A fairly common problem when using double-circuit gas boilers, when hot water turns on and the pressure inside the boiler begins to drop sharply. The pressure drops almost to zero, and warm water has a pungent odor. Sometimes it even happens that due to a pressure reduction error, the heating boiler automatically turns off. Another case is when a drop in pressure is observed when the water supply in the house is temporarily interrupted, after which the boiler fuses do not allow it to start again. When you try to turn it on, the tank will display an error about pressure problems and simply will not turn on. In general, a drop in pressure in the boiler is very harmful for the boiler and water supply systems, so you need to immediately diagnose the problem, and then begin to immediately solve it. What's the matter and what needs to be done, read below.

Types of contours

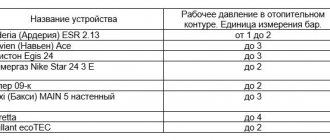

To stabilize surges in the pressure gauge needle, special compensating tanks are installed in the circuit.

The pressure in the heating expansion tank forces the working fluid back into the pipe. They come in two types. Design differences allow them to be used in systems of different types: with access of coolant to air;

In open circuits, the circulation of the working fluid occurs due to gravity. What pressure is in the expansion tank of an open-type heating system is not of key importance; its volume is more important. These systems are designed in such a way that there is an expansion tank at the highest point. This is a vessel of certain dimensions made of metal or plastic. It is not sealed and the coolant in it comes into contact with air. An open-type tank may not have a lid, but it’s still better when it has one. Thanks to it, garbage or insects, if any, will not get into it;

without access of the working fluid to air;

The pressure in the expansion tank of a closed type heating tank is higher than that of a conventional one. In closed circuits, water is pumped by an electric pump, which is the root cause of pressure. Without a pump, circulation is impossible. Schemes of such systems require the installation of a sealed expansion tank. It can be installed at any point on the contour, with the exception of segments:

- after the electric pump;

- after the heater.

Its location in space also matters. Air bubbles are pushed upward by the coolant. They can't get into the tank. Since this will affect what pressure will be in the expansion tank of a sealed heating system.

People often start talking online about what the pressure should be in the expansion tank of the heating system. To find out the latter, the average person will have to sift through a decent amount of information, since the answers of the participants often contradict. Let's try to sort everything out and start with the design.

When should you definitely call a professional?

If it is not clear why the pressure in the gas boiler drops, you will need the help of an experienced specialist. He will confirm that there are no leaks and will repair the gas boiler "Ariston", "Baksi" or another model. If you have never had to restore boiler equipment yourself before, you should not attempt DIY repairs. Amateur activities without knowledge of the circuits and operating principles of the units can damage the entire system.

In order to repair equipment, it is necessary to carry out a number of complex measures. First of all, it is important to determine why the pressure in the boiler drops in a double-circuit installation. If the problem is related to malfunctions in the expansion tank, it means that the wrong volume was selected or the membrane was damaged. Repairs will require re-calculations or replacement of the tank. You will need specialized equipment to find the source of the problem if the heat exchanger has been damaged due to heavy use and wear.

To prevent numerous problems in the operation of the heating system, which includes pressure reduction, it is important to carry out comprehensive prevention and follow a number of rules of use. Be sure to ensure that the pipeline and heating elements are connected correctly, since many mistakes are made during the installation stage.

Problems with measuring equipment

Sometimes pressure gauges give erroneous readings. Low pressure readings on the measuring equipment can be explained by a malfunction of the device itself. If there are no visible defects, it is worth checking the automation and instrumentation. During operation, they may fail and display incorrect values. It is very difficult to find such an error on your own, so it is recommended to take professional help from specialists. How to solve the problem of pressure drop in the boiler, and how to increase it.

Raising pressure in the boiler

If the reason is a malfunction of the expansion tank, then its volume was calculated incorrectly or the membrane was damaged. In this case, you should either more accurately calculate the required volume, or simply replace the tank

Don't worry about the pressure starting to drop immediately after the initial start - this is normal. There is a large amount of air present in a circuit that has recently been filled with tap water. Over time, it will turn into bubbles and be removed from the pipeline, and the circuit parameters will return to normal. To remove bubbles more quickly, you should use a manual air release. Before a set of actions to increase the pressure in the system, you need to make sure that it is tight. To do this, you need to inspect the following parts of it:

Navien boiler error 10

This error is related to the smoke removal system of the gas boiler. Combustion products must be removed; for this purpose, the boilers are equipped with a fan. To control the operation of the fan and determine the presence of permissible draft for boiler operation, a differential relay is used, which is connected to the turbine by two plastic tubes. When the fan is running, a vacuum is created, the relay closes, and the boiler functions normally.

