Extruded PENOPLEX boards have a number of properties that make this material the best choice for thermal insulation in a wide variety of construction areas:

- LOW THERMAL CONSIDERABILITY of the material gives it high thermal insulation characteristics.

- The almost COMPLETE LACK OF WATER ABSORPTION, which distinguishes PENOPLEX slabs, is one of the most important requirements for any heat-insulating material.

- In addition, extruded polystyrene foam "PENOPLEX" has a LOW PERMEABILITY.

- INCREASED COMPRESSION RESISTANCE.

- RESISTANT TO BIOLOGICAL DEGRADATION.

- This material is DURABLE.

- SAFE for the environment and human health.

- RESISTANT TO HIGH TEMPERATURES and open flames.

- It is also worth noting the EASY USE AND EASY INSTALLATION of PENOPLEX slabs.

Thanks to their structure, PENOPLEX boards have stable thermal performance and unusually high compressive strength.

Production of penoplex and types of material

The production of penoplex is organized using the following technology: small polystyrene granules in a sealed chamber are exposed to high temperatures (1300C-1400C), as a result of which they melt, and after adding blowing agents they foam. Porophores are synthetic additives that, when heated, release nitrogen and carbon dioxide, which, after the penoplex cools, turn into frozen air bubbles, evenly distributed throughout the material.

Comparison of thermal conductivity of penoplex and other building materials

Components of blowing agents for the production of extruded polystyrene foam (penoplex):

| Penoplex components | Volume by mass |

| Polystyrene | 100 |

| Fine perlite | 1 |

| Sodium bicarbonate Na2CO3 | 1 |

| Citric acid C6H8O7 | 0,8 |

| Zinc stearate (C36H70O4Zn / Zn(C18H35O2)2) or barium stearate (C36H70BaO4) | 0,2 |

| Tetrabromoparaxylene - an additive to provide self-extinguishing properties to foaming polystyrene | 1,2 |

Production of penoplex

Cured foam may contain some synthetic fillers, the presence of which determines the direction of application of the insulation - for walls, foundations, etc. The most common additives are flame retardants to increase fire safety (reduce the degree of flammability), antioxidants to protect the material from oxidation in the open air, antistatic substances to relieve static and dynamic stress during insulation operation, light stabilizers (protection from the negative effects of UV radiation), modifying additives and etc.

Polystyrene foam is pressed under pressure from the extruder chamber onto a conveyor for final formation into slabs or blocks. The percentage of gases in the insulation reaches 98% of the total volume of the finished penoplex, so the products are light in weight with impressive dimensions. Dimensions for each functional line of insulation are given in the tables below.

Sizes and types of penoplex

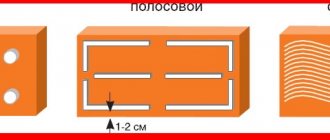

The small size of the pores (0.1-0.3 mm) and their complete isolation from each other guarantees high thermal insulation performance of any brand of penoplex. For different construction projects, it is necessary to select the appropriate series and brands of insulation, since structures can be operated under different conditions:

- Brand “K” is designed for insulation of pitched or flat roofs and roofs. Specific gravity (density) of the “K” series – 28-33 kg/m3;

- Series “C” – insulation for internal and external walls with a substance density of 25-35 kg/m3;

- Brand “F” is used to insulate foundations, basements and basements. Material with high moisture resistance, biological stability and specific gravity ≥37 kg/m3;

- Penoplex brand "Comfort" is a universal series of insulation with a density of 25-35 kg/m3. Direction of application – insulation of apartments, houses, basements, balconies and loggias;

- Brand “45” has the highest frost resistance and strength, specific gravity 35-47 kg/m3. Designed for thermal insulation of road surfaces, runways, and other heavily loaded objects and structures.

Expanded polystyrene sandwich panels

A separate category produces sandwich panels, which are an improved thermal insulator for insulating attics and mansards, facades and foundations of buildings. The sandwich panel has 2-3 layers and a cement bonded particle board as the bottom layer.

Low vapor permeability - good or evil?

As you know, the same property of a material can be considered a plus in one situation and a minus in another. This is exactly the case with the low vapor conductivity that extruded polystyrene foam is characterized by. Moreover, it does not conduct steam in any direction. Moisture does not penetrate from one side or the other. This distinguishes it from vapor barrier membranes, which may have one-way conductivity.

It is ideal on flat roofs

Where is vapor non-conductivity needed?

If installed correctly (without gaps and cracks) with joints taped, EPPS does not require the use of vapor barrier membranes. It hardly lets through steam. Neither in liquid nor in gaseous state. So the use of membranes and waterproofing is unnecessary. When using floors in a cake, this is excellent, because moisture usually comes from the ground. When using polystyrene foam, it does not penetrate either by capillary action or in the form of steam. In this case, this is definitely a plus.

