To provide the coolant with the opportunity to expand when heated, it is necessary to install an expansion tank in the heating system. This is a very important event. It will protect pipes and radiators from unnecessary loads and significantly increase the service life of the functional elements of the autonomous heating system.

We will talk about how the expansion tank works in open and closed circuits. We'll show you how to install it correctly in both versions of the system. In our article you will find a description of the technology for connecting this backup capacity and useful recommendations.

Features of a heating system with an expansion tank

The heating system can be closed or open. The choice of location of the expansion tank depends on the type.

Open systems have long been outdated and at this time they can only be found in old buildings. Here the expansion tank is an open top tank. The bottom of the container is equipped with a threaded connection to which pipes are connected.

- The membrane system is equipped with a tank with a closed top.

- By design, it is a sealed capsule, inside of which there is a membrane made of durable rubber.

- This device can be installed anywhere.

It must be taken into account that it cannot be placed close to the circulation pump. Otherwise, it is likely that pressure surges will occur throughout the heating system.

Types and functions of heating expanders

An expansion tank is needed to compensate for the effect that an increase in the volume of coolant during heating has on the heating system. An additional container connected to the circuit becomes a storage place for the resulting excess water. When the temperature drops, part of the coolant leaves the tank and returns to the pipes.

The process is repeated with each heating and cooling cycle. If there was no such reservoir in the system, then when the water inside the pipes was heated, the pressure would increase and then decrease.

Such differences negatively affect the state of the system. They lead to leaks at the junctions of devices and pipes and can even cause equipment failure.

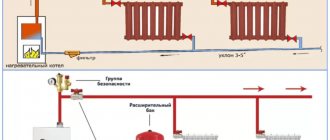

A membrane heating tank is usually installed in a boiler room. A suitable location is on the return line between the pump and the heating device

The expansion tank is selected depending on the characteristics of the heating system. For closed circuits, you need a special closed capsule with a membrane, and for open circuits, an unsealed container of a convenient configuration and the required size is suitable.

You should choose a membrane tank that is designed for contact with hot water. Typically, the body of such devices is painted red. You can make a container for installation in an open circuit yourself, for example, weld it from sheet metal. But it is important not only to choose the right device, but also to install it correctly.

For closed heating systems, containers with a membrane are used as an expansion tank, which allows the coolant to be stored under a certain pressure

Open type

Open type expansion tanks are installed at the highest point of the system. Often the location of the tank is chosen to be in the attic.

In addition to the fact that the device prevents the expansion of the coolant in the pipes, it also serves to prevent boiling of the coolant, and also replenishes its reserves in cases of leaks.

Volume calculation

There is a very simple method for determining the volume of an expansion tank for heating: 10% of the volume of coolant in the system is calculated. You should have calculated it when developing the project. If this data is not available, you can determine the volume experimentally - drain the coolant, and then fill in a new one, measuring it at the same time (put it through a meter). The second way is to calculate. Determine the volume of pipes in the system, add the volume of radiators. This will be the volume of the heating system. From this figure we find 10%.

Shape may vary

The second way to determine the volume of an expansion tank for heating is to calculate it using the formula. Here you will also need the system volume (indicated by the letter C), but other data will also be needed:

- the maximum pressure Pmax at which the system can operate (usually the maximum boiler pressure is taken);

- initial pressure Pmin - from which the system begins operation (this is the pressure in the expansion tank, indicated in the passport);

- coolant expansion coefficient E (for water 0.04 or 0.05, for antifreeze it is indicated on the label, but usually in the range of 0.1-0.13);

Having all these values, we calculate the exact volume of the expansion tank for the heating system using the formula:

Formula for calculating the volume of an expansion tank for heating

The calculations are not very complicated, but is it worth bothering with them? If the system is open, the answer is clear - no. The cost of the container does not depend very much on the volume, plus you can make it yourself.

Expansion tanks for closed type heating are worth counting. Their price depends greatly on volume. But, in this case, it is better to take it with a reserve, since insufficient volume leads to rapid wear of the system or even its failure.