Reasons for error 10

may be a clogged chimney, the presence of reverse draft, or incorrect connection of the air pressure control sensor to the fan. For the latter case, you need to check that the yellow tube is connected to the bottom of the fan, and the transparent one is connected to the top, and the tubes themselves are not damaged, deformed or condensation inside.

Increased resistance in the chimney can occur due to direct gusts of wind or blockage of the chimney (bird nest or cobwebs, freezing in winter). That's right, the location of the chimney should be taken into account the direction of the winds of a particular region at the design stage and the chimney should not be installed on the leeward side of the house.

We focused on the most common malfunctions of Navien boilers, but in fact there are significantly more error codes. Methods for checking and troubleshooting are the topic of a separate article. For convenience, here is a summary table of codes with a brief description:

| Fault number | Brief description of the problem |

| 02 | Low water pressure in the heating system or breakdown of the flow sensor |

| 03 | No signal from the ionization electrode |

| 04 | Incorrect signal from flame sensor or short circuit. Make sure there is no contact of the ionization electrode with the boiler or burner body, and diagnose the control board. |

| 05 | Damage to the heating temperature sensor. Measure the electrical resistance of the sensor and its compliance with the temperature table, and make sure that the connection between the sensor and the control board is secure. |

| 06 | Short circuit of the heating water temperature sensor circuit. Ring or replace the sensor. |

| 07 | Damage to the DHW temperature sensor. Check the dependence of the resistance on the temperature on the sensor, make sure that the connection of the sensor to the control unit is secure. |

| 08 | Short circuit of the DHW temperature sensor. Ring or replace the sensor. |

| 09 | Fan failure. Measure the resistance of the fan winding (test value is approximately 23 Ohms). Make sure that there is a voltage of 220 V at the fan terminals. There may be a problem with the control board circuit (diagnostics of the Navien board is required) |

| 10 | Malfunction of the combustion products removal system |

| 13 | Short circuit of the CO flow sensor. The sensor is stuck or the control unit is faulty. |

| 15 | Internal control board error (requires diagnosis and repair) |

| 16 | Boiler overheating. Signal from the emergency thermostat. The causes of overheating may be insufficient coolant circulation (see error 02), a clogged heat exchanger, or a malfunction of the thermostat itself. Operation occurs at 98 degrees, the alarm turns off when it cools down to 83 degrees. |

| 27 | Open or short circuit of the air pressure sensor circuit |

Why doesn’t the boiler maintain water pressure and what to do when the gas pressure drops?

Sometimes it happens that your boiler releases pressure and turns off. Let's look at several reasons why the boiler does not maintain pressure in the heating system and how this can be corrected.

If there is a constant decrease in pressure, even after refilling, then your radiators in your heating system may be leaking. At first glance, you may not notice this, since the leak will not be noticeable if the batteries are hot and the moisture on them evaporates.

Take a paper napkin and wipe the joints, tap connections, and joints with it. Look at the floor, you may be able to spot dried puddles. If nothing is found, you can use a compressor.

The batteries are cut off from the boiler using valves, water is drained from the radiators, a compressor is connected to the drain taps using hoses and air is pumped. In places where there are fistulas or other defects, you will hear a characteristic sound.

Using tow or sealant, eliminate the leak; if the faucet is at fault, replace it. If your heating system is built into the wall and wet spots do not appear on it, you will have to contact specialists, since a leak can only be detected using a thermal imager. A thermal imager can detect problem areas. To eliminate the leak in this case, you will have to open the problem area.

Another reason for low pressure in the system may be incorrectly selected unit power. The main parameter in the calculation is the volume of the room and the presence of standard radiators. If you have regular pipes installed instead of radiators, the volume of liquid in them will be larger, and accordingly, the volume of expanded liquid will also be larger.

Low water pressure in the boiler - what to do?

If no leaks are found in the radiators, then the reason why the pressure is lost lies in the boiler. Why does this happen and how to increase (gain, pump up, increase) blood pressure? If you frequently pump up water and the boiler does not hold pressure, there is a possibility that microcracks have formed in the heat exchanger. When the boiler heats up, the cracks increase and leakage occurs. The intervention of a specialist is urgently required, or you can eliminate the fistula yourself.

