Modern solid fuel stoves have long been used as the main equipment for heating private houses and baths. And if the basic operating rules are observed, the costs of their maintenance are minimal.

To ensure the efficiency and duration of the combustion process, as well as reduce fuel consumption, every homeowner should know how to fire a stove with coal.

Is it possible to fire a stove with charcoal?

Coal is used to fire stoves and boilers - stone, wood and brown. Hard coal has the highest energy value, brown coal has the lowest energy value. Wood is less often used as the main fuel material, although its specific calorific value is higher than that of firewood or fuel briquettes.

The benefits of charcoal are as follows:

- During the combustion process, no unpleasant odors or smoke are released.

- Does not contain hazardous components.

- Has a high calorific value.

- Burns longer than other fuels.

- Does not crumble during transportation.

Despite all the advantages, fuel has a significant drawback - high cost. So, for 1 kg of charcoal you will have to pay twice as much as for the same volume of hard coal. You can reduce the cost of purchasing raw materials by making them yourself. To produce 1000 kg of charcoal, you will need to burn 10 cubic meters. m of wood.

It is possible to use charcoal to kindle heating equipment, but it is not economically profitable.

Important points

Today, several types of this solid fuel are known:

A well-built stove is designed for a specific operating temperature. It is not advisable to deviate from this value. To maintain such indicators, you need to heat the stove only with a certain type of fuel: wood or “local” coal.

Standard brick devices can operate on almost any fuel. There are no problems with this.

When firing a furnace with coking coal, you must not miss the moment of its coking. To avoid getting burned, you need to fully open the ashpit and use the poker more often.

Types of coal

Such fuel is a rock consisting of a carbon compound and non-combustible components that, when burned, form ash. In different regions there are deposits with different amounts of impurities.

Depending on the level of specific heat of combustion, humidity and age of impurities, the following types of fuel are distinguished:

Lignite

A young type of coal with a specific calorific value of no more than 2.8 thousand kcal/kg. The raw material has a loose structure and a high percentage of ash formation. Lignite ensures the operation of industrial facilities - plants, factories, power plants, but is poorly suited for domestic use as fuel.

Brown coal

Product of the transition phase between black lignite and coal. During the combustion process, it forms a large volume of ash and coking derivatives. The calorific value of the fuel is 5 thousand kcal/kg. With an average humidity of 50%, the raw material is used for industrial boiler houses and chemical production plants. Due to the rapid clogging of the chimney system and heat exchanger, it is not recommended to burn household stoves and boilers with brown coal.

Coal

High-quality fuel with a calorific value in the range from 5 to 5.7 thousand kcal/kg. It is an intermediate link between brown coal and anthracite. It contains about 70% carbon and only 3% ash. Due to low humidity (20%), the raw material is not used for gas generating units, but is suitable for most models of household boilers and stoves.

Hard coal is divided into two groups:

- Long flame. The fuel is suitable for most domestic heating installations, provides a high flame and long-lasting combustion, and does not require additional blowing. You can use a small amount of wood or wood chips to light it.

- Low caking. The raw materials are suitable for heating a private home, bathhouse or industrial facilities. It is characterized by high thermal conductivity and lack of caking. The combustion process takes place without flame or smoke.

Anthracite

The best type of fuel raw material with a dense structure and rich black color with a calorific value from 7.1 to 9 thousand kcal/kg. At a relatively low level of humidity (7%), anthracite forms a small amount of ash, which is removed from the heating equipment along with gases. It comes in different sizes: small as a seed, medium as a pea, and large as a fist.

As a result of the release of a large amount of heat, heating of rooms with anthracite occurs quickly and efficiently.

User reviews

Igor writes:

I have a brick stove equipped with fireclay lining. I recently fired up the unit with DPK coal. I want to say thank you to the company that sold this fuel. Even when raw, it burned perfectly, which surprised me very much.

There was no need to use coal before. I expected intense heat to appear and the radiator to instantly boil. It seemed that because of the coal, the grate would quickly burn out, the underside would fail, and the foundation of the furnace would have to be restored. It's good that all my fears were in vain.

