Many country property owners complain about pressure drops in autonomous heating systems in a private home. This problem may be intermittent and occur without any reason. To eliminate a malfunction, it must be identified, and only after that the “healing of the system” begins. Good constant pressure is observed in a properly designed circuit with a circulation pump and a properly located sealed tank.

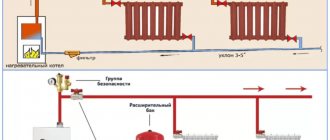

All elements of the heating system are located according to the following diagram. The boiler is installed first. Pipelines and radiators depart from this unit, then an expansion tank and a circulation pump are installed. Please note that the membrane tank can be installed at any point in the system. The optimal location for installing the pump is considered to be the pipe gap between the boiler and the tank.

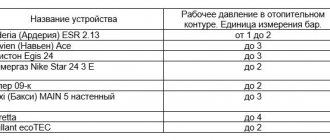

Important! Not everyone knows what pressure should be in a closed heating system. Normal values are considered to be 1.5…2 atmospheres.

Reason 1. Dumping excess air

During the first start-up, air gradually leaves the system. Therefore, the pressure in the heating system drops . Initially, it comes out of the boilers themselves. And since there are automatic air vents on the boilers and inside the boilers, usually on the walls, the air comes out of the boilers on its own.

Plus, when you start a wall-mounted boiler, there is a screw on the boiler pump that serves to bleed air right down the middle of the pump. If you unscrew it, air will come out first. Then water will flow in a thin stream. After this, you need to lightly tighten the screw, usually it is on a rubber band, and after that the wall-mounted boiler will not contain air and will be able to function normally.

Often, upon first start-up, the pressure in the heating system of water heated floors drops significantly. Huge floors can be one hundred or two hundred square meters in size. Below them are long pipes that initially contain air. Subsequently, they are filled with coolant. So when you start the heated floor circulation pump, the automatic air vents that are located on the heated floor manifold immediately begin to hiss. Those. The coolant that begins to circulate through the water-heated floor begins to push this air into the collector. And as a result, air begins to flow out of the air vents intensively, especially at the very beginning. This causes the pressure in the heating system to drop.

It is imperative to monitor the pressure on the safety group and on the pressure gauge of the wall-mounted boiler, and if necessary, top it up. Air may be escaping from the boiler coil. It can also break through to an automatic air vent. And possibly to radiators on other floors. It will accumulate in radiators, so they must have Mayevsky taps. If you see that the radiator has stopped heating, open the Mayevsky tap. At first the air will also hiss, then water will flow in a thin stream. This means that the air has completely escaped.

After the start of operation, for another week or two, maybe longer, air may escape from the water-heated floor. Accordingly, the pressure in the heating system will drop. This should not scare you, because over time the intensity will subside and after a few weeks it will practically stop.

Preventing the formation of air jams

Preventative measures against the occurrence of air locks are as follows:

- Pay attention to the correct installation of pipes and connections of heating devices. Many problems are caused precisely by mistakes made at this initial stage.

- To prevent air locks, proper commissioning of the equipment is necessary, before which it is important to first check all components and connections.

- Before putting devices into operation, check them for functionality. Using a compressor, you need to apply a pressure level that is ¼ higher than its normal operating value. If it does not weaken within 30 minutes, then everything is in order and the system is ready for operation. If the pressure drops sharply, then leaks are possible, which should be promptly identified and repaired before starting operation.

We recommend: Operating principle of infrared heaters

Reason 2. Air is escaping from the expansion tank

A few months after the start of operation, the pressure in the heating system may drop unpredictably when air leaves the membrane expansion tank. There is a nipple at the top of the tank, which gradually, over the course of perhaps several months, bleeds the air. And it turns out that under the influence of the coolant, all the air is squeezed out and the entire expansion tank is filled with coolant.

