If the attic of the house is not supposed to be heated, there is no point in insulating the roof itself. Its function is to protect from precipitation and wind. But it is necessary to prevent heat loss, and insulating the ceiling in a house with a cold roof will help with this. By the way, thermal insulation effectively saves the room not only from cooling, but also from overheating by the sun. This makes it possible to survive the summer heat without much discomfort.

Types of insulation

Heat insulators can be classified according to different criteria:

- according to the shape of the products - rolled, slab, bulk, liquid;

- by installation method - for dry and wet installation, sprayed;

- composition - mineral, organic, mixed;

- by structure - fibrous, porous, cellular, film.

These materials not only retain heat, but also serve as sound insulation, which is quite important for ceilings. A cold roof is not always able to protect against external noise, and sometimes it itself becomes a source of noise (for example, a metal tile roof during rain).

From the attic

For insulation using this method, any of the insulation materials, even bulk ones, are suitable. The only condition for full and long-term operation is the installation of walkways that do not allow the material to be compressed. Craftsmen do not recommend mineral wool for external use due to the high risk of dampness.

- The attic floor is cleared of furniture and other items.

- A vapor barrier is laid on the floor with allowances for the walls.

- If necessary, a sheathing is installed to define the space between the ceiling and the attic floor. It should be at least 0.5 cm greater than the thickness of the insulation.

- The space between the beams or grating is covered with vapor barriers and covered or covered with insulation. Basalt or expanded clay is poured in a layer of 2-2.5 cm. Sheet or roll insulation is laid close to the beams, if possible without gaps between them and the sheets themselves.

- A vapor barrier is again placed on top. Film or foil that prevents the insulation from becoming damp can be joined with ordinary tape.

- The floor is covered with a gap from the insulation.

Insulating the ceiling from the attic side

How to choose insulation for a cold roof

Materials for thermal insulation of residential buildings must have:

- low thermal conductivity;

- light weight;

- environmental cleanliness;

- fire safety;

- ease of installation;

- at an affordable price.

Most modern insulation materials meet all requirements. And considering that savings on heating are noticeable in the first season, the costs of their purchase and installation quickly pay off.

Foam

Among the common foam insulation materials, materials based on polyurethane and polystyrene (penoizol) are most often used.

- Polyurethane foam - a relatively new and expensive insulation material, its structure resembles foam plastic. Moisture resistant, retains performance properties for more than 50 years, low thermal conductivity (0.02 W/mK). Disadvantages: high cost (from 20,000 rubles per 1m3), application requires special equipment.

- Penoizol. In fact, this is ordinary foam plastic, the main difference is a seamless monolithic coating.

The process of applying penoizol to a cold attic

Thermal conductivity is almost twice as high as that of polyurethane foam - 0.42 W/mK. It does not rot, does not bloom, rodents and other living creatures do not grow in it. It is airtight, so it should not be used to fill the wooden floor of the attic. Relatively high toxicity does not allow indoor use. Price from 2500 RUR per m3.

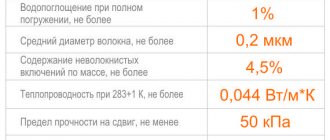

Mineral wool

This is a large group of materials made from mineral raw materials - rocks, broken glass, waste from the metallurgical industry. For insulation of residential buildings, 2 types are used - basalt (stone) and glass wool. Slag wool is prone to strong shrinkage and water absorption, therefore it is used mainly for thermal insulation of outbuildings or industrial facilities.

Mineral wool is the most common insulation for frame wooden houses, since it does not burn and is close in technical characteristics to wood. It is produced in the form of rolls, slabs or stitched mats of standard sizes, suitable for laying between elements of the supporting frame. The loose fibrous structure retains heat well, and due to the elasticity of the fibers, cotton wool shrinks little under its own weight. The synthetic binder is present in a very small amount - up to 3.5%, which ensures harmlessness to health. For installation on the ceiling, roll material, soft or semi-rigid slabs are used. In the absence of load, they do not wrinkle and retain high thermal insulation qualities for a long time.

If you intend to walk on the floor, it is necessary to lay a flooring made of boards, OSB or plywood. This will protect the mineral wool from deformation. It is prohibited to step on it both during installation and operation. The disadvantage of fiber insulation is its high hygroscopicity. To protect the material from waterlogging, it is recommended to install a vapor barrier on the side of the warm room. It will prevent water vapor from penetrating the thermal insulation and deteriorating its properties.

