Efficient and economical heating or cooling of the working environment in modern industry, housing and communal services, food and chemical industries is carried out using heat exchangers (HE). There are several types of heat exchange units, but plate heat exchangers are the most widespread.

The article will discuss in detail the design, scope and operating principle of a plate heat exchanger. Particular attention will be paid to the design features of various models, operating rules and maintenance features. In addition, a list of leading domestic and foreign manufacturers of plate heat exchangers, whose products are in high demand among Russian consumers, will be presented.

Design and principle of operation

The design of a gasketed plate heat exchanger includes:

- a stationary front plate on which the inlet and outlet pipes are mounted;

- fixed pressure plate;

- movable pressure plate;

- package of heat exchange plates;

- seals made of material that is heat-resistant and resistant to aggressive environments;

- upper supporting base;

- lower guide base;

- bed;

- set of coupling bolts;

- Set of support feet.

This arrangement of the unit ensures maximum intensity of heat exchange between working media and compact dimensions of the device.

Design of a gasketed plate heat exchanger

Most often, heat exchange plates are made by cold stamping from stainless steel with a thickness of 0.5 to 1 mm, however, when using chemically active compounds as a working medium, titanium or nickel plates can be used.

All plates included in the working kit have the same shape and are installed sequentially, in a mirror image. This method of installing heat exchange plates ensures not only the formation of slot channels, but also the alternation of primary and secondary circuits.

Each plate has 4 holes, two of which provide circulation of the primary working fluid, and the other two are isolated by additional contour gaskets, eliminating the possibility of mixing working fluids. The tightness of the connection between the plates is ensured by special contour sealing gaskets made from a material that is heat-resistant and resistant to active chemical compounds. The gaskets are installed in the profile grooves and secured using a clip lock.

Operating principle of plate heat exchanger

The effectiveness of any plate maintenance is assessed according to the following criteria:

- power;

- maximum temperature of the working environment;

- bandwidth;

- hydraulic resistance.

Based on these parameters, the required heat exchanger model is selected. In collapsible plate heat exchangers, the throughput and hydraulic resistance can be adjusted by changing the number and type of plate elements.

The intensity of heat transfer is determined by the flow regime of the working medium:

- with laminar flow of the coolant, the intensity of heat transfer is minimal;

- the transition regime is characterized by an increase in the intensity of heat transfer due to the appearance of turbulence in the working environment;

- The maximum intensity of heat exchange is achieved with turbulent movement of the coolant.

The performance characteristics of the plate heat exchanger are calculated for a turbulent flow of the working medium.

Depending on the location of the grooves, there are three types of heat exchange plates:

- with “soft”

channels (grooves are located at an angle of 600). Such plates are characterized by slight turbulence and low heat transfer intensity, however, “soft” plates have minimal hydraulic resistance; - with “medium”

channels (corrugation angle from 60 to 300). The plates are a transitional option and are distinguished by average turbulence and heat transfer rates; - with “hard”

channels (corrugation angle 300). Such plates are characterized by maximum turbulence, intense heat transfer and a significant increase in hydraulic resistance.

To increase the efficiency of heat exchange, the movement of the primary and secondary working fluid is carried out in the opposite direction. The heat exchange process between the primary and secondary working fluids occurs as follows:

- The coolant is supplied to the inlet pipes of the heat exchanger;

- When moving the working media along the corresponding circuits formed from heat-exchange plate elements, intense heat transfer occurs from the heated medium to the heated one;

- Through the outlet pipes of the heat exchanger, the heated coolant is directed to its destination (heating, ventilation, water supply systems), and the cooled coolant again enters the working area of the heat generator.

Operating principle of a plate heat exchanger

To ensure efficient operation of the system, complete tightness of the heat exchange channels is necessary, which is ensured by sealing gaskets.

Features of operation

The key element of the heat exchanger is the working fluid (boiler water or water-glycol coolant). Flows move through channels created by corrugated plates. The wall corrugated layer creates a turbulence effect due to the high speed of liquid flow. Each medium moves along its own plate, but from different sides to protect it from mixing. The device forms a structure in which 4 manifolds are located for the input and output of various liquid media. All plates of the heat exchanger except the first and last participate in the heat exchange between liquids with different temperatures.

