Your Lemax gas boiler, which worked properly last season or even yesterday, does not turn on? Perhaps some problems arose before, but now it completely refuses to work? Agree, staying in the cold without heating in the house is not a bright prospect.

Most Lemax gas heating boilers have fairly simple, fully mechanical automation. This means that you can fix most problems yourself. This article will help you find and eliminate the reason why the boiler does not light up.

Let's consider both external factors that interfere with the operation of the unit and its internal breakdowns. We will provide instructions for actions in different situations, and also describe the features of electronically controlled boilers.

Recommendations for use - how to turn on a gas boiler correctly

Before lighting the Lemax boiler, you need to make sure that there is water inside it and other elements of the heating system.

Next, they check the level of traction and select the most optimal algorithm of action. Its formation is influenced by the power of the equipment and the presence of automatic units. The Lemax boiler is classified as non-volatile, so the problem of how to ignite a Lemax gas boiler is solved using conventional piezo ignition. Some models have a special traction sensor, which ensures safe operation of the device. To connect a boiler like this to a heating system, you don’t need any special skills. In addition, no special care is required during operation, and minor faults can be eliminated with your own hands. To avoid surprises during startup, you must always check all your actions with the manual on how to light a Lemax gas boiler.

List of actions on how to turn on a Lemax boiler with automation:

- Open the gas tap.

- Set the control knob to the ignition position.

- Press the handle all the way for 10 - 60 seconds until the burner lights up.

- Conduct temperature adjustment.

What models are there?

The main types of Lemax gas boilers are:

- Floor-standing models with steel or cast iron heat exchanger.

- Wall mounted solid fuel.

The solid fuel type of equipment is represented by two models:

- Wood stoves.

- Coal boilers.

Wall-mounted boilers are produced only as double-circuit boilers: they are capable of operating at pressures up to 3 bar. In all cases, Italian automation and circulation pumps are used. Wall-mounted models include a 6-liter expansion tank. This equipment is guaranteed for 2 years. Floor-mounted modifications equipped with steel heat exchangers are also in high demand. For their manufacture, high-strength metal with a thickness of 2 mm is used.

There are 5 models of steel boilers with different capacities:

- Lemax premium.

- Premium nova.

- Gazovik.

- Clever.

- Patriot.

The Premium nova model is considered the most advanced today. Thanks to automatic settings, the device can independently both start a Lemax gas boiler and set optimal operating parameters in the system. The Patriot series devices are characterized by the presence of a closed combustion chamber. They are produced exclusively as single-circuit ones, without the need for electrical power and a chimney. The presence of a 4 mm thick cast iron heat exchanger for the Leader and Wise units extends the service life by approximately 2 years. They are not afraid of various contaminants and the effects of corrosion.

Power outages

It happens that the voltage in the electrical network drops below the permissible level. In this case, the boiler immediately goes out, since modern automation can detect low voltage. When the power supply is restored, the same automation will turn on the burner, so most of these failures can go unnoticed. However, this mode of operation is harmful to electronics, so they may fail over time. So if suddenly the gas does not light up when voltage appears in the network, something may have happened to the automation. To avoid such a scenario, it is better to buy a voltage stabilizer.

Reasons for private switching on and off of a gas boiler

A situation may happen that you have just installed a new gas heating boiler at home, just set it up and put it into operation, and then it starts turning on and off every five minutes. In fact, it should independently regulate its operation, but turning off and turning on on its own too often indicates that something is wrong here. In addition, this behavior of heating equipment negatively affects the duration of the operating period, since the working parts wear out and the boiler fails.

There are several reasons why the heating boiler often turns on. If you do not have enough experience, you should call a specialist for help, since blue fuel does not tolerate careless treatment. So, the main factors that provoke frequent switching off and on of gas heating equipment:

- The boiler was selected incorrectly. Its power is designed for large rooms, and it was installed to heat a small room.

- Errors when installing the circulation pump.

- The temperature range is set incorrectly.

- There is no thermostat in the room, the boiler operation is adjusted only according to the coolant temperature.

The problem is not complicated, but in some cases the solution is to replace the heating device.

Problems with the ignition piezo in a gas boiler

Model range of Mimax equipment

The mimax company offers the consumer the following products of its own production:

- Heating gas boilers Vega KSGV and KSG.

- Parapet boilers KGS (P).

- Solid fuel boiler Titan.

- Gas burners AGU-T-M, AGU-T-E and Optima.

Let's look at the most popular gas models.

VEGA Series

This floor-standing gas boiler is available in two variations:

- With one heating circuit (CHC).

- With an additional water heating circuit for heating water for domestic needs (KSGV).

In addition to the high efficiency of 92% for this type of boiler, the operating instructions contain the following technical characteristics:

- Atmospheric gas burner made of stainless steel.

- Turbulizers are used in the heat exchanger, which will allow for more efficient use of all thermal energy.

- Each boiler in this series is equipped with Italian SIT automatic equipment. This automation is simple, reliable and easy to use.

- The wall thickness of the heat exchanger is 3 mm, it is made of cold-rolled steel sheets.

- Additional thermal insulation of the combustion chamber and the unit body makes it completely safe.

Devices MIMAX KSG and KSGV

In this model of gas heating apparatus, the Mimax company installs open burners of its own production and automatic equipment from the Italian company Optima. The attached instructions contain the following technical characteristics and design features:

- Power from 7 to 40 kW.

