Following a failure of pressure in the heating system comes a problem - the quality of heating the premises in the house decreases. You can, of course, set up the heating once and for a long time, but this period will not be indefinitely long. One day, the normal pressure in the heating system will change, and significantly.

We will tell you how to keep the physical parameters of the coolant under control. Here you will learn how to ensure a stable speed of movement of heated water through the pipeline to the devices. You will understand how to obtain and maintain a comfortable indoor temperature.

The article proposed for consideration describes in detail the reasons for the pressure drop in closed and open systems. Effective balancing methods are given. The information presented for review is supplemented with diagrams, step-by-step instructions, photos and video tutorials.

Pressure in an open heating system

Unlike a closed thermal circuit, a properly constructed open heating system does not require balancing over years of operation - it is self-regulating. Boiler operation and static pressure ensure constant circulation of water in the system.

The density of the heated water following the supply riser is lower than the density of the cooled coolant. Hot water tends to occupy the highest possible point of the circuit, and cooled water tends to be at its very bottom.

The pressure required for water circulation is achieved by the pressure in the supply riser or by a booster pump (+)

The pressure developed by the water column in the supply riser promotes the circulation of the coolant and compensates for the resistance present in the circuit pipeline. It is caused by the friction of water on the inner surface of the pipes, as well as local resistance (turns and branches of the pipeline, boiler, fittings).

By the way, pipes of increased diameter are used to assemble an open heating system precisely to reduce friction.

To understand how to increase pressure in an open heating system, you must first understand the principle of achieving circulation pressure in the thermal circuit.

Its formula:

Rts = h • (ro-rg),

Where:

- Рc – circulation pressure;

- h – vertical distance between the centers of the boiler and the lower heating radiator;

- рг – density of the heated coolant;

- ro – density of the cooled coolant.

The static pressure will be higher if the distance between the central axes of the boiler and the battery closest to it is as significant as possible. Accordingly, the intensity of coolant circulation will be higher.

To achieve the maximum possible pressure in the heating circuit, it is necessary to lower the boiler as low as possible - into the basement.

The closer the radiator is to the boiler on the supply circuit, the better it warms up. Regulators allow you to distribute heat between all radiators of the heating system

The second reason for the drop in pressure in an open heating system is related to its self-regulation. When the heating temperature of the coolant changes, the intensity of its flow changes. By increasing the heating of water for the heating circuit on cold winter days, owners sharply reduce its density.

However, when passing through heating radiators, water gives off heat to the room atmosphere, and its density increases. And according to the formula presented above, a high difference in the densities of hot and chilled water helps to increase the circulation pressure.

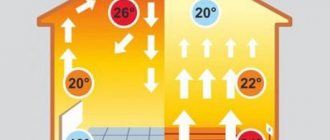

The more the coolant is heated and the colder it is in the rooms of the house, the higher the pressure in the system will be. However, after the atmosphere of the premises warms up and the heat transfer from the radiators decreases, the pressure in the open system will drop - the difference between the supply and return water temperatures will decrease.

Balancing a double-circuit open heating system

Gravity heating systems are made with one or more circuits. In this case, the horizontal length of each looped pipeline should not exceed 30 m.

But to achieve optimal pressure and pressure in an open system with natural coolant movement, it is better to make the pipelines even shorter - less than 25 m. Then it will be easier for water to deal with hydraulic resistance. In a circuit with several rings, in addition to limiting the length, the condition for heating radiators must be observed - the number of sections in all rings must be approximately equal.

Lack of pressure in an open double-circuit thermal system occurs due to design errors or contamination of the pipeline (+)

Balancing of the horizontal rings included in the vertical circuit is required at the design stage of the heating system. If the hydraulic resistance of any ring turns out to be higher than that of the others, the static pressure in it will not be enough and the pressure will practically stop.

