In order to keep your house or apartment warm and cozy, you need to take care of a reliable (and at the same time quite efficient) heating boiler. The Lemax double-circuit floor-mounted gas boiler fully meets these requirements: being a multifunctional unit, it will not only provide heat, but also heat water for household needs.

What are the advantages of a double-circuit boiler over others, and why this model is preferable to foreign analogues, will become clear if you carefully read the material below.

Floor-standing single-circuit gas boilers and their features

The design of floor-standing single-circuit gas boilers is economical and simple.

They are capable of performing a single basic function - heating the coolant for the heating system. These units do not perform any additional tasks, therefore the set of units and parts of the unit is limited - only the most necessary elements are involved in the work.

In addition, the floor mounting method allows the use of durable and powerful units with increased weight and capabilities.

This makes the design more powerful and capable of high performance.

Most models are equipped with massive heat exchangers that have a high heat transfer capacity and can accommodate an increased volume of liquid. There are no restrictions on weight or dimensions for floor-standing boilers, so the power can be 100 kW or more.

Many units can be connected in a cascade (usually up to 4 units), creating a high-power thermal station.

Another feature of single-circuit floor-standing boilers is the ability to connect an external storage boiler.

This combination allows you to get not only heating of the house, but also a stable supply of hot water.

Most experts consider this option more preferable than using a double-circuit boiler, since the mode of supply of hot water from the boiler is smooth, without temperature jumps or pauses.

What are the installation requirements?

Standard requirements have been established for the installation of a Lemax double-circuit gas boiler. It is necessary to comply with the usual provisions for heating units, the presence of connection points to the water supply, gas mains, and the presence of a chimney.

Important. Installation should be carried out by qualified specialists who have experience working with gas equipment; amateur activities are not allowed here.

A prerequisite is the installation of all components and parts provided by the manufacturer (and specified in the manual): expansion tank, shut-off valves, flaps, and sensors. The base for the equipment must be stable and solid, preventing subsidence and distortions of the boiler, especially its displacement. When choosing the installation location, you should take into account the possibility of servicing the unit and its parts, so that, if necessary, it is convenient to dismantle the burner block or sectional heat exchanger.

Regarding the chimney, there are several options: solid, brick, or assembled from separate sections of the pipe. The latter option is very popular (and recommended by companies specializing in the production of gas exhaust systems), and it is also easy and quick to install.

The best Russian floor-standing single-circuit boilers

Let's look at the most popular models of Russian floor-standing gas boilers:

Lemax Premium-20

Products of the plant of the same name from Taganrog. A non-volatile floor-standing boiler with a power of 20 kW is capable of heating a house of 200 square meters. m.

Its main characteristics:

- Efficiency - 90%;

- coolant temperature (max) - 90°;

- heating system pressure (max) - 3 Bar;

- fuel consumption - 2.4 m3/hour;

- dimensions - 556x961x470 mm;

- weight - 78 kg.

The high demand for Lemax boilers indicates the demand and positive attitude of users towards domestic heating units.

Lemax Premium-12.5

Another representative of the Taganrog plant, designed for work in relatively small spaces. With a power of 12.5 kW, this boiler can heat an area of 125 square meters. m., which is suitable for country houses or country houses.

Unit parameters:

- Efficiency - 90%;

- coolant temperature - 90°;

- heating system pressure (max) - 3 Bar;

- fuel consumption - 1.5 m3/hour;

- dimensions - 416x744x491 mm;

- weight - 60 kg.

The boiler is relatively small, but its capabilities allow you to get the maximum effect.

Lemax Leader-35

Powerful (35 kW) floor-standing boiler, capable of serving a house or public space of 350 square meters. m. The combustion chamber is open type, which requires connection to the central chimney.

Other parameters:

- Efficiency - 90%;

- coolant temperature - 95°;

- heating system pressure (max) - 4 Bar;

- fuel consumption - 4 m3/hour;

- dimensions - 600x856x520 mm;

- weight - 140 kg.

A special feature of this model is a cast iron heat exchanger, which provides high heat transfer and stable heating mode.

ZhMZ AOGV-17.4-3 Comfort N

Product of the Zhukovsky Mechanical Plant. Power 17.4 kW, which is designed to heat 140 sq. m. The non-volatile design makes the unit resistant to all changes in the situation.

Boiler parameters:

- Efficiency - 88%;

- coolant temperature - 90°;

- heating system pressure (max) - 1 Bar;

- fuel consumption - 1.87 m3/hour;

- dimensions - 420x1050x480 mm;

- weight - 49 kg.

If necessary, the boiler can be reconfigured to be powered by liquefied gas, which further increases its autonomy.

Rostovgazoapparat AOGV

A unit from the Rostov plant with a power of 11.6 kW. Designed for heating 125 sq. m. usable area.

Its operating parameters:

- Efficiency - 90%;

- coolant temperature - 95°;

- heating system pressure (max) - 1 Bar;

- fuel consumption - 1.18 m3/hour;

- dimensions - 410x865x410 mm;

- weight - 49 kg.

The unit differs from other models in its cylindrical shape, which looks somewhat old-fashioned. However, this does not affect the quality and parameters of the boiler in any way.

teplomex.ru

In the fast-growing heating equipment market, almost every year more and more brands and models of floor-standing gas heating boilers appear. This often concerns imported equipment, although Russian manufacturers are also trying to keep up and meet European quality standards and modern technologies.

for floor-standing gas boilers Lemax manufactured in Taganrog can increasingly be seen on the global network in various reviews on heating topics.

