The gas heating system chosen for heating a home has a large number of parameters. Choosing the right boiler among the offered models, taking into account the climatic characteristics of the area where you live, is quite a complex engineering task. First of all, it is necessary to distinguish among the selected equipment groups that are fundamentally different from each other in parameters. Among them, two large groups of boilers stand out:

…

- With an open combustion chamber,

- With a closed combustion chamber.

Each of these groups has its own pros and cons, and certain requirements for placement.

Let's look at the advantages and disadvantages of boilers with a closed combustion chamber.

Features of the device and principle of operation

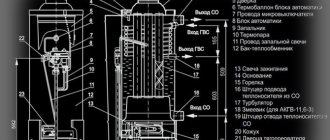

A gas boiler with a closed combustion chamber is a device that operates regardless of the presence of natural ventilation. Structurally, it is a metal casing, inside of which there is a burner, a heat exchanger and a coaxial pipe. Some models can be equipped with a built-in boiler and circulation pump.

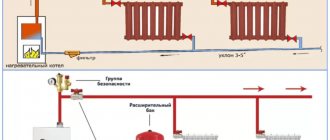

A coaxial chimney is a must for closed boilers. It consists of pipes of different diameters inserted into one another. Through the larger one, air from the street enters the boiler; the smaller pipe serves to remove exhaust gases from the room. This arrangement of boilers made it possible to use them even where there is no natural ventilation.

The coaxial pipe is laid horizontally through the wall and brought out. In this case, a vertically routed pipe is not necessary, because Air injection is performed forcibly due to the operation of the built-in fan. He is also responsible for removing combustion products.

Gas combustion is carried out by forced-air burners. The combustion intensity is adjusted in parallel with the fan rotation speed. Gas consumption is minimized due to the optimal ratio of the mixture of gas and air, which is achieved taking into account the pressure in the overall gas pipeline system.

The heat exchanger can be steel, cast iron or copper. Through it, the energy from the burned fuel is transferred to the coolant. The best performance indicators are shown by cast iron elements, because... They are resistant to high temperatures and are not subject to corrosion, so they will last longer than steel or copper.

Control sensors for a closed gas boiler

Using control sensors, the necessary parameters are set: temperature, amount of water used for heating, power, etc. The built-in protection system will prevent the boiler from burning out if there are interruptions in water supply or the burner flame is blown out.

Rating of the most popular models

It included the following units:

- Single-circuit parapet unit “Lemax Patriot 6” without pressure control. It has a power of 6 kW and an efficiency of 87%.

- Aton Compact 7E (mini). Produced by a Ukrainian company and demonstrates 90% efficiency. Its thermal power is 7 kW.

- “Lemax Patriot 16” without USD. Thermal power is 16 kW, and efficiency is 87%.

- Baxi Slim 1.230 FiN. Has a power of 22.1 kW.

- Sime RX 26 BF. 31-kilowatt boiler with an efficiency of 91.1%.

The listed models are in great demand in the domestic market.

Pros and cons of gas boilers with a closed chamber

Closed boilers have many advantages over open devices. The user does not need to make any effort to provide heat in the house. The following advantages of such devices can be highlighted:

- no separate room is required for installation. Installation is possible in any place where there is a supply to a gas pipe and an electrical outlet;

- exhaust gases exit through a pipe laid through the wall, and not through a vertical chimney, so there is no need to equip it;

- The boiler operates using electricity and does not depend on natural ventilation;

- the functionality of heating equipment does not affect the oxygen level in the room, because all his activities are carried out outside;

- Due to the intake of air from the street, closed units have high efficiency, are characterized by complete combustion of fuel and save fuel consumption.

The disadvantage of closed boilers is their dependence on electricity. If for some reason there is no electricity, then in severe frosts the house may freeze. There is also a possibility of freezing of the combustion chamber due to the short coaxial pipe.

Types of closed gas boilers

When choosing a gas boiler, you need to take into account what tasks it must perform, as well as the size of the room. Depending on the functionality, power and dimensions of the heating device, they are divided into single-circuit and double-circuit.

Single-circuit closed-type boilers perform only the heating task. Because of this, they have a lower cost. They can be either wall-mounted or floor-mounted.