During installation, mineral wool is laid out on a horizontal surface between the floor beams. The seams are filled with scraps to eliminate cold bridges. If there is a risk of leaks from above, waterproofing is spread over the insulation.

The thickness of the thermal insulation layer for reliable protection from cold is determined by thermal engineering calculations. Depending on the climatic zone, design and composition of the ceiling pie, from 150 to 300 mm of insulation thickness will be required.

Modern glass wool is somewhat cheaper than stone wool, but is not inferior to it in thermal conductivity and other indicators. Many people are afraid of the tiny glass dust that is released during installation. To protect yourself from its harmful effects, it is necessary to observe safety measures, as when laying basalt wool.

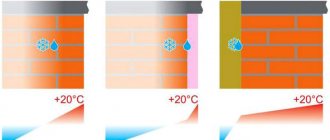

What to choose - external or internal insulation

The choice between these types of work is based on a combination of factors:

- in the absence of finishing, they are equal in the degree of thermal insulation;

- if the renovation of the room is completed, you will have to remove the ceiling covering, which will increase the cost and time of work;

- laying from the inside reduces shrinkage of the material, but increases the thickness of the ceiling, reducing the total volume of the room;

- with internal insulation, the ceiling ceiling is not protected from low temperatures;

- external insulation allows the use of a wider range of heat insulators.

Before insulating the ceiling in a private house, you need to carefully calculate all the pros and cons, only after that can you make a clear decision on what is best to use in your case.

Foam insulation

This group includes foamed polymer materials manufactured using press, pressless, autoclave, extrusion and autoclave-extrusion technologies. The raw material for them is polystyrene and its derivatives. As a result of processing, slabs of different sizes and colors are obtained, which, by the way, does not mean anything; it is an indicator of the brand.

The most common in construction are pressless PSB and extruded EPS. The first type is better known as household foam. It is more fragile and loose than EPS, but is cheaper. Polymer insulation is characterized by low density and thermal conductivity, sufficient strength under compressive loads and durability. The service life with UV protection can reach 50 years.

A common drawback of all materials is flammability. When burning, particularly dangerous substances are released. To reduce flammability, the addition of fire retardants is introduced. The result is self-extinguishing grades, which are more preferable for residential construction. But even insulation with fire retardants is recommended to be protected with a layer of non-combustible material of at least 30 mm. This means that the thermal insulation must be laid on a concrete slab and filled with screed.

If the ceiling is made of wooden beams and sheathed with wood materials, the use of foam insulation is not recommended. Wooden structures are classified as fire hazards, so the risk of fire is very high. The slabs are laid in several layers with overlapping joints. The seams are carefully filled with polyurethane foam. No vapor barrier required. Expanded polystyrene has zero vapor permeability, that is, in fact it is itself a vapor barrier.

He feels good surrounded by concrete. But wood doesn’t like polystyrene foam. In the place where wooden structures are tightly adjacent to polymer materials, a zone of high humidity is formed. Wood is not ventilated and rots quickly, so this proximity reduces the service life of the load-bearing beams.

Option No. 2 - installation of mineral wool from the inside

It can be done in two ways. The first of these is similar to gluing and plastering foam. The second option, no less common, is internal installation, carried out under a suspended sheathing, which is installed on concrete or wooden ceilings.

The frame for the sheathing can be made from wooden blocks or from two types - UD and CD profiles. Experts recommend using metal products, since they will not move in the event of a temperature change.

The sequence of actions is as follows:

- First of all, a horizontal line is struck along the perimeter of the room at the level of the future ceiling plane. The easiest way to do this is with a laser level, but if you don’t have one, you can use a hydraulic level, which is a long soft tube with graduated tips that operates using the communicating vessels method.

- Then, according to the applied markings, two UD profiles are fixed on two opposite, longer walls.

- Perpendicular to them, the location of CD profiles is marked on the ceiling, usually observing an installation step of about 50 centimeters.

- In accordance with the markings, the perforated suspensions are secured with dowels at intervals of one meter, their wings are bent downwards.

- Next, they begin to glue the mineral wool slabs to the ceiling. The insulation under the wings of the suspension is cut with a knife.

- To complete the work, CD profiles are inserted into the UD profiles and fastened to each other and to the hangers using self-tapping screws. Now you can begin covering the frame with plasterboard or other finishing material.

Expanded clay, vermiculite, perlite

These bulk insulation materials are made from mineral raw materials - clay, shale, volcanic rocks. High-temperature swelling results in the formation of porous granules with low thermal conductivity.

Mineral materials do not burn, tolerate waterlogging well, and shrink little. But there is a significant drawback - it is quite heavy in comparison with fibrous or polymer heat insulators.

