If you don’t dream of autonomous gas heating with hot water supply, then every householder has probably seriously thought about it, both in a city apartment and in a private house. Only today it can reliably provide a comfortable temperature in the house cheaper than the central one. However, installing a gas boiler with your own hands is a complex, responsible matter that requires a permit. Actually, taking on it yourself makes complete sense only if you have sufficient funds to purchase a double-circuit boiler with a boiler and a full set of automation, and your home according to the specifications is suitable for installing a boiler.

The second case when you need a gas boiler is if you are not rich, and there is no hot water in the house and is not expected. In this case, you need a simple budget single-circuit instantaneous hot water boiler that allows you to wash dishes and take a shower. A gas boiler is more expensive than an electric boiler, but taking into account the cost of installing a gas meter, at current rates it will pay for itself in a year and a half over the winter, depending on where you live. If, again, you can install it in your apartment, and you are not afraid of going through the authorities.

Two big differences

The boilers mentioned above are the extremes of a huge variety of models of gas water heating devices. They are available for self-installation. Any other gas heating boiler requires professional work for installation. However, every cloud has a silver lining - specialized companies also take on the preparation of the premises and the preparation of documents. But why can you install only the “tips of scissors” yourself?

Simple water heater

The simplest boiler is really very simple: a gas burner, a heat exchanger - that's all. It is enough to connect water and gas to it, vent the exhaust into the chimney - and you can use it. If the papers have already been completed; otherwise - an inevitable large fine.

Home boiler room

A double-circuit boiler with a boiler and full automation is so “smart” that installing it is as easy as the simplest one. Automation is important not only for simplicity: a complete system with a double thermostat and a microprocessor monitors the temperature in the house and outside, according to a given program, reduces heating to a minimum according to sanitary standards when no one is at home (for example, when everyone is at work). The gas consumption of such a boiler is 30-70% less than with manual or semi-automatic adjustment, and the savings are greater the more severe the weather.

But such a home boiler room has a serious drawback: if you find yourself in a natural disaster zone and the power supply is disrupted, the automation “stalls” and the boiler goes into the mode of minimal heating of the room. Therefore, such a boiler requires additional costs for guaranteed power supply. It is not difficult to provide it yourself, see below.

Chimney issue

As mentioned above, the chimney must be led outside through the wall or connected to a common one. If you do not equip it with a cap, air, water, debris, and foreign objects will get in there, which will inevitably lead to clogging of all devices connected to it. Even if the boilers connected to the system are in full working order, a clogged or dirty chimney will affect the quality of heating. What other reasons can there be for a boiler to not work? Read here.

Where you can and where you can’t install a gas boiler

The rules for installing a gas boiler provide the following requirements for installing a HEATING boiler, regardless of whether it also provides DHW or not:

- The boiler must be installed in a separate room - a furnace (boiler room) with an area of at least 4 square meters. m., with a ceiling height of at least 2.5 m. The rules also state that the volume of the room must be at least 8 cubic meters. Based on this, you can find indications that a ceiling of 2 m is acceptable. This is incorrect. 8 cubic meters is the minimum free volume.

- The furnace room must have an opening window, and the width of the door (not the doorway) must be at least 0.8 m.

- Finishing the furnace with flammable materials and the presence of a false ceiling or false floor are unacceptable.

- The combustion chamber must be provided with an air flow through a through, non-closed vent with a cross-section of at least 8 sq.cm. per 1 kW of boiler power.

Note: 8 cubic meters free - with a boiler power of up to 30 kW. For power from 31 to 60 kW – 13.5 cubic meters; for power from 61 to 200 kW 15 cubic meters. For boilers with a closed combustion chamber, the volume of the combustion chamber is not standardized, but the dimensions must still be observed.

For any boilers, including wall-mounted hot water boilers, the following general standards must also be met:

- The boiler exhaust must exit into a separate flue (often incorrectly called a chimney); using ventilation ducts for this is unacceptable - life-threatening combustion products can reach neighbors or other rooms.

- The length of the horizontal part of the flue should not exceed 3 m within the combustion chamber and have no more than 3 rotation angles.

- The flue outlet must be vertical and raised above the ridge of the roof or the highest point of the gable on a flat roof by at least 1 m.

- Since combustion products form chemically aggressive substances when cooling, the chimney must be made of heat- and chemically resistant solid materials. Use of layered materials, e.g. asbestos-cement pipes, permissible at a distance of at least 5 m from the edge of the boiler exhaust pipe.