I suggest that we take a closer look at the boilers of the Russian Lemax brand. Let's analyze the model range, technical characteristics, how different models differ, consider the types of automation installed on them, and the principle of operation, according to the operating instructions.

Model range and technical characteristics

Lemax gas floor-standing boilers of the Premium series are produced from high-strength steel 2 mm thick. They have a model range: from household ones - with a power from 7.5 kW to large industrial ones, with a power of up to 100 kW.

The most popular models among the population are KSG Premium-7.5, -10, -12.5, -16, -20. Even the lowest-power boiler of 7.5 kW is capable of heating a small private house with an area of up to 70 square meters, 10 kW up to 100 m2, etc.

Lemax floor-standing gas boilers

The Lemax gas boiler is completely energy independent. Starting is carried out using a piezo ignition button. Unlike Mimax boilers, these models are equipped with a draft sensor for safe operation of the boiler, which is triggered in case of a problem with the draft in the chimney.

Just like Conord boilers, they can be used on natural gas with natural or forced circulation of coolant in the heating system. These models are not equipped with a circulation pump, but it can always be installed separately in the system. When replacing jets (nozzles), the boiler can also operate on liquefied (cylinder) gas.

In addition, you can find Lemax floor-standing gas boilers of the “Leader” series on the market. A distinctive feature of this model is that they are made of cast iron with a wall thickness of 4 mm, equipped with imported SIT automatic equipment, a draft sensor, protection against overheating and soot formation. But we will talk about them in more detail next time.

Lemax steel heating gas boilers are produced as single-circuit, designed only for heating, and double-circuit - heating and hot domestic water. Double-circuit boilers have a built-in copper heat exchanger for hot water supply.

Lemax Premium double-circuit boilers are designated KSGV - steel gas hot water boiler. They are produced with power from 12.5 to 40 kW. But, as practice and reviews show, in order for the performance of the secondary circuit to be normal, you need to purchase a boiler with a capacity of at least 20 kW, or better yet, more.

The diameter of the fittings for connection to the heating system is:

— 40 mm (1 1/2′) for models KSG-7.5 and KSG-10 — 50 mm (2′) for models of higher power

The diameter of the pipe for installing the chimney is:

— 100 mm for models KSG-7.5 and KSG-10 — 130 mm for models KSG-12.5, KSG-16, KSG-20, KSG-25 and KSG-30

The diameter of the gas connection for models with a rated thermal power of up to 30 m2 is 15 mm or 1/2 inch.

Automation for gas boilers Lemax

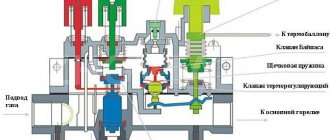

A characteristic feature of these heating boilers is the presence of various types of automatic devices on them. They are equipped with imported Italian type “NOVA SIT”. Let's look at the gas burner device in detail using the diagrams below.

Design of a Lemax boiler with GGU automation (gas burner device)

Automation of GGU

1 - gas boiler 2 - gas burner 3.4 - shutdown and start buttons, respectively 5 - thermostat 6 - gas connection 7.8 - forward and return lines of the heating circuit 9 - thermometer 10.11 - DHW outlet and inlet (at dual-circuit models) 12 - temperature sensor tube

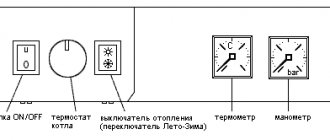

How to use the boiler automation:

- open the gas tap, then turn the thermostat knob to position “0”

— bring a burning match through the viewing window to the igniter, press the button to turn on the magnetic valve (ignition of the pilot burner)

- hold the button for 1 minute until the pilot light starts to burn

— to ignite the main burner, you must move the thermostat knob to position “4”

— then we set the handle to the position we need

— to turn off, press the “off” button

Design of a Lemax boiler with imported NOVA SIT automatic equipment

Automation EuroSIT boiler Lemax

1 - gas boiler 2 - gas burner 3 - knob for adjusting the temperature and ignition of the burner 4 - piezo ignition button 5 - temperature sensor tube 6 - viewing window 7 - gas connection 8.9 - direct and return for connecting the coolant 10 - thermometer 11.12 - inlet and DHW circuit outlet (for dual-circuit models) 13 - stainless steel gas hose

How to use Euro SIT automation:

- open the gas tap

— set the thermostat knob to the ignition position

- press it all the way and hold it for 1 minute, while simultaneously pressing the “piezo” button until a flame appears

- the main burner is turned on by setting the thermostat knob to position from 1 to 7

— to turn off the burner, turn the knob to the “off” position

Specifications

Technical characteristics of Lemax boilers

Possible malfunctions in the operation of the Lemax floor-standing gas boiler

1. Spontaneous shutdown of the main burner.

Reason: poor draft in the chimney or malfunction of the thermostat.

2. Smell of gas, leak.

It will be necessary to check the threaded connections and replace the gaskets.

3. The flame is elongated and burns red-orange.

Poor draft in the chimney, clogged burners.

4. Cold heating radiators in the system, but the boiler itself is hot.

Lack of coolant volume in the system or errors during installation of the system.

Let's watch the video So, we have disassembled Lemax gas boilers , examined the main models of this brand, their features and internal structure, operating principle and technical characteristics. We clearly learned how to use automation, as well as promptly identify possible problems in the operation of the heating boiler.