- Compact dimensions allow this boiler to be installed in small spaces in compliance with all safety requirements.

- Reliable thermal insulation of the combustion chamber with non-asbestos materials reliably protects the housing from overheating.

Mimax parapet models

The heating boiler of this series has the following features:

- The sealed combustion chamber allows installation of units in rooms that are not equipped with a chimney.

- Exhaust gases are discharged into a coaxial chimney. Air is also taken in through it to support the combustion process.

- Versatility of installation: such a boiler can be mounted on an external wall or installed on the floor.

- The steel heat exchanger ensures high heat transfer and durability.

- Sit automation and additional safety elements: pressure sensor, piezo ignition and thermostat in the heating circuit ensure high reliability and safe operation of the equipment.

All these design features of Mimax parapet boilers have received approval and positive feedback from consumers.

The worthy technical and operational characteristics of gas units of the Mimax brand are deservedly in demand among domestic consumers. A low price with excellent quality, reliability and safety is another advantage of this equipment, which is confirmed by numerous reviews on the manufacturer’s website.

Automation of boilers - the wick goes out after releasing the button

There is also a decrease in gas pressure in the inlet pipeline. Sometimes there is a lack of voltage on the control board. Remind us what service work needs to be performed in case of conversion from methane to propane? First, you need to change the nozzles of the main burner of the GGU. Then change the supply voltage of the modulator.

And at the end, adjust the parameters of the highest and lowest pressure. What principle of operation does the safety valve have in a heating system? This component, which is adjusted to the required pressure, protects the heating system. It is prohibited to use a safety valve to drain heating water. The heating system pressure often rises. In the expansion tank we lower the pressure to 2.

Can heating circuit water leak from the DHW system? The increase in pressure in the heating system is formed by the following main factors. The pressure for the expansion tank is not adjusted.

The make-up tap is leaking.

Main reasons: why the gas boiler goes out

Starting up is difficult. The igniter lights, but the main burner has no fire. Please tell me what is the reason? Apparently, the ignition unit is faulty. You will need to do a technical inspection of the unit and clean the ignition mechanism. Can anyone help clarify the situation with the chimney pipe? Soon it will be three days before a return draft arises, due to which the smoke passes directly into the room. I made the chimney myself.

It is a steel pipe. There may be a discrepancy in the calculations. The main reason is an incorrectly manufactured chimney pipe design. Soot contamination often occurs, which significantly reduces its efficiency.

In addition, it is necessary to check the exhaust openings in residential areas. Heating system control. Transfer to another type of gas.

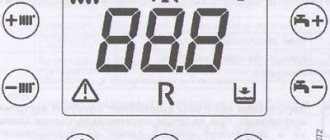

Adjustment devices and protection devices. After starting, a malfunction appeared. It doesn’t want to turn on, it worked for two years, now the whole display lights up, just like when the boiler is turned on, when the self-diagnosis mode is in progress, then it clicks, turns off for miles and seconds and turns on the whole display again. It turned on once, but it gives the error E10 water pressure, although the pressure in the system is 1. Tell me, what could be wrong? In operation, the Baxi main four boiler turns off with error E35 stray flame. Tell me what to do?

First season in operation. We installed and connected the Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW device? Bosch boiler 24 kW, single-circuit with built-in three-way valve. The boiler sensor does not see it and gives an error.

Tell me how to do it so that it doesn’t give an error and works normally for both the heating and the boiler?

Question: Lemax floor-standing boiler, with two buttons, red and white. It stopped starting automatically, the wick is burning, but it starts when you turn the gas regulator to zero, and then raise the temperature and the boiler lights up, please kind people tell me what the problem could be, otherwise we freeze at night. Answer: the rod is jammed in the middle part of the automation. Question: my Lemax KSGD boiler with a GTU 24D burner goes out when there is wind on the igniter. Answer: it is necessary to increase the gas supply to the pilot burner; most likely, when the main burner is turned on, the flame on the pilot burner decreases, which leads to the activation of the automatic protection.

If you turn off the DHW flow sensor, maybe it will be possible to reprogram it into a single-circuit device through menu L3? We installed an Arderia esr 2 boiler. If my coolant pressure drops a little over the course of a day by a couple of notches, could the reason be a faulty three-way valve? Are there no leaks from the radiators?

The gas boiler Arderia 2 is in operation.

Let's get started

To determine the cause of the malfunction, we will check the thermocouple circuit - solenoid valve. First, let's check the traction sensor. In this boiler it is located on the gas duct. To do this, remove two terminals from the sensor.

We close the two terminals together; they should connect tightly (to do this, you can press them a little with pliers).

We are trying to ignite the igniter. If this was possible, the cause of the malfunction is in the traction sensor. However, do not rush to change it. Let's check it first.

Note: in this work we dismantle the sensor in order to show the features of its installation on the boiler and the markings. This is not necessary for verification.

Unscrew the two screws securing the draft sensor to the boiler flue.

Please note that the sensor is not attached tightly to the flue body, but is mounted on paronite gaskets. This is necessary in order to reduce the heating of the sensor through its contact with the body, and also to ensure a gap between the hole in the flue duct and the plane of the sensor.

We inspect the sensor. Its contacts must be firmly attached to the body. There should be no oxidation on them. The sensor rating (the temperature at which the sensor contact opens) in this case is 75 °C (designation on the housing L75C).