When installing a wall-mounted hot water gas boiler in the kitchen, additional conditions must be met:

- The height of the boiler suspension along the edge of the lowest pipe is not lower than the top of the sink spout, but not less than 800 mm from the floor.

- The space under the boiler must be free.

- A durable fireproof metal sheet 1x1 m should be laid on the floor under the boiler. Gas workers and firefighters do not recognize the strength of asbestos cement - it wears out, and the SES prohibits having anything containing asbestos in the house.

- There should be no cavities in the room in which combustion products or an explosive gas mixture can accumulate.

If the boiler is used for heating, then the gas workers (who, by the way, are not very friendly with the heating network - it always owes them for gas) will also check the condition of the heating system in the apartment/house:

- The slope of horizontal sections of pipes must be positive, but not more than 5 mm per linear meter of water flow.

- An expansion tank and an air valve must be installed at the highest point of the system. It is useless to convince you that you will buy a “cool” boiler that has everything provided for: rules are rules.

- The condition of the heating system must allow it to be pressurized under a pressure of 1.8 atm.

The requirements, as we see, are strict, but justified - gas is gas. Therefore, it is better not to think about a gas boiler, even a water heating one, if:

- You live in a Khrushchev block or other apartment building without a main gas duct.

- If you have a false ceiling in your kitchen that you don’t want to remove, or a permanent mezzanine. On a mezzanine with a bottom made of wood or fiberboard, which in principle can be removed, and then there will be no mezzanine, gas workers turn a blind eye.

- If your apartment is not privatized, you can only rely on a hot water boiler: allocating a room for a furnace means redevelopment, which only the owner can do.

In all other cases, it is possible to install a hot water boiler in an apartment; wall heating is possible, but floor heating is very problematic.

In a private house, you can install any boiler: the rules do not require that the furnace be located directly in the house. If you make an extension to the house from the outside to serve as a furnace room, then the authorities will only have less reason to find fault. You can install a high-power floor-standing gas boiler in it to heat not only the mansion, but also the office premises.

For middle-class private housing, the optimal solution is a wall-mounted boiler; it does not require, as for a floor one, to install a brick or concrete tray with sides of half a meter. Installing a wall-mounted gas boiler in a private house also avoids technical and organizational difficulties: a fireproof closet under the furnace can always be fenced off, at least in the attic.

Electricity

The internal automation of the equipment does not require much power. However, the rules require the installation of a separate power line containing a circuit breaker with a rating of 20A. A computer uninterruptible power supply is quite suitable as a backup power supply during a power outage. For example, with a power of 1 kW it can keep the boiler in working condition for up to 1 day. This time is usually enough to restore power.

About the gas duct

The cross-sectional area of the house flue for it depends on the required boiler power (see below). At any power, the diameter of the flue must be at least 110 mm and not less than the diameter of the exhaust pipe. The dependence of the flue diameter on the boiler power is as follows:

- up to 24 kW – 120 mm.

- 30 kW – 130 mm.

- 40 kW – 170 mm.

- 60 kW – 190 mm

- 80 kW – 220 mm.

- 100 kW – 230 mm.

Basic design requirements

Boiler design is the most important step in the construction process. All requirements for the installation of boilers operating on gas fuel must comply with the following sections of SNIP:

- Single-apartment residential houses, No. 31-02/2001.

- Gas supply, No. 2.04.08/87.

- Heating, ventilation and air conditioning, No. 41-01/2003.

- Fire safety of buildings and structures, No. 21-01/97.

- Internal water supply and sewerage of buildings, No. 2.04.01/85.

In order to eliminate mistakes that could lead to financial losses, it is necessary to contact a design company that has experience in performing design work on installing boilers.

Before concluding a contract, make sure that the contractor has a full package of permits to carry out this type of work. Next, the customer, together with the design organization, draws up a technical specification, which outlines all the requirements for the future installation.

Based on this document, designers develop engineering solutions, compile a feasibility study, and calculate thermal loads.

This organization, at the request of the customer, can also undertake the preparation of project approvals from regulatory authorities and provide a complete set of boiler equipment.