To maintain the required pressure in a double-circuit heating system, it is necessary to reduce the cross-section of the pipes approaching the radiators. You can also install valves in front of the radiators that perform thermoregulation (manual or automatic).

You can balance an open-type dual-circuit system:

- Manually. We start the heating system, then measure the temperature of the atmosphere of each heated room. Where it is higher, we screw the valve, where it is lower, we unscrew it. To adjust the thermal balance, you will have to perform temperature measurements and adjust the valves several times;

- Using thermostatic valves. Balancing occurs almost independently; you just need to set the desired temperature in each room on the valve handles. Each such device will control the supply of coolant to the radiator itself, increasing or decreasing the supply of coolant.

It is especially important that the value of the total hydraulic resistance of the heating system (all rings in the circuits) does not exceed the value of the circulation pressure. Otherwise, warming up the coolant and attempting to balance the system will not improve circulation.

Circulation pump for open heating system

It happens that measures to balance the heating circuit of a gravity system have no effect. Not all causes of low pressure can be solved by adjustment - choosing the wrong pipe diameter cannot be corrected without a complete reconstruction of the circuit.

Then, in order to increase the pressure and improve the movement of water without significant modifications to the heating, a circulation pump or booster pumping device is installed in the system. The only thing that its installation will require is moving the expansion tank or replacing it with a membrane expansion tank (closed tank).

In case of a serious drop in pressure, not a circulation pump, but a more powerful booster pump is needed. However, booster pumps are not suitable for open heating systems, because develop significant dynamic pressure

The energy consumption of circulation pumps does not exceed 100 W. Therefore, there is no need to fear that it will push the coolant out of the circuit.

The volume of water in the heating system is more or less constant, provided that the filling of the open circuit is controlled. Therefore, no matter how much water the circulation pump pushes along the circuit in front of it, the same amount will flow into it from the return pipe.

By bringing the pressure in the thermal system to the required level, the pump will make it possible to lengthen it, reduce the diameter of the pipeline and achieve circuit balance with high hydraulic resistance.

Does water temperature play a role?

When the installation of the heating system is completed, working fluid is pumped into it (the system). The pressure is minimal - no more than one and a half atmospheres. But it will increase as the temperature of the liquid increases, since the latter will expand - this is explained by the simplest physical laws. It turns out that if you change the temperature, you can influence the pressure.

In order for the pressure to be regulated completely automatically, special expansion tanks are cut into the systems, which prevent excessive pressure build-up. The device automatically turns on after the pressure has reached two atmospheres. Excess liquid remains in the tank.

Note! It happens that the volume of the tank is not enough to get rid of all the liquid. But if the pressure exceeds 3 atmospheres, is it possible to do anything? Yes, you can, it is precisely for such situations that the safety valve was developed.

Conclusions and useful video on the topic

Video #1. How to balance heating radiators in a home heating system. Let us remind you that without valves on each heating radiator it will not be possible to balance the system.

Video #2. Recommendations from a heating engineer for restoring operating pressure in closed-type heating circuits. The video also explains the procedure for pumping an expansion tank that has lost its “factory” gas:

A properly balanced heating system will perform its functions for several years. But one day the characteristics of the coolant will change or critical elements of the thermal circuit will fail. Therefore, it is necessary to constantly monitor coolant indicators using pressure gauges in order to promptly respond to pressure changes.

Please write comments if you have any questions about the topic of the article. We are waiting for your stories about your own experience in normalizing pressure in the heating circuit. We and site visitors are ready to discuss controversial issues in the block located under the text of the article.

Leak test

Perhaps every resident of an apartment building knows how such a check is carried out. Specialists arrive (often before the heating season has begun) and check the system with a liquid pressure as close to critical as possible. This checks the efficiency and performance of the system.

Note! Often when carrying out such tests, pipes or radiators burst. Therefore, change all equipment in a timely manner so that such troubles do not arise.