We check the traction sensor with a tester, measuring its resistance. It should be minimal (equal to the resistance of the probes) - 1–2 Ohms. If the sensor does not ring, it is clearly necessary to replace it with a similar one (with the appropriate response temperature).

If the sensor was able to ring, wipe the contacts of the sensor and the circuit terminals with alcohol, tighten them with pliers and dry them. We mount the sensor in place and connect it. We are trying to ignite.

If ignition was successful, the cause of the malfunction has been found and eliminated.

Be sure to check the draft after igniting the main burner. To do this, you can bring your hand to the place where the traction sensor is installed. No heat should come out of this hole. If this happens, it is necessary to eliminate the cause causing insufficient traction. In this case, the sensor works correctly.

Attention! Operating a boiler with a faulty chimney is strictly prohibited!

If ignition fails, we move further along the chain. The contacts from the draft sensor go to the draft breaker (thermocouple breaker).

We remove the terminals from the contacts of the traction breaker and measure the resistance of the circuit. It should be no more than 3 ohms.

If this condition is met, we perform the following actions. Using wrench No. 9, unscrew the nut securing the thermocouple to the traction breaker. Using wrench No. 12, unscrew the traction breaker, which consists of two parts: a brass sleeve and a plastic insert, by half a turn.

Types of gas boilers

Based on the type of installation, boilers are divided into wall-mounted and floor-mounted units.

Floor-standing gas boilers are characterized by greater power, which means the ability to heat large areas of premises, and longer service lives due to the fact that the heat exchangers for such heat generators are made of steel or cast iron. Floor-standing boilers require a separate room - a furnace room.

Floor standing gas boiler

Wall-mounted boilers are more compact and lighter, which allows them to be installed on the walls of rooms. This type of heat generator is characterized by limited power, shorter service life, and increased requirements for the quality of purification of the coolant and heated water. Gas boiler malfunctions may vary depending on the type of installation.

Wall-mounted gas boiler

By design, boilers are divided into single-circuit, used only for space heating, and double-circuit, intended, in addition to heating, to heat hot water.

Depending on the type of removal of combustion products, heat generators are equipped with systems with natural or forced draft. In the first case, the units are connected to a traditional chimney, which is discharged to the roof of the building, and exhaust gases are released due to natural draft. To ensure this, ventilation ducts are arranged according to certain rules. One of them is that the upper level of the chimney must be located above the roof ridge by at least 500 mm, or at the same level with it at certain distances from the ridge. The reason why the gas boiler blows out may be failure to meet these conditions. Boiler units with natural draft are equipped with open combustion chambers or atmospheric burners, the air for the burner is taken from inside the room.

In the second case, the boilers are equipped with a coaxial chimney, which is a “pipe-in-pipe” design, which is discharged outside through the wall of the room. The air necessary to support combustion comes from the outside pipe through the outer pipe, and combustion products are discharged through the inner pipe. Forced draft boilers have closed combustion chambers.

Traditional and coaxial gas removal systems

And finally, according to the method of ensuring coolant circulation, boiler units are divided into volatile and non-volatile. Volatile boilers have circulation pumps that operate from the electrical network and create pressure in the heating system. In addition, volatile boilers are equipped with sophisticated automation that controls and maintains established operating modes, including an electronic ignition system. Non-volatile heat generators do not require connection to electrical networks, and the movement of the coolant occurs due to natural pressure drops as a result of its heating. Non-volatile boilers can be ignited using a piezoelectric element by pressing a button.

Marking

All versions of the line can be divided into 4 groups:

- AKGV

- KSGV

- AOGV

- KSG

This non-volatile equipment is capable of operating in closed and open heating systems. Coolant circulation - forced or natural. Next to the abbreviation - marking, there is a number indicating the power - 7-35 kW. The marking also indicates the type of automation:

- T or AT – SABC AT;

- C – SABC S RD;

- E or EM – Eurosit.

Almost all modifications are made in accordance with current trends in minimalism. There is a pressure gauge in front, and other automatic elements are hidden in the housing. A distinctive feature of the products from “ServisGaz” is their white color. The radiator is made of steel, the burners are made of heat-resistant stainless steel. Equipped with a condensate collection device.

Why is blood pressure rising?

Increased pressure is a serious and dangerous situation. An increase in pressure in the system can only mean an increase in the amount of water.

This occurs due to the expansion of the coolant when heated. Any liquid is incompressible, so an increase in its volume can lead to rupture of the heat exchanger, or, in the most serious case, provoke an explosion.

To eliminate this possibility, an expansion tank is used in the design of boilers. It absorbs excess water volume, compensating for its increase when heated.

An increase in pressure most often indicates a problem with the expansion tank. Its design consists of a container and an elastic membrane installed approximately in the middle.

When the liquid begins to flow, the membrane sag and makes room for excess water.

When the volume decreases, it returns to its previous position. If the membrane is torn or not firmly attached to the expansion tank stacks, the coolant will fill the entire volume of the tank.

When expanding, the water will have nowhere to go, which will provoke a constant increase in pressure. The solution to the problem is to restore the condition of the membrane or replace the expansion tank with another, serviceable copy.

What causes blood pressure to drop?

A drop in pressure (the boiler goes out) indicates the appearance of leaks. It is necessary to check the condition of pipelines, threaded connections, gaskets and other external elements of the heating system . If there is no visible damage, you should look for problems with the boiler.