Excellent for laying under screed

These properties are also a plus when using extruded polystyrene foam in blind areas, under paths, etc. In addition to protecting against freezing, it does not get wet. This allows, with a competent approach, to get rid of frost heaving and make, for example, not a deep strip foundation, but a shallow strip or Swedish slab.

The use of EPS in the roofing pie of a flat roof is also optimal - leaks are minimized, and almost no heat is lost. When using on pitched roofs, it’s already worth thinking about. The fact that Penoplex Roofing does not allow moisture into the attic space is good. But it will be possible to remove excess moisture from the attic only with the help of very good ventilation, which includes not only dormer windows. Additional elements will be needed on the ridge, in the roof plane. In general, given the cost of Penoplex, this is not always reasonable.

On the walls: yes or no?

Insulating walls with Penoplex is permissible only if you agree to make an effective ventilation system that will regulate the humidity in the house. In this case there are two options:

- Insulate the walls with EPS from the inside. With this solution, moisture practically does not enter the enclosing structures (the material from which the walls are made) due to the low vapor permeability of the material. In this case, the Penoplex layer for walls can be of small thickness. Specifically, it is necessary to count, since it depends on the material and thickness of the walls, and the region of residence. But, with such insulation, it is necessary to select the external finishing of the facade so that moisture is not trapped inside the wall. Ventilated facades are most suitable for this purpose.

- Stick the EPS on the outside. But at the same time, it is necessary to make an effective vapor barrier inside the room. It is needed to prevent moisture from entering the walls. Since there is EPS on the outside, it will not come out. To prevent moisture from accumulating in the wall, a vapor barrier is required. In this case, the thickness of Penoplex will be large. So large that the dew point is not in the wall, but in the thickness of the insulation. That is, in this case it will be necessary to insulate EPS walls with a thickness of 100 mm or more.

As you can see, there are options for using extruded polystyrene foam for wall insulation, but they are far from the best. Despite the fact that the material itself is good, it is poorly suited for this purpose.

When used on a pitched roof

And we must also take into account that the second option is only for non-hygroscopic materials.

Such a scheme is very undesirable for wooden, frame buildings; it is poorly suited for foam blocks. The fact is that no matter how good the vapor barrier is, some of the moisture will still get into the walls. If the material is non-hygroscopic, moisture will gradually be removed from the wall during the dry season. With hygroscopic materials this process is more complicated. As a result, the wood rots and the foam block walls “bloom.” Date: September 25, 2022

Operational and technical properties of penoplex, advantages and disadvantages

- Thermal conductivity – 0.03 Wm·0С, the indicator does not decrease even with strong humidification;

- Water resistance – 0.4-0.6% when immersed in water for 24 hours and for a month;

- The vapor permeability of the material can be compared with the same indicators of roofing felt with a layer thickness of 20 mm;

- Chemical passivity: penoplex does not react to contact with building mortars and most aggressive substances. Substances with which penoplex contact is contraindicated: kerosene, acetone, formaldehyde, benzene, xylene, toluene, formaldehyde, methyl ethyl ketone, ether, diesel fuel, gasoline, tar, paints and epoxy resins;

- High mechanical resistance to stretching, compression, tensile forces and multi-vector pressure. The compressive strength of penoplex is 0.2-0.5 MPa;

- Biological neutrality - penoplex does not develop mold, does not decompose and does not rot;

- Wide range of operating temperatures – from -50 to +750С. The temperature range for each brand is indicated on the packaging;

- Flammability groups for different brands are different, from G1 to G4, depending on operating conditions;

- Environmentally friendly material without the use of phenols and freons in the production;

- Guaranteed service life ≥55 years without noticeable loss in properties.

Insulation of the balcony with penoplex brand "Comfort"

Advantages of penoplex:

- Thermal conductivity properties make it possible to use penoplex even in the Far North - multiple freezing/thawing cycles of the material do not affect its characteristics;

- Light weight makes transportation, warehousing, storage and insulation of the object easier, allows you to lighten the foundation and not strengthen the ceilings;

- Simple installation without the help of specialists and special tools - penoplex can be easily cut with a regular hacksaw or cutter;

- Safety and environmental friendliness - you can work with the material without personal protective equipment;

- Low cost of all brands of insulation. Even with a large consumption of heat insulator, the costs of its purchase and installation pay off in 2-3 seasons.