Advantages

There are a large number of models of Russian Lemax gas boilers on the market with different power ranges. Lemax wall-mounted and floor-mounted boilers are available. Floor-mounted units are in wider demand

If you need a boiler that will be solely responsible for heating the building, then you should pay attention to single-circuit models. If you want to supply your home with hot water, then you should take a closer look at boilers with two circuits

More information about Russian-made boilers here

The main advantages that are common to all Lemax gas heating appliances:

- high productivity, efficiency reaches 90%;

- a wide selection of models allows you to select a unit based on the requirements you place on the boiler;

- ergonomic design;

- the boiler operation process is safe;

- boilers are considered very reliable, this is achieved through control over production processes;

- a large number of service centers, so in case of any failures or malfunctions, you can easily repair the boiler;

- since heating devices are developed and produced in Russia, they are completely suitable for domestic operating conditions;

- long service life.

Operating principle of Lemax gas floor boilers

It is not much different from the operating principle of standard gas units: the gas-air mixture coming from the burners is ignited in the firebox, and the heat of the burning fuel heats the working fluid (water) in a special block (heat exchanger). Hot water periodically enters the heating line, and cold water comes in instead. Excess coolant generated during operation is discharged into the expansion tank.

Automation controls the temperature of the water in the circuit (and therefore a similar indicator for the air in the room), as well as several other parameters:

- presence of draft in the chimney;

- water and gas pressure in the main;

- operation of the ignition system.

Lemax double-circuit gas boilers, in addition to the main heating function, have an additional function: heating water. This is necessary so as not to install a boiler or hot water column together with the unit.

Very convenient: one device successfully replaces two.

The heat exchanger in such installations is most often of a cast design - this indicates that it is made of cast iron. This design guarantees high corrosion resistance (the material is less susceptible to the destructive action of water and salts dissolved in it), as well as good boiler performance. Cast iron has a higher heat transfer rate than steel, so it is no coincidence that radiators for heating systems are still made from it. In addition, components for Lemax are produced at the factories of well-established Czech manufacturers.

Attention. Despite the above, steel parts also have certain advantages: they are less susceptible to damage from accidental impacts, and a unit with such a heat exchanger weighs less (which is important when choosing a mounted model).

Recommendations for use

You can light the boiler only after the water pressure in the system has been accurately measured and it is not higher or lower than the permissible values. You cannot refill the circuit with water if the main burner is running or the line is heated to 50 degrees or higher. You should avoid using a boiler with coolant heated to less than 50 degrees. As practice shows, this quickly provokes significant malfunctions in various parts of the system. It is prohibited to put boilers into operation without connecting them to the chimneys.

Before starting, you should make sure that the smoke exhaust channels are not blocked by anything and that normal draft develops in them. According to technical standards, it is prohibited to use hot water from the heating system for any extraneous needs, as well as to check gas lines and parts of the boiler using open flame. A very dangerous decision is to turn on the gas burner if there is no necessary air pressure in the firebox. Of course, if the boiler suddenly goes out frequently, independent adjustments to the draft sensor and other components of the device are unacceptable.

The formation of condensation in the initial period after ignition is completely normal and does not require any special actions. It is strictly forbidden to raise the temperature of the coolant to more than 95 degrees. If you discover this, you should immediately stop the heating and do not turn it on until the problem is resolved by professionals. Preparation for operation involves placing the boiler on a sheet of metal. This is mandatory even in rooms with non-combustible floors.

How much coolant to pour into the heating system is determined by the individual project. The accompanying materials provide approximate data that can be adjusted in one direction or another. It is advisable to install a fuse that discharges water from the heating system when the normal operating pressure is exceeded. Adjusting and checking the functionality of automatic safety equipment is the prerogative of gas workers or other authorized, certified organizations.

It is not advisable to drain the water from the boiler and heating system at the end of the heating period. Only the need to repair, dismantle, reconstruct or rework the system justifies this. The return pipeline in the area in front of the boiler must be equipped with a device that collects dirt from the water and prevents it from penetrating into other parts of the system. It is recommended to annually call employees of the territorial gas service or an equivalent organization to inspect and test the boiler. Filling the pipeline is allowed only with water; consuming a liquid with properties different from it means the user automatically waives all claims for service under the warranty.

If the boiler can supply hot water to the tap, the greatest efficiency of this mode is ensured by setting the thermostat to the maximum value and turning off the pump that provides circulation. The draft in the chimney and the serviceability of its circuits are checked annually. A special mixer helps prevent burns. But if it is not there, you will have to first open the “cold” tap, and only then gradually add hot water.

Compatibility with older chimneys is limited. Since, with a calculated efficiency of 90% and above, the temperature of the flue gases does not exceed 120 degrees, problems may arise. According to statistics from authorized service centers, only 6% of cases of excessively low performance are not associated with the removal of gaseous combustion products. In the room where the boiler is located, it is unacceptable to block the ventilation ducts.

For a review of Lemax gas boilers, see the video below.

Known malfunctions of Lemax boilers

Serious service complaints for Lemax boilers are rare. However, as with any other equipment, breakdowns are possible, the most common of which are a thermocouple that converts thermal energy, a weak electric current sufficient for the operation of the automation, as well as a draft sensor necessary to control draft and emergency stop of the boiler in its absence .

It is worth noting that often the thermocouple does not necessarily need to be replaced. If its contacts have oxidized, you need to carefully clean it with sandpaper and check the operation again. Otherwise, the service life of boilers is limited only by the life of the heat exchanger.

Now let's look at the most common questions that are usually not related to a malfunction (click to expand the answer):

+ Why does the main burner go out?

There can be many reasons, we have already listed all of them in one of the previous articles. Usually the cause is low gas pressure, clogging, weak draft, but most often the cause is reverse draft, when the burner flame blows out during strong gusts of wind. This happens due to errors in the design of the chimney: its overall height and height relative to the roof ridge are insufficient, and the lack of a protective deflector on the headband.