Only one small bookmark smoldered much longer than the firewood. The flame was calm and even. The burning coals had a normal color. Nothing happened to the grate bars: they did not melt, no deformation occurred. The coal burned completely, leaving only ashes. Now you need to check the ash pan for the presence of ash and the formation of slag.

From now on, I will definitely add several small coal stones to the firewood in my “Sudarushka”. I have never seen a red-hot pipe before.

Oleg's opinion:

I made a homemade construction like a potbelly stove, with a firebox height of 42 cm. I lit the unit infrequently for five years. After they started heating it weekly, it worked properly for another 24 months. Then the equipment burned out in the place where the smoke duct comes out.

The heating device was repaired by scalding the pipe using a filler rod. The equipment worked for another year.

I recently replaced my old one. I made the stove myself from a pipe with a diameter of 530 mm and a steel casing made from a sheet 6 mm thick. The device was equipped with a cast iron grate purchased from a store.

The first fire was fired with coal unknown to me. Later I learned that I used stone fuel from the Kansk-Achinsk basin. Its negative side is strong caking: all the coals are covered with a caked crust, and the heat goes down and hits the grate.

While stirring the fuel, I noticed that the grate was so hot that it turned white. This has never happened before. However, I did not notice any deformations or breakages.

Currently, I use long-flame raw coal to fire the furnace. I decided not to use firewood anymore. It is much easier to bring home several buckets of solid fuel than to prepare a huge stack of logs for the winter.

Konstantin:

We have a Russian bathhouse. To kindle it, we use firewood and add a small amount of coal. The result is intense heat, the heat lasts much longer.

Anton:

In my opinion, you can heat the stove with coal, and for those who like the smell of firewood, I advise you to throw a few logs into the firebox at the end of the fire. The only problem when igniting a stove with coal is the combustion temperature - 900-1300 °C. Wood smolders at temperatures of 800 °C.

To constantly burn coal, you need to have an appropriate stove.

From my own experience I was convinced that equipment lined with ordinary clay bricks would burn out in a few months. A tin stove will fail much faster.

To burn with coal, you need to install special equipment, for example, a steam boiler. First you need to heat the device with wood chips, and only then add coal to it in small portions.

What kind of coal burns for the longest time?

Often, long-flame coals are used to heat private homes, which are suitable for any type of solid fuel boilers, stoves and fireplaces. This is due to their long combustion process, rapid combustion and high calorific value. Charcoal for the firebox is easy to use and burns for a long time due to the formation of a flame with long tongues.

The combustion process of one load of fuel lasts several hours and contributes to the release of a large amount of thermal energy.

In addition, it is cheaper than anthracite, so it is used as the main fuel for heating government buildings. Marked with the letter "D".

The best known manufacturers and models: characteristics and prices

Recently, Russian coal boilers have become increasingly popular: their quality is constantly improving, and the cost remains quite low compared to foreign analogues. However, boilers from European manufacturers are still the most functional and automated.

Please note that almost all models have different power versions

Direct combustion

ZOTA "Master" 20

ZOTA “Master” with a power of 20 kW is a very budget-friendly insulated (basalt cardboard) boiler that can withstand pressure up to 3 bar and runs on almost any fuel: coal, wood, pellets and gas (optional). It also uses electricity as an auxiliary heat source (TEH).

Country of origin: Russia, LLC TPK KrasnoyarskEnergoKomplekt.

Cost: 25,690–31,889 rubles.

Protherm “Beaver” 20 DLO

Protherm “Beaver” with a power of 20 kW is a non-volatile boiler with an operating pressure of up to 4 bar, which has an increased service life because it uses a high-tech (GG20) cast iron heat exchanger that is resistant to corrosion and thermal shock. You can only burn with various types of coal and wood.

Country of origin: Slovakia, Vaillant Group LLC (Vailant Group rus).

Cost: 67,600–68,445 rubles.

