Home / Gas boilers

Back

Published: 05/14/2019

Reading time: 3 min

0

29169

As a result of an increase in pressure on the boiler above the nominal value, periodic blocking occurs, and excess coolant is released from the safety valve.

The heating system is not designed to operate in a mode where all its components are under excessive load. Overloads can lead to negative consequences due to the failure of expensive elements.

Therefore, the reason why pressure increases in a double-circuit boiler must be eliminated immediately. For users of an autonomous heating system, a list of probable malfunctions that can lead to increased pressure and ways to eliminate them is presented.

- 1 Why you need to monitor the pressure in the boiler

- 2 Reasons for increased pressure in case of boiler damage

- 3 Why does the pressure rise in the heating boiler 3.1 Air lock in the system

- 3.2 Malfunctions of the expansion tank

- 3.3 Other causes of increased pressure

Why do you need to monitor the pressure in the boiler?

Safety group

The operation of the boiler is accompanied by changes in pressure in the circuit, which must be kept within established limits. This means that when the boiler is turned on, the pressure gauge must show a minimum bar value, and during operation the pressure cannot exceed the permissible level. Thus, three types of pressure are defined:

- dynamic pressure is the magnitude of the coolant voltage circulating in the heating circuit;

- static pressure - measured at idle and determines the load exerted by the coolant on the heating circuit;

- maximum pressure is the permissible load limit at which normal operation of the system is allowed.

If the pressure in the gas boiler increases, the consequence is that the normal operation of the system ceases; water is periodically released through the relief valve or from the expansion tank.

How to install

Installing an expansion tank is not particularly difficult, that is, it is not at all necessary to have any skills or craftsmanship. The installation process will also not take much time. Installation is easy and quick. But, nevertheless, you should follow the instructions and carefully follow each step.

- First you should turn off the heating system, that is, turn off the boiler. Then you should take the tank and use a regular car pump to inflate it with air. To do this, remove the special plug located on the top of the device. This is the first stage of preparatory work.

- Then you need to drain all the water from the heating lines. To do this, you need to open the tap and wait until all the liquid is released from the pipes and radiators.

- Now you can install the tank. In general, the tank can be mounted anywhere, but it is advisable to install it near the boiler on the pipe through which water enters the boiler. For installation, special tees are used. It is also recommended to use a shut-off type valve. It is needed in order to, if necessary, block the coolant inlet into the tank.

- Now open the tap and fill the system with coolant. Then turn on the boiler.

That's all! If the tank is installed in accordance with all instructions, it will function correctly.

When the temperature of the coolant rises, excess liquid will flow into the tank, and when the temperature returns to normal, the liquid will return to the pipes.

If the tank is not selected correctly, then its capacity may not be enough for the amount of coolant that expands when heated. If this happens, the pressure will increase, resulting in liquid being discharged from the system automatically and the boiler will stop operating. After turning off the boiler, it can be turned on again. If there are no residents in the house for a long time, and there is no one to turn on the system, then due to frost, it will simply stop functioning. The boiler will have to be replaced.

Based on the foregoing, we can conclude that the expansion tank is one of the most important elements of any heating. It plays the role of a kind of fuse, where part of the coolant will flow in the event of its thermal expansion. If the system does not have such a tank, then as the temperature of the liquid rises, constant emergency shutdowns will occur.

So, in order for all heating to work uninterruptedly and bring warmth and comfort to the house, the tank must be selected correctly, because it is the correct expansion tank that contributes to the correct operation of the entire heating system.

Reasons for increased pressure in case of boiler damage

It is difficult for a person who does not have experience in servicing heating systems to independently determine the true reason why the pressure in the heating boiler rises. However, to give you an idea of possible malfunctions, a list of probable causes is provided.

- Increasing pressure up to 1 atm. may occur as a result of depressurization of the heat exchanger. Such consequences result from the formation of cracks in the housing during prolonged operation. The appearance of cracks may be the result of a manufacturing defect or poor strength of the material, the consequences of a water hammer or equipment wear. In this case, the coolant volume systematically begins to replenish. However, it is not possible to visually determine the location of the leak due to the instantaneous evaporation of the liquid when the burner is running. This malfunction leads to replacement of the heat exchanger.