+ The boiler does not turn on, the wick or main burner does not light

If you checked the draft, it is there, there are no backdraft phenomena, most likely the problem is a clogged ignition nozzle. It is necessary to disassemble the boiler, removing the burner module and carefully clean the igniter first (blow it out, pierce the clogged hole with wire), and then the burner. Be careful not to allow even the slightest scratches or deformations; before disassembling, always photograph the position of all components. If there is no spark when igniting, the piezo ignition is faulty, but first you should try to carefully clean all contacts with sandpaper.

How to clean a gas boiler yourself: detailed instructions

Gas wall-mounted boiler Lemax

The Lemax company produces only one line of prime-v wall heaters. Each device is equipped with SIT automation made in Italy. All models in this series are dual-circuit and can operate in heating systems with a pressure of up to 3 atmospheres.

Chimney of a parapet boiler.

The boilers are equipped with a closed combustion chamber, so they require the installation of a coaxial chimney. A fan is located above the combustion chamber. Turbocharging is needed to pump in air from the street and at the same time remove smoke outside. The maximum length of a coaxial chimney can be up to 5.5 m.

All characteristics of the Lemax wall-mounted boiler are specified in the instructions for use. The main ones:

- 4 adjustable power options (minimum 9 kW, maximum 34.6 kW depending on model);

- Efficiency 92.5%;

- minimum cold water pressure 0.02 MPa;

- nominal gas pressure 1.3 MPa;

- power consumption 125 or 135 W/hour.

The boiler is equipped with a circulation pump and a 6-liter expansion tank. The rated pressure in the tank is 0.1 MPa. If the expansion machine is configured incorrectly, there will be pressure drops in the heating system. The manufacturer provides a 2-year warranty.

Requirements for installing Lemax gas boilers

All the basic requirements for the installation and operation of Lemax heating equipment are exactly the same as those of many other manufacturers. The technical characteristics of all products are high, but subject to compliance with all installation and operation rules.

- The device has a draft sensor; if the intensity is insufficient, the burner turns off. The main task during installation is to create all conditions for good traction. The company's manufacturers recommend using a chimney when connecting, which is best made from sandwich pipes.

- The models need some modifications; for example, floor-standing gas boilers can often heat water insufficiently to be used for domestic needs. Experts advise choosing a single-circuit unit in order to connect an indirect heating boiler to it, in this form it will be able to heat a large amount of water at the required temperature.

- Boiler piping. The circulation pump is installed on the return line of the heating system directly in front of the unit.

Boiler maintenance rules

Lemax double-circuit floor-standing gas boilers are distinguished by their unpretentiousness in operation, due to the fact that they are manufactured in domestic conditions, they are easy and simple to maintain. The manufacturer is constantly improving the design of its products, as service specialists say, they are characterized by high maintainability. Moreover, some common problems can be easily fixed without calling an adjuster.

Read the link about the advantages and features of double-circuit gas boilers.

You might be interested >> The operating principle of a condensing gas boiler

Owners of boilers (and not only this brand) often complain that the burner ignition is blocked due to an allegedly clogged chimney. Smart automation is adjusted in such a way that it reacts to a lack of traction: in order to avoid emergency situations, a special device does not allow the gas to be ignited. The problem most often lies in the sensor, or rather, in the oxidation of its contact group. It is enough to remove the contamination, and the boiler works normally again.

In domestic gas networks, with their not always stable pressure, poor operation of the burner of heating units occurs. In other words, a low flame level on the igniter does not allow the gas to ignite normally in the boiler furnace. This situation can be resolved by carefully studying the instructions and adjusting the ignition unit.

Important. For steel heat exchangers, which are extremely sensitive to corrosion, service center workers recommend using treated water in the heating system. To do this, you will need to install an additional unit; specialized stores will tell you how to choose it.

Lemax gas boiler: types of models

Lemax gas boilers are divided into the following main types: floor-standing boilers with a steel or cast iron heat exchanger, wall-mounted appliances and units operating on solid fuel. Heaters that run on solid fuel are available in two types. This is a potbelly stove that runs on wood and a solid fuel boiler that is intended only for coal.

Floor-standing boilers that have a steel heat exchanger have become widely used. Such devices are made of very durable metal, the thickness of which is 2 mm. Steel boilers have five representatives of this type, differing in the power of the device.

Classification of floor-standing boilers with a steel heat exchanger:

- Lemax premium;

- Premium nova;

- Gazovik;

- Clever;

- Patriot.

Premium nova boilers are, today, more advanced. Their automation system is capable of setting the necessary indicators for the boiler, and you can also regulate the required water pressure. But the Patriot series boilers are distinguished by their closed combustion chamber. All of them are single-circuit, do not require an electrical network and can be installed without a chimney. Boilers with a cast iron heat exchanger are more durable; the thickness of the cast iron is 4 mm. Such devices, unlike steel ones, are less susceptible to various contaminations, and their service life exceeds 2 years. This type is represented by two units: Leader and Wise.

The best and most famous models: characteristics and prices

Floor-standing

Premium

A non-volatile boiler unit with a steel heat exchanger, this is one of the most successful and popular models among the entire Lemax line of heating boilers. The series is represented by models with a power of 7.5; 10; 12.5; 16; 20; 25; thirty; 35; 40; 50; 60; 70; 80; 90; 100 kW. There are also double-circuit boilers; they come with the prefix “B”, for example Lemax Premium-16V, and cost an average of 5 thousand rubles. more expensive than a single-circuit analogue.