With low hydraulic resistance, heat transfer is improved due to additional turbulence and fine flow. Both methods allow you to clean the heat exchanger plates from persistent deposits and products of thermal decomposition of the coolant. The back and front plates are equipped with holes that are connected to the pipeline and are responsible for heating the working environment. After passing through the channels created by the plates and holes, the coolant leaves the equipment.

Requirements for gaskets

To ensure complete tightness of the profile channels and prevent leakage of working media, sealing gaskets must have the necessary heat resistance and sufficient resistance to the effects of an aggressive working environment.

The following types of gaskets are used in modern plate heat exchangers:

- ethylene propylene (EPDM). Used when working with hot water and steam in the temperature range from -35 to +1600C, unsuitable for fatty and oily environments;

- NITRIL gaskets (NBR) are used for working with oily working media, the temperature of which does not exceed 1350C;

- VITOR gaskets are designed to work with aggressive working environments at temperatures not exceeding 1800C.

The graphs show the dependence of the service life of seals on operating conditions:

As for attaching the sealing gaskets, there are two ways:

- on glue;

- using a clip.

The first method is rarely used due to the complexity and duration of installation; in addition, when using glue, maintenance of the unit and replacement of seals is significantly more complicated.

The clip lock ensures quick installation of plates and ease of replacement of failed seals.

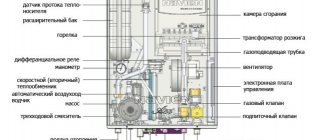

Manufacturers of boilers with bithermic heat exchanger

Buyers have a choice when choosing a boiler with a combined heat exchanger. Many companies produce such units. For example:

- Baxi (Italy). Wall-mounted dual-circuit models Mainfour 24i and Mainfour 24Fi.

- Beretta (Italy). Wall-mounted models for heating and hot water supply Ciao Cai 28 kW, Ciao Cai 24 kW, Ciao Csi 28 kW, Ciao Csi 24 kW.

- Buderus (Germany). Wall-mounted models Logamax UO42-24K (single-circuit), double-circuit Logamax UO44-24K, Logamax UO52-24K, Logamax UO52-28K, Logamax UO54-24K.

- Roca (Spain). Wall-mounted models for hot water supply and heating Neobit S 24/24, Neobit S 24/24 F.

- Sime (Italy). Wall-mounted double-circuit models Metropolis DGT 25 BF, Metropolis DGT 25 ОF, Metropolis 25 ОF, Metropolis 30 ОF.

- Solly (China). Wall-mounted models for hot water supply and heating H Standart 18, H Standart 26, H Standart 18F, H Standart 26F.

- Termal (China). Wall-mounted dual-circuit models M 18 i, M 18Fi.

- Unical (Italy). Wall-mounted model for heating and hot water supply Eve 05 Ctn 24F.

Thus, boilers with a bithermic (combined) heat exchanger cost less and are more reliable due to their design features, however, they are less productive and require a certain quality of water for good operation.

Specifications

As a rule, the technical characteristics of a plate heat exchanger are determined by the number of plates and the way they are connected. Below are the technical characteristics of gasketed, brazed, semi-welded and welded plate heat exchangers:

| Operating Parameters | Units | Collapsible | Soldered | Semi-welded | Welded |

| Efficiency | % | 95 | 90 | 85 | 85 |

| Maximum operating temperature | 0C | 200 | 220 | 350 | 900 |

| Maximum working pressure | bar | 25 | 25 | 55 | 100 |

| Maximum power | MW | 75 | 5 | 75 | 100 |

| Average period of operation | years | 20 | 20 | 10 — 15 | 10 — 15 |

Based on the parameters given in the table, the required heat exchanger model is determined. In addition to these characteristics, one should take into account the fact that semi-welded and welded heat exchangers are more suitable for working with aggressive working environments.

Operating principle

In such an apparatus, several processes occur at once: convection, thermal radiation and thermal conductivity. The heat exchanger functions as follows:

- through the holes in the front and rear plates of the device, heat enters the heat exchanger from the pipes;

- the wall layer at a high rate of heat supply starts a process that is commonly called turbulence. In other words, there is an exchange of spheres on different sides of the plate;

- those plates that are located parallel to each other form special corridors - working channels. They allow the media to directly carry out heat exchange.

There are two principles for moving heat through a heat exchanger:

- multi-pass: provides for movements along the same number of channels;

- single-pass: the flows immediately exit the heat exchanger, without re-cycling.