- An increase in pressure can occur when the make-up valve is open. The weak pressure inside the boiler contrasts with the increased pressure in the pipeline. This causes additional water to flow through the open valve. Thus, the water pressure will gradually increase until it is released. If the pressure in the pipeline decreases, the water supply to the boiler is shut off by the coolant, reducing the pressure in the circuit. The make-up valve must be kept closed, and if it is broken, replaced.

- An increase in pressure may occur due to a malfunction of the three-way valve. Such a breakdown leads to water entering the circuit from the expansion tank. Debris periodically collects on the valve, which can cause it to break. This element must be cleaned periodically and, if faulty, replaced. To prevent contaminants from entering the water supply, you can install a simple corner filter.

- If all signs indicate that the pressure in the circuit is increasing, and the pressure gauge needle does not respond, this means that it has failed. A broken device makes it impossible to control the operation of the system and needs to be replaced.

Excessive pressure in the heating circuit is determined by the readings of the pressure gauge; if the indicator exceeds the permissible level, measures must be taken immediately. In addition to the pressure gauge, an excess of the permissible norm can be indicated by a safety valve, from which water will begin to flow if the pressure has risen.

Diaphragm expansion tank - calculation principles

Often the reason why there is a loss of pressure in the heating system is the wrong choice of a double-circuit heating boiler

That is, the calculation takes into account the area of the premises in which heating will be carried out. This parameter affects the choice of area of heating radiators - and they use a relatively small amount of coolant

However, sometimes after the calculation, radiators are replaced with pipes, which use a significantly larger amount of water (and this fact is not taken into account). Accordingly, it is precisely this error in the calculation that leads to an insufficient level of pressure in the system.

Expansion tanks come in a variety of sizesFor the normal functioning of a double-circuit system with 120 liters of coolant, an expansion tank with a volume of 6-8 liters is sufficient. However, this amount is calculated for a system that uses radiators. When using pipes instead of radiators, there is more water in the system. Accordingly, it expands more strongly, thereby filling the expansion tank completely. This situation leads to an emergency release of excess liquid using a special valve. This causes the system to shut down. The water gradually cools down and its volume decreases. And it turns out that there is not enough fluid in the system to maintain the pressure at a normal level.

In order to avoid such an unpleasant situation (hardly anyone will be happy about the breakdown of the heating system in the cold season), it is necessary to carefully calculate the volume of the required expansion tank. In closed systems supplemented by a circulation pump, the most rational is to use a membrane expansion tank, which functions as an element such as a heating pressure regulator.

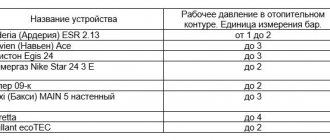

Table for determining the maximum volume of liquid that the tank can hold

Of course, it is quite difficult to calculate the exact amount of water in the pipes of the heating system. However, an approximate figure can be obtained by multiplying the boiler power by 15. That is, if a boiler with a capacity of 17 kW is installed in the system, then the approximate volume of coolant in the system will be 255 liters. This indicator is useful for calculating the appropriate volume of the expansion tank.

The volume of the expansion tank can be found using the formula (V*E)/D. In this case, V is an indicator of the volume of coolant in the system, E is the expansion coefficient of the coolant, and D is the efficiency level of the tank.

D is calculated this way:

D = (Pmax-Ps)/(Pmax +1).

Here Pmax is the maximum pressure level permissible during system operation. In most cases - 2.5 bar. But Ps is the tank charging pressure coefficient, usually 0.5 bar. Accordingly, substituting all the values, we get: D = (2.5-0.5)/(2.5 +1)=0.57. Next, taking into account that we have a 17 kW boiler, we calculate the most suitable tank volume - (255*0.0359)/0.57=16.06 liters.

You should definitely pay attention to the technical documentation of the boiler. In particular, a 17 kW boiler has a built-in expansion tank with a volume of 6.5 l

Thus, for the correct functioning of the system and to prevent such cases as pressure drop in the heating system, it is necessary to supplement it with an auxiliary tank with a volume of 10 liters. Such a pressure regulator in the heating system can normalize it.

