Homemade long-burning stove Bubafonya from a gas cylinder with your own hands: drawings, dimensions, diagram, photo, video.

We continue the topic of homemade long-burning stoves and this time we will look at a stove with a very original design, the stove is called Bubafonya.

This original name was given to it by users of the forum, where in 2008 the design of the stove was presented by a craftsman with the nickname Bubafonja.

The stove really deserves attention, its design is extremely simple, the stove works on any wood, it can be not only firewood, but also sawdust, wood chips and branches.

You can make Bubafonya from an ordinary gas propane cylinder and heat it for almost pennies - a greenhouse, a country house, utility rooms, a box or a garage.

Bubafonya is truly a long-burning stove; on one stack of wood, the burning time in this stove, depending on the type of wood, is 5 – 8 hours. In a conventional stove, this amount of firewood will burn in an hour, and most of the heat will simply go out into the chimney, but in Bubafon, the same amount of firewood will burn 5 - 6 times longer and the heat will evenly flow into the room, and not fly out into the chimney.

What is the long burning process?

To understand how to properly make a metal stove, you need to consider what the combustion process is. This needs to be done using the example of the most common type of fuel - wood.

Ignition is carried out with flammable objects from wood chips and birch bark to flammable liquids. Until the surface temperature of the firewood reaches 100 degrees, a whitish smoke rises from it, which is the vapor of escaping moisture. It is always contained in them, regardless of storage conditions.

When the temperature reaches 250 degrees, the surface of the wood begins to char, decomposing into simpler chemical components. Under the influence of oxygen in the air, the reaction becomes more and more intense. When the temperature reaches 300 degrees, the wood substance begins to decompose into gaseous components that actively enter into an oxidation reaction. They are flammable and produce a high flame temperature. Unfortunately, the fuel supply quickly burns out and the stove “requires feeding.”

What fuel is suitable

Even a correctly executed design can disappoint the master if the “wrong” fuel is loaded into it. Experiments have shown that the following burn best:

- sawdust;

- wood chips;

- pallets;

- peat briquettes;

- small branches;

- cardboard.

The stove is suitable for fuel that can be well compacted by the gravity of the piston. If you place logs placed vertically in the oven, it is impossible to compact them. They will burn, but with the slightest malfunction of the chimney and one damp log, the piston will stall and a phenomenon such as backdraft will occur and the room will be filled with smoke. Horizontally placed logs also burn, but still weakly and the effect of the process is far from the desired one.

Long-burning stoves “Bubafonya”

There are many designs of long-burning stoves. The difference between their device is the dosed supply of air into the firebox. Reducing its supply leads to slower oxidation and more complete use of fuel. The intake is adjusted through the firebox and ash pan using special dampers, that is, from below.

Sawdust stove design option

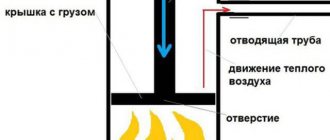

In the bubafonya oven, air is supplied from above through a hollow rod. In this way, the effect of gradual combustion of fuel is achieved without heating the underlying layers. When such a thermal unit warms up to a temperature of 300 degrees or more, the process of wood pyrolysis begins. Combustible furnace gases enter the upper part of the furnace and burn there, releasing a large amount of heat. That is, wood fiber burns at the bottom, releasing flammable gases that ignite above the piston.

Operating principle of the Bubafonya long-burning stove with a water-heating jacket and ash pan

Application area

Depending on the capacity of the stove, combustion of one load of fuel can last from 12 to 24 hours. This is convenient when used in heating systems of a country house, greenhouses, garages and industrial premises.

Advantages and disadvantages of a thermal unit

The advantages of such a stove include the following factors:

- Simplicity of design, allowing you to make it yourself.

The simplest stove design bubafonya

- A pyrolysis furnace of this design provides ample opportunities in choosing the type of fuel. It can successfully burn wood processing waste in the form of sawdust, wood chips, and small trimmings. Such a heating unit can also operate on peat briquettes, low-grade coal and fuel pellets.

- Long working time, up to a day. But this depends on the air supply speed and the volume of the combustion chamber.