The power of the equipment is influenced primarily by the number of plates. The more there are, the more powerful the device is. We must not forget about installing a cleaning filter and regular maintenance of equipment to extend its service life.

Why is a heat exchanger needed in a heating system?

Explaining the presence of a heat exchanger in a heating system is quite simple. Most heating systems in our country are designed in such a way that the temperature of the coolant is regulated in the boiler room and the heated working environment is supplied directly to the radiators installed in the apartment.

If there is a heat exchanger, the working medium from the boiler room is released with clearly defined parameters, for example, 1000C. Once in the primary circuit, the heated coolant does not enter the heating devices, but heats the secondary working medium, which enters the radiators.

The advantage of this scheme is that the temperature of the coolant is adjusted at intermediate individual heating stations, from where it is supplied to consumers.

Types by method of heat transfer

- Superficial. Heat exchange between media with different temperatures occurs through walls made of material with high thermal conductivity. The circuits are completely sealed. Surface-type equipment is further divided into recuperative and regenerative. In recuperative heat exchangers, energy is transferred through thin walls of circuits that separate fluid flows with a constant direction. In regenerative ones, the direction of flow changes.

- Mixing. The transfer of thermal energy is carried out by mixing two media. This type is used less often than surface ones.

Advantages and disadvantages

The widespread use of plate heat exchangers is due to the following advantages:

- compact dimensions. Due to the use of plates, the heat exchange area significantly increases, which reduces the overall overall dimensions of the structure;

- ease of installation, operation and maintenance. The modular design of the unit makes it easy to disassemble and wash elements that require cleaning;

- high efficiency. PHE productivity ranges from 85 to 90%;

- affordable price. Shell-and-tube, spiral and block installations, with similar technical characteristics, are much more expensive.

The disadvantages of the plate design are:

- need for grounding. Under the influence of stray currents, fistulas and other defects can form in thin stamped plates;

- the need to use high-quality working environments. Since the cross-section of the working channels is small, the use of hard water or low-quality coolant can lead to blockage, which reduces the intensity of heat transfer.

Types of heat exchangers by method of application

- Shell and tube. They are made from a bundle of pipes connected into a lattice. The integrity of the structure is ensured by high-quality welding or soldering.

- Lamellar. The surface area for heat transfer is created by plates connected into a solid structure with heat-resistant seals.

- Twisted. Made from metal concentric coils. The coolant circulates through curved pipes and the interpipe space.

- Spiral - thin sheet steel rolled into a spiral.

- Water and air.

Plate heat exchanger piping diagrams

There are several ways to connect a PHE to a heating system. The simplest is considered to be parallel connection with a control valve, the circuit diagram of which is shown below:

PHE parallel connection diagram

The disadvantages of such a connection include increased load on the heating circuit and low efficiency of water heating at a significant temperature difference.

Parallel connection of two heat exchangers in a two-stage scheme will ensure more productive and reliable operation of the system:

Two-stage parallel connection diagram

1 – plate heat exchanger; 2 – temperature regulator; 2.1 – valve; 2.2 – thermostat; 3 – circulation pump; 4 – hot water flow meter; 5 – pressure gauge.

The heating medium for the first stage is the return circuit of the heating system, and the heated medium is cold water. In the second circuit, the heating medium is the coolant from the direct line of the heating system, and the heated medium is the preheated coolant from the first stage.

What determines the efficiency of a heat exchanger?

Shell and tube t/o

Surface heat transfer always occurs through the wall. In this case, heat loss occurs. The thinner the partition, the less loss. The new shell-and-tube heat exchanger has an efficiency of 75%, but as the internal and upper surfaces become overgrown with sediment, the efficiency of the device decreases. It cannot maintain temperature. Therefore, the devices have a removable beam, which is cleaned under high pressure with a special gun.

Plate devices have an efficiency of 90%, but the gaps between the plates become clogged and require cleaning. The equipment is disassembled for cleaning. It is important to install a magnetic mesh filter in place, which prevents the formation of sediment. Plate heat exchangers can be connected to automated control.

Plate collapsible t/o

The efficiency of the process depends on the connection diagram. Heat transfer is more complete in a counterflow apparatus when the flows move towards each other.