Soldering the heat exchanger

The reason for the appearance of microcracks is wear of the heat exchanger, frequent washing with reagents, poor quality of the metal from which it is made, water hammer when the pressure in the line increases sharply. They usually happen after accidents in water mains.

Places where there are microcracks can be identified by the scale layer. If removing the heat exchanger is easy, you can try to solder them. Bithermal heat exchangers are almost impossible to repair due to their design features; they will have to be replaced.

The pressure in the boiler does not rise (gain) when the feed tap is flowing. If the pressure in the line is higher than the pressure in the boiler, the liquid through the make-up valve increases the pressure in the boiler to a critical point, and a discharge occurs through the safety valve.

As a result of this, the pressure decreases, the water from the heating system presses the liquid in the water supply and heating system. Close the tap, check the tightness of its connection or replace it if it is faulty.

The pressure turns off (falls) to 0 if the three-way valve malfunctions. Large pieces of scale or rust may get into the valve and obstruct flow; clean the valve.

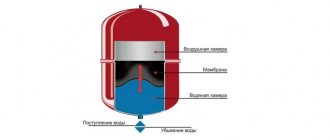

A problem with the expansion tank can cause pressure changes. When heated, the volume of water in the system increases, this excess enters the expansion tank. There is a rubber membrane inside the tank.

The space between the outer wall and the tank membrane is filled with gas. Excess liquid fills the membrane and the pressure in the heating system is released. Gas equalizes excess pressure.

Differences between Navien Ace and Navien Delux

Navien Delux is a modified model that replaced Navien Ace. Navien Delux Coaxial is a series of boilers with two heat exchangers with a power from 10 to 30 kW with a closed combustion chamber and forced smoke removal using a turbine. The manufacturer notes the following features of Navien Delux:

- Frost protection system. Unlike boilers from other manufacturers, in addition to automatically turning on the burner when the temperature drops below 6 degrees, at temperatures below 10 degrees the boiler ensures continuous movement of the coolant by activating the circulation pump.

- Fan with variable speed. Navien Delux boilers are equipped with a turbine with adjustable blade rotation speed depending on the readings of a special air pressure sensor. This ensures an optimal gas-air mixture ratio and increases boiler performance.

- The heat exchanger is made of stainless steel. By using a fan with variable rotation speed and increasing combustion efficiency, it became possible to replace the copper heat exchanger with a stainless steel heat exchanger, which certainly has a significantly longer service life.

- It is also noted that the boilers are protected from the influence of mains voltage surges by a special protective chip and the ability to operate at low (up to 4 mBar) pressure of main gas and water. In other words, the manufacturer tried to make a product that is maximally adapted to the worst operating conditions.

What are the advantages of Navien Ace boilers

Navien Ace is a double-circuit version of a wall-mounted boiler. It is equipped with an open combustion chamber with natural release of combustion products. The advantages of Navien boilers are eloquently demonstrated by the instructions for their operation - they work even in conditions under which competitors’ equipment fails.

Did you know?

To increase the service life of Navien boilers, they are made of stainless steel, since stainless steel has a fairly high thermal conductivity.

Among the main advantages of Navien Ace boilers it should be noted:

- versatility;

- simplicity of control commands;

- compactness;

- High-quality anti-corrosion material was used in production;

- fully electronic, Russified control system;

- compliance with high European standards (quality, comfort, safety);

- reliability and resistance to various conditions (voltage surges up to 30%);

- the ability to work in a frankly emergency situation (low gas and liquid coolant pressure, low-quality gas, unstable pressure in the water supply system);

- economical fuel consumption;

- environmental friendliness (mainly carbon dioxide is emitted);

- acceptable price.

Important! In the event of power surges, the SMPS function in the unit is activated, and the boiler continues to operate uninterruptedly.

Operating principle of the Navien boiler

The operating principles of modern gas boilers are almost the same for all manufacturers, the only differences are in the configuration of the equipment and the internal arrangement of the actuators. The flow diagram of water in the boiler is shown in the figures. The Navien boiler works either to maintain the required temperature in the CO, when heated water from the first heat exchanger is pumped by a circulation pump in a large circle, or in the DHW preparation mode. The DHW mode is a priority, which means that if it is necessary to heat the water, a special three-way valve switches the circulation to the DHW plate heat exchanger, and the coolant flow through the heating circuit is blocked. The signal to switch the boiler to the DHW preparation mode comes from the flow sensor located on the hydraulic unit with the make-up tap.