However, there are a number of significant disadvantages of this design:

- Bubafonya has a low efficiency. This can be associated with uneven heating of the furnace body, which results in a decrease in the degree of heat transfer of the unit. For pyrolysis furnaces of improved designs, the efficiency can reach 90%.

- The classically designed bubafon is inconvenient for cleaning from fuel combustion residues. They have to be removed through the top. But this drawback is easily eliminated by installing a door at the bottom of the fuel tank. The door should close tightly enough to minimize the flow of air through it.

- Unattractive appearance. The stove looks rough and does not decorate the interior when installed in a residential building.

Ignition rules

After making all the listed parts, you can assemble the Bubafonya stove and start lighting it. The process of heating the stove begins with adding fuel. They fill the body with it, laying it tightly to a height just below the chimney or less. Place wood chips, small branches, rags soaked in flammable material or other material on top of the main fuel to speed up ignition.

Then press the filling with the piston and put the lid on the body. Throw a piece of burning rags or paper through the air duct opening. A match will not work because it will go out before it reaches the fuel. The bookmark will light up in 10 – 15 minutes. After this, close the valve on the air duct. After this, the flow of air into the combustion chamber will be limited and the fuel will begin to smolder slowly. This is the operating mode of the furnace.

Do not place firewood vertically in the stove. Unburned logs will stand on edge in the primary chamber and provoke the appearance of a real fire. This will disrupt the entire operating principle of the oven. And in addition, it will start to smoke.

Do-it-yourself Bubafonya oven

Definition of basic parameters

The main proportion taken into account when calculating the dimensions of the furnace is the ratio of the internal diameter to the height of the body. Optimally it should be 3–5:1. The recommended internal size is 30–80 centimeters. A smaller housing is inefficient because air will move too quickly through the combustion chamber. Contact with fuel will be inadequate, reducing the efficiency of the device. If the size is more than 80 centimeters, the outer layers of fuel will burn slower than the inner layers, the rod will fall inside the fill and combustion in the firebox will become impossible.

Optimal body wall thickness

Optimal heat transfer occurs with a wall thickness of 4–5 millimeters. If the thickness is smaller, the casing may quickly burn out.

Pressure piston diameter

The gap between the walls of the housing and this part should optimally be about 5% of the internal diameter of the firebox. That is, the piston diameter is determined from the relationship:

D = Dpcs * 0.9

D – internal diameter of the swamp

Dsht – rod diameter.

For example, with an internal diameter of the body of 40 centimeters, the size of the rod will be: 400 * 0.9 = 360 millimeters.

Pressure plate thickness

This parameter also depends on the size of the combustion chamber, but in inverse proportion. Functionally, this part is needed to create pressure on the fuel. If the exposure is insufficient, the principle of operation of the furnace may be disrupted - the reverse action. As a result, the firebox ignites with the formation of reverse draft. In this case, combustion products will go into the suction pipe. If the pressure is too high, the rod will simply fall into the fuel layer and the burning of the bubafon will stop.

Here are sample data on the dependence of the thickness of the pancake on the diameter of the firebox in centimeters:

- 30 – 6–10.

- 40 – 6–8.

- 60 – 4–6.

- 80 – 2,5–5.

There are no categorical requirements or strict restrictions on this parameter, but it is better to adhere to the given proportions.

Chimney outlet size

This indicator is the most important, since the gas flow regime in the thermal unit depends on it. Thermal engineering calculations are very complex and are carried out taking into account a large number of parameters. In practice, an empirical relationship has been established:

S = 1.75E where

S - cross-sectional area of the chimney:

E is the energy power of the furnace, kW/hour.

Indicator E can be determined from the ratio:

E = e * M where

e is a tabular value representing the specific thermal output of a particular fuel:

M is the mass of a disposable fuel load, determined as the product of the mass of the specific load and the volume of the fuel space, kg/dm3.

Here are some reference data on the specific heat capacity of solid fuel, kW/hour:

- Standard size aspen firewood is 2.84.

- Sawdust or softwood shavings - 3.2.

- Alder pellets - 3.5.

- Coal grade DPK - 4.85.

- Coal grade ССОМ - 5.59.

- Peat briquettes - 2.36.

The most commonly used chimney size is a diameter of 150 mm, if the fuel part of the stove is at least 2/3 of the total height of the body.