Results of wall insulation with penoplex

Disadvantages of penoplex:

- Low fire safety - material of any flammability group, even with fire retardant additives, can catch fire and release caustic toxic smoke;

- Low coefficient of vapor permeability, and under certain weather conditions - negative. Therefore, it is not recommended to use penoplex for internal insulation of house walls. To maintain optimal operating conditions for the insulation, it is necessary to provide forced-air ventilation in the house and ventilation of channels in walls insulated with penoplex;

- Destruction of the material when exposed to ultraviolet radiation - sunlight. It is necessary to protect the insulation layer with plaster or other methods;

- Due to the smooth surface, the adhesion of penoplex to mortars is quite low, so the insulation should only be attached to dowels or special expensive glue, but not to mortars.

Penoplex "Wall"

Choose what you need

Despite the fact that the production of Penoplex with technical characteristics corresponding to those declared is carried out by many manufacturers, one should take a responsible approach to the choice of the “homeland” and “parent” of the insulation. One should not discount the need to choose it to achieve maximum insulation in a particular case for certain conditions, materials, surfaces.

When selecting, you need to focus on:

- brand and series of heat insulator required for the work;

- the size of the slabs, especially if you plan to insulate a small room;

- the density of Penoplex slabs, which should not be less than 25 kg/m3 (the quality of insulation and strength depend on this indicator);

- manufacturer's brand;

- block packaging (it must be intact, which guarantees the integrity of the slabs).

If in doubt, read the characteristics on the Penoplex packaging. The description contains all the necessary data to make a selection decision.

If you are in doubt about the indicated density, weigh the slabs to determine the density yourself, subsequently dividing the weight by the volume. For example, a Comfort slab with a thickness of 50 mm and normal density should not weigh less than 1.3 kg. At the fracture of the “regular” Penoplex, you can see many polyhedra of regular shape, along the boundaries of which the fracture occurs. The fracture should be orange due to the coloring pigment included in the composition. Purchasing products from well-known European factories will guarantee the quality of the products. The domestic manufacturer, represented by the Penoplex and TechnoNIKOL enterprises, is not far behind them.

After reading about penoplex, understanding what it is, where it can be used, assessing its pros and cons, you can be confident in the targeted choice of the right brand and in its correct use. Having done insulation once using Penoplex, ensure that heat is retained in the house for many years.

Thermal insulation material “Wall” - properties and characteristics

The “Wall” brand is a renamed Penoplex 31 insulation with fire retardant additives, which has been improved for use in insulating “wet” facades, building foundations, plinths and basements, partitions and walls of houses outside and inside, roofs and attics. The characteristics of penoplex brand “Wall” are in the table below:

| Properties | Meaning |

| Specific gravity | 25.0-32.0 kg/m³ |

| Compressive strength | 0.20 MPa (kgf/cm2) |

| Bend limit | 0.25 MPa |

| Moisture absorption in 1 day | 0,4% |

| Moisture absorption in 28 days | 0,5% |

| Fire resistance | Group G3 |

| Thermal conductivity | 0.030 W/(m K) |

| Sound insulation threshold | 41 dB |

| Dimensions (width, length, height) | 600 mm x 1200 mm x 20, 30, 40, 50, 60, 80, 100 mm |

| Temperature range | -50/+750С |

Insulation series “Foundation”

Price

The prices in the table are valid in spring 2022:

| Model | Price in rubles |

| Foundation (50 mm thick, 8 pieces per pack) | 1400 |

| Roof (80 mm, 5 pcs.) | 1420 |

| Facade, (50 mm, 8 pcs.) | 1350 |

| Comfort, (40 mm, 10 pcs.) | 1200 |

| Wall, (50 mm, 8 pcs.) | 1350 |

| Base, (50 mm, 8 pcs.) | 1655 |

That, in fact, is all I wanted to tell you about penoplex.

Insulation brand "Foundation" - parameters and properties

The “Foundation” brand is a renamed Penoplex 35 insulation without fire retardant additives, which can now be used to create thermal insulation for the bases and plinths of buildings, blind areas and basements. The strength, waterproofness and thermal conductivity of the “Foundation” penoplex series are its main advantages. The characteristics of the “Foundation” are given in the table below:

| Properties | Meaning |

| Specific gravity | 29.0-33.0 kg/m³ |

| Compressive strength | 0.27 (2.7; 27) MPa (kgf/cm2) |

| Bend limit | 0.4 MPa |

| Moisture absorption in 1 day | 0,4 % |

| Moisture absorption in 28 days | 0,5 % |

| Fire resistance | Group G4 |

| Sound insulation threshold | 39 dB |

| Thermal conductivity | 0.03-031 W/(m K) |

| Dimensions (width, length, height) | 600 mm x 1200 mm x 20, 30, 40, 50, 60, 80, 100 mm |

| Temperature range | -50/+750C |

Penoplex brand "Roof"

Mineral wool

Mineral wool is a material based on basalt fiber.