Bosch "Solid" 2000 B SFU 12

Bosch “Solid” 2000 B SFU with a power of 13.5 kW is a simple, reliable boiler designed for the use of brown coal, but can also burn coal, coke, firewood and wood waste. Equipped with a built-in pressure control device (no more than 2 bar), thermal protection and gas swirlers.

Country of origin: Germany, Bosch LLC (Bosch Thermotekhnika rus).

Cost: 48,764–51,436 rubles.

Long burning

Stropuva S15U

Stropuva S15U with a power of 15 kW - thanks to the volumetric firebox that can hold up to 240 kg of coal, this innovative boiler is an unsurpassed leader (among compact devices) in terms of burning time on one fill: up to 7 days. Consumes coal, pellets, briquettes and firewood, at a maximum pressure of up to 3 bar.

Country of origin: Russia–Lithuania, STROPUVA LLC (STROPUVA).

Cost: 81,500–99,778 rubles.

Buderus "Logano" S181-15 E

Buderus “Logano” S181-15 E with a power of 15 kW is one of the best automatic bunker coal boilers for heating a private home, with built-in water and gas temperature sensors. The improved heat exchanger design ensures long-lasting combustion of coal/pellets and can withstand pressures of up to 3 bar.

Country of origin: Germany, Bosch LLC (Bosch Thermotekhnika rus).

Cost: 252,000–258,840 rubles.

LIEPSNELE L20U

LIEPSNELE L20U with a power of 20 kW is an almost “omnivorous” solid fuel unit that consumes coal, firewood, coal briquettes and pellets, peat, wood shavings, other wood waste, etc. When fully loaded with coal, it maintains combustion for up to 7 days. The pressure level is limited to 1.5 bar.

Country- UAB (Vakaro Rasa).

Cost: 85,449–90,456 rubles.

Galmet "CARBO" 21

Galmet “CARBO” 21 with a power of 22 kW - a Polish semi-automatic coal-fired boiler already in the basic configuration has quite a lot of equipment: a smart PID controller that controls all components of the boiler and controls the combustion process, a flue gas sensor, a thermometer and a pressure gauge. Pressure limit – up to 2 bar.

Country of origin: Poland-Russia, GALMET LLC (GALMET-RUS).

Cost: 113,890–116,759 rubles.

Improved combustion process

The intensity of fuel combustion in the stove is regulated by the volume of air entering the fuel compartment. You can properly regulate the air exchange in the firebox using a blower and a viewer.

The intensity of combustion can be determined by the color of the flame. Too much air results in a white flame and a humming furnace, while too little air results in a red flame and black smoke.

Normal combustion mode is an orange or golden flame with transparent smoke.

To improve the fuel combustion process, it is necessary to adjust the chimney view. Insufficient opening of the view leads to the penetration of carbon monoxide into the room, excessive opening leads to heat loss and poor heating of the heating equipment.

The selection of the optimal combustion mode is carried out taking into account the operational characteristics of the stove or boiler, as well as the type of fuel.

Features of kindling in winter

How to properly heat a coal stove in winter? In winter, cold air creates a special draft. It prevents smoke from escaping into the street.

- To ignite the stove in severe frost, you can use improvised means.

- If you have a hair dryer, take it.

- Close the ash pan door, open the firebox and valve.

- Preheat the oven for a few minutes and proceed with normal operations.

- After heating, smoke will not go into the room, and the fuel will ignite.

Is it possible to leave dead coals in the stove?

Many homeowners are interested in a completely logical question - what to do with the extinct coals that remain after fuel combustion?

After finishing the fire, you need to make sure that all the coals are really extinguished and do not give off flames. Extinguished coals can be left in the fuel compartment until the next filling. They will help you quickly and easily light up an already cooled stove and reduce overall fuel consumption. At the same time, it is recommended to complete the process of heating a potbelly stove or boiler 1.5 hours before going to bed or leaving the house.

If there is no free time for the fuel to burn out, the remains are laid out in a free container and filled with water.

Where to buy a coal boiler for heating a private house

In Moscow

- Comfort-Eco, Dmitrovskoe shosse, 100, building 2, tel. +7 (495) 921–37–61.

