There is a large selection of insulation materials on the building materials market. Izover – This is a modern and improved version of glass wool, known from Soviet times.

It is widely used in Russia and abroad; it has been present on the Russian market for about 20 years. In Europe, every second house is insulated with this material, and in the USA, every fifth one.

What is the material?

The name of the material “Isover” is a brand of the French concern Saint-Gobain, a manufacturer of various types of insulation. Since this concern began on the Russian building materials market by selling fiberglass mineral wool, the name “Isover” was firmly assigned to this material. The name "isover" comes from two French words - "isolation" - insulation and "verre" - glass.

Isover is a material made of fiberglass or basalt fiber with a porous structure; it is produced in the form of rolls and slabs of different hardness. It is used for sound insulation and insulation of walls, partitions, floors, roofs, air ducts and heating systems.

It is used in the design and construction of private, civil, industrial and transport facilities. It is used both in new construction and in the reconstruction of buildings and structures, for heating mains. In this article we will look at the technical characteristics.

Properties

Basic properties:

- high elasticity;

- low thermal conductivity - 0.041 watts per meter per Kelvin;

- good sound insulation due to the air gap between the fibers;

- Izover is much lighter than its analogues and is used for facades where excessive load is unacceptable;

- the presence of water repellents with water-repellent properties;

- service life of at least 50 years;

- all types of isover are considered non-flammable;

- low smoke generating ability;

- the ability to compress up to 60%, which is very convenient for transportation;

- environmental friendliness - no harmful substances are released during operation.

Basic composition

Isover consists of basalt or fiberglass with the addition of recycled sand, limestone and soda. The basis of isover is glass fibers about 5 microns thick and 150 microns long. In the production of isover, recycled materials are used, which ensures an affordable cost of insulation.

The material production technology consists of the following stages:

- mix quartz sand , soda, limestone, and other minerals;

- bring the composition to a temperature of 1300 degrees Celsius until liquid glass forms;

- From a special device, the plastic mass enters a container in the walls of which small holes are made. The container rotates at high speed and, thanks to centrifugal force, liquid glass is squeezed out of the holes in the form of thin, long threads;

- the resulting glass threads are mixed with yellow polymer glue, resulting in the formation of an adhesive mass;

- Then the mass is placed in a drying oven with rollers. Hot air dries the mass, and steel rollers level and form a layer;

- the finished layers are cut into the required sizes.

Release forms

Isover is produced in the form of rolls (mats) and slabs. Each type is used for specific insulation and sound insulation work. The slabs are produced in different hardnesses, they are treated with water-repellent compounds, with additives from extruded polystyrene foam.

Insulation rolls can be single-layer or double-layer; they are used for horizontal surfaces – floors, ceilings. Plates and rolls are packed in dense heat-shrinkable plastic containers.

Dimensions

The slabs are produced in different sizes, the maximum size is meter per meter with a thickness of 5 to 10 cm. Dimensions of the slabs are 610×1170 (dimensions are given in mm), there are 14 pieces in a package. Rolls are produced single-layer and double-layer with a width of 120 cm. The length of the roll varies from 7 to 14 m.

Single-layer rolls are produced with a thickness of 5 or 10 cm, double-layer rolls with a thickness of 10 cm, with the thickness of each layer being 5 cm.

How many square meters are in a package of mineral wool?

What sizes does mineral wool come in?

| Brand name | Dimensions of mineral wool in rolls , mm | Total area, m2 |

| Length | ||

| Hydrophobized mineral wool Teploroll, TechnoNIKOL | 5000 | 6 |

| Thermal insulation Izover Classic | 8200 | 20 |

| Vapor barrier Isover Sauna | 12500 | 15 |

Types of isover insulation

Isover insulation has nine popular varieties:

Isover KL34 – slabs 5 or 10 centimeters thick, suitable for any surface;- Isover KL37 – slabs are produced in pressed packages;

- Isover KT37 – roll material;

- Isover KT40 – two-layer mats; .