Mineral wool cannot be used everywhere, as it has a lower temperature limit. For example, this insulation cannot be used in a refrigerator.

Under the influence of low temperatures, mineral wool becomes brittle and deformed, which is unacceptable for insulation. Here, as a comparison of thermal conductivity insulation shows, the advantage is on the side of polystyrene foam, which has no lower temperature limit.

As for the upper temperature limit, it all depends on the mechanical loads during exposure to high temperatures and the duration of this exposure. If you are interested in the thermal conductivity of insulation, the table that is on our website will help in obtaining information about this. In particular, the thermal conductivity coefficient of mineral wool is given there.

Mineral wool insulation is also hygroscopic, which is why it is necessary to build ventilated walls and roofing. This in some cases leads to a large expenditure of money.

Mineral wool insulation is 1.5-3 times heavier than its polystyrene foam counterpart. Hence the higher cost of its transportation. Another disadvantage is that such insulation can only be used when the foundation of the structure that is insulated with its help is strong enough. Of course, it is more difficult to carry out loading and unloading and construction and installation work using a large mass of insulation.

Penoplex "Roof" - properties and characteristics

Penoplex insulation of the “Roofing” series is a renamed material “Penoplex 35”, which is recommended for use in insulating pitched and flat roofs of any design. The use of the “Roof” series makes the further operation of the roof as simplified as possible, since the reliability and long service life of the insulation minimize the possibility of repairing the roof surface. The popularity of this innovative insulating material is also due to the fact that greenhouses and summer gardens can be built on such a surface - such trends are now in fashion. Penoplex can withstand such high loads that it doesn’t care about soil loads of up to several tons. Characteristics of the foam insulation brand “Roof” are in the table below:

| Properties | Meaning |

| Specific gravity | 28.0-33.0 kg/m³ |

| Compressive strength | 0.25 (2.5; 25) MPa (kgf/cm2) |

| Bend limit | 0.4 MPa |

| Elasticity modulus | 15 |

| Moisture absorption in 1 day | 0,4 % |

| Moisture absorption in 28 days | 0,5 % |

| Fire resistance | Group G3 |

| Sound insulation threshold | 23 dB |

| Thermal conductivity | 0.03-032 W/(m K) |

| Dimensions (width, length, height) | 600 mm x 1200 mm x 20, 30, 40, 50, 60, 80, 100 mm |

| Temperature range | -50/+750C |

“Comfort” is a universal brand of heat insulator

Warm floor - what is it?

The warm floor consists of mats and a heating system.

The first heated floor surfaces were used by the ancient Romans to heat baths. Hot air passed through special channels installed under the floor. The principle of modern heating designs has remained the same, but during this time the heating system has been significantly improved. The design is used for installation in premises of any purpose; it is considered an excellent alternative to conventional central heating. Efficiency is achieved due to increased heat transfer. Installation of the structure does not take much time; the procedure can be carried out in any room.

Brand of heat insulator “Comfort” - properties and characteristics

Penoplex "Comfort" is a modified and improved "Penoplex 31C" with universal characteristics. The material is actively used for insulating country houses, country houses and cottages. The high speed of installation and minimal labor costs popularize the insulation among private homeowners - it is used to insulate the subfloor, foundation and basement of a house, basement and roof, walls and partitions from the inside and outside of the building. Penoplex "Comfort" has high levels of moisture resistance and thermal conductivity. In the penoplex series line, the Comfort brand is recognized as universal.

Penoplex protects the soil from heaving when it freezes - when the soil is insulated with this material, the freezing point of the soil will rise. This series is optimal for insulating road and railway surfaces, runways and technical areas of airfields. Comfort slabs retain their unique characteristics throughout the entire period of operation. Characteristics of the “Comfort” penoplex insulation brand are in the table below:

| Properties | Meaning |

| Specific gravity | 25.0-35.0 kg/m³ |

| Compressive strength | 0.18(1.8; 18) MPa (kgf/cm2) |

| Bend limit | 0.4 MPa |

| Moisture absorption in 1 day | 0,4 % |

| Moisture absorption in 28 days | 0,5 % |

| Fire resistance | Group G4 |

| Sound insulation threshold | 40 dB |

| Vapor permeability | 0.007-0.008 Mg/(m h Pa) |

| Thermal conductivity | 0.030–0.032 W/(m K) |

| Dimensions (width, length, height) | 600 mm x 1200 mm x 20, 30, 40, 50, 60, 80, 100 mm |

| Temperature range | -50/+750C |

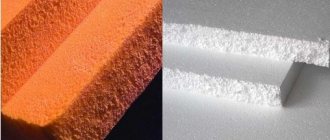

It is a misconception to think that penoplex and foam plastic are brother materials. Some properties of penoplex can be equated to the parameters of polystyrene foam, but not flammability and water absorption.