Double-circuit boilers are divided into devices with separate ducts and a bithermal heat exchanger made in the form of a coil. Inside the main pipe there is a pipe for hot water supply. Water in the circuits flows in opposite directions. Thanks to a boiler with two circuits, there is no need to purchase a boiler, because its job is not only to heat the house and supply hot water for domestic needs.

Closed double-circuit gas boiler

The disadvantages of some models of double-circuit gas boilers with a closed combustion chamber are that the supply of hot water depends on the pressure in the centralized water supply. The weaker the pressure, the less heating the liquid will be. The temperature will also be low if you open two taps at once, for example, in the bathroom and kitchen.

In addition to the number of circuits, boilers are divided according to the installation method into floor-mounted and wall-mounted. The difference between floor and wall devices is in the method of their installation and size. For floor-standing ones, more space is needed, and maybe a separate room. The cast iron heat exchanger adds additional weight to the boiler, but it also extends its service life to 25-30 years. The high power of floor-standing models may be excessive for heating a small apartment or one-story house, so it is more rational to install such devices in at least a two-story building.

Wall-mounted units are more compact; they can be placed even in a small kitchen or bathroom. Heating equipment hung on the wall can be easily hidden in the kitchen unit, thereby making it part of the interior.

Floor standing boilers

Additional space may be required to accommodate floor-standing boilers, as they have greater power and are larger in size than wall-mounted ones.

Floor-standing boilers, advantages:

- The heat exchangers in them are made of cast iron, which increases the weight of the product, but has a long service life - up to 30 years. Other inexpensive parts are easy to replace during operation;

- A chimney with increased draft is not required.

Minuses:

- Due to the cast iron heat exchanger, it takes up a lot of space on the floor, since the weight and dimensions do not allow the boiler to be hung on the wall;

- It is necessary to purchase and install an expansion tank, the heater is connected;

Criteria for choosing heating equipment

The comfort of people living in the house for several years will depend on the purchase of gas heating equipment. When choosing a particular model, you need to pay attention to the following parameters:

- the power must correspond to the area of the heated room;

- electricity stabilization options: voltage generator or uninterruptible power supply;

- the number of people living, on which the consumption of hot water depends;

- DHW options - from the boiler circuit or by connecting an indirect heating boiler;

- water hardness, which determines the possibility of installing a bithermal boiler;

- the distance between water intake points, on which the efficiency of the gas boiler depends.

Calculation of the required power must be carried out taking into account heat loss through ventilation and building structures.

Principle of operation

A boiler with a closed combustion chamber operates through forced air intake. Inside the main unit there is a nozzle and a special compartment that supplies air from the outside.

Between the walls there is a liquid that heats up during gas combustion. To remove by-products from the operation of the unit, a smoke exhaust duct and pressure from the supercharger are used.

Installation nuances

Installing a closed-type gas boiler will not cause difficulties, but it is better to leave this work to a specialist. Depending on the selected type of equipment, installation is carried out with fixation on the floor or mounting on the wall. In both cases, the boiler is connected to the heating system and other communications, and piping is performed. The coaxial chimney duct is led out into the street in the shortest way - horizontally. In this case, you need to maintain a slight slope in the direction opposite to the boiler. In cases where the heating device is located in a room that does not have an outer wall, the pipe is led up through the roof. A sleeve is mounted into the wall through which the pipe is passed. The seams are sealed with a sealant that is resistant to high temperatures. Internal connections of the pipe to the device are carried out according to the instructions. At the end of this stage, the installation of the gas boiler can be considered complete.

Features of operating a closed gas boiler

Any equipment, despite its quality, can fail and the reason for this is improper operation. There are several functions for safe use of the boiler, which almost all models are equipped with:

- temperature control of incoming liquid;

- post-circulation of coolant. The pump does not turn off immediately after shutting off the gas, but runs for some time and circulates water around the circuit. If this does not happen, the liquid in the heat exchanger will simply boil;

- summer mode. In summer there is no need for hot water for heating, but it is needed in everyday life. To ensure this, the boiler heats it through a three-way valve and two heat exchangers. To prevent stagnation inside the heating system, the circulation pump turns on once a day and circulates water through the circuit;

- antifreeze. It is necessary to maintain a stable temperature in the house, approximately +5 degrees, when no one lives in it.