- Isover STYROFOAM 300A – solid boards with the addition of extruded polystyrene foam;

- Isover VENTITERM – slabs treated with a water repellent;

- Isover “Pitched roof” – used for roof insulation;

- Isover “Ventfacade” – two-layer facade slabs;

- Isover “ Sound protection” – available in the form of plates and rolls, used for sound insulation.

Many types of insulation can be interchanged with each other.

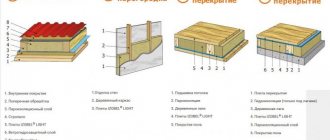

Application of isover insulation

Izover is used for insulation of internal and external walls, roofs, floors of residential, public and industrial buildings. It is also used to minimize noise in wall, ceiling and floor structures.

Isover KL34 is used for any surfaces: horizontal, vertical, with any angle of inclination. To install the slabs, a frame is used in which the isover is mounted, and no additional fastenings are needed.

Isover KL37 is used for interfloor slabs, walls and roof slopes. Available in the form of pressed slabs and packaged. This type of insulation must be pressed tightly against the working surface; installation does not require additional fasteners.

Isover KT37 is produced in roll form, used mainly for horizontal surfaces, but can be used for internal walls and partitions and roof insulation. The material does not require additional fastenings; it must be pressed tightly to the surface.

Isover KT40 is a two-layer roll material used for horizontal surfaces. During installation it does not require additional fastenings.

Isover STYROFOAM 300A has improved thermal insulation and moisture resistance properties thanks to additives in the form of extruded polystyrene foam. The material is produced in the form of rigid slabs and requires additional fastenings. Depending on the base, the slabs are fastened with: plastic dowels, special mastics based on cold bitumen, or polyurethane foam glue.

Isover VENTITERM and Isover VENTITERM PLUS

boards are new products from the Isover concern, with dimensions of 1000x600 mm, with a thickness of 50, 80, 100 mm.

They are used in single-layer and two-layer facade insulation systems. Isover VENTITERM is produced in the form of dense slabs and is used for external insulation of facades, ventilation and water supply pipes, for sound and thermal insulation of ventilated facades.

Isover VENTITERM PLUS is available in slabs with the same dimensions as Isover VENTITERM . The main difference is the improved helicopter protection properties, due to the fact that on one side these plates are covered with special fiberglass.

Isover “Pitched roofing” is used for structures with changes in humidity conditions. It is also a good sound and heat insulator, used in any climatic conditions. It is used for pitched roofing and soundproofing of internal walls and partitions. The dimensions of the Isover “Pitched Roof” slab are 610x1170 with a thickness of 100 mm.

Isover “Ventfacade” is available in the form of slabs of different sizes, with a thickness of 50, 100, 150 mm. Consists of two layers, but can be used as a single layer material. Thanks to its elasticity and elasticity, it fits tightly to the base and does not require additional fastenings.

Isover “Sound Protection” is produced in the form of slabs with dimensions 610×1170 and a thickness of 50 mm. This material reduces noise levels and is used for sound insulation of roofs, facade walls, internal walls and partitions. Can be used in any climatic conditions.

Isover “Sauna” The product is intended for insulating walls and ceiling structures of saunas and baths from the inside. The foil product is also good for

insulating

other damp areas. ISOVER SAUNA also works as an effective heat insulator.

Isover “ Optimal”

– stone wool slabs for frame structures. The product is recommended for thermal insulation of the roof, walls, and floors of the house.

Isover “Facade- Master”

is a high-tech facade insulation for low-rise and private construction.

Isover “ Classic”

Used in lightly loaded horizontal structures.

Isover “ Pro”

, judging by the characteristics and reviews, is the most durable material in this line.

Isover “Ruf N” is a non-flammable basalt insulation. Made from stone fiber with the addition of a synthetic binder. High-density material can withstand significant loads. It is used as a bottom layer when insulating flat roofs in private housing construction.

Isover Venti

a special product for insulation systems for ventilated facades.

Brand history

The rights to the brand belong to the Saint-Gobain company from France. Its main office is located in Paris, and its founding date is 1665. It appeared at the direction of Louis XIV and produced glass and mirrors. The name Isover insulation is formed from the words “glass” and “insulation”. In our country, the company's products were initially known under the Uteplyaev brand.