General characteristics of penoplex

Manufacturers have long mastered the production of both non-flammable polystyrene foam and high-burning polystyrene foam. But the truth is that penoplex cannot spontaneously ignite, and in an open fire zone it will only melt, releasing carbon monoxide (CO) and carbon dioxide (CO2) gases. If the fire is extinguished, the penoplex will not even smolder.

Easy to use, easy to buy

Penoplex is produced at factories under the same name in Perm, Leningrad region (Kirishi), Novosibirsk, Taganrog and Irkutsk. This manufacturer has 10 official representative offices in all federal districts of Russia.

Technoplex is produced at the enterprises of the TechnoNIKOL group of companies in Mineralnye Vody, Novoulyanovsk, Uchaly (Bashkortostan), Ryazan, Yurga (Khanty-Mansi Autonomous Okrug). And also has 10 representatives throughout Russia.

Both manufacturers have their dealers in each regional (territorial) center, as well as in large regional cities.

Physics of heat transfer

The phenomenon of heat exchange as a method of energy transfer can only occur in the presence of a temperature difference. There are three types of heat exchange in nature:

- convection;

- radiation;

- thermal conductivity.

Convection occurs due to the movement of warm and cold currents in liquid and gaseous media. For example, room air, heated by contact with a hot radiator, due to expansion, becomes lighter and rises, giving way to cold air. This process will continue continuously as long as there is a temperature difference in the room. The observed column of smoke from a chimney is a good illustration of convective heat transfer.

Radiation is a method of propagating thermal energy in the form of electromagnetic waves. All bodies around us are sources of radiation, the degree and intensity of which depends on their temperature. Some of the radiation from bodies with high temperatures can be seen with the naked eye; some bodies emit heat so weakly that it can only be detected using a thermal imager.

Thermal conduction occurs due to the transfer of energy between adjacent solid particles. Heating or cooling one area of a solid body will cause heat distribution within the body until the temperature in it equalizes. A wooden tea spoon and a metal spoon immersed in boiling water will not heat up equally. This happens because different materials conduct heat differently. Some are intense, and some are so bad that they can serve as thermal barriers.

The main types of insulation used to reduce heat loss

To carry out thermal insulation measures of any type, the following types of insulators are used:

- extruded polystyrene foam (XPS), refers to polystyrene derivatives (represented by various manufacturing enterprises, has many brands);

- polystyrene foam, its production also involves the processing of polystyrene, but using a different technology (it has a sufficient number of manufacturers, the breakdown by brand is not clear, it is positioned as “foam plastic”).

- mineral or basalt wool is fundamentally different from polystyrene products and acts as the main competitor of foamed polystyrenes (represented on the insulating goods market by a large number of manufacturers).

The number of manufacturing companies, both domestic and foreign, is measured in dozens. When choosing products, you need to rely on the physical properties of each individual product.

Density and thermal conductivity of thermal insulation in the form of plates and segments

The table shows the density values and temperature dependence of the thermal conductivity of thermal insulation molded in the form of slabs, segments, etc., as well as their maximum operating temperature.

Thermal insulation density, thermal conductivity and temperature are indicated for such thermal insulation as: diatom segments, sovelite segments and shells, newel shells, asbestos cement segments, vulcanite slabs, vermiculite shells, foam concrete segments, foam glass slabs, cork segments, peat segments, mineral wool segments, alfol smooth sheets (segments), corrugated aluminum foil (segments), ball insulation backfilled into segments, rod thermal insulation backfilled into segments (porcelain rods with a diameter of 0.5 mm).

The lightest thermal insulation is alfol; according to the table, it has a density of 200 kg/m3 and a maximum operating temperature of up to 500°C. High-temperature thermal insulation (up to 2000°C) includes ball and rod insulation. However, such thermal insulation has a high density and low thermal conductivity, equal to 0.23...0.39 W/(m deg). The thermal conductivity of thermal insulation depends on temperature. The table presents formulas for the temperature dependence of thermal conductivity of thermal insulation and its maximum operating temperature.

Note: to calculate the thermal conductivity coefficient from the dependencies in the table, it is necessary to enter the temperature in degrees Celsius.