The thinner the partition, the better the process. But for pressure vessels, the wall thickness depends on the ability to withstand the load on the walls. If it is impossible to thin the walls of the tubes, it is necessary to increase the heating surface and make the apparatus longer.

Each heating unit is manufactured in accordance with thermal engineering calculations, has a passport and is designed to work with a specific coolant.

User manual

Each factory plate heat exchanger must be accompanied by detailed operating instructions containing all the necessary information. Below are some basic provisions relevant to all types of VET.

PHE installation

- The location of the unit must provide easy access to the main components for maintenance.

- The fastening of supply and discharge lines must be rigid and airtight.

- The heat exchanger should be installed on a strictly horizontal concrete or metal base with sufficient load-bearing capacity.

Commissioning works

- Before starting the unit, it is necessary to check its tightness according to the recommendations given in the technical data sheet of the product.

- During the initial startup of the installation, the rate of temperature increase should not exceed 250 C/h, and the pressure in the system should not exceed 10 MPa/min.

- The procedure and scope of commissioning work must clearly comply with the list given in the unit’s passport.

Unit operation

- When using PHE, it is not allowed to exceed the temperature and pressure of the working medium. Overheating or increased pressure can lead to serious damage or complete failure of the unit.

- To ensure intensive heat exchange between working media and increase the efficiency of the installation, it is necessary to provide for the possibility of cleaning working media from mechanical impurities and harmful chemical compounds.

- Regular maintenance and timely replacement of damaged elements will significantly extend the service life of the device and increase its performance.

Appearance of the device

Any heat exchanger has technical characteristics:

- maximum operating temperature, for example 200 °C;

- maximum operating pressure, for example 30 bar;

- test pressure, for example 43 bar.

The country of origin is indicated, a technical passport in the manufacturer’s language, a diagram, contours are indicated. If necessary, the passport can be translated into Russian. The design and operating principle of a heat exchanger from different manufacturers can sometimes be slightly different. But the essence remains the same.

The heat exchanger circuits for heating can be located either vertically or diagonally. This does not affect the principle of operation. The simplest device is a diagonal arrangement. In this case, the heat exchanger must be mounted strictly in a vertical position.

Hot water from the central heating system will flow from top to bottom into the heat exchanger, transferring its heat to the autonomous system through the separation system. At the entrance it will be very hot water, at the exit it will be water with a dropped temperature. In the circuit of an autonomous system, the coolant will flow from bottom to top. At the bottom, the water heats up slightly, and the closer to the top, the stronger the heating will be. Due to such a device, it will be easier for the system to work.

The process of supplying water to the heat exchanger is carried out using forced circulation. The thermal power plant operates on its own pumps. And the autonomous floor heating system in the apartment will operate on its own circulation pump.

Flushing the plate heat exchanger

The functionality and performance of the unit largely depends on high-quality and timely washing. The frequency of washing is determined by the intensity of work and the characteristics of technological processes.

Methodology for cleaning work

Scale formation in heat exchange channels is the most common type of PHE contamination, leading to a decrease in heat exchange intensity and a decrease in the overall efficiency of the installation. Descaling is carried out using chemical washing. If, in addition to scale, other types of contamination are present, it is necessary to mechanically clean the heat exchanger plates.

Chemical washing

The method is used for cleaning all types of PHE, and is effective with minor contamination of the working area of the heat exchanger. To carry out chemical cleaning, disassembling the unit is not required, which can significantly reduce the work time. In addition, no other methods are used for cleaning brazed and welded heat exchangers.

Chemical washing of heat exchange equipment is carried out in the following sequence:

- a special cleaning solution is introduced into the working area of the heat exchanger, where scale and other deposits are intensively destroyed under the influence of chemically active reagents;

- ensuring circulation of detergent through the primary and secondary maintenance circuits;

- flushing heat exchange channels with water;

- draining cleaning agents from the heat exchanger.

During the chemical cleaning process, special attention should be paid to the final rinsing of the unit, since chemically active components of detergents can destroy seals.

The most common types of contamination and cleaning methods

Depending on the working media used, temperature conditions and pressure in the system, the nature of the contaminants can be different, so for effective cleaning it is necessary to choose the right detergent:

- cleaning from scale and metal deposits uses solutions of phosphoric, nitric or citric acid;

- inhibited mineral acid is suitable for removing iron oxide;

- organic deposits are intensively destroyed by sodium hydroxide, and mineral deposits by nitric acid;

- fatty stains are removed using special organic solvents.

