers include:

- The ability to provide the home with heat and hot water for domestic needs.

- Less dependence of installation conditions on the material of supporting structures.

- Increased power and reliability compared to wall-mounted models.

- Ability to work in conjunction with external storage tanks.

- The ability to be connected in a cascade, when several boilers form a complex of increased power, capable of serving premises of significant area and volume.

The disadvantages of floor-standing gas double-circuit boilers should be considered:

- Heavy weight, increased dimensions.

- The need to allocate a separate room, especially for high-power models.

- As power increases, fuel consumption increases proportionally.

NOTE!

The disadvantages of floor-standing gas boilers are a consequence of their design and specific operation. When choosing a floor-standing unit, you need to know about them in advance and treat them as design features.

Customer Reviews

Oleg K.

Lemax Premium-16

Italian boiler automation Lemax Premium is a guarantee of a long service life of the boiler without failures or problems. Modern boiler protection - gives complete confidence that its protection will work in the event of overheating, interruption of draft, soot formation or blowing out of the boiler. The boiler does not depend on electricity - this is the ability of the boiler to operate when the electricity is turned off. All these indicators are important to me, so I installed a Lemax Premium boiler and in 2 years I have not regretted my choice at all!

Evgeny A.

BAXI SLIM 1.230 iN, 22.1 kW

Pros: Well made! Will fit into any interior if there is no boiler room. There is access from all sides. Cast iron! Working with an indirect heating boiler. Disadvantages: It is inconvenient to connect the upper supply pipe. The thread is also internal. Doesn’t keep the flame on the socket, constantly ignites it... resulting in unusually audible popping noises every time it starts.

Ivan Chirkov

Lemax Premium-10

I installed Lemax Premium at the end of last summer. Just a couple of years ago I wouldn’t have even looked at it. Before it there was an expensive but popular unit. And I understand very well those who say that Europe is doing great. Yes it is. And when everything is fine with your expensive boiler, you live and don’t give a damn. But as soon as problems appear, that’s it. Do you know how much it costs to change a heat exchanger or automatic ignition? Yes, it’s easier to install a new boiler. I had no illusions about Lemax, but at least I knew that if something happened they would help me, our service technicians know our products better and spare parts are always within easy reach. That's why I took the course that it would be cheaper to maintain. There is little to say about the boiler itself yet. It works and doesn't make any noise. At first I was confused by the condensation that appears when it warms up to 50 degrees. But the support service assured that this was normal for such a temperature, and I myself later saw in the passport that this was written. Pah-pah, let it continue to work.

Roman Belov

Lemax Premium-20

I tried to find a powerful and compact gas boiler. For my 180 square meters (2 floors and an attic) I picked up Lemax-premium for 20 kW. During the first heating season, it seemed that I paid a lot on gas. It’s easy to control: I set it to 5-6, that is, up to 80 degrees. The boiler was ticking. But it was warm. This season I thought about saving, but the craftsmen shrugged their shoulders, saying the settings were correct. Only the neighbor came up with the idea to insulate the walls so that the warmth would remain inside. When I had already completed 2 rooms, less gas began to escape.

Klochkov Oleg

Siberia 17, 17.4 kW

An excellent boiler for the money, very heavy, more than 50 kg, which speaks of the thickness and durability of the heat exchanger steel. Piezo ignition, flame control, maintaining and regulating the set temperature using the best Italian mechanical automation. With a well-made heating system, this boiler will last a lifetime, which will not have to be repaired or even maintained.

Elena S.

Lemax Premium-10

Problems with commissioning initially spoiled the impression of Lemax. The burner went out, it was an infection. I later found out that it was due to pressure. I called the Lemax hotline, and that’s what they answered. And it seems like the gas pressure is written down in the passport, right? But the gas was still not adjusted properly, the pressure was lower, the burner went out. And so I chose a simple boiler without unnecessary automation, so that no power surges would “eat up” my brain, but here is such a setup. I had to invite the gas workers, but they screwed it up and that’s it, and it doesn’t matter that I suffered for a week

Nikolay V.

Lemax Premium-30B

Last year we selected a gas boiler for heating. We looked at more than one option and chose the Lemax Premium-30V boiler. We consulted with neighbors and gas workers. We looked on the Internet. Lemax is produced in Russia. This means they are adapted to our Russian realities, unlike imported ones. This is a floor-standing, double-circuit boiler with an open combustion chamber; combustion products are removed naturally through the chimney. It will heat the house and heat the water. Electronic control. The quality is top notch. This is confirmed by those who already use such boilers and those who service them. The boilers are reliable, and if something happens, they are repairable. Spare parts are always available and at low prices compared to imported ones. We ourselves were convinced of the quality of the boiler. Last winter, and it was frosty, he proved himself to be the best.