Initial Izover products in Russia

Over more than 350 years of history, Saint-Gobain has grown into an international industrial group represented in 67 countries and employing over 170 thousand employees. Sales in 2015 amounted to 39.6 billion euros. The company is included in the following ratings:

- The hundred largest industrial enterprises according to Forbes.

- Top 100 innovative organizations in the construction sector.

- Best Employer - 2016

Experience and the latest technologies have made the company a world leader in creating a comfortable living space. The main activities of Saint-Gobain are:

- Innovative technologies in the field of high-tech products in the production of ordinary and special glass.

- Building materials represented by ISOVER, ISOTEC, ISOROC brands in insulation; GYPROC in gypsum solutions; WEBER dry mixes; ECOPHON for acoustic ceilings and panels; in siding and tiles - CERTAINTEED; RAM pipes

- Distribution activities in the field of building materials.

Saint Gobain Campaign:

The company's products have been known on the Russian market for more than 20 years. Ten years ago, a plant was opened in the Moscow region (Egoryevsk), and since 2011 in Chelyabinsk, the Minvata company began producing stone fiber insulation. All products have international environmental certificates and comply not only with internal corporate standards, but also EN 13162—ISO 9001.

Specifications

Isover is a heat and sound insulating material; it is used to insulate any structural elements inside and outside the building. It is necessary to level the surface under this insulation, since the main condition for using this insulation is a tight fit to the surface.

Main characteristics:

- low thermal conductivity;

- high level of sound insulation;

- resistance to infestation by fungi, small insects, and rodents due to special impregnations;

- ease of transportation and installation ensures the light weight of the material, its density is 13 kg/cub.m;

- elasticity of the material;

- resistance to chemicals;

- long service life.

Thermal conductivity

For thermal insulation materials, thermal conductivity is the main characteristic. For various types of isover it ranges from 0.035 to 0.044 W/mK, which is much less compared to other analogues.

Provided the installation technology is followed, this characteristic will not change over time. This ensures the prevention of heat loss through the load-bearing and enclosing structures of the building.

Soundproofing

The structure of Isover insulation, consisting of thin glass fibers and an air layer, and low dynamic rigidity create effective noise insulation. It is used to provide sound insulation in structures where the soundproofing material does not bear the load.

Flammability

According to the current GOST 30244-94 “Construction materials. Combustibility test methods", isover belongs to the class of non-combustible materials. Therefore, it is used for insulation and sound insulation indoors for various purposes and in low-rise construction.

Isover is also used as an effective insulation in log, frame or panel wooden residential and public buildings.

Vapor permeability

The vapor permeability of isover is 0.50 - 0.55 mg/mchPa and is one of the main disadvantages of this material. In the absence of a vapor barrier, the quality of the insulation will decrease as moisture accumulates.

When the humidity level increases by 1%, the level of thermal insulation decreases to 10%. But under the influence of temperature or sufficient ventilation, the material dries quickly.

To prevent moisture absorption, a vapor barrier is used, and a ventilation gap of 2–4 cm is left between the isover and the wall.

Life time

The heat and sound insulation qualities of the material do not deteriorate over time if the installation technology is followed. For 50 years, the thermal insulation parameters of isover in building structures have not deteriorated.

Environmentally friendly and harmless

Izover is made from natural materials and does not contain harmful substances such as artificial resins or formaldehydes. This is a hypoallergenic material that is safe for human life. Based on the research, it was revealed that there are no harmful emissions during operation.

Insulation weight

What is the weight of the insulation? The weight of isover is much less than similar insulation materials. The specific gravity of isover is 2.5. Therefore, it is used for insulating buildings made of wood, slag concrete, and thin-walled brick.

Release form

Isover is produced in the form of slabs and rolls in packaging. The elasticity of the material allows it to be compressed in packaging, which is very convenient for storage and transportation. After opening the package, the isover quickly acquires its initial dimensions. Roll sizes are 7-14 meters long, 1.2 meters wide.