The main problem element may be the heat exchanger. Welded joints sometimes crack or break due to frequent temperature changes. Sectional cast iron heat exchangers used on powerful floor-standing models are risk factors at section connections.

In addition, the pressure relief valve may be triggered or jammed open..

Threaded connections of pipes can also lose their tightness due to drying out or destruction of gaskets, non-threaded connections, etc. All detected problems are eliminated in accordance with their specifics.

How to repair boiler fault codes?

Boiler overheating error

Gas boiler malfunction in the form of overheating can occur due to lack of circulation. In this case, you need to check the pump and filter. The overheating thermostat may also be broken.

Low system pressure

If the pressure does not rise when the boiler warms up, then the tightness of the system may simply be broken and you need to tighten the connections, and then add a little pressure. If this problem arose almost immediately after installing the boiler, then you just need to remove the air through an automatic air vent and add a little water.

There is no draft of the gas boiler

If the boiler has an open combustion chamber, just check to see if it is clogged with anything. If the combustion chamber is closed, then condensate drips from the outer pipe, entering the inner one and freezing in the winter, turning into an icicle, blocking the access of air to the boiler. To eliminate this problem, you need to pour hot water over the resulting icicle. Another foreign object may also get into the chimney.

The boiler does not light a flame when ignited

This indicates a malfunction of the gas valve in the boiler. To verify this, you can unscrew the hose and see if gas is supplied. If there is gas, then you should call a specialist who will replace this valve.

The boiler lights up, but the flame goes out immediately

In this case, the panel may show a malfunction of the gas boiler in the form of a lack of ionization current. You need to check this by turning on the boiler again, turning the plug over, thereby changing the phases. If nothing has changed, then the operation of the ionization current may be disrupted due to some electrical work in the house. If the boiler periodically extinguishes the flame, then this is due to power surges and a stabilizer is needed.

The panel displays incorrect errors

Sometimes electronic board errors may occur. This happens due to poor electricity and poor quality power supply. This causes some parasitic charges to appear on the boards, which is why such errors are observed. To eliminate this, you need to disconnect the boiler from the network and let it stand for about 30 minutes. During this time, the capacitors will discharge and these unnecessary charges will disappear. After this, the boiler should work well.

In general, that's all. If the material was useful, do not forget to share it by clicking on the social media buttons below this text.

Also find out how to choose the right gas boiler so that there are no problems in the future:

How to distinguish the norm from the problem?

If your boiler turns off briefly from time to time while working, this is a normal phenomenon; this is how an automatic system works, protecting the equipment from overheating and you from overpaying for bills for housing and communal services. The heat exchanger heats up periodically, heating the water to the set temperature.

But in the case when the boiler, after working for several minutes, immediately turns off without completing its direct task of heating, this indicates a malfunction. This is called a short cycle, which is dangerous not only due to insufficient heating of the room, but also large gas bills, and in the long term this malfunction will lead to serious damage to the boiler, which will require expensive repairs or even its complete replacement.

This is why it is important to take appropriate action as soon as you notice that the boiler has started to short cycle

What is short cycle mode?

When your heating system doesn't need to be turned on, the heated water in the heat exchanger will naturally cool as heat escapes through the flue and around the boiler body itself.

The boiler has its own internal thermostat. When the boiler cycles briefly, this internal thermostat detects that the water in the heat exchanger is cooling and, although the temperature in your home has not dropped, starts the boiler to heat the water again. It doesn't take long for the heat exchanger to heat this small amount of water back up to the thermostat temperature, so the boiler quickly turns off again.

If the boiler is burning every few minutes, it is using gas but not heating your home. This wastes fuel which will increase your heating bills and carbon emissions, which in turn can cause damage to the heat exchanger as it is overworked.

If a heat exchanger malfunctions, it usually costs more than thirty thousand rubles (depending on the boiler model) without taking into account the labor costs of a gas safety engineer. Therefore, it is much more advisable to take appropriate measures before a major breakdown occurs at a time when replacing a faulty part does not become an expensive and time-consuming process.

Why does the device go out?

There may be several reasons for the burner to go out:

- Stopping the gas supply. Turn off the boiler and wait until the supply is restored.

- Unstable or absent voltage in the power supply network (for volatile Lemax boilers).

- Failure or activation of the traction sensor. We need to check whether it is there and whether the chimney is clogged. Sometimes cleaning the sensor contacts helps.

- The thermocouple contacts have oxidized and do not close. It should be cleaned with fine-grained sandpaper.

- Reverse, insufficient or excessive draft. The draft sensor responds to all situations by turning off the burner.

Problems with traction are most common in non-volatile installations, where the stability of the unit’s operation depends on it.

If the draft is too weak, the sensor turns off the burner due to the possibility of smoke in the room.

Excessive draft is dangerous due to the possibility of the flame on the burner exploding, which will provoke the supply of gas into the room with unpredictable consequences. Therefore, an increase in draft against the set value is also an emergency event, leading to the boiler stopping.

Doesn't start (ignite)

The unit is ignited according to a certain pattern. It does not always start the first time, and this is quite normal. But, if after repeated attempts the boiler does not ignite, it is necessary to check the condition of the components responsible for ignition.

Possible reasons could be:

- Failure of the electronic or mechanical ignition system. It is necessary to replace the system, or clean the thermocouple contacts.