Lev D.

Lemax Premium-10

I installed it in the fall, at first when I started it for the first time there was something rustling inside, I thought it was a leaky heat exchanger, but everything went well - just factory paint and condensation. There was a problem: the gas went out. We figured it out - it turned out that because the exhaust pipe was made of asbestos and there was no insulation, the exhaust hood was weak and disappeared, so the automation was triggered and plus condensation formed. I insulated the pipe and the problem disappeared. For a log house of 60 m in position 3, the temperature in the house is 24 degrees while the outside temperature is -20.

Ksenia S.

Lemax Premium-30B

I specifically took a boiler from Lemax for a private home, because I already had a bitter experience with imported ones - they focus on the milder European climate, but here we have even -20, sorry. I heard only good things about the manufacturer, and a colleague advised my husband that he has Lemax, only a different model. This particular model suited us, the house is 200 m2, it is enough for him with a margin, and it is also efficient in terms of gas consumption. We haven’t regretted it even once; finally we don’t freeze in winter. It was installed for us by invited gas workers) and they did it quickly. The only thing is that it’s really, as they wrote here, a little noisy (it’s not really critical for me, but suddenly for someone it will be a problem.

Device

The design of floor-standing gas boilers differs only in the increased strength of components and parts. There are no fundamental differences.

The main elements are:

- Primary heat exchanger. This is the main unit in which the basic function of the boiler is performed - the coolant is heated.

- Gas-burner. It is located directly under the primary heat exchanger and performs an equally important function - it is a source of thermal energy for heating the coolant.

- Secondary heat exchanger. Provides heating of hot water for domestic needs. There are different types of such units, designed for different performance and operating modes.

- Circulation pump. Present only in volatile installations. Ensures the coolant moves through the system at a given speed.

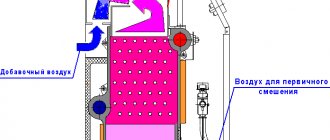

- Turbocharger fan. Available only in closed type boilers. Creates excess pressure, displacing smoke and combustion products out.

- Gas equipment. Performs the functions of supplying and timely shutting off gas in case of emergency situations.

- Control board. Present only on volatile installations. Performs the functions of monitoring the operation of all components of the boiler, ensures the stability of the coolant heating mode and the operation of all other elements. It comes complete with a self-diagnosis system - a network of sensors installed on all important parts of the unit and notifying the owner of any problems.

The operating process consists of the coolant flowing from the return line of the heating circuit into the heat exchanger, heating it using a gas burner and feeding it into the system with the specified parameters.

At the exit from the primary heat exchanger, the coolant passes through a secondary unit, where it transfers part of the thermal energy to the water flow, heating it to operating temperature.

Then the coolant enters the three-way valve, partially mixes with colder return water and receives the desired temperature, at which it enters the heating circuit.

Flue gases are removed either naturally, using a stove-type draft, or under the influence of excess pressure created by a turbofan. Its additional function is to provide a supply of fresh air that supports gas combustion.

IMPORTANT!

The most common operating cycle of a floor-standing gas boiler is described. There are other design options that have some differences.

Which is better - convection or condensation?

First of all, it is necessary to understand the difference between the operation of one and another unit.:

- Convection - works on the usual principle of heat transfer. The coolant is heated due to the thermal energy released during fuel combustion.

- Condensing is a boiler that produces two-stage heating of the coolant. First, the OM receives a certain amount of thermal energy from the condensation of water vapor, which is contained in the exhaust combustion products. The partially heated coolant then enters the primary heat exchanger and is finally heated in the usual way.

The advantage of condensing boilers is the ability to reduce fuel consumption and, accordingly, reduce the heating intensity of the heat exchanger. Since the liquid has already received some heat, the burner operating mode can be reduced.

All this together allows you to increase the service life of the boiler components and parts and increase its efficiency. The efficiency of condensing boilers, declared by all manufacturers, is 107-109%, although in this case the usual marketing ploy takes place.

Such efficiency cannot exist by definition, but this is not the main problem . Condensing boilers are able to demonstrate proper efficiency only in low-temperature systems, where the degree of return heating is lower than the condensate temperature.

This is only possible if the difference between external and internal temperatures does not exceed 20°, which is simply impossible in Russian realities.

Therefore, you can choose a condensing boiler only in southern regions with warm winters.

NOTE!

The price of a condensing boiler is almost twice the cost of convection models of the same power. If operating conditions do not allow you to obtain the expected effect, you should refuse to purchase a condensing model.