Causes of pressure drop

Despite the fact that a gas boiler is a complex engineering system, the pressure in it can drop due to just a few reasons:

Typically, low pressure in the boiler automatically stops its operation. So, for example, if the coolant level in the heating system drops to a minimum, then it simply stops flowing into the boiler. If there is insufficient atmosphere in the gas pipe, the equipment automatically turns off. To solve the last problem, you need to call a specialist from the appropriate service, who has all the necessary knowledge and tools that allow him to determine the cause and get rid of it. At a minimum, he knows the tools that allow him to raise the readings to the required value. It is not recommended to solve this problem yourself.

In addition, insufficient pressure appears due to the formation of air pockets, which arise due to several reasons:

The most common malfunctions and troubleshooting of boiler operation

Despite its functionality and electronics, there are certain disadvantages and malfunctions that can be encountered when operating the Navien Ace boiler.

Most often, users encounter a problem when the unit stops working and the electronics signal a critical error. This situation can be caused by various factors, including the sensitivity of the sensors. The most common mistakes:

Smoke removal. Fault code “10” indicates problems with the removal of combustion products. Possible reasons: turbine malfunction, pressure sensor tubes are connected incorrectly, chimney is clogged, pipe is too long.

If none of this reason is identified, and the Navien Ace boiler continues to signal an error, then the cause may be ordinary gusts of wind. This problem can be solved by redoing the chimney. As a quick response option, you can open the boiler body and disconnect the air supply hose. However, this measure is temporary. For common errors on the Navien gas boiler, see this video:

Important! The manufacturer recommends installing boilers with a chimney outlet on the leeward side

- Flame sensor failure. Fault code “03” may indicate poor gas quality. The problem can only be solved by elimination. First of all, the cleanliness of the gas supply nozzles is checked. If they are in order, you need to select the optimal position of the controller electrode (it should be in the hot phase of the flame).

- Equipment overheating. Fault code "01". A possible cause is a clogged heating system, a malfunction of the circulation pump or a decrease in flow. Ways to solve the problem: check the system and filter for the presence of air, check the serviceability of the pump and the coil resistance for short circuits, check the impeller in the circulation pump.

- The Navien gas boiler is working, there is heating, but no hot water. Error code "02". The remote control shows a jump in the water temperature (sharply increases to a maximum and immediately drops). There may be a blockage in the hot water system. Reasons may include: lack of pressure in the water supply system, airiness of the system, the circulation pump cannot gain momentum, the distribution valve is closed, or the flow controller does not work. To eliminate this malfunction, you first need to adjust the pressure, bleed the air in the system, check the resistance of the pump coil and impeller for damage, open the boiler distribution valve, disassemble the regulator body and clean the flag.

In addition, when turning on hot water, the Navien boiler may hum or make an incomprehensible noise. In this case, there is no error information on the display and the pressure is normal. As a rule, this is due to a clogged heat exchanger. To fix the problem, you can clean the heat exchanger or replace it.

Did you know?

It is best to choose boilers that are equipped with smooth adjustment - this will allow you to change the performance depending on the air temperature.

Navien Ace gas boilers are distinguished by high quality indicators and operational reliability. However, the duration and features of operation depend on how correctly you were able to install and configure the Navien Ace boiler, as well as on the quality of the fuel used.

The pressure in the Navien gas boiler constantly drops

A fairly common problem when using double-circuit gas boilers, when hot water turns on and the pressure inside the boiler begins to drop sharply. The pressure drops almost to zero, and warm water has a pungent odor. Sometimes it even happens that due to a pressure reduction error, the heating boiler automatically turns off. Another case is when a drop in pressure is observed when the water supply in the house is temporarily interrupted, after which the boiler fuses do not allow it to start again. When you try to turn it on, the tank will display an error about pressure problems and simply will not turn on. In general, a drop in pressure in the boiler is very harmful for the boiler and water supply systems, so you need to immediately diagnose the problem, and then begin to immediately solve it. What's the matter and what needs to be done, read below.

Location of expansion tanks

There are several options for expansion tanks depending on their location in the system.

- Built-in closed - all modern boiler models are already equipped with expansion tanks. Their volume directly depends on the size and performance of the boiler. The greater the expected load on the tank, the larger the displacement of its expander.

- External open - usually used under conditions of natural gravitational circulation of fluid in the system. It is an open container installed at the top point. The liquid displaced from the pipes rises up along with the air, and goes back into the system under the influence of natural atmospheric pressure and gravitational force.