A higher load may not be critical for load-bearing structures if they are calculated with a margin. But bringing, pouring out and leveling several dozen cubes of expanded clay in the attic is not such an easy task. For comparison, the weight of 1 cubic meter of mineral wool weighs 50 kg, foam plastic - 35 kg, and expanded clay of fractions 5-40 mm - 300-400 kg. In terms of an attic area of 100 sq.m and a layer height of 25 cm, the result is 7.5-10 tons.

The second drawback is that a fairly thick layer is required. Its thickness should be determined by calculation. On average, it is 25-30 cm. In the southern regions, it is allowed to reduce the thickness of the insulation to 15-20 cm. In the northern regions, it should be increased to 35 and even 40 cm.

Bulk materials must be protected from moisture from steam. To do this, a vapor barrier made of dense film is spread on the base under the insulation layer. There is no need to cover the top with anything; moisture evaporation should occur naturally.

Calculation of the thickness of the thermal insulation layer

The efficiency of thermal insulation depends on the accuracy of determining the thickness of the insulation, which is part of the thermal engineering calculation. In addition, the indicator allows you to calculate the loads placed on the ceiling structure. When calculating, the values of the permissible weight and the required thermal protection are compared.

The thickness of the insulation is determined by the formula

q = R * k,

Where:

- q – thickness of heat-insulating material, m;

- R – thermal resistance, m2°С/W;

- k – thermal conductivity coefficient of insulation, W/(m°C).

The R value is determined from tabular data - the indicator is calculated for each region, taking into account the climate characteristics.

For example, the standardized thermal resistance of floors for Nizhny Novgorod is 4.26 m2°C/W. If you use penoplex to insulate the ceiling, you will need a layer of thermal insulation 12 cm thick

To calculate, it is enough to multiply the indicators 4.26 and 0.038. The last value is the thermal conductivity coefficient of extruded polystyrene foam. The weight of the ceiling is calculated based on the volume of insulation and its density. The first indicator is determined by the product of the area and thickness of the thermal insulation, the second - the table value.

The minimum load on the ceiling is exerted by polyurethane foam and ecowool, their density is in the range of 25-60 kg/cu. m. One of the heaviest insulation materials is expanded clay - 180-330 kg/cu.m. m.

Spray polyurethane foam

The advantage of this type of insulation is the creation of a seamless coating and high installation speed. PPU is sprayed using a compressor unit or a hand-held spray can with a gun. The polymer hardens very quickly, and the surface shape can be any.

The vapor permeability of polyurethane foam is close to that of wood. Unlike the foam shell, which does not allow the wood to breathe, polyurethane foam does not retain moisture, so it freely migrates between layers and evaporates into the atmosphere.

Spraying is done in one layer. One can is enough for 1.2 square meters with a coating thickness of 50 mm. But this is not enough for the middle zone. According to the standards, floors under a cold roof in a temperate climate zone must be insulated to a thickness of at least 81 mm, that is, the cylinder will be consumed for 0.74 sq.m.

Polyurethane foam, like any polymer, is afraid of ultraviolet radiation, so leaving it unprotected in direct sunlight is not recommended. It is also necessary to take into account that polyurethane foam is low-flammable, so it is advisable to spray it on a non-flammable substrate.

Worker skills and tools

Popular insulation methods do not require expensive equipment or high qualifications. For insulation, a home craftsman will only need general construction skills and ordinary tools:

- knife

- hammer

- screwdriver

- hacksaw

- stepladders

- roulette

When installing the guides, it is best to call an assistant. Help with cutting and laying rolled materials would also be helpful.

Before starting work and purchasing materials, it is necessary to make a sketch drawing. This will help you avoid making mistakes with dimensions and correctly calculate the amount of materials purchased.

Polyethylene foam films

Most often used as a vapor barrier. They retain heat to a small extent, so they are practically not used as the main insulation. The metallized coating increases the amount of infrared rays reflected into the room. But during installation you need to follow some rules:

- the foil layer should be directed downwards;

- the distance from it to the nearest surface is at least 20-25 mm.

If these conditions are met, the foil will actually work. Otherwise, the reflection effect is practically absent.

Important. Multilayer thermal insulation effectively retains heat. The main thing is that it is safe to use.

Other insulation materials

To insulate ceilings in a house with a cold roof, you can use:

- Linen, straw, reed mats treated with fire retardants and antiseptics are laid outside on the ceiling spaced between the joists. The seams are filled with straw or sawdust.