Why does the pressure rise in the heating boiler?

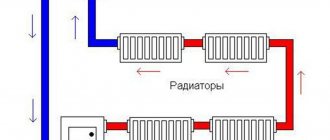

Filling the heating circuit is carried out subject to the exact sequence of actions; deviation from the rules leads to malfunctions of the system. When starting the system seasonally, it is necessary to adjust the adjustable auxiliary elements and fix the position of the valves in the correct position.

Air lock in the system

Thermal imager shows a plug

If the heating system malfunctions, expressed in an arbitrary increase in pressure, the temperature of the coolant sometimes drops and the boiler blocks. As a consequence, in such situations, an imbalance occurs in the functioning of the system, leading to the failure of expensive elements.

Airing of the circuit can lead to similar consequences, and the resulting plugs are recognized as a common reason why the pressure in the boiler increases.

Air locks can occur for a number of reasons:

- equipment malfunction;

- the system was launched with violations;

- automation failure;

- formation of cracks in the heat exchanger housing.

The above consequences are the result of neglecting the established rules for operating the heating system.

The following actions can lead to these breakdowns:

- the DHW circuit is filled from the top point;

- upon startup, the system is rapidly filled with water;

- before launch, the check required for the air vents, as well as each Mayevsky valve, was not carried out;

- air was not bled from the radiators after repair;

- The vibrating impeller with which the circulation pump is equipped slowly pumps air, causing a circulation problem.

Such problems are eliminated by relieving pressure from the heating circuit. Next, the circuit is filled with water, carried out from the bottom point. It is important to consider that while filling the system, it is necessary to keep the air bleed valves open. Filling is done gradually without undue haste, and the end of the process is signaled by the appearance of water at the top point of the system.

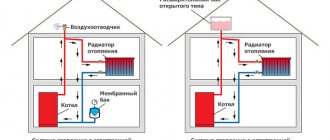

Expansion tank malfunctions

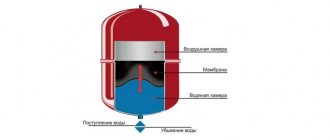

The expansion tank can look like a separate wall element or as part of the boiler. It is designed to collect excess coolant from the heating circuit. When water in the system is heated, its volume can increase by up to 4%, and the expansion tank is designed to compensate for this difference.

Incorrect calculation of the system volume may lead to the installation of a tank with a smaller capacity than necessary for compensation. In this case, all the excess water cannot leave the system and this becomes the explanation why the pressure increases. The dimensions of the tank are also affected by the power of the installed boiler.

When choosing a Navien gas unit, you should install a tank whose volume is 10% of the total displacement of the system, and if solid fuel equipment is installed, this figure doubles.

A hidden breakdown is considered to be a rupture of the membrane in the expansion tank. Such damage may not be noticed immediately, but in the meantime, unfixed coolant can fill the entire internal cavity. The pressure in the circuit will decrease, but if, in this situation, the system is recharged, this will lead to an arbitrary increase in pressure.

Other causes of high blood pressure

Other malfunctions also come into view, which may explain why the pressure in the heating system increases. If you do not regularly check the pressure readings in the system, then inconspicuous problems can cause expensive repairs.

- If the fittings are blocked, then at the time of intake the pressure will increase, and the control sensors will block the equipment. To avoid consequences caused by this reason, during startup it is necessary to inspect the valves and taps to ensure that the valves are in good condition.

- Dirt and rust that gradually accumulate in the system can clog the mesh filter. Therefore, you should either clean this element regularly, and if washing the filters does not help, then you should install a washable or magnetic filter. With the correct design of such elements, the pressure does not rise above the permissible level.

- A controller or thermostat can fail, and problems with automation lead to negative consequences. The cause may be either premature wear or a manufacturing defect. In addition, a malfunction of these elements can be caused by an incorrect connection.