If the boiler has an expansion tank, but its capacity is not enough for your system, install a second one. In total, they should give the required volume (the installation is no different).

What will result from insufficient expansion tank volume?

When heated, the coolant expands, its excess ends up in the expansion tank for heating. If all the excess does not fit, it is released through the emergency pressure relief valve. That is, the coolant goes into the sewer.

Working principle in graphical representation

Then, when the temperature drops, the volume of coolant decreases. But since there is already less of it in the system than there was, the pressure in the system drops. If the lack of volume is insignificant, such a decrease may not be critical, but if it is too small, the boiler may not work. This equipment has a lower pressure limit at which it is operational. When the lower limit is reached, the equipment is locked. If you are at home at this time, you can correct the situation by adding coolant. If you are not there, the system may unfreeze. By the way, working at the limit also does not lead to anything good - the equipment quickly breaks down. Therefore, it is better to play it safe and take a slightly larger volume.

Circulation

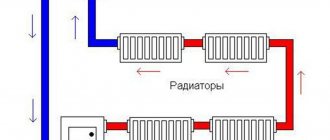

The tank can be installed in systems with natural or forced circulation.

- With natural circulation, the device should be built into the main line, thanks to which it will additionally serve as an air collector;

- With forced circulation, the device is connected to the return pipe so that the water does not boil in the system.

Connection system

Essentially, an open-type expansion tank is a container with four pipe outlets:

- Circulating;

- Expansion;

- Overflow;

- Signal purpose.

The heating system is connected to an expansion pipe located on top of the tank. An overflow is needed to drain water into the sewer when the tank overflows.

At the bottom there is a signal pipe with a locking device. Circulation is necessary to permanently maintain the overall temperature, in order to avoid freezing of the coolant in the tank.

Installation safety precautions

Based on the design of the pumped storage tank and the materials used, companies set some restrictions on the operation of heat supply systems.

Typically, this concerns the corrosiveness of the liquid medium in the system. For example, the percentage of ethylene glycol content is limited.

The conditions for using such devices are specified in the factory instructions; general safety requirements include:

- Operating the tank at pressures above the permissible size.

- At the point where the tank is mounted to the heat supply system, it is necessary to place a safety group that is triggered when the pressure in the network is exceeded.

- In autonomous heating systems, collectors with a maximum pressure of at least 3.0 bar are used.

Minuses

Recently, such products are not used in heating systems, as they have many disadvantages. Among them the following can be noted:

- Cannot withstand high pressure;

- The design is quite bulky and has large dimensions;

- Air penetrates into the open system along with the coolant, which has a negative effect on the surface of the metal elements, which causes pockets of corrosion to appear - corrosion will soon form on them;

- Such a device must be installed at the highest point of the system, which incurs additional costs.

Models of the Zilmet OEM-Pro series

This expansion tank for the heating system usually receives positive reviews. Many buyers praise it for its durable body. The device also uses a good fuse. Only one membrane is used at the tank. If you trust the experts, it wears off slowly. It is recommended to install the model behind the radiator grille.

It is also worth noting that the modification is not afraid of high temperatures. A maximum of 10 liters of coolant is allowed. The air chamber is used with a small volume. The outlet valve in the device is designed for heavy loads. The maximum pressure indicator is at least 2 Pa. It is recommended to connect the thermostat behind the counter above the mixer. The modification is great for gas boilers. The price for it fluctuates around 1,700 rubles.

Closed type

The membrane expansion tank does not have all the disadvantages inherent in the system described above.

However, installing it requires some additions and rules:

- Requires a pressure gauge;

- A device for manual pressure adjustment is required, otherwise the pressure may exceed all standard tolerances;

- The tank should be installed as close to the boiler as possible and with a connection to the return pipe. This is necessary to prevent the water from boiling.

You should not ignore the reliability of the fasteners, since during operation the weight of the expansion tank can increase significantly.