Devices that control water pressure

In order to control the optimal liquid pressure in a gas boiler, pressure gauges and thermomanometers are used. Gas boilers contain various elements that are responsible for regulating the parameters of the equipment and maintaining it in working condition. This system operates under constant monitoring. Some systems use electronic sensors instead of conventional dial gauges. They are needed to transmit and receive information to an electronic unit, which processes it and displays it on the screen. Another approach is also possible - if the heating unit does not have a pressure gauge, it is equipped with a safety group.

Security group nodes

The following security group nodes exist:

How to install

Installing an expansion tank is not particularly difficult, that is, it is not at all necessary to have any skills or craftsmanship. The installation process will also not take much time. Installation is easy and quick. But, nevertheless, you should follow the instructions and carefully follow each step.

- First you should turn off the heating system, that is, turn off the boiler. Then you should take the tank and use a regular car pump to inflate it with air. To do this, remove the special plug located on the top of the device. This is the first stage of preparatory work.

- Then you need to drain all the water from the heating lines. To do this, you need to open the tap and wait until all the liquid is released from the pipes and radiators.

- Now you can install the tank. In general, the tank can be mounted anywhere, but it is advisable to install it near the boiler on the pipe through which water enters the boiler. For installation, special tees are used. It is also recommended to use a shut-off type valve. It is needed in order to, if necessary, block the coolant inlet into the tank.

- Now open the tap and fill the system with coolant. Then turn on the boiler.

That's all! If the tank is installed in accordance with all instructions, it will function correctly.

When the temperature of the coolant rises, excess liquid will flow into the tank, and when the temperature returns to normal, the liquid will return to the pipes.

If the tank is not selected correctly, then its capacity may not be enough for the amount of coolant that expands when heated. If this happens, the pressure will increase, resulting in liquid being discharged from the system automatically and the boiler will stop operating. After turning off the boiler, it can be turned on again. If there are no residents in the house for a long time, and there is no one to turn on the system, then due to frost, it will simply stop functioning. The boiler will have to be replaced.

Based on the foregoing, we can conclude that the expansion tank is one of the most important elements of any heating. It plays the role of a kind of fuse, where part of the coolant will flow in the event of its thermal expansion. If the system does not have such a tank, then as the temperature of the liquid rises, constant emergency shutdowns will occur.

So, in order for all heating to work uninterruptedly and bring warmth and comfort to the house, the tank must be selected correctly, because it is the correct expansion tank that contributes to the correct operation of the entire heating system.

Why does the fall occur - reasons

Sometimes it happens that the pressure constantly drops. Of course, you can ignore it and just feed the system occasionally. But these are short-term measures. It is better to determine the cause, since the consequences of low pressure can be disastrous.

Important! It is not necessary to contact specialists. Most of the reasons are easy to identify and eliminate on your own.

A leak

A leak is an unplanned decrease in the volume of coolant. This usually happens because the joints are not tight enough or welded incorrectly.

Sometimes a leak can be detected visually. It is enough to look at all the connections in the heating. If everything looks normal, you will have to turn off the heating and check differently.

To do this you will need:

- Turn off the boiler.

- Wait until the system cools down completely.

- Turn off the taps on the radiators.

- Raise the pressure to 1.5 bar.

- Turn on the boiler.

If there are two heating wings, check one first, then the other. Now all that remains is to monitor the pressure. If it falls, the cause is the boiler or pipes.

If the pressure remains within normal limits, you need to open the taps at each radiator one by one. The reason is one of them.

Attention! Sometimes leakage occurs due to corrosion of the metal when it comes into contact with air. Therefore, it is not recommended to drain water from heating in summer.

Water may leak through threaded connections. Then they need to be tightened or the gasket replaced. Sometimes the taps leak.

In this case, you will have to install new ones. If water escapes through welding joints, you can use cold welding. If it is a polypropylene seam, you will have to desolder and resolder the fitting.

Cracks

Nowadays, in most cases, pipes made of polypropylene or cross-linked polyethylene are used for heating.

Metal and metal-plastic pipes are also installed, but much less frequently. Cracks almost never occur on them. But the radiators and heat exchanger in the boiler may crack.

Identifying a crack in a radiator is easy. Water will leak out of it.

Even if there is no puddle underneath, smudges will still appear. If the radiator is sectional, this will not cause any special costs.

Of course, you will have to remove it and unscrew it, but only the broken sections will need to be replaced. If the radiator is a panel one, you will have to replace it completely. Or try brewing it.