Air supply pipe cross-section

This size is 0.5–0.57 of the diameter of the chimney pipe. In our case, we can recommend a size of 76–83 mm.

Frequently asked questions from DIYers

Is it possible to use the Bubafonya stove in residential premises?

You shouldn't do this. With any reboot, reverse draft may occur, and this is dangerous, especially at night.

Can a stove run on raw fuel?

Yes maybe. But the efficiency will drop to a minimum. To increase it, you can make adjustments to the chimney design. It needs to be extended downwards by making an elbow to collect condensate, and install a drain valve on it.

Why might the stove smoke?

If Bubafonya is blowing smoke from the very “birth”, it means that one of the channels is narrowed, the firebox is too wide and the diameter of the gas outlet is small. The outlet may be too low, or the chimney pipe may be too low. When smoke appears later than the start of operation, this indicates clogging of the channels or a failure of the draft.

Making a Bubafonya stove with your own hands is not difficult. The main condition is to adhere to the recommendations of specialists, follow the assembly sequence and carry out ignition correctly.

Materials and tools

To make a bubafonya stove you will need:

- An old gas cylinder or a piece of steel pipe of the required diameter.

Using an old gas cylinder for a stove

- Steel sheet 6–8 millimeters thick (if the stove is from a cylinder).

- The same, 1.5–2 mm thick for the ash pan.

- Non-equal angle angle 25x40 mm for making a wedge shutter pocket for the lid.

- Profile pipe or channel for additional heat exchangers.

Application of additional heat exchangers

- Steel strip measuring 40x2–4 mm for the shutter wedge and handles on the lid.

- Galvanized steel sheet 1200x1200x0.7 mm.

- Asbestos sheet 10 mm thick.

The listed materials can be replaced with other suitable ones from stock.

List of tools:

- Angle grinder (grinder) – for cutting metal parts.

- Household welding machine.

- Electrodes corresponding to the material of the parts.

- Apparatus for flame cutting of metal.

- Electric drill.

- Steel brush for electric drill.

- The file is semicircular.

- Personal protective equipment - shields, mittens, etc.

Photo gallery: tools for making a stove

Bulgarian

Household inverter

Drill

Gas cutter

In addition to those listed, you may need other general purpose tools.

With water jacket

Option for a stove with a water jacket on the chimney.

The capabilities of Bubafoni will increase significantly if you add a water circuit to the stove. To do this, adapt 1 more cylinder to heat the coolant in it. Its diameter is 2.5-3 cm larger; sometimes a square body is adapted for this purpose.

If there is a ready-made heating circuit in the room, the stove is connected to it and the coolant from the water jacket is transported to the heating system using a circulation pump. Such a stove is advantageous in that it can provide heat to several rooms.

The water circuit is installed not only on the stove body, but also on the chimney. The principle of such a system is “pipe in pipe”. The ends of the “jacket” are sealed, and pipes are cut in for the coolant inlet and outlet. The outlet is located at the top, and the return is located at the bottom.

A water pipe can also act as a heat exchanger. A coil is made from it, enclosed in a steel casing so that the heat is distributed more evenly, and sand is poured in. Sometimes brickwork is made around the stove, and the same coil is placed inside.

Features of operation

The thermal unit needs increased attention only in the first period after the start of operation. This is necessary to understand all the features of a particular oven. For this:

- After starting, you need to burn several loads of fuel of varying humidity to determine the time of complete combustion. But you can also obtain information about the amount required under different combustion modes.

- It is better to make the chimney dismountable to make it easier to clean.

- There should be a fire extinguisher and a box of sand in the room with the stove.

- It is necessary to regularly inspect the stove to identify burnouts and leaks of combustion products.

Lifehacks to increase efficiency

Craftsmen who use stoves to heat various rooms have come up with ways to increase its efficiency.

There are several ways to refine the design:

- "Shirt" made of metal profile . This is a method of increasing the heating area of the lower part of the oven by stimulating the convection process using hollow fins. Pieces of metal profiles are welded to the bottom of the furnace body at a distance of 10 - 15 cm from each other.

- Protective metal screen . A sheet of iron is mounted around the furnace body at a distance of 3–5 cm. A convection flow is also created inside such a “blanket”. Alternatively, the body can be wrapped with a piece of metal profile with a high wave.