- There is no voltage in the power supply network (for volatile units).

- The valve on the gas supply pipe is closed.

- The gas pressure in the system does not correspond to the nominal values.

- The main burner nozzles are clogged. It is necessary to clean them and start the boiler.

All these reasons are the most common, but far from the only possible ones. Any malfunction in the system can negatively affect the ignition of the boiler .

The pump is not working well

Users of gas boilers sometimes encounter various problems with the operation of the pumping unit. Such equipment stops pumping water if the rotor fails or a significant amount of air has accumulated in the internal part. To prevent such a breakdown, it is necessary to unscrew the nut from the unit and drain the water, after which the axle is forced to rotate using a flat screwdriver.

Pump in a gas boiler

Free-standing equipment requires compliance with installation rules. It is advisable to install the pump before the gas boiler, which will extend the life of the heating system. This rule is due to the presence of high temperature conditions at the boiler outlet, which can cause damage to the device. Of course, the design characteristics of the circulation pump must also be taken into account, as well as the need to mount a filter or sump directly in front of the pump.

Manipulations used to solve the problem

A good solution to prevent the wind from blowing in and turning off the boiler would be to manufacture and install fungi or deflectors at the upper end of the chimney.

The cause of the flame extinction can also be forced ventilation.

In this case, opening the front door will help, after which the gas will light up again.

Increasing air exchange in individual boiler rooms can be done by installing a ventilation window at the bottom of the door, which is covered with a fine mesh.

Malfunctions of heating boilers

Common boiler breakdowns include:

- coolant leak;

- water hammer;

- after turning on the burner, the lock is activated;

- the burner does not turn on;

- fuel burns unevenly, in waves;

- soot is formed;

- decreased productivity;

- During operation of the burner, the ignition is switched on;

- soot forms on the walls of the chimney and combustion chamber.

To resolve a problem, you must first determine the cause of the problem.

Built-in pump malfunction

An important part in the heating system is the circulation pump. The quality of heating and the functioning of hot water supply depend on its uninterrupted operation. There are several signs and causes of breakdowns:

There are several signs and causes of breakdowns:

- The unit makes uncharacteristic sounds. This occurs due to oxidation of the shaft, the entry of a foreign object into the structure, problems with the power supply, air in the pipes, dry running of the mechanism, and the appearance of cavitation.

- After turning on the boiler, the pump does not start. Perhaps there is no power supply, the fuse has tripped.

- After a short period of time after switching on, the structure switches off: limescale deposits in the stator shell.

- Hot water does not turn on in a double-circuit boiler.

Also, the reasons for poor operation of the circulation pump are poor pressure in the system, wear of the bearing, which causes additional vibrations in the line, and low pressure.

The heat exchanger is clogged

Heated gases are transported through channels, which are collectively called a heat exchanger. The design features are that the walls of the artery simultaneously serve as partitions of the water circuit, along which the coolant constantly moves, heating the metal surface. The combustion process is associated with the intense release of flue gases, partly consisting of soot and tar, which create a deposit inside the boiler, on the chimney. Therefore, the manufacturer recommends regularly cleaning the equipment at least once every 30 days and during the preparation of the device for the heating season.

When soot settles on surfaces, the performance of the mechanism decreases, fuel consumption increases, and the risk of costly breakdowns and internal fire in the contaminated area increases.

Clogged igniter and burner nozzles

Natural gas, which runs in household pipelines, is not a 100% pure substance - it contains additives and impurities. Some of them are added intentionally (for example, to create a specific “gas smell”), others are formed as a result of careless cleaning.

And the gas itself (a mixture of methane and in small quantities - propane, butane and ethane) does not burn without a residue - hours of operation of the burner generate soot and soot, which gradually settles on the boiler parts and can lead to clogging and clogging of thin channels and holes - jets , through which gas is supplied to the igniter and the burner itself.

An atmospheric boiler igniter is a special device that allows a small flame to burn. When the gas supply is turned on cyclically, it is the gas that ignites the mixture supplied from the burner. A constantly burning “wick” smokes even more than a burner, since the pressure in the igniter is low. If soot clogs the pilot nozzle, the boiler will not be able to turn on the next time.

Burner nozzles become clogged much less frequently, since gas is supplied there under pressure in large portions, but this situation cannot be completely excluded.

Expert opinion Filimonov Sergey Vinokurovich Heating equipment repairman

If you decide to clean the jets yourself, be careful. The fact is that the nozzle channels are made of relatively soft metals - copper or brass

Using steel wire or a brush can damage the equipment. Use copper wire or a brass brush.

Availability of automation

The automation of the Lemax gas boiler sometimes significantly expands the scope of use of the device. Above is a list of some characteristics that should be followed when choosing gas heating equipment. Knowing them, you will be able to independently determine the modification of the unit, which is the highest priority. Initially, you have to determine the heat loss of the building, and only then calculate the power of the boiler.

Sources

- https://teploclass.ru/kotly/gazovye/gazovyj-kotel-lemaks

- https://www.stroy-podskazka.ru/otoplenie/kotly/lemaks/

- https://utepleniedoma.com/otoplenie/otoplenie-doma/kotly-lemaks

- https://teplospec.com/gazovoe-otoplenie/kak-vklyuchit-kotel-lemaks-pravila-ekspluatatsii.html

- https://fb.ru/article/229439/gazovyie-kotlyi-lemaks-otzyivyi-i-instruktsiya

Other causes and solutions

If a gas boiler was working properly, and then began to constantly go out, then the problem often lies in a change in air flow in the room with the heat generator. Installing new sealed windows, tightly closing doors, kitchen hoods, ventilation systems - all this leads to a lack or excess of oxygen in the firebox. Initially, the thrust was designed for one set of conditions, but they suddenly changed dramatically.