Comparison using a table

| N | Name | Density | Thermal conductivity | Price, euro per cubic meter | Energy costs for | ||

| kg/cub.m | min | Max | European Union | Russia | kW*h/cubic m. | ||

| 1 | cellulose wadding | 30-70 | 0,038 | 0,045 | 48-96 | 15-30 | 6 |

| 2 | fibreboard | 150-230 | 0,039 | 0,052 | 150 | 800-1400 | |

| 3 | wood fiber | 30-50 | 0,037 | 0,05 | 200-250 | 13-50 | |

| 4 | flax fiber whales | 30 | 0,037 | 0,04 | 150-200 | 210 | 30 |

| 5 | foam glass | 100-150 | 0.05 | 0,07 | 135-168 | 1600 | |

| 6 | perlite | 100-150 | 0,05 | 0.062 | 200-400 | 25-30 | 230 |

| 7 | cork | 100-250 | 0,039 | 0,05 | 300 | 80 | |

| 8 | hemp, hemp | 35-40 | 0,04 | 0.041 | 150 | 55 | |

| 9 | cotton wool | 25-30 | 0,04 | 0,041 | 200 | 50 | |

| 10 | sheep's wool | 15-35 | 0,035 | 0,045 | 150 | 55 | |

| 11 | duck down | 25-35 | 0,035 | 0,045 | 150-200 | ||

| 12 | straw | 300-400 | 0,08 | 0,12 | 165 | ||

| 13 | mineral (stone) wool | 20-80 | 0.038 | 0,047 | 50-100 | 30-50 | 150-180 |

| 14 | glass fiber wool | 15-65 | 0,035 | 0,05 | 50-100 | 28-45 | 180-250 |

| 15 | expanded polystyrene (pressless) | 15-30 | 0.035 | 0.047 | 50 | 28-75 | 450 |

| 16 | extruded polystyrene foam | 25-40 | 0,035 | 0,042 | 188 | 75-90 | 850 |

| 17 | polyurethane foam | 27-35 | 0,03 | 0,035 | 250 | 220-350 | 1100 |

The indicator of thermal conductivity properties is the main criterion when choosing an insulation material. All that remains is to compare the pricing policies of different suppliers and determine the required quantity.

Insulation is one of the main ways to obtain a structure with the required energy efficiency. Before making your final choice, carefully determine the conditions of use and, armed with the table provided, make the right choice.

Installation technology of polystyrene insulation boards

Insulation of external, internal walls and other structures using extruded polystyrene is carried out in several stages. Let's look at each of them:

- The preparatory stage consists of preparing the walls for insulation, cleaning them from dirt, dust, old finishing materials, and paint coatings. In case of large unevenness, it is recommended to level the surface using a plaster mixture (and other methods depending on the design) and treat it with an antifungal compound.

- Fixation using special adhesive facade compounds . The adhesive is applied directly to the insulating board using a comb.

- Mechanical fastening is done using dowels.

- Installation of facade mesh . For better adhesion of the glue to the insulation, you can create roughness on the surface of the slabs. The first plaster layer of façade adhesive is used to fix the reinforcing polymer mesh. Next, a second layer of plaster is applied, after which has dried, the walls are covered with decorative plaster (optional) and painted.

- Instead of plaster, it is possible to decorate the walls with siding, wood, as well as the use of ventilated facades.

EPS installation technology

Thermal insulation of roofs is carried out either at the construction stage or during the reconstruction process, for example, when converting a cold attic into a living space. In this case, the insulation is laid on the base in several layers (the joints of the top layer should not coincide with the joints of the bottom). Next, a vapor-permeable membrane is spread over the penoplex. The resulting cake is secured with longitudinal slats with a thickness of at least 40 mm to ensure ventilation between the insulation and the roofing material.

Example of heat loss calculation

If we take, for example, a wall made of a material with a thermal conductivity coefficient of 1, then if the temperature difference on the two sides of this wall is 1°, the heat loss will be 1 W. If the wall thickness is not 1 meter, but 10 cm, then the losses will already be 10 W. If the temperature difference is 10°, then the heat loss will also be 10 W.

Let us now consider, using a specific example, the calculation of heat loss of an entire building. Let’s take its height to be 6 meters (8 with the ridge), width – 10 meters, and length – 15 meters. To simplify the calculations, we take 10 windows with an area of 1 m2. We will assume the indoor temperature to be 25°C, and outdoor temperature -15°C. We calculate the area of all surfaces through which heat loss occurs:

- Windows – 10 m2.

- Floor – 150 m2.

- Walls – 300 m2.

- Roof (with slopes along the long side) – 160 m2.