In case of any breakdown, you should immediately contact the service center and do not try to fix the situation yourself.

Rating of the best boilers with a closed chamber for heating

Today you can find a wide range of heating devices on sale, varying in their characteristics. We invite you to familiarize yourself with the rating of the best gas boilers from foreign and domestic manufacturers.

- Wolf CGG 1K 24 is a wall-mounted boiler with two circuits and a power of 24 kW. Can heat an area of up to 180 square meters. The maximum heating temperature is 80 degrees, hot water - 60 degrees. The boiler operates efficiently in any conditions, even with constant power surges and a drop in gas pressure.

- Navien DELUXE 24K is a double-circuit boiler with automatic control. The protective chip is triggered when pressure and voltage deviate by 30% from the norm. The boiler is designed to heat water at a speed of 13 l/min. Switching between the column and the boiler is performed manually or automatically.

- Hephaestus LUCKY STAR - a domestic device will provide heat even if the gas pressure in the system drops. The boiler is easy to operate, and a small number of controls reduces the risk of breakdowns. The package includes weather-dependent automation, a control system connected to apartment temperature sensors and a security group. Water is heated at the rate of 13.3 l/min.

- Baxi Luna-3 Comfort 240 Fi is a double-circuit boiler with the option of being mounted on a wall and can operate even with reduced gas pressure. The device is equipped with a wireless control panel, which can be hung in a convenient place for use. A boiler can be connected to the boiler as additional equipment.

- Protherm Gepard 23 MOV is dual-circuit, has an efficiency of up to 93.2%. Productivity is 11 l/min. The front panel is equipped with an LCD display, which makes it easy to adjust the operation of the equipment. The boiler operates in three modes: comfort, winter-summer and warm floor. It can operate on both liquefied and main gas.

- Bosch Gaz 4000 W ZWA 24-2 A - heats the room and heats the water. The temperature of the water and coolant in the circuit is changed using a power regulator. Capable of heating a house up to 240 square meters. Reconfiguring the boiler will allow it to operate on liquefied fuel.

- Ariston CLAS B 24 FF is a compact wall-mounted boiler that can be installed even in a small room without taking up useful space. Capacity is 20 l/min. It has a built-in 40 liter boiler, thanks to which there will be a constant supply of hot water. The boiler is controlled using a digital display.

Closed gas boiler Wolf CGG 1K 24

Gas boilers with a closed combustion chamber are the best option for efficiently heating your home. The range of models allows you to select equipment that fully meets the individual needs of the user.

Similar

| Basic concepts of ergonomics, design, artistic design. Main types of correspondence between man and technology taken into account when designing cars. | Interstate standard unified system of design documentation main provisions types and completeness of design documents GOST 102-68 ipk publishing house of standards This standard establishes the types and completeness of design documents for products of all industries |

| 1. Conceptual foundations of strategic analysis The concept of strategy and types of strategies. Management, main types of management and stages of its development. The concept of the organizational environment as an object of strategic analysis. The subject of strategic Strategic analysis is a normative discipline provided for in the curriculum for the preparation of masters in the specialty “Accounting and... | Hydrogen is expected to be used as automobile, aviation and rocket fuel, as well as fuel for gas turbines and gas turbine units. For example, the fuel supply in the form of liquid hydrogen is 3-4 times less in weight than traditional fuel, which increases 2.5 times... |

| Test questions for the discipline “Fundamentals of Management” The essence and content of the term “management”, the main types of management and their characteristics | List of questions for testing in the discipline “Fundamentals of Ergonomics and Design” Main types of correspondence between man and technology taken into account when designing cars |

| Guidelines for performing laboratory work in the discipline Cover fuels with a sulfur content of up to 2%, the second - fuels with a sulfur content of 2 to 3.5% | Low-energy-intensive technology for the production of foam concrete c. N. TarasenkoAnalysis of heat consumption showed that about... |

| Group T58 state standard of the Union of the USSR This standard establishes the main types of fire fighting equipment designed to protect enterprises, buildings and structures from fires... | Changes in the properties of soils under the influence of external factors: the main types of technogenic impact on soils and their classification. Destruction, chemical transformation, compaction and other impacts occur, as a result of which the physical and mechanical properties change... |

Documents

Documents