If the reason cannot be found, call a specialist

Here, it is often impossible to do without arranging a forced air flow into a room with a gas water heater. Moreover, the price of these additional systems often turns out to be such that it is better to look at electric boilers for heating a private home. They need a lot of electricity, but there will definitely be no problems with draft and smoke removal.

A gas boiler is an important component of an autonomous heating mode. Proper operation in cold weather pleases every owner and does not require additional intervention in the work process

However, there are times when the boiler suddenly goes out or turns off on its own some time after being turned on. This article will tell you what to do and how to get rid of this problem.

Gas burner goes out

It is also possible that gas and electricity in the AOGV (Gas Water Heating Unit) are available in the required volume, but the burner constantly goes out. The equipment turns on, works, and then the flame in the firebox goes out. Here the problem may lie in the draft or the thermocouple that controls the presence of fire. It is possible that there is either a lack of air for combustion or a breakdown of the internal elements of the boiler.

The first option is a malfunction of the traction sensor or its absence in principle. To check whether there is an air flow into the firebox, just hold a burning match to the inspection window of the gas boiler. The flame should deviate towards the firebox. If it is motionless, then there is no traction.

In this case, first you need to open the windows and door slightly so that the air enters the furnace room. If this does not help, then you will have to clean the boiler and chimney. The cause of the problems lies in them, or more precisely in the accumulations of soot on the walls of the pipe and firebox.

The second option is a thermocouple. The contacts of this sensor may simply come off. As a result, the relay that shuts off the nozzles constantly receives signals that the fire has been extinguished. Fuel should not flow into the combustion chamber; the solenoid valve shuts off its supply. It is necessary to check the connection of this device to the damper. The connector should be free of oxides and dirt. If there are any, you will have to clean them with fine sandpaper.

Two-pipe and one-pipe heating systems: errors and their elimination

In a private house there are two options for pipe routing: a two-pipe and a single-pipe heating system. Previously, most people preferred to install a single-pipe system because it was believed that this was the most cost-effective option. However, in this system it is difficult to adjust the temperature of the heat exchangers as they move away from the boiler room. If in a single-pipe system the last battery remains the coldest (you need to increase the sections), there is no return in such a system, and therefore there will be no problems when the battery return is cold. Therefore, it often happens that some of the batteries are cold in a private house, since the coolant flows through only one pipe.

In a two-pipe wiring there may be errors in the installation of shut-off valves, the boiler is connected incorrectly, or the diameter of the bends is incorrectly selected. For these reasons, with a two-pipe heating system, the last battery may be cold.

Irregularities in connecting heat exchangers:

- The boiler heat exchanger is clogged - a common reason; then it will need to be flushed using special chemicals.

- Incorrect installation of the hydraulic part. As a result, poor circulation and low coolant temperature.

Now the reasons why there are cold batteries in a private house and why in a 2-circuit boiler one battery is cold have become clear. Some problems can be fixed on your own; in more complex cases, it is better to contact a specialist. On our website you can find out why the battery is hot on top and cold on the bottom.

How to choose the right table

The student should not be cramped at his workplace: he needs to have enough space to conveniently lay out books and notebooks, an album with paints, or other necessary things.

You should also consider the presence of lockers and hanging shelves where you can place school supplies. The child must have enough lockers to place his supplies.

There are several nuances to consider that will help you choose the best option:

- The size of the table should be optimal for the child’s age: it is required that the upper part of the table surface be below chest level, that is, if the student’s height is 130 cm, its optimal height will be 55-57 cm.

- The child’s feet should comfortably reach the floor, while the free space from the knees to the table top cannot be more than 15 cm.

- The depth of the table should be optimal in order to fit all the necessary things, they can be easily reached, and at the same time the elbows are comfortable.

- With this arrangement, there is often no space left to install side cabinets. Therefore, you need to take care to equip it with pull-out cabinets that can be placed under the work surface.

- Safety. Considering the age of your child, you should, if necessary, install a special handle lock so that the child cannot open the window on his own.

When choosing a table, several nuances should be observed. The radiator can be closed using a special partition.

Boiler problems

All systems have been checked, but there is still no heat? So, the problem is still in the boiler itself. Let's figure out why it doesn't work. Malfunctions may appear as follows:

- The burner does not turn on or burns weakly

. The injectors may be clogged. They can be cleaned with a soft brush or thin wire. In addition, air could get into the gas line (especially if the connection unit was disassembled). Usually in such cases the gas boiler is blocked and an error code lights up on the display. It is necessary to restart by resetting the lock (how to do this is written in the instructions); - The burner does not turn on when trying to manually or automatically ignite.

Perhaps the gap in the ignition electrode is broken, contact with the current-carrying wire is lost, or the air supply filter to the burner is clogged. It is quite difficult to adjust the gap yourself, but cleaning the filter and checking the wire connection is quite possible; - The burner goes out after burning for some time.