Boiler selection

Power

It is obvious that the boiler power must be sufficient. But it should not be excessive, especially if the heat exchanger is cast iron. Drops of condensate from the flue cause hot cast iron to crack. There is another dangerous effect: the dew point temperature of the exhaust gases is approximately 56 degrees Celsius. If the water temperature in the heating return is lower, acidic condensate may form in the combustion chamber. What does this have to do with excess power? A boiler that is too powerful will quickly warm up the system and go into standby mode until it cools down. The thermal inertia of a powerful heat exchanger is high, and while it warms up again, acid dew may form.

With correctly selected boiler power, the temperature in the combustion chamber will be 80-90 degrees. The permissible difference in power is quite large, but if you install a 60 kW boiler in a medium-sized private house, then acid rain from the inside will quickly damage it.

The required boiler power for a specific room is determined by thermal engineering calculations. It’s easier for residents of high-rise buildings: the data is available in the DEZ, the technical inventory bureau or the owner. In any case, you can use approximate data by calculating an intermediate value for yourself. Maximum power values are given for cases of minimum outside temperature of –25/-40 degrees:

- One-room apartment on the middle floors – 8/14 kW.

- Corner apartment 60 sq.m. the total area on the top floor of the Khrushchev block is 20/28 kW.

- Private house 100 sq.m. common – 24/38 kW.

Boiler

The purpose of the boiler is to accumulate hot water for domestic needs. If you look at the instructions for the boiler, the power will be indicated there as a fraction, for example - 10/22 kW. The first number is the heating power for average conditions; it determines gas consumption by 80%. The second power, maximum, is for quickly heating domestic water.

If the boiler is emptied, the boiler temporarily stops heating the heating (it does not have time to cool down) and heats domestic water at maximum. Gas consumption is, of course, maximum. If you take a little water from the boiler, then it will be heated in operating mode, without force majeure. Based on this, the capabilities of the boiler can be judged by its capacity:

- 2-10 l – wash hands and wash dishes.

- 30-50 l – take a quick shower.

- 100 l – wash thoroughly in the shower.

- 150 liters or more - you can take a bath and connect a washing machine to the hot water supply.

Note: if you already have a household electric boiler, it is advisable to leave it by turning off its machine. It will make a good hot water accumulator, and if you have problems with a gas boiler, you can turn it on.

Video: expert opinion on choosing gas boilers

Types of equipment

There are two types of boilers:

- storage water heater;

- flow boiler.

Storage type equipment is a boiler that is similar to a boiler. The device is equipped with a reservoir of various capacities. Storage elements are placed inside the tank. As hot water is consumed from the tank, the tank is filled with tap water. The automatic control panel allows you to regulate the heating temperature, prevents overheating and boiling of the liquid in the tank. Such boilers are produced in two modifications:

- hanging - they are mounted on the wall;

- stationary - installed on the floor.

A flow-through boiler has a more complex design. The column heats up quickly thanks to the heat exchanger. The liquid will become hot in 7-10 minutes. The main advantages of flow-through boilers:

- efficiency;

- ease of operation;

- reliability of the unit.

In addition, such devices have an automatic ignition system. This guarantees the safety of using the equipment - gas vapors are burned in full.

As practice shows, flow-type boilers are more popular. The device has small parameters, it is convenient to place it in small rooms. At the same time, the boiler’s power is enough for a family of 5 people.

Documents for the boiler

Let's say you have equipped the furnace room in compliance with all requirements. Are we buying a boiler? It is too early. First of all, check if the previous gas papers have been lost, and bring them out into the light of day:

- Gas supply contract if the boiler is a heating boiler. Subconsumers can only install hot water boilers.

- All documents for the gas meter. Any boiler cannot be installed without a meter. If it doesn’t exist yet, there’s nothing you can do, you need to install it and arrange it, but that’s a different topic.

Now you can buy a boiler. But, having bought it, it’s too early to install:

- The BTI needs to make changes to the registration certificate of the house. For privatized apartments - through the organization operating the house. In the new plan, a closet under the boiler should be shown, and clearly marked: “Furnace room” or “Boiler room”.

- Submit an application to the gas service for the project and specifications. The required documents also include a technical passport for the boiler, so it must already be purchased.

- Install the boiler (see next section), except for the gas system. This can be done while the gas workers are preparing the project, if the premises are approved.

- Call a specialist to make a gas connection.

- Submit an application to gas workers for commissioning.

- Wait for the gas service engineer to arrive, he will check everything, draw up a conclusion on suitability and give permission to open the gas shut-off valve to the boiler.