Since the thickness of the heat exchange plates is only 0.4 - 1 mm, special attention should be paid to the concentration of active elements in the detergent composition. Exceeding the permissible concentration of aggressive components can lead to destruction of plates and sealing gaskets.

The widespread use of plate heat exchangers in various sectors of modern industry and public utilities is due to their high performance, compact overall dimensions, ease of installation and maintenance. Another advantage of VET is the optimal price/quality ratio.

Materials, their pros and cons

For the manufacture of heat exchangers, durable materials are used that have a high thermal conductivity coefficient, are not prone to corrosion, and are resistant to liquid pressure. There are a number of metals that meet these conditions: steel, cast iron, aluminum, copper, aluminum. Each material has advantages and disadvantages. In most cases, if necessary, the metal plates of the heat exchanger can be replaced, which significantly increases its service life.

Steel

Steel is the most popular metal used in gas equipment. It attracts with its low cost, durability, ease of processing, and long service life. Due to the good ductility of the material, the surfaces of steel heat exchangers do not deform or form cracks even under high thermal stress and significant fluid pressure.

The main disadvantage of a steel heat exchanger is its susceptibility to corrosion processes. In addition, it is heavy and quite bulky. When operating steel equipment, gas costs increase. Warming up its walls and internal cavities, which have a large volume, requires additional fuel consumption. Stainless steel heat exchangers are durable, but have low heat transfer. This reduces the efficiency of the gas boiler.

Cast iron

Cast iron heat exchangers are strong, durable, and resistant to acid anhydrides, since the material is less susceptible to corrosion than steel. This significantly increases the service life of cast iron appliances (on average, up to 50 years).

One of the disadvantages of cast iron heat exchangers is the tendency to leaks, because the material is quite fragile. High thermal pressure on the walls leads to cracking. Cast iron equipment requires careful maintenance, since scale build-up can lead to uneven heating of the walls.

The frequency of cavity rinsing is as follows:

- If running water serves as the coolant, then washing is carried out once a year.

- In the case when antifreeze is used as a coolant, the heat exchanger is washed every two years.

- A device that uses purified water only needs to be washed once every four years.

- Special cleaning fluids are also widely used.

Copper

Copper is a light, ductile, noble metal. It is ideally suited for the manufacture of equipment in which heat exchange occurs. The device, made of copper, is durable, has a high strength coefficient, and is not subject to corrosion. Due to the excellent thermal conductivity of the material, the copper heat exchanger has maximum efficiency, and its maintenance is easy and not burdensome.

Heat exchangers made of copper also have their disadvantages. They are very expensive, and when heated to high temperatures, they tend to melt and burn out. The high chemical activity of the metal requires the use of neutral materials (pipes made of polypropylene or polyethylene) in the heating system.

Aluminum

Aluminum heat exchangers have quite significant advantages. They are compact and reliable. Aluminum, due to its high ductility, is suitable for creating complex devices. It has good thermal conductivity, which ensures a high level of efficiency. The aluminum-silicon alloy is chemically stable, which makes it possible to use it in heat exchangers of condensing boilers to withstand aggressive condensate.

Along with a lot of advantages, there are also disadvantages. Aluminum heat exchangers are susceptible to scale deposits, which is especially dangerous in the presence of water of increased hardness.

Small, solid inclusions dissolved in running water can damage the protective layer of the heat exchanger walls, acting as an abrasive on them. In this case, installation of a hard type cleaning filter system is required. In addition, it is important to clean and flush aluminum heat exchangers in a timely manner. This will avoid damage to the device and leaks.

The heat exchanger is an important part, without which normal operation of gas equipment is impossible. There are devices from various brands on the household appliances market, for example, Alfa Laval. When choosing, take into account the recommended operating pressure ranges, manufacturing technology features, and the material used. The final price of the heating equipment will depend on the brand, design, and basic technical characteristics of the heat exchanger.

Design of heat exchange equipment

Corrugated plates are made of stainless steel (most often acid-resistant) and are connected to each other using sealing gaskets. This structure is then attached to the frame (size depends on the equipment model). In this case, the plates can be removed or added at any time (both before installation and during operation), which allows you to achieve the most effective heat transfer coefficient.