Other characteristics

Double-layer rolls can be divided into layers before installation. Isover cannot be used at temperatures above 250 degrees Celsius

In a humid environment, isover:

- has water-repellent properties;

- slowly absorbs moisture and water.

These Isover insulation materials have a certificate of conformity and meet all safety standards listed in the requirements of the Customs Union.

Safety

The safety of stone wool for health is evidenced by its natural origin , production method and the conclusion based on the results of product testing and audit of the enterprise . It is no coincidence that professional builders use mineral insulation in the construction or reconstruction of even children's, medical and sports institutions . ISOVER stone wool creates a comfortable temperature in the building of the Federal Center for Cardiovascular Surgery (Chelyabinsk), in an emergency hospital (Kazan), in many kindergartens in Moscow, St. Petersburg and other Russian cities. This material is chosen when it is important to use a safe product with a positive experience of use, the quality of which can be trusted. Fire safety Mineral wool belongs to the group of non-combustible materials. Therefore, it does not burn, does not spread fire and does not emit harmful substances not only when in contact with an open fire, but also simply when heated.

Environmentally friendly and harmless

Fiberglass materials of this type are absolutely harmless to human health and life. During their operation, no harmful substances are released. Finnish scientists have been checking this fact for half a century. No danger was detected - this verdict was repeatedly made by specialists from the Institute of Cancer Problems.

Rules for working with stone wool

Manufacturers of stone wool recommend installing stone wool in accordance with the rules for working with any building material, i.e. wearing gloves and a respirator.

Insulation weight

If we compare Izover with other heat insulators in terms of weight, it will turn out to be much lighter than the others. Therefore, in those buildings whose walls are made of not very durable materials or excessive load is unacceptable, the use of Izover will be an excellent way out.

Disadvantages of isover

According to safety precautions, when working with materials containing fiberglass, you need to use protective equipment: gloves, long-sleeved workwear, safety glasses, gauze bandage. If safety precautions are not followed, skin irritation may occur.

To prevent glass dust from entering the room during internal insulation, a special film is laid between the isover layer and the finishing material (lining, drywall).

Also, if the isover is installed incorrectly or the finishing layer is deformed, insects or mice sometimes appear in the insulation. Isover does not have mechanical strength, so it should not bear the load.

Despite its shortcomings, Izover is not inferior to its competitors, such as Ecover, Knauf, TechnoNIKOL, Rockwool.

Isover insulation of walls

insulate the external walls of a building from the facade side.

But in some cases this is not possible, for example, if it is an architectural monument. To insulate the inside of a building, the following conditions must be met:

- perform insulation from environmentally friendly and non-combustible materials;

- prevent the formation of condensation between the insulation and the outer wall.

Installation of insulation is carried out in the following order:

- make a frame from wood or profiles for installing drywall;

- lay the isomer slabs, ensuring a tight fit to the wall and to the frame. This can be achieved if the sheathing is done in increments of 1 cm less than the width of the isover.

- install a vapor barrier film with an overlap, and tape the joints with a special vapor barrier tape;

- cover with plasterboard.

Insulating walls from outside under sheathing:

- install the sheathing in increments of 1 cm less than the width of the slab;

- lay insulation;

- install a block that provides an air gap;

- installation of a waterproof and windproof membrane;

- installation of external finishing (lining, siding).

Sound insulation based on Izover

The use of isover in walls , floors and ceilings prevents noise from entering neighboring rooms.

The air gap between the fiberglass provides the sound-absorbing properties of the material. With an isover layer thickness of 50 mm, the airborne noise level decreases by 45 dB. To soundproof floors, the technology used is “floating floors”. Rolled isover is used for installation of floating floors. This material can also be used for sound insulation in the construction of suspended ceilings.

For sound insulation in walls and partitions, a structure made of a metal frame filled with isover slabs and covered with plasterboard is used.

Isover is also used for sound insulation of metal air ducts, mufflers of aerodynamic noise produced by fans and ventilation systems. Isover material provides noise absorption in the mid-frequency range. Isover is also used in cinema and concert halls as sound-absorbing panels.