Design Features

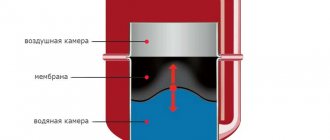

By design, the expansion tank is a metal container of a flat or cylindrical shape. The inside of the tank is divided into zones by means of a rubber membrane.

One zone contains compressed gas or air.

- In the non-working position, the entire volume of the container is filled with gas.

- Before starting the system, the pressure in the tank must be the same as that of the entire heating system.

- After the temperature rises, water enters a separate zone, and in the part where the gas is located, the pressure increases to the value created in the entire system.

If there is a sufficient amount of coolant, the gas pressure requires careful monitoring. For this purpose, a special compressor is installed that maintains a certain pressure. It turns out that the main element in the tank is the membrane.

Manufacturers and prices

Currently, the problem of buying an expansion tank for heating lies only in the correct selection of the type and volume of the device, as well as the financial capabilities of the buyer.

The market offers a wide selection of instrument models from both domestic and foreign manufacturers. However, it should be noted that if the purchase price for such devices as a closed-type expansion tank for heating is much lower than that of its main competitors, then it is better to refuse such a purchase. The low cost indicates the unreliability of the manufacturer and the low quality of the materials used in its manufacture. Often these are products from China. As with all other goods, the price for a high-quality expansion tank for heating will not have a significant difference of about two to three times. Conscientious manufacturers use approximately the same materials, and the difference in price of models with similar parameters of about 10-15% is determined only by the location of production and the pricing policy of sellers. Domestic manufacturers have proven themselves well in this market segment. By installing modern technological lines in their production, they achieved the production of products whose parameters are not inferior to the best global brands at a lower cost. It should be borne in mind that it is important not only to buy an expansion tank for closed-type heating, it also requires its correct installation. Having the necessary skills and following the instructions, you can install it yourself

If the master still has any doubts about his knowledge, then it is best to turn to professionals to guarantee stable operation of the heating network and eliminate possible malfunctions

Having the necessary skills and following the instructions, you can install it yourself. If the technician still has any doubts about his knowledge, then it is best to turn to professionals to guarantee stable operation of the heating network and eliminate possible malfunctions.

Membrane types

There are two types of membranes:

- Diaphragm, often such an element cannot be replaced with anything if it fails. This type is used more often in small-volume tanks;

- The balloon is easily replaced if it malfunctions. The coolant in such a membrane does not have contact directly with the surface of the container, because of this the service life of the product is significantly extended.

Setting the optimal pressure in the tank

Before connecting the expansion tank and filling it with coolant, it is necessary to set the optimal pressure in its air chamber corresponding to this parameter in the heating network. To perform this procedure, a plastic cover is removed from the air compartment, under which there is a nipple, the same as in car tires. The pressure measured by the pressure gauge is adjusted to the desired value by pumping it up using a pump or by bleeding it by pressing the nipple rod.

The optimal pressure in the tank is obtained by adjusting the internal pressure in a closed heating system downwards. This is done so that the rubber diaphragm is pressed on the coolant side. Otherwise, when it cools down, air will be drawn through the automatic vents, which should not be allowed under any circumstances. For example, if the internal pressure in the network is 1.2 atmospheres, then its optimal value in the expansion tank will be one atmosphere. After setting this value, you can open the tap and fill the system with coolant.

DIY connection

A closed type system is more common, so it is better to familiarize yourself with the process of connecting the tank, just this option.

- First you need to decide on the capacity. It should be about a tenth of the total volume of the coolant.

- Make correct technical calculations. Particular attention should be paid to the overall volume of the heating system.

- Disconnect the boiler from the heating source. Shut off the coolant supply using the valve to connect the expansion tank.

- Completely empty the circuit of liquid.

- To connect the container to the system, you will need a special soldering iron, fasteners, and a set of tees and fittings.

It is recommended to install the tank in a place with the lowest pressure. But you need to calculate so that the expansion tank does not interfere. Despite the ease of installation, it is advisable to entrust the connection of the expansion tank and boiler to a specialist.

An expansion tank of a simple design is not that difficult to install yourself. This procedure does not require special skills or special tools.