What is the difference between non-volatile and conventional boilers?

Non-volatile boilers operate without the use of electricity. In a simplified way, their work can be represented as the functioning of a conventional gas stove heating a tank of water .

This specificity has its drawbacks - there is no self-diagnosis, coolant circulation occurs naturally, which requires specific placement of heating devices in the system. However, there is a very important advantage - such a boiler works in any conditions.

A sudden power outage, which is quite possible and often occurs due to overload and severe wear and tear of the networks, threatens users of conventional boilers with the cessation of heating their home.

For a non-volatile boiler, this event does not mean anything - it will continue to operate in the specified mode . In addition, the absence of all electrical appliances and devices greatly simplifies the boiler design, which reduces the risk of breakdown.

Controlling non-volatile boilers is simpler, although many complain about the complexity of the ignition procedure.

Rating of the best models

The most popular in the Russian Federation are:

ATON Atmo 10ЕВМ

A distinctive feature of the device is its complete energy independence. The coolant circulates naturally, without the use of a circulation pump. The installation power is 10 kW, and the heating temperature of running water in the DHW circuit reaches 45 0C. The unit has compact overall dimensions (765x385x390), economically consumes gas (1.3 m3/h) and has an original design. The average cost is 17,700 rubles.

Lemax premium – 10

The thermal power of a double-circuit boiler is 10 kW with an average fuel consumption of 0.6 m3/h. The unit is equipped with an Italian micro-flare burner Polidoro, which provides optimal gas combustion mode and precision flame modulation. In addition, there is an auto-ignition mode, protection against overheating of the coolant and blowing out. The manufacturer provides a 3-year warranty, and the average service life, without replacing the main elements, is 15 years. The average cost is 16,600 rubles.

KITURAMI STSG 13 GAS

With a power of 15.1 kW, the device can effectively heat an area of up to 150 m2 and heat running water in the DHW circuit to 80 0C, and the heating system coolant to 85 0C. The installation control is fully automated, with the possibility of remote control and programming. The gas boiler is equipped with a closed combustion chamber, which avoids additional costs for installing a vertical chimney. The average cost is 41,500 rubles.

BUDERUS LOGANO G125-32 WS

The main advantage of the model under consideration is its efficiency of 96%. Another feature of the installation is the possibility of conversion to diesel fuel. A combined mechanical-electronic control system ensures coordinated operation of all modules of the unit and safe operation. The boiler power is 32 kW, which is quite enough to effectively heat 320 m2 and provide hot water supply. The design of the unit provides the possibility of connecting additional modules. The average cost of installation is 52,000 rubles.

BaxiSlim 2.230

An electronic self-diagnosis system and a whole range of protective systems ensure a long service life of the unit. The rated power of the floor-standing boiler is 22.1 kW, the device can be connected to a heated floor system. Three circulation pumps provide intensive circulation of the coolant, and the productivity of the DHW circuit can reach up to 12.5 l/min. This performance fully satisfies the needs of 3-5 people. The device is intended for heating residential and industrial premises with an area of up to 220 m2 and providing hot water supply. Installation cost 112,500 rubles.

When choosing a boiler for heating a private home, you should not neglect the reviews of the owners of such equipment, who have assessed its advantages and disadvantages in practice.

Types of heat exchanger materials – what to choose?

There are heat exchangers made of different materials:

- Stainless steel . This is the cheapest and most common option. Moreover, the initiative in assembling boilers with such components comes from the manufacturers themselves. In this way they reduce the cost of their products. Units with a steel heat exchanger demonstrate quite decent performance, but they are inferior to other types in terms of durability and operating efficiency (albeit not by much).

- Copper . Copper heat exchangers are much more expensive, but also more efficient. They are able to reduce heat loss during transmission, have a long service life, and are less prone to the formation of limescale on the inner walls of pipes. Top companies install copper components on their products.

- Cast iron . This is a common heat exchanger option specifically for floor-standing boilers. A special, plastic grade of material is used that does not crack due to temperature changes. Cast iron heat exchangers are massive and have high inertia, which somewhat slows down the initial heating, but significantly smoothes out the operating process afterwards . Typically, they have a large volume and are able to demonstrate high productivity and efficiency.

The choice of a heat exchanger for a floor-standing gas double-circuit boiler must be made based on operating conditions and hot water needs.

Experts and ordinary users recommend choosing cast iron boilers, which provide stable and even heating of the coolant, are reliable and stable in operation.

Difference in power level

Floor heating boilers are divided into working ones:

- at one power level, they are called single-stage;

- at two power levels, called two-stage;

- continuously adjustable, called boilers with modulation.