Which Bubafonya stove do you use?

StandardModified

A little history

The development of the Bubafonya stove is attributed to folk craftsman Afanasy Bubyakin from Kolyma. Subsequently, a new invention was named in his honor. During his experiments, Afanasy relied on the design of the Lithuanian-made Stropuva pyrolysis boiler.

The domestic inventor tried to simplify the design as much as possible so that it could be built with your own hands. This specificity of Bubafoni explains its high popularity. Considering that the material for the manufacture of this device is mainly improvised means, it cannot boast of external aesthetics. The strengths of the stove are its simplicity, efficiency and reliability.

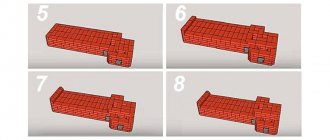

Stages of building a bubafoni from a balloon

Before manufacturing itself, you need to decide on the size of the oven.

Preparing the balloon

- Carefully cut off the top part. Save it. In the future it will play the role of a lid.

- Weld a strip of steel to the stove body. This will be a side that will prevent the lid from moving from the body.

- Now you need to make a pressure circle, thanks to which the fuel will be pressed down and oxygen will flow into the firebox, ensuring long-term combustion.

- Take a thick (3-4 millimeters) sheet of steel and cut a circle out of it. Let's make an air distributor out of it. Its diameter should be slightly smaller than the main frame of the furnace. The gap between the edge of the air distributor and the walls of the gas cylinder is equal to 1/20 of the diameter of the “pancake”. Make a hole in the middle. In order for traction to be effective, this hole must be at least 10 centimeters. Weld the air duct pipe to it. Its height should be 20 centimeters greater than the stove body.

- Weld 6 metal blades at the bottom of the air distributor plate. They are needed so that the fuel burns evenly in the lower chamber, and the pyrolysis gases in the upper chamber burn completely.

Chimney and fuel storage area

- At the bottom of the frame, make a hole in the shape of a rectangle using a grinder. Weld the curtains to it and hang the door. To ensure complete tightness, line the door with asbestos cord around the edges. A little lower, you can make another door in the same way, but a little smaller. It will be convenient to clean the bubafon through it.

- To make a chimney, you need to make a hole in the lid through which the exhaust gases will exit and create the necessary draft. The diameter of the pipe for it should be 10–15 centimeters. Smaller sizes are not advisable.

- Make a chimney elbow from two pipes. Trim their edges at a 45 degree angle and weld them together to form a 90 degree angle. 0e60f6749268fd9c27e615bba3f77700.jpe

- All parts of the oven are ready. Now you need to put them together and load them with fuel. You can sprinkle sawdust and paper on the firewood for faster and more convenient ignition.

If the stove is supposed to be heated not only with dry wood, then the pipe should be extended downwards and a place should be made to collect condensate.

Drawing of the furnace indicating all details and dimensions

Assembling the structure

- Load fuel into the stove. Place the firewood vertically, sprinkle it with wood chips and place paper.

- Install the air distributor or "piston".

- The last step is to install the cover.

Piston pressing block

The distance from the piston to the inner surface of the piston is calculated using the formula 0.5xD. To calculate the diameter of the pancake, accordingly, the formula d = D – 2xH is used. Calculating the height of the pressing ribs from a metal profile is more difficult, because The relationship between the parameter values is nonlinear. Theoretically, for a furnace body with a diameter of 60-80 cm, this parameter is taken as a number of 0.1xD. The Bubafonya stove from a smaller gas cylinder is calculated using a proportional equation, taking into account that with D0 = 30 cm h0 = 4 cm.

Test run

The last step in assembling the Bubafonya stove is its assembly and test run. We install it on a pre-prepared base, weld the chimney to it, and then fill the combustion chamber with fuel. The next task is to light the fire. The most convenient way to do this is with a rag soaked in kerosene or using special lighter fluids. Make sure the top of the fuel is lit, install the piston inside and close the cap. At the first stage, the gate valve must be completely open. Subsequently, you can use it to adjust the intensity of the flame.

When starting the Bubafonya stove, under no circumstances use gasoline for ignition - it can ignite with a bang and lead to unpredictable consequences.