This is due to the fact that when the boiler is turned on, the coolant heats up, the pressure in the system quickly begins to increase, and the following happens: when the pressure becomes higher than permissible, the safety valve is activated and relieves the pressure. And when the pressure decreases, you gradually feed it, and this happens more and more often. And a condition imperceptibly occurs in the expansion tank when the entire or almost the entire tank is filled with coolant (water) and there is practically no air in it. Consequently, the pressure rises when the boiler starts operating, and as soon as it rises above the limit, the safety valve, which is precisely designed to protect the system, is activated, and the coolant is discharged. Accordingly, the pressure in the heating system drops.

Application of aluminum batteries

Installation of aluminum radiators

When water comes into contact with aluminum, a thin film forms on the surface of the metal. This produces hydrogen as a by-product, which can be compressed. And due to this, the pressure decreases. But this phenomenon does not happen all the time, but only in new radiators. Over time it stops and the problem resolves itself.

Along with a decrease in pressure in the pipeline of your own or multi-story building, its increase may also occur.

The reasons for the increase in pressure in the boiler can be different:

- Broken boiler feed tap. The rubber seal in it may sag or simply become rough. Once a defect is identified, the gaskets must be replaced.

- The heat exchanger is leaking. To check, you need to dismantle the boiler and test it with air. If a breakdown is detected, the part must be replaced with a new one.

When repairing the boiler, you need to unplug it and turn off the cold water.

Reason 3. Leak in the heating system

And, of course, the most unpleasant case of loss of pressure in a heating system is a leak. It can be either in a visible place or appear somewhere where it is difficult to visually detect. Regardless of its location, it will sooner or later make itself felt.

For example, if a leak occurred inside a water-heated floor. This happens when someone accidentally drills into his branch, either from above or below. This is easy to detect, because a stain immediately appears or even water gushes out like a fountain. To eliminate this problem, it is necessary, of course, to carefully disassemble the floor at the leak site, install the necessary coupling, and, upon completion of the installation, re-cement this area.

Repairing the leak

After identifying the location of the leak, the necessary repairs are carried out, which includes the following actions:

- cutting out and replacing the damaged section of the pipeline;

- securing weak connections;

- wrapping with sealing tape;

- replacement of faulty system components with working elements.

Repairs to broken pipes should be carried out by a qualified plumber. If the pressure loss is not determined, then you should check whether the boiler equipment is working properly.

What other reasons are possible?

Several other reasons deserve mention that will affect the pressure drop in the heating system.

- If the coolant used is leaking at the intersection of pipelines;

- corrosion (places affected by rust);

- poor quality work when installing the heating system;

- the appearance of microcracks on the boiler heat exchanger;

- or a rupture of the membrane of the already mentioned expansion tank;

- failure of the boiler automation (this only happens after a long period of operation).

A malfunction noticed in a timely manner or avoided altogether will provide your home or apartment with the constant necessary heat, which will be provided by uninterrupted and stable pressure in your heating systems

The normal pressure in the heating system of a private house is considered to be 1.5-2 atmospheres. But a situation may arise when this parameter gradually or suddenly decreases below normal. It is necessary to understand why the pressure in the heating system drops, and what actions should be taken to eliminate the problem. To do this, you need to clearly understand the design of the heating system and its main technical parameters.

Why are changes dangerous?

With low pressure, radiators on upper floors or distant rooms do not warm up well.

Low and high pressure lead to malfunctions in the entire heating system or breakdowns that require expensive repairs.

When the indicators are reduced, the automation (for modern models) stops the energy supply and the boiler turns off. If heating is stopped for a long time during the frosty season, the pipes, radiators, and boiler heat exchanger will be destroyed.

In addition, if the rate is low, the pressure may not be enough to effectively pump coolant throughout the system. The upper floors and radiators furthest from the riser pipes will remain without heat.

An important indicator for the operation of a warm water floor. The maximum length of the circuit reaches 100–120 m, which creates resistance to the movement of the coolant. If the pressure is insufficient, the circuit will stop heating.