Reference! To see the crack in the heat exchanger, you will have to disassemble the boiler. To do this you will need a screwdriver or torx. It all depends on the model.

First you need to remove the front cover. In non-turbocharged boilers, the combustion chamber is open, so it is easier to get to the heat exchanger. But a closed chamber does not cause any particular difficulties.

Now you need to inspect the heat exchanger. Usually, in the place where the crack is located, the metal oxidizes and acquires a greenish tint.

If there is one, then the heat exchanger needs to be changed . Sometimes it is possible to weld a crack using a gas torch , but most models cannot be repaired.

Expansion tank

The reason may also be that the membrane in the tank has broken.

This is especially common in flat expansion tanks , which are installed in wall-mounted boilers.

The fact is that in the summer the membrane sticks to the walls, and when the heating is turned on, it simply breaks. In this case, you will have to change the membrane or the entire tank.

If the pressure rises or falls immediately after starting the heating, this may be due to the incorrect selection of the expansion tank. Its volume should be a tenth of the volume of liters of water in the system. Or one seventh if antifreeze was poured into the pipes.

Open tap

To fill water into the heating, use a make-up tap. It connects the water supply and the boiler. Users often forget to close it, and this is precisely why the pressure may decrease.

Important! If the boiler is double-circuit, it works both for heating and for heating hot water. In this case, the effect of communicating vessels occurs.

When hot water is not used, the pressure is normal. As soon as the mixer is opened, the pressure drops sharply. This happens because water from the heating goes into the water supply.

By the way, this can be understood by the smell that comes from the water supply. Typically, heating water does not smell very pleasant. If the make-up valve is working properly, just close it. If it is broken, you will have to change it.

Proper installation of boilers involves installing ball valves at all outlets and inlets. Therefore, you can simply turn off the water taps when not in use. But this is a short-term solution.

Air in the system

When the system is filled with water, some air may remain in the pipes.

This problem is solved by automatic drains, which are installed at the highest heating points.

Unfortunately, the air is not always removed completely. Much depends on the design of the system. For example, aluminum radiators emit hydrogen. It also comes out through the drains, but it is precisely because of this that the pressure in the system drops.

Over time, this process may slow down or disappear altogether. But at first you will have to put up with the problem. Or replace the radiators with others.

There are other reasons for the appearance of air in the system:

- Incorrect installation.

- Long downtime of heating.

- Water itself releases oxygen.

- Various chemical reactions.

Attention! Practice shows that it is impossible to achieve complete sealing of the system by any means. Air gets into the heating anyway.

Air jams

Most of the air exits through automatic vents. But sometimes the air simply does not reach them, as it remains in one place. This usually happens at the top of radiators.

This is called air locks. A Mayevsky tap must be installed on each radiator. If you open it, air will escape, but in this case the pressure in the system will drop. It should be kept open until water flows.

It also happens that air accumulates in another part of the radiator, where a plug is usually installed instead of the Mayevsky valve.

Of course, you can remove it and install another Mayevsky tap, but it is better to redo the connection. The pipe will enter from above and exit from the other side from below. In this case, air pockets may still appear, but getting rid of them will be much easier.

Faulty valve

In order for the heating system to work properly, the pressure must not be allowed to drop below normal. But the increase is also fraught with unpleasant consequences.

Therefore, a safety valve is used to prevent overpressure. For domestic needs, 3 bars are sufficient.

If the pressure reaches this limit, the valve will open and release excess water.

This technique allows you to avoid breakdown of all weak elements of the system. But sometimes the valve can break.

In this case, it will constantly discharge water, which will lead to a decrease in pressure. It is very easy to determine such a breakdown - there will be a puddle next to the valve. Getting rid of the problem is also easy. You just need to replace the valve.

Faulty pressure gauge

If the system is working normally, but the pressure readings are still below normal, the cause may be a broken pressure gauge. Usually his arrow just stays in one place. Although it also happens that she continues to move. It can be difficult to understand this visually, so the pressure gauge needs to be removed.

Reference! You cannot unscrew the pressure gauge while holding it by the body. For these purposes, use a fitting and a regular wrench.

If the pressure gauge is unscrewed and it continues to show pressure, then it is faulty. They usually have a very thin entrance that can simply become clogged. In some cases it is enough to clean it, but sometimes it is easier to replace it.