The formula for thermal conductivity of building materials allows you to calculate coefficients for all parts of the building. But it’s easier to use ready-made data from the directory. There is a table of thermal conductivity of building materials. Let's consider each element separately and determine its thermal resistance. It is calculated by the formula R = d/λ, where d is the thickness of the material, and λ is the coefficient of its thermal conductivity.

Floor – 10 cm of concrete (R=0.058 (m2*°C)/W) and 10 cm of mineral wool (R=2.8 (m2*°C)/W). Now we add these two indicators. Thus, the thermal resistance of the floor is 2.858 (m2*°C)/W.

Walls, windows and roofs are considered similarly. Material – cellular concrete (aerated concrete), thickness 30 cm. In this case, R=3.75 (m2*°C)/W. Thermal resistance of a plastic window is 0.4 (m2*°C)/W.

We will consider the roof to be made of mineral wool 10 cm thick and corrugated sheets. Since metal has a high coefficient of thermal conductivity, we do not take the profiled sheet into account. Then R of the roof will be 2.8 (m2*°C)/W.

The following formula allows you to find out the loss of thermal energy.

Q = S * T / R, where S is the surface area, T is the temperature difference between outside and inside (40°C). Let's calculate the heat loss for each element:

- For the roof: Q = 160*40/2.8=2.3 kW.

- For walls: Q = 300*40/3.75=3.2 kW.

- For windows: Q = 10*40/0.4=1 kW.

- For the floor: Q = 150*40/2.858=2.1 kW.

Next, all these indicators are summarized. Thus, for this cottage the heat loss will be 8.6 kW. And to maintain the optimal temperature, you will need boiler equipment with a power of at least 10 kW.

Thermal conductivity of polystyrene foam exact numbers

The ability to conduct heat is influenced by many factors, in particular:

- Layer thickness. Sometimes, in order to achieve high-quality energy savings, it is necessary to use a large amount of insulation. For example, the thermal conductivity of 5 cm foam plastic boards will be lower than 1 cm with the same density.

- Structure. The porous structure leads to increased insulating properties, because the cells contain air that perfectly retains heat.

- Humidity. During storage, slabs must be protected from moisture. This is due to the fact that liquid does not have a very favorable effect on the characteristics of thermal insulation foams: the more it accumulates, the worse it is.

- Average layer temperature. Its increase leads to a deterioration in the efficiency of the insulator.

Types of foam plastic and their indicators

There are a huge number of insulation boards on the construction market. In general, polystyrene foam has low thermal conductivity, but this varies depending on its type. Examples: sheets marked PSB-S 15 have a density of up to 15 kg/m3 and a thickness of 2 cm, while the described indicator is up to 0.037 W/(m*K) at an ambient temperature of 20-30 °C. Its value for sheets 2-50 cm marked PSB-S 35, with a density of no more than 35 kg/m3 and 16-25 kg/m3 marked PSB-S 25 of the same size is 0.033 W/(m*K) and 0.035 W/ (m*K) respectively.

The dependence of the thermal conductivity of foam insulation on its thickness is best seen when comparing it with various materials. Thus, a sheet of 50-60 mm replaces twice the volume of mineral wool, and 100 mm is equivalent to 123 mm of expanded polystyrene foam, which has approximately similar characteristics. Basalt wool also loses greatly. But the thermal conductivity of Penoplex is slightly lower than that of polystyrene foam: in order to obtain normal temperature conditions in the room, you will need 20 and 25 mm, respectively.

How do you know which sheets to buy?

In order to most effectively apply this or that insulation method, it is necessary to select the correct dimensions of the material. Calculations are performed according to the following algorithm:

- Find out the total thermal resistance. This is a constant value that depends on the climate in a particular region. For example, for the southern regions of Russia it is 2.8, and for the central zone - 4.2 kW/m2.

- Calculate the thermal resistance of the wall itself using the formula R = p / k, which can be done knowing its thickness (p) and the coefficient of ability to conduct heat (k).

- Based on constant indicators, find out what resistance value the insulation should have.

- Calculate the required value using the formula p = R * k, where R is the value from the previous step, and k is the calculated thermal conductivity coefficient for the foam.

As an example, it is worth finding out what layer of slabs with a density of 30 kg/m3 is needed for a wall of one brick (about 0.25 m) in one of the southern regions. The total thermal resistance should not be less than 2.8 kW/m2, despite the fact that the coefficient determined using special tables is 0.047 (W/m*k). Now you need to find out other parameters.

Coefficient for sand-lime brick k = 0.7 (W/m*k). You should calculate its thermal resistance:

R = 0.25 / 0.7 = 0.36 (kW/m2).

The same indicator is calculated for insulation:

R = 2.8 – 0.36 = 2.44 (kW/m2).