Note: gas workers are not allowed to give permission to private individuals to work on gas equipment. Therefore, to connect gas to the boiler, you will have to call a specialist or then “resolve the issue” with an inspector during commissioning. As a rule, the former is cheaper.

What do you need to know before installing it yourself?

Any type of boiler equipment should be installed by specialists. If you still plan to do the installation yourself, it will be useful to know the following nuances:

- The vast majority of boiler manufacturers officially require installation of their products with the assistance of specialists.

- The overwhelming majority of boiler unit manufacturers remove the equipment installed independently (without the involvement of specialists) from warranty. If the boiler is installed by yourself, it will be impossible to demand replacement of the equipment or its consumables under warranty from the manufacturer.

- Before starting installation, it is necessary to prepare and coordinate with the supervisory authorities a technical design of the installation.

- Before installation, it is recommended to familiarize yourself with the current standards, requirements and regulations for the installation of gas boiler apparatus, described in SP-41-104-2000 and SNiP 42-01-2002.

- In case of self-installation, you still need to call a specialist to check the quality and safety of the installation and especially the connection of the boiler to the gas main. The specialist must have special permission to perform the work.

- After installation and testing, you must obtain a special permit to allow the device to be operated. Permission should be provided to supervisory authorities to avoid fines and sanctions.

Boiler installation

It is unacceptable for the boiler body to be adjacent to any of the walls, so redo the fastenings of wall-mounted boilers, recess the boiler into a niche, etc. it is forbidden. After installing the boiler in place, its piping is done - connecting three systems: gas, hydraulic and electric. The gas connection should be done, as indicated, by a gas specialist, and last but not least, when everything else is already connected.

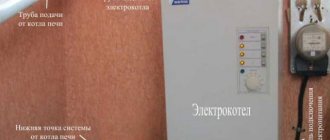

Diagram of hydraulic piping of a gas boiler

You can do the electrical and hydraulic connections yourself. The main guiding document here is the instructions for the boiler. A typical boiler hydraulic circuit is shown in the figure. For any boiler, the following conditions must be strictly met:

- Water and hot gases in the boiler heat exchanger must flow countercurrently, otherwise it can simply explode with any automation. Therefore, it is extremely important not to confuse, either through negligence or for the sake of ease of installation, cold and hot pipes. After hydropiping, carefully inspect the entire system again, then rest for an hour and inspect it again.

- If antifreeze has been poured into the heating system, drain it completely and rinse the system twice with clean water. An admixture of antifreeze in the water entering the heat exchanger is also explosive.

- Do not neglect the “mud collectors” - coarse water filters. They should be located at the lowest points of the system. The accumulation of dirt between the thin fins of the heat exchanger also creates a dangerous situation, not to mention excessive gas consumption. At the beginning and end of the heating season, drain the sediment through the mud traps, check their condition and, if necessary, flush the system.

- If the boiler has a built-in expansion tank and a deaeration system, remove the old expansion tank and turn off the old air valve tightly, having first checked its condition: air leakage will also create a dangerous situation.

Floor-standing

In order to save money, the owners themselves are trying to figure out how to install a floor-standing gas heating boiler in a one-story wooden house. Basic requirements include the following points:

- Strengthening the place where the boiler will be located. It is best to make a screed or carefully lay concrete slabs.

- A gap of at least 15 cm is left between the boiler and the wall surface.

- If the base of the house is not fireproof, then additional cladding with metal sheets is necessary. It is best to insulate the walls with roofing steel, which is laid on an asbestos sheet at least 30 mm wide.

- Using a building level, the condition of the floor is assessed, since the surface under the boiler must be perfectly flat.

- Connecting the chimney is prohibited without first checking the draft.

- Filters are installed that do not trap debris at the entrance to the heat exchanger.

- At the final stage, the prepared double-circuit boiler is connected to the water pipes.

The video provides up-to-date information about installing the boiler:

Ventilation

It is very important to ensure that the room where the gas appliance is installed has good ventilation.

Supply and exhaust ventilation is a prerequisite for any boiler room

- The kitchen area in a multi-storey building is equipped with a common building ventilation system, so there will be no problems with it. When installing the device in a boiler room, a ventilation duct is installed in the ceiling of the room and vented outside.

- Supply ventilation can be installed in the door by making a hole and installing a ventilation grille.

- Special standards have been defined for ventilation inlets. So, for one kW of device power, the grille must have a size of no less than 8-10 cm² (air intake from outside the house) and no less than 30 square meters. cm (air intake from inside - from other rooms).