Advantages and disadvantages

Closed expansion tanks have a number of advantages over open ones:

- Closed analogues do not necessarily need to be installed in the attic; they can be installed near the boiler itself. And open ones must be installed at the highest point of the system.

- In closed tanks, water does not have access to contact with air, which means that oxygen will not dissolve in the water and interfere with the movement of the coolant.

- Most people have converted the attics of their homes into living spaces, so using closed tanks saves space as they can be installed anywhere.

The disadvantages of closed tanks are as follows:

- High price.

- It is necessary to pump air into the device from time to time.

Design and principle of operation

Tank diagram

The pressure in a sealed, closed-type heating expansion tank is created due to its design. It consists of two chambers, which are separated by a rubber membrane. In one of the chambers there is a coolant, it is connected to a common circuit, and in the other, sealed, there is air. Its quantity is regulated depending on the characteristics of the heating system. For this purpose, a nipple is provided in the air compartment, to which a conventional machine pump fits. There is no connection between air and coolant. In order for the coolant from the circuit to enter the expansion tank for closed-type heating and back, the pressure must be correctly adjusted. This is a prerequisite to compensate for the expansion of the liquid when heated. Increasing in volume, it acts with greater force on the walls of the pipes. Slowly, excess coolant is forced into the reservoir. After the temperature of the working fluid decreases and it decreases in volume, the air in the gas chamber will displace it back into the circuit.

How to solve the pressure problem?

The very first thing to do in such cases is to check the valve. Before starting the test, make sure that the make-up valve is closed as tightly as possible. Check what happens when the gas boiler is turned off. To do this, disconnect it from the power supply. The same thing happens even when it is turned off - there is only one solution - call a service center that will replace the faucet for you. It is not recommended to replace the faucet yourself at home, as this work may require special equipment.

If the pressure drops only while the boiler is on, and this does not happen while warm water is being used, but only when the boiler is turned on and off, then the cause of the breakdown is most likely in the expansion tank. You can easily fix the problem yourself, at home. It is enough to find a fault by external inspection, most often it is some kind of scratch or small hole, then patch it with special glue. If the hole is large, then repairing it will require the help of specialists or a complete replacement of the expansion tank.

Gas autonomous heating and heating of running water is a measure that many people think about. After all, this type of fuel is considered one of the most economical. Sometimes the owners of such installations encounter a situation where the pressure in the gas boiler drops, and the reasons may be different. Don't get upset or panic. First of all, you need to establish the “symptoms” of the malfunction. After this, the main factor that led to this situation is identified and then eliminated.

Calculating pressure in two ways

- design. At this stage, a decision is made about which rooms will be heated and which will not, diagrams are drawn and the volume of the system in liters is calculated;

- boiler selection. Based on the volume of the system and the area of the heated premises, a heater is selected. For 15 liters of coolant, one kilowatt of heater power is required;

- determining the required volume of the expansion tank.

Now let's look at several different methods for calculating the pressure in the expansion tank of a sealed heating system.

Option #1.

For this we need the following quantities:

- system volume (OS);

- tank volume (VT);

- the maximum permissible value of the pressure gauge scale for a given system (DM);

- water expansion – 5%.

By the time you have to make calculations, you already know how many liters the system holds. The required volume of the tank is calculated by dividing the capacity of the circuit in liters by ten. Although this is an approximate calculation, it is very working.

The volume of the tank in a closed system may be more than necessary, but it cannot be less. An error will lead to replacement or installation of an additional one.

Air vent

Option #2.

It's good that we live in a world of fierce competition. To ensure that the client is satisfied with the purchase and does not have any problems with operation, boiler manufacturers indicate the required pressure of the heating expansion tank in the product data sheet. If for some reason this cannot be found out, then you can calculate this value, knowing what the pressure gauge readings should be in the operating mode of the system.

The latter can be found with one hundred percent probability in the technical documentation or on the boiler. Then 0.2-0.3 atmospheres should be subtracted from the working pressure. What is it for? If the pressure in the tank is greater than the working pressure in the system, the coolant will not be squeezed into the tank. He simply cannot do this, as an even greater force acts on him from the side of the tank. And if there is not enough air in the tank, then there will be difficulties with returning the coolant to the system.

How to monitor your blood pressure?

Each equipment must have sensors to monitor the operation of the unit, especially a low-pressure steam boiler. They collect information about the system and provide it to the user through a monitor or other devices. Indicators in the system are considered normal at a level of 1.5 to 2 atm. If the indicator is high or, on the contrary, does not reach the required interval, there are some problems with the boiler.