- OSB boards, moisture-resistant chipboard, plywood - are usually used for internal and external cladding of ceiling beams. They also play the role of additional thermal insulation.

- Sprayed ecowool is a mixture of crushed waste paper, boric acid and borax. It is spread dry or wet by a compressor unit. Manual installation possible.

- Cork is a roll or sheet material that is glued to the ceiling from the inside. It is quite decorative, has good soundproofing properties, is not afraid of moisture and does not contribute to the spread of fire.

- Sintepon or felt are non-woven materials made from synthetic fibers. They have low thermal conductivity, vapor permeability, moisture resistance and environmental safety. There is no dust during installation, so installation can be carried out without gloves, goggles or respirators.

Video description

Which insulation divides heat better, watch the video:

Advice! When working with penoizol, it is recommended to wait until it hardens completely; it has a slight shrinkage that will have to be compensated to prevent the formation of voids.

The process of thermal insulation of the ceiling with foam insulation Source lestorg32.ru

How to insulate the ceiling in a house with a cold roof: 2 simple effective ways

Thermal insulation can be installed on both the upper and lower sides of the ceiling. Before starting work, the frame beams must be installed. Electrical communications are carried out in protective non-flammable casings.

Insulating the ceiling from the outside

It is very convenient to carry out thermal insulation from the upper side of the ceiling. The material is laid on a horizontal surface without the need to hold it suspended. The rough filing of the ceiling should already be ready.

Laying vapor barrier

This is the most important issue in the entire insulation process. If mineral wool or other material with high moisture absorption is used, it is necessary to use a vapor barrier film with a thickness of at least 200 microns.

The panels are connected to each other with an overlap and glued with tape. It is important not to leave even the slightest gaps for the penetration of warm air from the room into the insulation.

The vapor barrier can be attached either from below to the sheathing or laid on top along the joists. The edges of the film should be 30-40 cm higher than the ceiling and wrapped up onto mineral wool. This way there will be no way for warm air to get into the insulation layer.

In a frame house, the vapor barrier should form a continuous closed loop. Ceiling insulation is combined with wall insulation and this must be considered during construction. The film on the top of the walls is laid with a margin of 20-30 cm in order to glue it with the vapor barrier of the ceiling. You can overlap from the ceiling side.

To protect mineral wool from moisture, vapor barrier diffuse membranes are also used, which differ from polyethylene films in their breathable structure. The smallest conical holes ensure the movement of steam in only one direction - out of the insulation. When installing, it is important not to mix it up and turn the membrane the correct way. Usually the manufacturer's logo is on the surface facing the room.

Installation of insulation

Plates or rolls are laid between the joists. It is advisable to break the large thickness into several thinner layers. At the same time, overlaps of at least 20-30 cm must be made in adjacent rows to avoid the formation of through seams.

When laying, it is recommended to avoid strong compaction of the material. This worsens its thermal insulation properties and provokes early shrinkage. The distance between the lags should be only 2 cm less than the width of the slab, then a slight expansion will be provided without excessive compression.

To fill the gaps, pieces of appropriate sizes are cut out. They are installed in the slots also with slight pressing.

If you plan to walk on top, a flooring made of boards or OSB is installed. When installing a continuous floor, it is necessary to leave a ventilation gap between it and the surface of the mineral wool to ventilate moisture.

Insulation of the ceiling from the inside

If there is no easy access to the attic or there are already subfloors there, you can insulate the floor from the bottom side. The ceiling pie will be the same, and this will not affect the performance of the thermal insulation in any way.

Mineral wool slabs are laid between the beams with a slight spacer (the width of the strip of material should be 10-20 mm greater than the lag pitch). To prevent the insulation from falling, it is secured from below with stretched lines or thin slats. As a vapor barrier, you can use foil film or aluminum foil. They are applied from below and secured to the beams with a stapler. The seams are sealed with metallized tape.

For the air gap, slats with a thickness of 20-25 mm are installed. They are nailed at such a pitch that it is then convenient to attach the sheathing to them - lining, drywall, OSB, etc. When installing suspended ceilings, such lathing is not done.

Important. A suspended ceiling does not work as a vapor barrier. In the openings for lamps or communications, warm air with vapor penetrates into the ceiling, so it is necessary to install a full vapor barrier layer.

Video description

Insulating the ceiling from the inside, watch the video:

The process of insulating the ceiling from the inside with polystyrene foam Source nl.decorexpro.com

Thermal insulation of the ceiling from the inside with polystyrene foam boards Source barmanlive.ru