- My Boiler, Volokolamskoe highway, 116 building 2, tel. +7 (495) 221–56–79.

In St. Petersburg

- TechnoDom, Stachek Ave. 57, Komsomolskaya Square, tel. +7 (812) 671–00–88.

- Kit-Teplo, st. Litovskaya 8, +7 (812) 295–00–05, +7 (812) 248–18–88.

To summarize, it is worth saying that coal boilers are the “golden mean” between ease of use and fuel costs, so if the house is not connected to the gas main, then its installation is completely justified. Even better is the automatic version: it will help you survive even the harsh winter in comfort.

What is more profitable: wood or coal?

Why is it more profitable to use coal than firewood for heating rooms in winter and organizing hot water supply?

Firewood is much cheaper than coal; it seems that it is economically profitable to use it. But is this really so?

The main parameter of choice is the calorific value of the fuel material, i.e. the amount of thermal energy that is released during its combustion.

Firewood has a low level of heat transfer in the range from 1400 to 2500 kcal. High calorific value is provided by raw materials from oak, alder and birch, low - from pine, spruce, white alder and linden.

When determining the calorific value of firewood, one should take into account its moisture level, which should not exceed 15%.

Coal of various grades is capable of releasing from 5000 to 9000 kcal of thermal energy, which is several times higher than that of firewood.

Firewood will be cheaper than coal, so 1 kW of energy obtained by burning it will also be cheap. In this case, the volume of thermal energy when burning 1 ton of raw materials will be: for coal - 6.46 Gcal, for firewood - 3.44 Gcal.

Heating a boiler with coal is beneficial for the following reasons:

- low fuel consumption;

- high heat transfer;

- burning duration.

The main disadvantage is the formation of slag and unpleasant odor during the combustion process.

The main reasons why it is profitable to heat a wood-burning stove or solid fuel boiler with wood:

- environmental safety of raw materials;

- affordable price;

- possibility of storage in bulk or boxes;

- a small amount of ash and no unpleasant smoke.

Despite its cheapness, firewood has a lower calorific value, which means burning with coal is more efficient and profitable.

Coal heating equipment

Coal ovens

A conventional stove can only heat one or two rooms, even if you use coal rather than wood to heat the house. True, it can be improved by embedding a heat exchanger for water heating inside the brickwork. The stove is good in its own way, but sometimes it can be dangerous due to the fact that it provokes carbon monoxide poisoning.

Important. The stove chimney valve can be closed only after the coal has completely burned and the flames have disappeared from the firebox.

For heating a cottage with coal, a heating unit such as a boiler is much more efficient, reliable and safe.

Coal solid fuel heating boilers

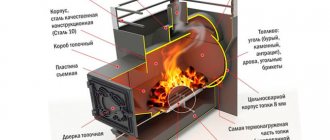

The diagram shows the design of an improved coal boiler

The design of a coal heating boiler is simple, but very effective. Its cast iron heat exchanger and powerful grate are resistant to burnout and corrosion. Even the simplest of these devices have been regularly heating homes for many decades. But still, old-style boilers are inferior in performance and heat transfer to their current competitors.

The operating principle of a heating boiler looks like this:

- as soon as a fire is lit in the firebox, a draft is created in the chimney and air is drawn into the fuel chamber;

- the coal heats up and partially burns;

- gaseous products of coal combustion are mixed with the secondary air supplied inside and finally burn;

- the resulting gases give up their temperature to the coolant and are then discharged through the chimney.

Modern coal-fired heating boilers consistently heat residential premises and outbuildings. They consume 2 times less fuel compared to outdated models. Advanced technologies have improved not only the design and design of heating units, but also the very principle of fuel combustion. As a result, now the homeowner does not have to load the next portion of coal into the boiler several times a day and remove accumulated slag.

The enlarged combustion chamber is designed for simultaneous loading of a large amount of coal, which gradually burns out over 6–12 hours. Forced air injection promotes the most complete combustion of fuel. Thanks to this, coal consumption for heating the house is significantly reduced.