You can find out how to change a heating radiator yourself here

At the highest and lowest points of the system, special devices are installed, from which the received data will be taken at the end of the test. You should also check the heating for leaks so that there are no breakdowns or leaks in the future.

This verification consists of two stages.

The first stage is cold testing

To begin with, all elements of the line are filled with cold liquid and a preliminary pressure measurement is made. Moreover, in the first half hour it should not drop more than 0.06 MPa.

Over the next two hours, the pressure drop should be a maximum of 0.02 MPa. If everything meets the requirements, then the heating system can be safely started.

Stage two – hot testing

It should be carried out immediately before heating starts. Hot liquid is launched under pressure, which should be extremely close to the maximum for a particular type of equipment.

Note! If you are hungry for better testing, then you need to contact one of the private companies. Its employees will not only take measurements, but also flush the pipeline (of course, they will have to pay extra for this).

Such tests allow you to check how efficient the heating system is in each of the multi-storey buildings. As already mentioned, they are carried out before heating begins, otherwise the consequences of malfunctions can be the most dire - even accidents.

Battery Performance

The abundance of various heating radiators that have flooded the modern plumbing market literally provokes consumers to replace outdated cast-iron heating equipment.

The criteria for their selection, first of all, are:

- material,

- operating pressure,

- nameplate thermal power,

- appearance.

At the same time, the possible difficulties of operating the purchased heating device as part of the unpredictable domestic central heating system are not taken into account at all. Foreign manufacturers of beautiful radiators made of aluminum or steel do not at all protect against water hammer when the pressure in the heating radiators jumps to 20-30 atm. corrosion of internal cavities when water is released for six months, from gas formation in aluminum radiators during the flow of coolant with copper impurities and sudden temperature changes. They simply do not have these problems, which cannot be said about the heating systems of our high-rise buildings.

Characteristics of cast iron radiators

- inertness to poor quality coolant;

- working pressure - 9 atm. pressure testing - 15 atm.;

- withstands coolant temperature of 120 0 C;

- disadvantages - afraid of water hammer.

Characteristics of steel radiators

- working - up to 10 atm.;

- coolant temperature - up to 120 0 C;

- well regulated by thermal valve;

- Disadvantage: They are not resistant to corrosion.

Characteristics of aluminum radiators

- working - up to 6 atm. but for reinforced structures - up to 10 atm;

- well regulated by thermal valve;

- disadvantage is susceptibility to electrochemical corrosion and gas formation, which leads to the formation of air pockets.

Characteristics of bimetallic radiators

- working - up to 20 atm. for reinforced structures - up to 35 atm;

- good corrosion resistance;

- coolant temperature - over 120 0 C.

It is important! When planning to purchase new radiators, do not hesitate to contact your housing and communal services structure to find out exactly the operating and test pressure values in your home. Once a year it is submitted, higher than the working one, to identify weaknesses in the system

It may be higher than allowed for your new radiator.

- Tired of barrel water heaters? Buy a flat boiler!

- Brief overview of some models of water heated towel rails

- Manufacturers of tubular radiators

- A little about aluminum radiators

Materials

- The pressure a polypropylene pipe can withstand is always indicated by the manufacturer in its labeling. Marking PN20 (typical for pipes without reinforcement) indicates a working pressure of 20 atmospheres, PN25 (standard for pipes reinforced with fiber and aluminum) - 25 kgf/cm2;

- The temperature of the coolant influences the pressure polypropylene pipes are designed for. Manufacturers always indicate operating pressure at a temperature of 20C. When heated to a maximum of 90 - 95C, the maximum operating pressure decreases to 7 - 9 atmospheres. The service life is also reduced: already at 80 degrees, polypropylene will last not 50, but not more than 25 years;

- All polypropylene fittings are without reinforcement and are designed for a working pressure of 25 atmospheres;