The model is characterized by excellent efficiency - 90% and low gas consumption, for example, the maximum figure for the 10 kW version is 1.2 m3/hour, for the 16 kW version - 1.9 m3/hour. It is known among experts as a win-win and hassle-free option, which is recommended in the top three options for budget floor-mounted aspirated air conditioners.

One of the disadvantages is the rather thin (2 mm) steel of the heat exchanger, although due to its high quality, in practice boilers last a standard 10-14 years. Otherwise, the boiler has all the previously described disadvantages that are also characteristic of other Lemax models: demands on the initial setting and chimney, maintaining cleanliness, large dimensions, the burner flame goes out if there is a backdraft in the chimney (despite the presence of protection against blowing out).

Please note that the maximum permissible operating pressure is only 1 bar, so it is not recommended to use the model in closed systems, where the operating pressure is usually 1.5-2 bar.

Leader

Still the same non-volatile model, but with a cast iron, much more durable, corrosion-resistant heat exchanger (service life from 25-30 years). They are distinguished by a higher operating pressure - 4 bar, have the same efficiency of 90% and the same fuel consumption indicators. The model is presented exclusively in single-circuit versions with a power of 16, 25, 40, 50 kW. Models with the “N” prefix are equipped with an updated, more advanced version of the EuroSit automation – 820 NOVA SIT, in which the thermostat now has a temperature designation, and it is possible to connect external control (for example, a room thermostat).

How to choose a room thermostat and save up to 30% per month on heating

The disadvantage is that the build quality is not as excellent as in the case of other models, namely the quality of fastening and fixing elements. It is also worth noting the relatively high price, for which some more advanced European analogues can already be considered.

Wise

One of the best Lemax gas boilers for heating a private home. It is an energy-dependent aspirated unit with a cast iron heat exchanger, characterized by a modulated burner and the presence of automatic ignition.

Despite the same maximum gas consumption figures, the model is known for its truly low consumption; in practice, the 16 kW version is often in the range of 0.9-1.2 m3/hour. This is achieved thanks to energy-dependent functional automation and a modulating burner, capable of maintaining the most optimal fuel combustion mode - continuous combustion at minimum power.

Unlike any other boilers of the brand, Wise is well adapted to both power fluctuations and gas pressure differences, which makes it easier to set up. It is possible to connect external control and organize weather-dependent operation. This is the only model that is devoid of almost all of the characteristic disadvantages described earlier. The only significant drawback is the high price, comparable even to the most reliable and functional Japanese and Italian gas floor-standing boilers. Available in 16, 25, 35, 40 and 50 kW versions.

Wall mounted

Prime-V

Mounted double-circuit convection boiler with a closed combustion chamber. Available in versions with heating capacity 10, 12, 14, 16, 18, 20, 24, 26, 28, 32 kW.

A special feature of the model is its design, consisting entirely of foreign European components. The primary (main) heat exchanger is copper, the burner has the ability to modulate the flame, the combustion chamber is a closed type, the presence of a layer of heat and sound insulation - all this made it possible to achieve one of the best efficiency indicators for standard convection boilers - 92.5%, which, of course, is positive also affected gas consumption. For example, a model with a power of 18 kW has a maximum gas consumption of 2.04 m3/hour, which is less than many European models.

The main disadvantage of Prime-V is its cost, comparable to the same European and Japanese models. In fact, the direct competitor is the most widespread, efficient, proven and problem-free Italian BAXI ECO-4s, which has almost the same design with a copper heat exchanger and flame modulation, absolutely the same functionality and a slightly larger set of safety systems. However, it is slightly inferior in terms of gas consumption, hot water temperature and adaptability to voltage drops in the electrical network and gas pressure drops.

Having lost the main competitive advantage of domestic models - price, Prime-V directly competes with the best foreign models, which makes the choice in terms of price-quality ratio not so clear.

Parapet

Patriot

One of the most common and successful parapet energy-independent gas boilers. It has a good efficiency of 87% for parapet models and low gas consumption, for example, 1.2 m3/hour for a 10 kW model. Available in versions with a capacity of 6; 7.5; 10; 12.5; 16; 20 kW. The design provides only a steel heat exchanger made of the same 2 mm steel, Italian EuroSit automatics. Despite the combustion chamber being a closed type, the device remains as simple, understandable and reliable as possible.

The only noticeable drawback is the problem inherent in almost all parapet models with the flame being blown out by the wind, after which you have to manually start the boiler. This happens much more often than in the case of traditional gas boilers. Therefore, the choice of a parapet boiler is generally controversial, despite the fact that Lemax Patriot is one of the best of them. In our opinion, installing a parapet model is justified in garages, utility rooms, small apartments or houses for temporary residence.

Is it worth considering a parapet gas boiler for heating a house or apartment?

Model range of Mimax equipment

The mimax company offers the consumer the following products of its own production:

- Heating gas boilers Vega KSGV and KSG.

- Parapet boilers KGS (P).

- Solid fuel boiler Titan.

- Gas burners AGU-T-M, AGU-T-E and Optima.

Let's look at the most popular gas models.

VEGA Series

This floor-standing gas boiler is available in two variations:

- With one heating circuit (CHC).

- With an additional water heating circuit for heating water for domestic needs (KSGV).

In addition to the high efficiency of 92% for this type of boiler, the operating instructions contain the following technical characteristics:

- Atmospheric gas burner made of stainless steel.

- Turbulizers are used in the heat exchanger, which will allow for more efficient use of all thermal energy.