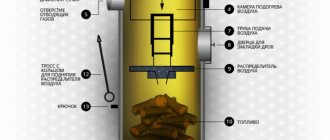

The large bunker of the automated heating boiler ensures long burning of coal

Automated fuel supply from the bunker to the boiler “frees the user’s hands.” He becomes free from the obligation to constantly monitor the operating heating device. The capacity of the bunker is enough for non-stop burning of coal for a week.

Reviews of coal heating demonstrate how satisfied users are with the practicality of automated coal boilers. It is very convenient to start the boiler at the beginning of the heating season, and throughout the winter just add coal to the bunker as it is emptied. You also don’t have to remove ash and slag too often, just a couple of times a month.

Lighting coal for heating in a boiler, especially anthracite, can be difficult for an unaccustomed person. First, the boiler is heated with wood or a special mixture, and then fine coal is added little by little. When combustion becomes stable, you can add anthracite in large portions. Exactly how much and how often will depend on the boiler model and will be more accurately determined in the practice of its use.

Do not use gasoline to ignite coal in a heating boiler!

What to do if the electricity in the house goes out? In this case, the automatic supply of coal to the fuel chamber of the boiler will be stopped. At the same time, the circulation pump will stop working, and water will stagnate in the heat exchanger. But the boiler will not boil, because coal combustion will go into low mode. Then, when power is restored, the coal will reignite.

Solid fuel boiler maintenance

Boiler maintenance measures boil down to the need to clean the heat exchanger and smoke exhaust channels. Soot settles on their surfaces, and this phenomenon reduces the efficiency of the heating unit by 15%. The frequency of cleaning a coal heating boiler can vary: old cast iron models have to be cleaned 2-3 times per season, and modern ones once every 2 years.

Alternative fuels

Today, the most popular type of fuel used for heating residential and industrial facilities is coal. If desired, it can be replaced with alternative raw materials:

Peat

One of the most efficient types of fuel raw materials. Peat is suitable for stoves with special fuel chambers that increase draft during its combustion.

The material is produced in pieces and pressed briquettes. Peat moisture levels range from 22 to 40%, which leads to the formation of large amounts of ash. In terms of its calorific characteristics, it is significantly inferior to firewood, which is the main disadvantage.

Pellets

Fuel pellets are produced from dry biomass (sawdust, wood chips, bark and wood dust) by hot pressing. These are small capsules whose humidity level does not exceed 10%, so they are an excellent fuel for a brick or metal stove.

Unlike firewood, pellets can burn for quite a long time, releasing carbon dioxide and water. They are distinguished by environmental friendliness, safety and high calorific value.

How to use solid fuel units correctly?

Coal boiler operation

The operating principle of a solid fuel boiler is known, and the issue of choosing the type of coal has been resolved. All that remains is to learn how to properly light the stove. There are several simple rules that everyone who chooses the described installations for organizing heating of a country house must learn.

Remember! First, the stove must be prepared for lighting, then fuel must be correctly loaded into it. During its combustion, the installation must be closely monitored, removing combustion products in a timely manner.

Let's look at all these points in more detail.

Preparing the stove for lighting

If the stove in a country house is used occasionally, before starting its operation, for safety reasons, it is necessary to exclude the presence of cracks inside the masonry.

Why are they dangerous? Through them, combustion products and carbon monoxide can enter the room, which must be removed outside using drafts. If such a defect is discovered, it must be eliminated before kindling by covering the cracks with a mixture of clay and sand. Otherwise, when heated, the cracks may increase in size even more. And this will lead to dangerous situations.

When inspecting the stove from the outside, we remove flammable objects away from it and clean it inside. We remove the ash and slag with a shovel, freeing the internal compartment. It is advisable to wipe the inner walls of the firebox with a dry cloth. If this is not done, then during kindling the dust will begin to burn, filling the room with an unpleasant odor.

The coal stove needs to be lit several times a day. The duration of one fire should not exceed two hours. For loading, it is better to use well-dried medium-fraction coal.