- What pressure can a metal-plastic pipe (with cross-linked polyethylene shells and an aluminum core) withstand? Manufacturers guarantee 10 - 16 atmospheres. The breaking pressure is usually not less than 25. From a practical point of view, metal-plastic can be installed in central heating systems only on the connections to the radiators after the shut-off valves, which make it possible to shut off the water in case of leaks;

- The pressure at which a polyethylene pipe can operate is determined by the ratio of its diameter to the wall thickness (this parameter is called SDR) and the type of polyethylene. Low-pressure polyethylene PE100 is noticeably stronger than high-pressure polyethylene PE32: for example, with the same diameter and wall thickness (SDR21), the first pipe can operate at a pressure of 8 kgf/cm2, and the second - only 2.5;

SDR is the ratio of outside diameter to wall thickness.

- The lower the SDR, the higher the tensile strength

; - There is an inverse relationship between pressure and pipe diameter with constant wall thickness. The larger the diameter, the larger the area of its internal surface, and if so, the greater the force with which the internal environment presses on them. Accordingly, at a constant operating pressure, the wall thickness, depending on the diameter of the pipe, decreases or increases;

- The most reliable and easy-to-install material for central heating systems is corrugated stainless pipe. Due to the corrugation, it absorbs water hammer and withstands the freezing of water in it without destruction. With a stated operating pressure of 10 - 15 atmospheres, the destruction pressure, according to the Lavita company, is 210 kgf/cm2;

Corrugated stainless steel is an ideal material for central heating systems.

- For steel pipes with welded joints, the strength calculation takes into account the strength coefficient of the weld. It is taken equal to 0.6 - 0.8. If a VGP pipe can withstand a pressure of 200 atmospheres without destruction, the design for the finished circuit includes a maximum of 120 - 160;

- All water and gas pipes are electric welded. Accordingly, during defrosting and the accompanying increase in pressure, they tear along the longitudinal seam. After welding a seam using electric arc welding, the strength of the pipe almost does not decrease;

- Central heating systems should be equipped with steel registers or bimetallic radiators. The strength of any system is equal to the strength of its weakest link: is there any point in using pipes that can withstand 150 atmospheres if the radiator collapses at 16?

- The champion in strength among bimetallic ones is Rifar Monolit of domestic production. A working pressure of 50 atmospheres and a destructive pressure of 100 are stated for it.

Factors influencing the operating pressure

The amount of coolant pressure in high-rise buildings depends on many circumstances that directly or indirectly contribute to a deviation from the nominal value prescribed by the standards.

These include:

- degree of wear and tear of boiler room equipment;

- removal of a residential building from the boiler room;

- the location of the apartment, on what floor and how far from the riser it is located. In an apartment located even next to the riser, in the corner room the pressure will be lower, since the extreme point of the heating pipeline is most often located there;

- sizes of pipes installed by residents without permission. For example, when installing a pipe in an apartment with a diameter larger than that of the inlet pipe, the total pressure in the system will decrease, and when installing pipes of a smaller diameter, it will increase;

- degree of wear of heating batteries.

Peak values

A closed-type heating system involves the movement of coolant in a closed circuit that does not communicate with the external atmosphere. The tightness of the circuit is ensured by a membrane expansion tank. Unlike a traditional tank, it can be installed at any point in the system. For example, such tanks are present in many wall-mounted heating boilers.

Rifar SUPReMO monolithic bimetallic radiators can withstand pressure of 100 atmospheres. A destructive indicator for them is the figure of 250 atmospheres.

Since the liquid circulates in the pipes in a closed volume, a certain pressure is created in the heating system. The norm for private houses with a height of 1-2 floors is 1.5-2 atmospheres. In larger cottages it may be higher. The upper limit is determined by the capabilities of the weakest node in the circuit. In most cases, the weakest link is the boiler - it can withstand up to 3 atmospheres. Less durable models (1-2 atmospheres) are also available for sale.