- Each boiler in this series is equipped with Italian SIT automatic equipment. This automation is simple, reliable and easy to use.

- The wall thickness of the heat exchanger is 3 mm, it is made of cold-rolled steel sheets.

- Additional thermal insulation of the combustion chamber and the unit body makes it completely safe.

Devices MIMAX KSG and KSGV

In this model of gas heating apparatus, the Mimax company installs open burners of its own production and automatic equipment from the Italian company Optima. The attached instructions contain the following technical characteristics and design features:

- Power from 7 to 40 kW.

- Compact dimensions allow this boiler to be installed in small spaces in compliance with all safety requirements.

- Reliable thermal insulation of the combustion chamber with non-asbestos materials reliably protects the housing from overheating.

Mimax parapet models

The heating boiler of this series has the following features:

- The sealed combustion chamber allows installation of units in rooms that are not equipped with a chimney.

- Exhaust gases are discharged into a coaxial chimney. Air is also taken in through it to support the combustion process.

- Versatility of installation: such a boiler can be mounted on an external wall or installed on the floor.

- The steel heat exchanger ensures high heat transfer and durability.

- Sit automation and additional safety elements: pressure sensor, piezo ignition and thermostat in the heating circuit ensure high reliability and safe operation of the equipment.

All these design features of Mimax parapet boilers have received approval and positive feedback from consumers.

The worthy technical and operational characteristics of gas units of the Mimax brand are deservedly in demand among domestic consumers. Low price with excellent quality, reliability and safety is another advantage of this equipment, which is confirmed by numerous reviews on the website in the country

Lemax heating equipment can be purchased in any city in our country.

There is a network of stores located in all regions that sell various types of Lemax gas heating boilers and have a wide catalog of equipment. A service network for gas heating equipment has also opened, and Taganrog is no exception.

The start of buying boilers begins in mid-autumn. Constant promotions are carried out. The Taganrog service can remove all the problems that have arisen with your gas heating equipment (boilers and stoves) - a real professional will do this.

Good to know: Premium gas boilers are sold, as well as KSG and AOGV models, which require a thorough study of the instructions before purchasing.

Durable material, saving you money, high efficiency (exceeds 90%), availability of shops and service points, ease of installation, long service life (about 15 years), the ability to choose the desired type of gas boiler, beautiful design (will fit into any room interior), relatively low price - all this attracts buyers.

Entrust the installation of heating equipment to professionals. Before use, carefully read the instructions for further successful use.

Watch the video that describes various models of Lemax gas boilers:

Geyser Lemax Alpha 20M

Gas instantaneous water heater - geyser "Lemax" series "Alpha" model "20M"

designed for instant heating of water, has an original front panel design and compact dimensions. Available in white lining. The water heater uses automatic ignition of the burner by a flow of water, in the absence of a constantly operating igniter.

- Low water pressure: the device operates even if the water pressure in the system is 0.25 atm, which means it is optimal for users living on upper floors or having low water pressure in the pipeline.

- Protection against water overpressure prevents damage to the water heater.

- Ion flame control will automatically turn off the gas supply when the burner flame goes out, which completely eliminates gas leakage.

- Dry combustion protection: when the device is turned on without water flow, the protection device will automatically turn off the gas supply.

- Economical gas consumption.

- Compact sizes.

- 1 year warranty.

To heat water in residential premises without a central hot water supply, household gas instantaneous water heaters, known to everyone as geysers, are most often used. These devices heat water using the energy of gas combustion and are connected to main gas supply systems, which makes heating water as economical as possible.

Despite their compact size, gas water heaters are able to quickly heat large quantities of water and, as a result, provide hot water to several water supply points simultaneously. Modern production technologies completely change the stereotype of the geyser as a technique that requires a special approach to use. Modern instantaneous water heaters differ from their predecessors in that they are equipped, at a minimum, with a safety system and thermostats, which means they can maintain the selected water temperature constantly. As a result, a modern speaker operates primarily in automatic mode and does not require the participation of its owner.

Household water heaters "Lemax" of the "Alpha" series have all the advantages of modern water heating technology and, in addition, are enhanced by the function of operating with low water pressure and operate at a minimum pressure of 0.25 atm. This solves the problems of many geyser users. Other advantages of Lemax water heaters:

- economical gas consumption

- absolute operational safety. The safety system includes protection against gas leaks, against combustion without water flow, against freezing and against damage from excessive water pressure

The line of water heaters of the "Alpha" series is represented by compact models of original design: models "Euro-20" and "Euro-24", models "Turbo-24" and "Balance-24", model "20M". Due to their compactness, efficiency and reliability, Lemax gas water heaters are one of the most interesting offers on the market of domestic and foreign geysers, and their continued popularity among buyers only confirms the high quality of the products.

An additional advantage of Lemax water heaters is their highly qualified service. The Lemax service network is today represented in almost all regions where you can buy equipment manufactured at the plant. This means high efficiency of warranty and post-warranty service and provides maximum comfort to owners of Lemax equipment.