Practical observations show that during the entire cold season, the boiler’s full capacity is used only 15-20 times, and the rest remains unclaimed.

From this circumstance we can conclude that the best purchase would be a boiler with modulation or two-level power, which will allow it to be adjusted to a specific temperature outside the window. The positive qualities of these options for heating devices include:

- longer operating life, which is achieved by reducing power at the right time;

— increase in environmental qualities, as the emission of combustion waste into the atmosphere is reduced;

— it is possible to connect, if necessary, additional water heating equipment.

Types by type of smoke removal and which one is better?

There are two types of smoke removal systems:

- Open (atmospheric). It works on the principle of stove draft; smoke is removed through a common house or its own vertical chimney.

- Closed (turbocharged). The smoke is forced out by the turbocharger fan.

Natural cravings are unstable and depend on many external factors. Sometimes a reverse draft occurs, which, instead of removing the smoke, begins to draw it indoors.

Turbocharged boilers are completely free of such problems and demonstrate a stable smoke removal regime in any conditions. This makes the choice of atmospheric installations less attractive, however, all non-volatile boilers operate on this principle.

In order to get rid of possible problems, external additional devices are used - turbo nozzles.

They help stabilize and equalize the smoke removal regime, although they can only work if there is a power supply.

Specific installation requirements

When installing an atmospheric boiler, two conditions must be met:

- from the gas service - requirements for the installation of a gas pipe inside the boiler room or kitchen, the ventilation and chimney system, the presence of supply windows, the layout of DVK and MPC sensors;

- from the equipment manufacturer - requirements for the location of the boiler inside the room, the distance from the front door, from the nearest window opening, gas meter, flammable objects.

An atmospheric boiler is considered a device whose operation may pose a threat to human health, so the walls must be lined with non-flammable material.

The distance to the wall for wall-mounted models must be at least 20 mm, for floor-mounted ones - 50 cm. All nuances will be checked by gas and fire inspection. Otherwise, the atmospheric one will not be connected to the gas pipe, and most importantly, permission to operate will not be given.

How to choose power for a room and calculation formula

The power of gas boilers is selected based on the area of the premises. The simplest formula is that 1 kW of boiler power is taken into account per 10 m2 of area.

This technique is most effective for rooms with a height of no more than 3 m . If the ceilings are higher, it is necessary to slightly reduce the ratio of the size and power of the unit.

For double-circuit boilers, the power should be increased by 20% to compensate for losses in water heating.

Types of ignition methods and which method is the most optimal?

There are two types - electric ignition and piezo ignition. The first option is used on volatile boilers and occurs automatically after setting the desired coolant temperature.

Piezo ignition is a method used on non-volatile units. The specifics of such a launch are much more complicated and require a certain procedure.

Electric ignition is much simpler, faster and more reliable, but in the absence of electricity, you have to use the available options.

Popular companies

Let's look at the most popular brands and models of floor-standing gas boilers:

- Vaillant . A popular German company, which is considered a leader in the production of thermal products among European manufacturers. It produces a wide range of equipment, which includes a large selection of floor-standing dual-circuit models.

- Buderus . An outstanding German manufacturer whose floor-standing boilers are widely known throughout the world. The Logano series consists of many models with optimal parameters for any room.

- Viessmann. A German concern that produces a large amount of equipment of various types. Floor-standing gas boilers are distinguished by their durability, high build quality, and reliability.

- Baxi . A famous Italian company producing high-quality gas units. The Baxi Slim and Power HT series represent floor-standing boilers with extensive capabilities and many additional functions.

- Ferroli . This is another Italian company known for its quality and reliability. Floor-standing boilers are presented in 7 series under the general name Pegasus. They have a wide range of capabilities and allow you to choose an option for any working conditions.

- Protherm . A Slovak company that names each series of its boilers after an animal. Double-circuit floor models are represented by the Bear series, capable of heating rooms up to 440 m2.

- Navien . Korean manufacturer of inexpensive and efficient gas boilers.

- Kiturami . Another Korean company that produces the STS GAS series of two models. The units are distinguished by high performance combined with low prices, which is typical of all Korean products.

- Daewoo . Floor-standing boilers from this world-famous company demonstrate high performance combined with affordability.

- Fondital . An Italian brand representing floor-standing double-circuit boilers of the Bali series, designed for heating and supplying hot water to residential, public and office premises of various sizes.

- Siberia . A domestic company that produces energy-independent floor-standing models for use in private homes. The power of the units is in the range of 11-50 kW.

The list of boiler manufacturers is much wider, but not all of them produce double-circuit models, specializing in installations with external additional boilers.