It remains to find out the thickness of the insulating layer:

p = 2.44 * 0.047 = 0.11 m.

You can also calculate this value for other conditions, for example, for a wall of 0.51 m, 70 mm insulation is suitable. Thus, when selecting the required sizes of polystyrene foam, time and money for laying the wall are saved. So, 10 cm of material with a density of 15-17 kg/m3 replaces the masonry of one brick, and if you take denser sheets, this will allow you to do without two rows of stone. It is traditionally believed that 2 cm of insulation is equivalent to about 50 cm of brick.

Other selection criteria

When choosing a suitable product, not only thermal conductivity and the price of the product should be taken into account.

You need to pay attention to other criteria:

- volumetric weight of insulation;

- dimensional stability of this material;

- vapor permeability;

- flammability of thermal insulation;

- soundproofing properties of the product.

Let's take a closer look at these characteristics. Let's start in order.

Volumetric weight of insulation

Volumetric weight is the mass of 1 m² of a product. Moreover, depending on the density of the material, this value can be different - from 11 kg to 350 kg.

Such thermal insulation will have a significant volumetric weight

The weight of thermal insulation must definitely be taken into account, especially when insulating a loggia. After all, the structure on which the insulation is attached must be designed for this weight. Depending on the mass, the method of installing heat-insulating products will also differ.

For example, when insulating a roof, lightweight insulation materials are installed in a frame of rafters and sheathing. Heavy specimens are mounted on top of the rafters, as required by the installation instructions.

Form stability

This parameter means nothing more than the creaseability of the product used. In other words, it should not change its size during its entire service life.

Any deformation will result in heat loss

Otherwise, deformation of the insulation may occur. And this will already lead to a deterioration in its thermal insulation properties. Research has proven that heat loss can be up to 40%.

Vapor permeability

According to this criterion, all insulation materials can be divided into two types:

- “cotton wool” – heat-insulating materials consisting of organic or mineral fibers. They are vapor permeable because they easily allow moisture to pass through them.

- “foams” are heat-insulating products made by hardening a special foam-like mass. They do not allow moisture to pass through.

Depending on the design features of the room, materials of the first or second type can be used. In addition, vapor-permeable products are often installed with your own hands along with a special vapor barrier film.

Flammability

It is highly, highly desirable that the thermal insulation used is non-flammable. An option is allowed when it is self-extinguishing.

But, unfortunately, in a real fire, even this will not help. At the epicenter of the fire, even things that do not light up under normal conditions will burn.

Distinctive features of PPE insulation

Specifications

Thermal insulation made of foamed polyethylene is a product with a closed-porous structure, soft and elastic, having a shape appropriate for its purpose. They have a number of properties that characterize gas-filled polymers:

- Density from 20 to 80 kg/m3,

- Operating temperature range from -60 to +100 0C,

- Excellent moisture resistance, in which moisture absorption is no more than 2% of the volume, and almost absolute vapor tightness,

- High noise absorption even with a thickness greater than or equal to 5 mm,

- Resistant to most chemically active substances,

- No rotting or fungal damage,

- Very long service life, in some cases reaching more than 80 years,

- Non-toxic and environmentally safe.

But the most important characteristic of polyethylene foam materials is their very low thermal conductivity, due to which they can be used for thermal insulation purposes. As you know, air retains heat best, and there is plenty of it in this material.

The heat transfer coefficient of polyethylene foam insulation is only 0.036 W/m2 * 0C (for comparison, the thermal conductivity of reinforced concrete is about 1.69, plasterboard - 0.15, wood - 0.09, mineral wool - 0.07 W/m2 * 0C).

INTERESTING! Thermal insulation made of foamed polyethylene with a layer thickness of 10 mm can replace a 150 mm thickness of brickwork.

Application area

Foamed polyethylene insulation is widely used in new and reconstructive construction of residential and industrial facilities, as well as in automotive and instrument making:

- To reduce heat transfer by convection and thermal radiation from walls, floors and roofs,

- As reflective insulation to increase the heat output of heating systems,

- To protect pipe systems and pipelines for various purposes,

- In the form of an insulating gasket for various cracks and openings,

- For insulating ventilation and air conditioning systems.

In addition, polyethylene foam is used as packaging material for transporting products that require thermal and mechanical protection.

Is polyethylene foam harmful?

Supporters of the use of natural materials in construction may talk about the harmfulness of chemically synthesized substances. Indeed, when heated above 120 0C, foamed polyethylene turns into a liquid mass, which can be toxic. But under standard living conditions it is absolutely harmless. Moreover, insulation materials made from polyethylene foam are superior to wood, iron and stone in most respects. Building structures using them are light, warm and low cost.