Note! Wet fuel produces steam when burned. It forms condensation, which settles inside the chimney

Mixing with soot, condensate forms coke, which gradually clogs the chimney passage, narrowing it. And this leads to problems with traction.

Do not use household waste or flammable liquids such as gasoline or kerosene to ignite coal. Do not leave the stove unattended while it is burning. This rule must be observed especially strictly if there are small children or animals in the house.

How to properly melt coal?

Laying solid fuel boilers

The stove must be lit as follows:

First, we place sheets of newspaper or any other dry paper on the bottom of the firebox. On top of it we place a layer of small wood chips. And on them we stack small firewood, for example, birch logs. To make them burn faster, they need to be folded in the form of a well or a small hut. Set fire to the paper. We close the oven door and open the ash pan. Using it, it is easy to control the intensity of fuel combustion. The stronger the air flow, the faster the stack of firewood burns out. After the firewood has completely burned out and only a pile of smoldering ash remains, you need to lay a 15-centimeter layer of fine coal directly on it.

Note! When opening the door to load fuel, be sure to close the vent. Note! Low-quality solid fuel tends to coke

Therefore, experienced stove makers advise laying a layer of coal with layers of firewood. Such a multi-layer cake will allow the unit to burn well and give off the maximum amount of heat.

When the 15-centimeter layer of coal burns out well, we place larger coal directly on it and build a cushion 60 cm high. It is useful to stir the burnt fuel thoroughly beforehand, which will improve air circulation and prevent caking of the coal mass. Coal can be placed by opening the firebox door.

Note! Low-quality solid fuel tends to coke. Therefore, experienced stove makers advise laying a layer of coal with layers of firewood.

Such a multi-layer cake will allow the unit to burn well and give off the maximum amount of heat.

To properly light the stove, it is better to do this - open the ash pan and let the paper with the wood chips burn out using natural circulation. This will allow the chimney to warm up well. As the fuel burns, the draft will increase, so you then need to close the ash pan and turn on the fan.

Why does smoke appear from a coal stove?

The stove is a complex structure that requires constant care, inspection and cleaning. This is a guarantee of safety and reliable operation of the stove, however, despite all efforts, troubles occur in the form of smoke. The main reasons for this situation may be a number of reasons:

- blockage in the smoke riser;

- the formation of cracks in the masonry, leading to a decrease in draft and temperature of exhaust gases, letting them into the room;

- quite strong cooling of the chimney;

- incorrect stove design;

- wear of the internal masonry.

Principle of operation

Due to the draft of the chimney, air enters the firebox and the fuel burns.

The resulting gases heat the walls of the firebox and transfer heat to the water circulating in the heat exchanger system. The heated coolant is supplied to the pipes, heats the house, and returns to the boiler. The gases then enter the chimney, where they maintain the temperature necessary to create draft. The most common coolant is water, but sometimes mixtures with antifreeze and antifreeze liquids are used. The smoke removal system includes thermally insulated pipes, which are sometimes supplemented with a forced ventilation unit.

Attention! It is forbidden to fire a regular wood-burning boiler with coal, since this type of fuel produces 2-3 times more heat than wood. Based on functionality, the equipment is divided into 2 groups:

Based on functionality, the equipment is divided into 2 groups:

- with one circuit - for heating the room;

- with two - for heating and organizing hot water supply.

Photo 1. Appearance and diagram with the operating principle of a coal-fired heating boiler.

There are classic (single-chamber) and pyrolysis boiler models. In the first case, traditional combustion of fuel in a chamber is implied, the efficiency of which is 70%. In pyrolysis models, coal and gases released during combustion burn in different chambers. The efficiency of such improved models reaches 92%. The fuel in them burns more efficiently with less soot and smoke.

Coal boilers are made of steel and cast iron. Steel models are most often bottom-burning devices and consist of welded elements. Cast iron - cast, characterized by high efficiency, less susceptible to corrosion and contamination. Long-burning devices have a vertical firebox, the fuel gradually burns from above, due to which they operate without additional loading for several days.