Such problems can be identified in a timely manner only if the readings of control devices are systematically monitored. They are not capable of dramatically disrupting the operation of the system, but are capable of gradually changing the indicators, leading to the critical point at which the boiler operates under load.

Finding a damaged node and troubleshooting

To identify a leak in a closed heating circuit, it is necessary to inspect the detachable and permanent elements of the pipeline and radiators, control water taps, threaded connections, welding and soldering points, and the Mayevsky tap for integrity.

If you notice an accumulation of water under radiators, pipes, etc., determine the cause of its appearance. Puddles can form under threaded connectors (with sudden temperature changes, this type of connection spontaneously unwinds), poor-quality soldered or welded seam, or parts with microcracks. To stop the leak at the threaded connection, it is enough to pull this unit. In rare cases, the sealing insert needs to be replaced. To inspect a part or area with a defect, you should partially or completely drain the water from the heat supply line. There is a direct relationship between the leakage of the make-up tap and the pressure in the central water supply. When water pressure increases or decreases, the pressure in the boiler also changes, although the boiler feed valve is in the closed position. Typically the pressure in the central pipeline is 0.5 - 3 bar. If you do not find a leak in the heating circuit, monitor the change in pressure in the boiler and the central pipeline. If a direct relationship is identified, replace the feed tap (in non-separable models) or change the sealing collar (in models with a removable rod).

Sometimes, for some reason (outdated model, lack of opportunity to purchase, etc.), it is not possible to purchase a new valve, then you can connect the pipes: cold water supply to the boiler and return from the heating circuit, using conventional shut-off valves.

Schematic placement of the heating system feed tap.

In this case, the standard feed tap must be in the closed position and not let water through. If it is very worn, it must be dismantled, the stem raised, the internal holes filled with silicone and the valve set to the closed position. Mount the tap in its original position and no longer use it for its intended purpose. But these manipulations should be performed only in extreme cases.

The pressure in a closed heating system also changes due to a large amount of air not removed from the system. Although modern boilers are equipped with automatic air vents, they can malfunction due to scale build-up. Carefully inspect the air vent for any foreign deposits. It is usually located near the circulation pump.

Air vent for wall-mounted gas boiler.

If there is scale, clean the air vent. Using a flathead screwdriver, lift the cap and turn on the pump in circulation mode. If such a function is not available in your boiler model, start the boiler in heating mode. All the air will come out of the pipes and radiators. Also, air can be removed through Mayevsky taps, which should be equipped with all heating radiators at the top point.

Mayevsky tap at the top point of the heating radiator.

Violation of the integrity of the membrane, spool, as well as a decrease in pressure in the air cavity of the make-up tank leads to a dynamic change in pressure. Before examining the condition of the expansion tank, determine its installation location. To check the tightness of the membrane and the mechanism for pumping air, unscrew the cap from the spool valve.

Signs of a leak in the expansion tank membrane.

The presence of water inside the valve indicates damage to the membrane. In this case, since the tank is sealed, it becomes unsuitable for repair and must be replaced with a similar one. The appearance of bubbles from the working hole of the distributor wetted with liquid indicates wear of the spool sealing ring. Tighten the valve core or replace it.

The listed measures have been tested and are effective ways to restore stable coolant pressure in a closed heating circuit.

When renovating a room or installing a heating system in it, the question arises of how to choose an electric heated floor and in what cases it is used.

Why does the pressure in the boiler drop?

The most common consequence of malfunctioning heating systems is a loss of pressure in the circuit. There are a number of common reasons why the pressure gauge will show a drop in pressure:

- violation of the functionality of the expansion tank;

- power outages;

- a leak formed in the heating circuit;

- incorrect calculations when choosing a boiler for a given room.

When the pressure in the boiler decreases, water stops flowing. If the gas pressure decreases, the automation will stop the boiler. To prevent breakdowns that occur every time at unexpected times, first of all, it is necessary to systematically monitor the operation of the system.

At the end of the heating season, you should regularly carry out diagnostics and, if necessary, repair the equipment, this will allow you to keep the pressure not lower than the minimum level.