Owner reviews of Lemax gas boilers: advantages and disadvantages

| Advantages | Flaws |

| High technical characteristics (efficiency, gas consumption, DHW performance) | High requirements for installation and commissioning, chimney |

| Simple, well-known design that ensures reliability | Some buyers note the models are somewhat “expensive” |

| With proper installation and commissioning, there are practically no cases of serious malfunctions in the first 8-10 years of operation | Some owners complain about claps and somewhat noisy operation |

| Availability of non-volatile models, availability of even more durable cast iron models | Sometimes they note more noticeable sizes of both floor and wall-mounted models |

| Availability of dual-circuit models | The boiler room must be kept clean and the boiler must be cleaned regularly, otherwise clogging and problems with starting or ignition may occur. |

| Excellent build quality, comparable to many European-made analogues | |

| Developed service structure, availability of competent specialists in almost all regions, availability of spare parts |

Recommendations for use

You can light the boiler only after the water pressure in the system has been accurately measured and it is not higher or lower than the permissible values. You cannot refill the circuit with water if the main burner is running or the line is heated to 50 degrees or higher. You should avoid using a boiler with coolant heated to less than 50 degrees. As practice shows, this quickly provokes significant malfunctions in various parts of the system. It is prohibited to put boilers into operation without connecting them to the chimneys.

Before starting, you should make sure that the smoke exhaust channels are not blocked by anything and that normal draft develops in them. According to technical standards, it is prohibited to use hot water from the heating system for any extraneous needs, as well as to check gas lines and parts of the boiler using open flame. A very dangerous decision is to turn on the gas burner if there is no necessary air pressure in the firebox. Of course, if the boiler suddenly goes out frequently, independent adjustments to the draft sensor and other components of the device are unacceptable.

The formation of condensation in the initial period after ignition is completely normal and does not require any special actions. It is strictly forbidden to raise the temperature of the coolant to more than 95 degrees. If you discover this, you should immediately stop the heating and do not turn it on until the problem is resolved by professionals. Preparation for operation involves placing the boiler on a sheet of metal. This is mandatory even in rooms with non-combustible floors.

How much coolant to pour into the heating system is determined by the individual project. The accompanying materials provide approximate data that can be adjusted in one direction or another. It is advisable to install a fuse that discharges water from the heating system when the normal operating pressure is exceeded. Adjusting and checking the functionality of automatic safety equipment is the prerogative of gas workers or other authorized, certified organizations.

It is not advisable to drain the water from the boiler and heating system at the end of the heating period. Only the need to repair, dismantle, reconstruct or rework the system justifies this. The return pipeline in the area in front of the boiler must be equipped with a device that collects dirt from the water and prevents it from penetrating into other parts of the system. It is recommended to annually call employees of the territorial gas service or an equivalent organization to inspect and test the boiler. Filling the pipeline is allowed only with water; consuming a liquid with properties different from it means the user automatically waives all claims for service under the warranty.

If the boiler can supply hot water to the tap, the greatest efficiency of this mode is ensured by setting the thermostat to the maximum value and turning off the pump that provides circulation. The draft in the chimney and the serviceability of its circuits are checked annually. A special mixer helps prevent burns. But if it is not there, you will have to first open the “cold” tap, and only then gradually add hot water.

Compatibility with older chimneys is limited. Since, with a calculated efficiency of 90% and above, the temperature of the flue gases does not exceed 120 degrees, problems may arise. According to statistics from authorized service centers, only 6% of cases of excessively low performance are not associated with the removal of gaseous combustion products. In the room where the boiler is located, it is unacceptable to block the ventilation ducts.

Manufacturer history

The Lemax company began its activities in 1992 in Taganrog. Professionals gathered here who were able to bring what was once a small enterprise to the level of the largest plant.

It is worth noting that products manufactured by Lemax are in great demand among users and occupy a leading position in the domestic heating equipment market. Today gas boilers are produced using modern high-tech equipment. The devices are of high quality and reasonable prices. Consumer reviews indicate that Lemax boilers are excellent value for money.

Reviews of the gas boiler Lemax Premium 10 GGU-12

Construction of Lemax boilers

The main components of any gas heater:

- Gas burner unit – burner (POLIDORO, Italy), wick (igniter), piezo ignition. By pressing the button, the piezoelectric element is activated and the wick is ignited with its help. The main burner is ignited by the igniter.

- Heat exchanger. Tubular type, pipes are connected to the heating system. The coolant is heated in it. If there is a hot water supply, you need to take into account that when the water heater mode is turned on, the heating system pauses operation.

- Automation. Control board and sensors from NordGas. Gas Valve Sit.

- CIMM expansion tank.

- Wilo circulation pump.

The company independently develops the layout of elements and components, operating instructions, and expands its network of service centers. The brand has repeatedly become the sales leader among floor-standing boilers for autonomous heating of private housing construction and industrial premises.

Official website: where to view all models and operating instructions

A snapshot of the official website of Lemax Russia.

In Russia, the official website of the manufacturer is located at https://lemax-kotel.ru/.

By going to the “Catalogue” menu section, you can see all available models and their descriptions, detailed technical specifications. Under each model there is a “Documents” tab, where you can find an electronic copy of the operating instructions (aka boiler passport), which describes in detail all the features of the device, installation requirements and connection diagrams, the algorithm for turning on and adjusting the operation, maintenance features, there are clear schematic images.

Types of boilers

You need to carefully select equipment, taking into account many factors, such as room area, the presence of thermal insulation and much more. In this matter, it is better to consult a specialist. Floor-standing gas boilers for private homes are presented according to some characteristics:

Availability of contours

Single-circuit boilers are the most popular among buyers. This is facilitated by the low price, especially from domestic producers. Accordingly, cost savings. Plus, repairing a Russian boiler will cost less. The presence of one circuit means that only the coolant will heat up. It follows that the dimensions are quite compact and maintenance is easier. Gas consumption is economical. The only caveat is that in order to have hot water in the house, you also need to buy a water heater or an indirect heating tank.