With increased pressure, water begins to leak through the threaded connections of pipes and radiators. Possible destruction of structural parts.

Water heating system design

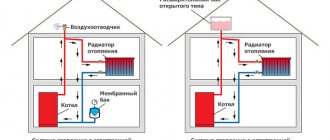

The method of heating a house using a liquid coolant (water, or water-based antifreeze) today is one of the most thorough and reliable schemes: water is heated in a boiler, transferred to heating radiators, transfers thermal energy to the air space in the house and completes the cycle by returning into the boiler.

The owner of a private house most often uses natural gas to power the boiler, but can also use wood, coal or kerosene. The design of the heating circuit consists of key components - boiler, pipes, heating radiators - and auxiliary components - expansion tank, hydraulic pump, thermostats, valves.

The most popular models of Navien Ace wall-mounted boilers

The most reliable Navien boilers, the work of which can only be met with positive reviews, are distinguished by an optimal price-quality ratio. They are divided into two categories:

- Ace ATMO. Traditional boiler with an open combustion chamber. Equipped with atmospheric exhaust of combustion products.

- Ace TURBO. An advanced boiler equipped with a turbocharged burner and a special SMPS control system that regulates the gas combustion process.

Important! Navien Ace gas boilers can operate in both automatic and manual modes, which allows you to more accurately set the boiler operating parameters and eliminate operating errors as much as possible

Causes of pressure drop

There are many factors that explain why blood pressure drops. Among them:

- Coolant leaking from the heating system.

- Power outages for a long time.

- Problems in the operation of the expansion tank.

- Incorrect selection and operation of equipment.

When the coolant pressure decreases, the heating unit stops functioning because water does not enter the tank. If the gas pressure decreases, the system automatically turns off. To prevent such troubles, it is necessary to timely service the boiler and take measures when it is turned off.

Pressure drops when hot water is turned on

If the pressure in the heating system drops when hot water is turned on, this may be due to air leaks into the heating circuit or malfunctions in the 3-way valve. A similar problem is associated with the special structure of boilers.

When figuring out what to do if a wall-mounted boiler begins to release pressure when you open a hot water tap, it is important to understand the specifics of its operation. To successfully eliminate defects, you should seek help from a specialist.

Formation of air jams

If cracks appear anywhere in the system and depressurization occurs, this leads to coolant leakage and air suction into the circuit. As a result, air bubbles form. Their appearance is also facilitated by incorrect filling of the circuit, which leads to sudden pressure surges. To troubleshoot problems, it is enough to carry out the procedure for de-aerating the installation by installing vents.

Expansion tank defects

The reasons for the pressure drop in a gas boiler include problems with the expansion tank. There may have been a rupture in the structure or depressurization of the nipple, causing it to leak air.

On the inside of the container there are 2 compartments with a membrane partition. One part contains air masses, and the second contains coolant. As the liquid consistency warms up, it expands and increases in volume, beginning to exert great force on the membrane. Under this influence, the membrane leads to compression of the gas mixture.

Control devices

To control the water pressure in the heating boiler and heating system, pressure gauges and thermomanometers are used. The latter are combined devices for monitoring two parameters at once. After starting the circuit, it is necessary to monitor the indicators so that they do not go beyond normal limits.

Some double-circuit floor-standing and wall-mounted boilers do not have traditional dial pressure gauges. Instead, electronic sensors are installed here, information from which is transmitted to the electronic unit, after which it is processed and displayed on the display. Another approach is also possible - if the heating unit does not have a pressure gauge, it is provided by the safety group.

The security group itself includes the following nodes:

- Pressure gauge or thermomanometer - for monitoring temperature and pressure in the heating circuit;

- Automatic air bleeder – prevents the circuit from becoming airy;

- Safety valve - relieves coolant pressure when it increases excessively.

Be sure to provide this unit in a closed heating system.