It is possible that the ionization electrode is dirty, the gap in it is broken, or the connecting wire is unsoldered. You need to do the same as in the previous case; - Flame separation

. With such a malfunction, the injector makes a lot of noise (or a characteristic whistle is heard from it). It is necessary to adjust the gas pressure at the igniter. Separation is also possible with excessively high draft and increased supply ventilation (air blows out the flame in the burner). This situation can arise, for example, if the chimney pipe is too high; - The boiler makes noise and switches off spontaneously

. The cause may be a breakdown in the pump or built-in fan (for turbocharged models), failure of the thermostat (water boils), flame separation or breakthrough.

In addition, some boiler models are phase-dependent, that is, sensitive to changes in the location of the “phase” and “zero” contacts on the power wire. Quite often, you can fix a non-working boiler by simply changing the location of the electrical plug in the outlet (rotating it 180 degrees).

Now, if none of the above helped, you can call a service specialist. And only if his diagnosis turns out to be disappointing, will he have to buy a new boiler.

Source: all-for-teplo.ru

Typical problems with turbo boilers

The problems described above also occur with turbocharged boilers. But in addition, given that boilers with a closed combustion chamber are equipped with additional elements, additional “troubles” can happen to them.

For example, during their operation you may encounter the following difficulties:

- icing of the coaxial chimney outside the house;

- failure of the built-in air blower.

Their design, of course, is more complex than that of models with an open combustion chamber. But at the same time, you can carry out all the same manipulations with them as with atmospheric boilers.

Condensation accumulation and icing are also common causes of boiler failure. This happens if during installation the standard slope was not observed to ensure the drainage of condensation moisture

But let us dwell in more detail on the breakdowns characteristic of this type of equipment.

Icing of the hood or chimney

If you observe that the boiler goes out most often in frosty conditions, then most likely the chimney opening is blocked by an ice mass.

This may happen due to:

- formation and accumulation of condensate;

- snow accumulation.

As you can see, the reason is bad weather conditions. Therefore, the solution to the problem is to protect the chimney from external factors.

In this case, again, it is worth considering the option of installing a “fungus”, i.e. deflector. But this is a preventative measure. But what to do if the problem has already “ripened”, and weather conditions further aggravate the situation? There is a way out in this situation too.

You can “melt” the chimney, that is, rid it of ice plugs, yourself using a hair dryer or a gas burner on a spray can

Condensate settling in pipes is typical for convection boilers with a coaxial chimney. Plugs form in them due to the difference in temperature of the air flows drawn into the burner from the street and coming out. These ice jams block the path both into and out of the combustion chamber.

To remove the ice crust from a coaxial chimney, you may even need to dismantle its outer part. Dismantling will not affect the daily operation of the system, but it is still better not to let it happen. Sometimes, in order to prevent the accumulation of condensate in the gap between the pipes, a pair of holes are drilled in the outer contour.

Simply breaking the ice is not the solution. Moreover, the chimney may be damaged. It is better to buy a portable gas burner with a can and “melt” the chimney with it. After the plug melts, the boiler will start working again. But to prevent such incidents from arising in the future, the pipes should be insulated.

The second prerequisite arises in cases of installation of eaves caps: they protect the chimney from precipitation, but in winter they cause more trouble than they are worth, impeding the outflow of flue gases.

Fan or turbine malfunction

When the wick of a gas boiler with a built-in supercharger suddenly goes out during operation or does not initially light up, listen to the sounds it makes.

During normal operation, the turbocharging system should hum steadily, so you should be wary of the appearance of extraneous noise.

Turbocharging, applied to the design of boilers with a closed combustion chamber, in most cases cannot be repaired - it is easier to replace it immediately

If there are none during operation, the breakdown is obvious: that is, the automation does not allow the safety valve to open, so the wick does not light up.

In this case, we strongly recommend not to engage in amateur activities, but to immediately call the gas workers. In most cases, turbocharging cannot be repaired - most likely it will have to be replaced, and such work is associated with the risk of carbon monoxide spreading throughout the room.

Therefore, it is better if this process is monitored by a gas engineer from a company with which an agreement has been concluded for equipment maintenance and gas supply.

Is the boiler always to blame?

In such cases, the main thing is not to panic. Obviously, a long period of idle time for a boiler can lead to extremely undesirable consequences not only for residents, but also for the entire system as a whole - it can defrost and become unusable. Therefore, if something incomprehensible periodically begins to happen to the boiler - it suddenly goes out, the wind makes noise in the combustion chamber and blows out the flame, or some emergency icon lights up on the dashboard display, you need to quickly diagnose and determine the causes of the malfunction.

First of all, you should not pay attention to the advice of “experts” who recommend “just” changing the boiler and chimney. This, of course, is an effective method, but you can always resort to it if there is nothing else left.

As soon as one of the sensors signals a malfunction, the automation immediately starts working and gives the command to stop the entire system. So the main reason why a gas boiler goes out may be in the heating unit itself or in one of the other components:

- gas pipeline;

- smoke removal system;

- heating and hot water supply circuits;

- electrical network.

Next, we'll look at the most common problems with a gas boiler, and explain why this usually happens.

Reasons for stopping work

There may be several reasons, let’s consider each one separately:

1. Long boiler downtime. As a result, the boiler may defrost and become unusable. As a result, there is a sharp attenuation, and the sounds of wind blowing out the flame are heard from the combustion chamber.