Double-circuit boilers are of course more expensive, but technical capabilities are also added to the price: first of all, simultaneous heating of water and heating of the room; secondly, most options are equipped with automation. Of course, the presence of automation increases the safety system during operation, which is a huge plus. In addition, if a breakdown is detected, the system stops the operation of the unit. This indicates high reliability. If we talk about the disadvantages, the main one is dependence on electricity, if the boiler is equipped with automation.

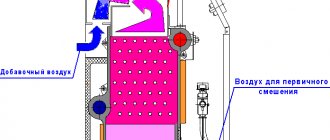

Combustion chambers

With an open-type chamber, the advantage is natural draft - oxygen is drawn from the room for combustion, and combustion products are accordingly removed through the chimney. A properly constructed chimney is a must! In addition, there should be ventilation in the room. This is also mandatory.

A significant disadvantage of such boilers is the dependence of the operation of a floor-standing boiler on external conditions. The colder it is outside, the weaker the draft. The weaker the draft, the worse the boiler burns and, accordingly, this directly affects productivity.

With a closed-type chamber, everything is simpler - it has a fan that removes gases and supplies air. In this case, the presence of a chimney is not necessary. The supply and exhaust ventilation system will do everything there. Such a chamber increases efficiency. Efficiency and lower fuel consumption. Safety. The downside is that such boilers are very noisy and electrically dependent. And they are also more expensive.

Heat exchangers

There are 3 types of heat exchangers for floor-standing gas boilers for a private home:

Cast iron: absolutely indifferent to corrosion, but temperature differences are very dangerous for them. They can crack easily. This will lead to repairs, and they are very heavy and difficult to replace. But they can last up to 30 years.

Steel: mostly light and very strong, and they also do not deform. The downside is that, unfortunately, they corrode over time. They may burn out. From this, their service life, again with proper handling, is about ten or fifteen years. At high temperatures for a long time, much more fuel will be consumed.

Copper: light weight, fortunately resistant to corrosion. Good thermal conductivity. But they are used extremely rarely. Metal is expensive and wears out quickly. This option is more often used for low-power wall-mounted boilers.

Burner type

There are atmospheric and inflatable boilers. Atmospheric ones are very noisy, but the cost is low. The burner is already included in the apparatus. Inflatable boilers are of course very noisy due to the presence of a fan. They also depend on electricity supply. The cost is high, but this is according to the configuration.

Use of flue gases

Typically, boilers are designed in such a way that flue gases, together with water vapor, are immediately discharged outside. Such floor solutions for a private home are called convection. But their temperature is high and the heat obtained at the output can be reused. Condensing units collect steam during the combustion of gaseous fuel and, as a result, the resulting heat is sent to the heating circuits. Due to this use of energy, the productivity of both the boiler as a whole and the heating circuit increases. This saves fuel and increases efficiency up to 100% and above. There is only one drawback - high cost. Convection appliances are simpler and much cheaper.

It is also important to take into account that condensing boilers are effective only in low-temperature systems, such as water heated floors. In other cases, they work similarly to a convection unit

Installation, connection and startup instructions

Installation of the boiler begins with ensuring the removal of flue gases. In the outer wall near which the unit will be installed, a hole with a diameter of 280 mm or 340 mm (for boilers with a power of 16 and 20 kW) must be punched. Then the internal and external chimneys are attached to the boiler and the unit is fixed to the wall using the lugs.

From the street side, the outer part of the chimney is connected and the hole is sealed to ensure an airtight and tight fixation of the pipe.

A deflector is secured to protect the chimney cavity from the penetration of insects or birds and precipitation.

After this, the coolant and gas supply pipelines and water make-up are connected. Check the tightness and tightness of the gas pipeline connection using a soap solution. Then fill the system with water, monitoring the pressure according to the pressure gauge.

Open the gas supply valve and turn the control knob to the “on” position. Press the handle all the way and simultaneously press and hold the piezo igniter button until a flame appears on the pilot burner. After this, hold the control knob for about another minute.

If the flame goes out, try again after 1 minute. The main burner starts when the knob is turned to position 1.

Position 7 corresponds to the maximum power and heating temperature of the coolant. To turn off the burner, turn the knob to the “off” position.

Floor and wall

As of 2022, Lemax's product range includes one line of wall-mounted gas boilers and six model ranges of floor-standing heating boilers.

Wall-mounted boilers:

PRIME-V series.

Wall-mounted boiler "Lemax" PRIME series Floor-standing boilers:

- "Premium" 7.5-60

- "Premium" 70-100

- "Patriot"

- "Leader"

- "Premium" NOVA

- AOGV "Gazovik"

The only line of wall-mounted models is a double-circuit boiler with a closed turbocharged combustion chamber. This allows the installation of equipment in the absence of a built-in ventilation system for gas equipment or a chimney in apartments and houses. The DHW circuit is made on an independent heat exchanger, which increases the reliability of the system, comfort of use, but also cost.

The line includes boilers with capacities: 19.5, 25.5, 30.3, 34.6 kW. Electronic microcontroller control. Ignition of the spark gap from the spark gap. The best option for heating an apartment or house with an area of up to 300 sq.m. It is possible to connect additional remote indoor temperature sensors to control actual heating.

Among floor-standing boilers, the emphasis is on the energy independence of the boilers; they do not require an electrical connection. Hydrothermal units are mainly used for control. The division into model series is based on power (6-100 kW), design and material of heat exchangers. Boilers of the “Leader” series are equipped with cast-iron heat exchangers, the rest are made of steel.

To fine-tune the boiler, an optional remote thermostat is used to control the room temperature. The main emphasis is on simplicity of design and reliability, which ensures both the affordable cost of the equipment and its durability.