However, it is necessary to strictly follow the recommendations relating to the characteristics of the heating system in which installation work is carried out.

Installation of membrane device

A hydraulic accumulator of this type is installed where there is a minimum probability of coolant turbulence, since a pump is used for normal circulation of water flow along the circuit.

Correct container position

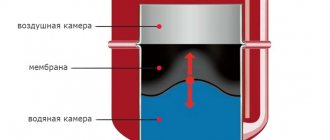

When connecting the expansion tank to a closed heating system, be sure to take into account the location of the air chamber of the device.

The rubber membrane periodically stretches and then contracts. Due to this impact, microcracks appear on it over time, which gradually increase. After this, the membrane has to be replaced with a new one.

It is better to install an expansion tank with a membrane so that the air-filled compartment is on top, this will extend the life of the device

If the air chamber of such a tank remains at the bottom during installation, the pressure on the membrane will increase due to gravitational influence. Cracks will appear faster and repairs will be needed sooner.

It makes more sense to install the expansion tank in such a way that the compartment filled with air remains on top. This will extend the life of the device.

Features of choosing an installation location

There are a number of requirements that must be taken into account when installing a membrane expansion tank:

- It cannot be placed close to the wall.

- The device should be freely accessible for regular maintenance and necessary repairs.

- The wall-hung tank should not be positioned too high.

- A shut-off valve should be placed between the tank and the heating pipes, which will allow you to remove the device without completely draining the coolant from the system.

- When installing on a wall, the pipes connected to the expansion tank must also be attached to the wall in order to remove possible additional load from the tank pipe.

For a membrane device, the most suitable connection point is the return section of the line between the circulation pump and the boiler. Theoretically, it is possible to install an expansion tank on the supply pipe, but high water temperatures will negatively affect the integrity of the membrane and its service life.

When installing an expansion tank, it is necessary to provide shut-off valves that will allow you to disconnect the device from the system and drain the water from it

When using solid fuel equipment, such placement is also dangerous because steam can enter the container due to overheating. This will seriously disrupt the operation of the membrane and may even damage it.

In addition to the shut-off valve and the “American” connection, it is recommended to install an additional tee and tap when connecting, which will allow you to empty the expansion tank before disconnecting.

Setting up the device before use

Before installation or immediately after it, it is necessary to correctly configure the expansion tank, otherwise called an expansion tank. This is not difficult to do, but first you need to find out what pressure should be in the heating system. Let's say an acceptable value is 1.5 bar.

Now you need to measure the pressure inside the air part of the membrane tank. It should be less by about 0.2-0.3 bar. Measurements are carried out with a pressure gauge with a suitable gradation through the nipple connection, which is located on the tank body. If necessary, air is pumped into the compartment or excess air is vented.

Before installing the membrane tank in the heating system, check the air pressure in the air compartment and adjust it according to the requirements

The technical documentation usually indicates the operating pressure, which is set by the manufacturer at the factory. But practice shows that this is not always true. During storage and transportation, some air may escape from the compartment. You must take your own measurements.

If the pressure in the tank is not set correctly, this can lead to air leakage through the air removal device. This phenomenon causes a gradual cooling of the coolant in the tank. There is no need to pre-fill the membrane tank with coolant; simply fill the system.

Tank as additional capacity

Modern models of heating boilers are often already equipped with a built-in expansion tank. However, its characteristics do not always correspond to the requirements of a specific heating system. If the built-in tank is too small, you need to install an additional tank.

It will ensure normal coolant pressure in the system. This addition will also be relevant if the heating circuit configuration changes. For example, when a gravity system is converted into a circulation pump and the old pipes are left behind.

This is true for any systems with a significant volume of coolant, for example, in a two- or three-story cottage or where, in addition to radiators, there is a heated floor. If a boiler with a small built-in membrane tank is used, installing another tank is almost inevitable.

An expansion tank will also be appropriate when using an indirect heating boiler. A relief valve, similar to that installed on electric boilers, will not be effective here; an expansomat is an adequate way out of the situation.