Due to these factors, an alarm appears on the dashboard, indicating the need for urgent diagnostics of the device. Modern boilers are a rather complex and fully automated system. Therefore, if one of the sensors signals a problem, the unit stops working. There is no need to immediately change the boiler or install a new chimney; it is very important to understand the problem and find a way to solve it.

2. Chimney malfunction. If there are problems in the form of boiler attenuation, it is also important to check the serviceability and functioning of the chimney. The first reason may be the formation of ice on the chimney walls, which occurs through the settling of hot steam followed by the formation of condensation. After a certain period of time, the condensate freezes and becomes a thick layer of ice. After this, the draft decreases and the boiler goes out. The solution to this problem is to clean the chimney and its insulation to minimize condensate freezing.

Breakdowns of gas boiler components

During power surges, the circulation pump may break. In this case, the fire will go out and the boiler will make noise. To eliminate the breakdown, it is necessary to replace the circulation pump. If the wrong pressure is set, the flame will come off the burner. The pressure must be adjusted correctly. If there are problems with the burner, the filters and the part itself become clogged.

If the thermocouple is burned out, it will not send signals to the safety valve or will send incorrect signals. The valve will stop the gas flow. If this problem occurs, the thermocouple must be replaced.

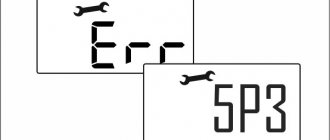

Modern gas boilers have an automatic system that automatically reports the reason for the extinguishing of the gas boiler. An error code will appear on the equipment display. Using the instructions, you can decipher the code and fix the problem.

Gas boilers go out most often for the reasons given above. If you are unable to identify or fix the problem yourself, it is recommended that you contact a specialist. Modern devices have a complex operating scheme, which is not always easy to understand.

It is necessary to periodically check the operation of the sensors

You should also pay attention to the condition of the chimney. To prevent breakdowns due to voltage surges, it is necessary to install a voltage stabilizer

In this case, you will be able to avoid problems with the electronics of the gas boiler.

Mechanical equipment is not as demanding on voltage.

In this case, you will avoid many problems with the operation of the gas boiler.

Sincerely, Baltgazservice company

Malfunctions of electrical and gas equipment

If the equipment is additionally connected to the network, check for voltage. Turn the plug over in the socket to change the phase.

What are the signs of failure:

- The unit does not work, the indicators do not light up.

- The LEDs light up, the display works, but ignition does not occur.

- The burner goes out after ignition.

Inspect the safety block. Found a burnt part? Install a new fuse - it is often glued to the front panel. If the steps do not help, then:

- Clean the heating system filter. To do this, turn off the product, turn off the valves and rinse the filter under running water.

- To remove air lock or excess water in the pump, unscrew the main screw in the center. Bleed the air, turn the pump rotor with a screwdriver. When the water has drained, return all parts to their place.

- Problems with low pressure in the system can be corrected by pumping air into the expansion tank. The product is located in the internal part of the structure. As a result, the pressure should be 0.2 bar less than in the general system.

If the burner goes out due to minor problems, you can deal with them thanks to our recommendations. It is better to entrust the replacement and repair of main components to a repairman. Gas boilers are highly dangerous equipment, so follow safety rules.

Heat loss does not correspond to boiler power

Constant operation of the boiler may be due to insufficient power of the device. The coolant, having passed through the pipes, returns, and by this time, the water has not had time to heat up due to insufficient power. Therefore, the gas boiler does not turn off. The boiler power is selected based on a number of key parameters:

- area of heated premises and number of storeys of the building;

- climate features of the region;

- the materials from which the house is built, the quality of thermal insulation materials, the quality of seam sealing, window insulation, the number of chambers of window profiles, etc.

- the number and volume of all heating devices and pipe circuits installed in the system, additional buffer tanks, separators;

- temperature level that needs to be maintained.

It is best to entrust the calculation of boiler power to a professional or use special formulas or online calculators that allow you to determine the main characteristics of the boiler as accurately as possible, taking into account all parameters.

Often, a simple formula is used to calculate power, which is defined as 1 kilowatt of power per 10 square meters. m of heated room. In this case, several correction factors are used, taking into account climatic conditions, the degree of thermal insulation of the house and other parameters

In addition to choosing the boiler itself, it is important to correctly select the remaining components of the system, pipes with the appropriate cross-section to ensure the required throughput

Connecting a room thermostat

A room thermostat is a convenient and useful device that allows you to regulate the temperature of the air, not the coolant, in the heating system. The default sensor monitors the outlet temperature of the heating agent.

This does not give a correct picture of the state of the microclimate in the room. For example, when the outside temperature rises, the room becomes hot .

But the sensor cannot track this, and the extract air temperature is within the limits specified by the mode, so from the point of view of the system, everything goes fine, in accordance with the boiler settings.

If a room thermostat is used, the burner will turn off much earlier, which will improve the microclimate in the room and significantly reduce gas consumption.

To connect the room thermostat, you need to set the boiler's own element to the maximum temperature.

It will only work as an overheat limiter . The external unit is connected at one end to the automation unit, and at the other to the boiler thermostat. By default, a jumper is installed between the contacts, which must be removed and the thermostat connected.

IMPORTANT!

It is necessary to use the appropriate brands, for example - CEWAL RQ10. Installation of a thermostat is only possible on boilers marked N (with the SIT 820 NOVA automation unit).