It must be remembered that insufficient pressure occurs only in a boiler system with a pump. In the case where natural circulation is provided, the owners may encounter “airing”. You can restore it and also remove the air yourself, but you need to have certain knowledge to do this. If the owners do not have enough information, it is better to call a specialist.

Navien boiler error 03

In gas boilers, the presence of a flame on the burner is checked by a special sensor - an ionization electrode. The operating logic of the unit is to continuously check for the presence of a flame after opening the gas valve. Symptoms of error 03 on Navien boilers can be divided into two groups:

- unsuccessful attempts to ignite (no flame appears)

- ignition occurs, but the flame goes out

If ignition does not occur, you need to check:

- gas pressure at the inlet and outlet of the gas valve (can only be carried out by a qualified specialist using special equipment - a differential pressure gauge)

- condition of the ignition electrodes (compliance of the gap with the manufacturer’s standard, contamination of the electrodes). The normal distance between the electrodes is 3.5-4.5 mm.

- integrity of the insulation of the electrode power wire (you can visually verify that the spark breakdown occurs specifically on the body of the gas burner, and not somewhere else)

- correct setting of the boiler power on the DIP switch (valid if there is a problem during the first start of the boiler or after replacing the electronic board)

- presence of voltage on the ignition transformer

Error 03

on the Navien boiler will also appear when combustion is unstable (intermittent flame) or if the control unit is unable to detect the presence of a flame. In this case, you need to make sure that the connection between the ionization electrode and the control board is reliable, check that the boiler is grounded and that there is no contamination on the electrode. Unstability of combustion can be caused by an increase in fan speed, so you need to make sure that the yellow hose going from the turbine to the APS sensor is securely connected and not damaged.

If during the checks it was not possible to normalize the operation of the boiler, diagnostics of the boiler board, repair or replacement will most likely be required. We recommend watching a video in which one of the users simulates error 03 on a Navien boiler:

Leak in the heating system

The first thing you should check when the pressure is slowly decreasing is coolant leakage from pipes or leaky radiators. What is most often used as a coolant? That's right, water!

Believe me! It’s not easy to detect such a leak during the heating season, but the fact is that you won’t see a puddle on the floor, well, of course, unless it’s a serious leak, but in that case the pressure will drop instantly. Most often, the leak will be in the form of droplets and you will not see these droplets, since they quickly evaporate from heated pipes.

As a result, slowly but surely the pressure will drop. You add water over and over again and this continues to kill the radiators. Because the oxygen released from the incoming fresh water does not benefit them. In addition, most boiler models have protection and if there is insufficient pressure they simply turn off. It’s good if you are at home and respond to the problem, but what if there is no one at home for a long time???? This could turn out to be even more difficult.

How and where to look for a leak

You need to pay attention to radiator plugs, joints or soldering of pipes and fittings. You can often see traces of water leaks in the form of rusty or salt stains. But this depends on the composition of the water in your area.

It is not uncommon for modern radiators, aluminum or bimetallic, to also become unusable, sometimes in extremely inconspicuous places, between the ribs or from below, they begin to dig in due to metal corrosion. Not rust, of course, but various chemical processes also damage them. Radiators must be carefully inspected while searching for leaks.

It will be easier to detect various types of leaks if you turn off the heating for a while, let the radiators cool and add pressure to about 2.5 Bar. After this, you will be able to see drops or puddles on the floor. Carefully inspect the floors under the radiators, pipe connections, and soldering areas.

The boiler can also be the cause of the leak. For example, the primary heat exchanger itself or its connections are leaking. But as long as these are small droplets, you will not notice anything; they evaporate during operation of the boiler. As it begins to leak more actively, you will notice “drops” from the boiler.

Regardless of whether the burner is on or not, the leaking feed taps or emergency relief valve will be clearly visible.

So, the first reason for the pressure drop in the system is a coolant leak.

The most popular models of Navien Ace wall-mounted boilers

The most reliable Navien boilers, the work of which can only be met with positive reviews, are distinguished by an optimal price-quality ratio. They are divided into two categories:

- Ace ATMO. Traditional boiler with an open combustion chamber. Equipped with atmospheric exhaust of combustion products.

- Ace TURBO. An advanced boiler equipped with a turbocharged burner and a special SMPS control system that regulates the gas combustion process.

Important! Navien Ace gas boilers can operate in both automatic and manual modes, which allows you to more accurately set the boiler operating parameters and eliminate operating errors as much as possible.