In multi-story buildings, peak rates are much higher. They reach up to 20 atmospheres or more. Water hammers also occur here - the pressure jumps to high values, which causes ruptures of pipelines and radiators. Therefore, in high-rise buildings, more durable and durable batteries are used that can withstand hydraulic shocks. Some of them are able to withstand pressures of up to 100 atmospheres.

Importance

Water pressure is necessary for the normal functioning of the plumbing system. For the equipment to function properly, the following minimum values are required:

- Dishwasher and washing machine - from 1.5 to 2 atm. units

- Faucet with mixer, bathroom - 0.2 atm. units

- Shower, bath - 0.3 atm. units

Basically, water flow is supplied to city apartments under a pressure of 2-4 atmospheres. Insufficient pressure can create situations where the use of water by neighbors causes a pressure drop in other apartments. Low blood pressure can be affected by:

- Blockages in water supply pipes.

- Turning off pumps to save money.

- Weak power of central pumps.

- Incorrect installation of pipes, etc.

Reasons for increasing power

An uncontrolled increase in pressure is an emergency.

May occur due to:

- the automatic control of the fuel supply process is faulty;

- the boiler operates in manual high-burning mode and is not switched to medium or low-burning;

- malfunction of the storage tank;

- malfunction of the fill valve.

The main reason is overheating of the coolant. What can be done?

- The operation of the boiler and automation should be checked. In manual mode, reduce the fuel supply.

- If the pressure gauge readings are critically high, drain some of the water until the readings drop into the work area. Next, check the readings.

- If no boiler malfunctions are identified, check the condition of the storage tank. It accepts a volume of water that increases when heated. If the damping rubber cuff of the tank is damaged, or there is no air in the air chamber, it will fill completely with water. When heated, the coolant will have nowhere to be displaced, and the increase in water pressure will be significant.

Checking the tank is easy. You need to press the nipple in the valve to fill the tank with air. If there is no air hissing, then the reason is a loss of air pressure. If water appears, the membrane is damaged.

A dangerous increase in power can lead to the following consequences:

- damage to heating elements, up to rupture;

- overheating of water, when a crack appears in the boiler structure, instantaneous vaporization will occur, releasing energy equal in power to an explosion;

- irreversible deformation of boiler and heating elements and rendering them unusable.

The most dangerous thing is a boiler explosion. At high pressure, water can heat up to a temperature of 140 C without boiling. When the slightest crack appears in the jacket of the boiler heat exchanger or even in the heating system next to the boiler, the pressure drops sharply.

Superheated water, with a sharp decrease in pressure, instantly boils with the formation of steam throughout the entire volume. The pressure instantly increases from steam formation, and this can lead to an explosion.

At high pressure and water temperature above 100 C, you cannot suddenly reduce power near the boiler. Do not fill the firebox with water: strong temperature changes may cause cracks.

It is necessary to take measures to lower the temperature and smoothly lower the pressure by draining the coolant in small portions at a point far from the boiler.

If the water temperature is below 95 C, adjusted for the thermometer error, then the pressure is reduced by releasing part of the water from the system. In this case, steam formation will not occur.

Control mechanisms

To prevent emergency situations in closed systems, relief and bypass valves are used.

Reset. It is installed with an outlet into the sewer for emergency drainage of excess energy from the system, protecting it from destruction.

Photo 4. Relief valve for the heating system. Used to drain excess coolant.

Bypass. Installed with access to an alternative circuit. Regulates the pressure drop by sending excess water into it to prevent an increase in the following sections of the main circuit.

Modern manufacturers of heating fittings produce “smart” fuses equipped with temperature sensors that respond not to an increase in pressure, but to the temperature indicators of the coolant.

Reference. It is not uncommon for pressure reduction valves to stick. Make sure that their design includes a rod for manually retracting the spring.

Don't forget that any problem in your home's heating system is fraught not only with loss of comfort and costs. Emergency situations in the heating network threaten the safety of residents and the building. Therefore, heating control requires care and competence.