If there is no expansion tank

The expansion tank for a home heating network is the second most important element (after the boiler). Water, when temperature changes, changes in volume. The volume inside the circuit is always constant, so an expansion tank is additionally connected to the circuit, where excess coolant can be diverted, i.e. acts as a compensator. Consequently, the RB is a safety device that prevents emergency situations - increased pressure, depressurization of pipes, etc.

The use of boiler equipment without an expansion tank is highly not recommended.

For stable operation, the pressure of the RB must correspond to the system volume, because when replacing radiators with pipes, the volume of coolant must be increased. At the same time, a too large RB will not maintain the operating pressure in the circuit.

The standard is an expansion tank designed for 120 liters of coolant in the circuit (typical two-room apartment). If the tank is too small, then the water will be discharged when heating and expanding the volume through a safety valve. When the boiler is turned off, when the liquid temperature decreases, starting the boiler will be impossible, because its volume, and, consequently, the pressure will be insufficient. In such cases, additional network feeding is necessary.

https://youtube.com/watch?v=tgwLKEVRgYk%3F

How does the operation of a hydraulic accumulator affect pressure?

Problems with the expansion tank that affect the pressure in the heating circuit are very common. Incorrectly calculated volume of the expansion tank is one of the most characteristic prerequisites.

Malfunctions can result from improper installation, low or high pressure in the air chamber of the tank, a damaged membrane - each of the reasons can lead to disruption of coolant circulation in the system.

Expansion tank: device features and volume

If a small volume tank is installed in the heating system, it cannot compensate for the expansion of heating water when heated. At a temperature of 85-95 °C, water expands by approximately 4% and its excess volume exits through the safety relief valve.

In order for the expanzomat to fully perform its compensatory function, its capacity for systems with a gas boiler must be at least 10 percent of the total volume of water in the circuit.

If you install a tank with a larger volume than normal, the pressure fluctuations will be even smaller. Reducing pressure differences has a positive effect on the operation of the system and the service life of heating equipment

Damage to the tank membrane leads to water completely filling its volume and the pressure in the circuit drops. If you fill the volume of the circuit by opening the make-up valve, this will create a new problem - when the coolant heats up, there will be no room for it to expand and the pressure in the system will increase more than normal. The situation can only be corrected by replacing the rubber partition.

The tank should only be installed on the return pipe, in front of the heating boiler. This way the tank will have minimal impact on the operation of the circulation pump, which is installed after the gas boiler. In addition, here the water temperature is lower and the negative impact on the pressure in the system and on the tank membrane will be less.

Setting the pressure in the air chamber

The pressure formed in the air chamber of the expansion chamber can also lead to an increase or decrease in pressure inside the heating system. You can check and pump up the air in the tank only if there is no coolant in the tank.

To do this, you need to shut off access to the common circuit using shut-off valves and drain the water through the drain. Then the pressure in the air chamber is measured and inflated/lowered to the required values.

You can check the pressure in the expansion tank using a car pressure gauge, and pump it up using a car pump.To set the pressure of the expansion tank in the air chamber, it must be 0.5 bar higher than the expected maximum pressure in the system. After the pressure in the equalizing part of the tank is adjusted, fill the circuit with cold water to the expected pressure value.

Then the air is released from the air chamber until the pressure in the heating circuit and the tank begins to decrease simultaneously - here it is necessary to simultaneously monitor the pressure in the system and in the expansion tank.

In this phase, changes in indicators are little noticeable, so you must be prepared to immediately stop bleeding air from the expansion tank as soon as a simultaneous decrease is detected.

Preventing the formation of air jams

Preventative measures against the occurrence of air locks are as follows:

Pay attention to the correct installation of pipes and connections of heating devices

Many problems are caused precisely by mistakes made at this initial stage. To prevent air locks, proper commissioning of the equipment is necessary, before which it is important to first check all components and connections. Before putting devices into operation, check them for operability. Using a compressor, you need to apply a pressure level that is ¼ higher than its normal operating value. If it does not weaken within 30 minutes, then everything is in order and the system is ready for operation.

If the pressure drops sharply, then leaks are possible, which should be promptly identified and repaired before starting operation.

Watch a video on how to restore normal boiler pressure