Boiler or stove heating in a house requires the installation of a chimney, which in most cases leads to the roof. An essential part of the chimney pipe is the cap, which is installed at the end of the chimney. It is also called an umbrella, visor, weather vane or cover, which can have different shapes, sizes and designs.

Construction stores sell ready-made products made of galvanized steel sheets, which can be immediately installed on the chimney head. But any person with minimal skills in working with metal can make a pipe cap on their own.

Why install a chimney on a pipe?

This design is applicable not only to chimneys.

As a rule, chimneys are installed on the pipes of ventilation outlets and flues. In appearance, they look like a kind of canopy over the chimney. There are many options for designing chimneys; in the overall design, they look attractive and aesthetically pleasing, so those who are not familiar with the intricacies of construction work may think that this is an exclusively decorative detail. In fact, the beautiful appearance of the chimney is far from its most important characteristic.

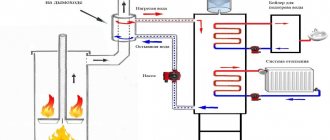

Installation diagram of the chimney on the pipe (sectional view)

In addition to the fact that the cap on the chimney pipe protects it from precipitation and debris getting inside, it also prevents premature destruction of the upper part of the pipe. This quality is especially important if you need to protect a brick pipe.

The important functional load and attractive appearance of the roof make the chimney cap an indispensable element when installing a chimney.

Materials for making chimneys

When choosing a chimney for a pipe, you should pay attention, first of all, not to the appearance, but to the functionality that is provided by the material used to make the structure.

- Copper. It is considered the most functional material, as it can provide both attractive appearance and excellent performance. A cap for a chimney pipe made of this material, provided that the installation work is carried out correctly, will last for many years, never ceasing to please the owners of the house. Over time, the copper umbrella becomes covered with patina and becomes similar to antique products. When installing a copper umbrella, you should remember that this material, when interacting with other metals, begins to actively oxidize. This process can damage the structure ahead of schedule. To avoid such problems, when installing the chimney, it is necessary to use parts made of copper or containing copper for fastening.

- Steel. A chimney cap made of steel is less durable than a copper one. But their cost is an order of magnitude lower. With proper installation and selection of fasteners, steel chimney caps will last 10-15 years, and a stainless steel umbrella will last about 30 years.

- Zinc-titanium. This material is often used in roofing and installation work, since its technical characteristics are similar to copper. Chimneys on zinc-titanium pipes can be used without loss of performance for up to 50 years. The main condition for a long service life is to install the structure correctly.

If firewood is used as fuel in a home stove or bathhouse, then chimney smokers are not made of painted metal, since under the influence of high temperatures the paint layer will quickly burn out and the umbrella itself will become covered with soot.

Copper chimney for brick chimney

If the height of such a pipe does not exceed 5 meters, then it is best to make a canopy for the chimney pipe or a deflector from heat-resistant materials - copper or stainless steel. Since these metals are resistant to oxidation and corrosion, chimney caps will last much longer.

Design Features

The simplest design of the umbrella looks like a flat or cone-shaped cover installed at the top of the pipe. Modern technical capabilities make it possible to make this chimney element in a wide variety of shapes, some of which can be compared to a real work of art, such as a forged umbrella.

Many owners prefer to install a deflector, which increases draft in the chimney.

Depending on the architectural shape of the house, you can make an original umbrella with your own hands or buy a ready-made one. So, for houses in the “modern” style, it would be most appropriate to choose chimneys on pipes with a flat roof. A house in the European style will be perfectly decorated with a chimney cap in the form of a hemisphere.

This is what an installed chimney looks like on a pipe with protective decorative grilles

Chimneys are often installed that have several slopes on their roof: in winter, snow and ice do not accumulate on them, and the shape of the lid ensures good ventilation of the chimney.

For houses in which stoves or fireplaces are heated with wood or peat, and the roof is made of flammable materials, an umbrella with a spark arrester is installed.

This part is a stainless mesh with small cells, mounted on a metal frame.

You can make a spark arrester yourself and install it either in the chimney shaft or along the perimeter of the canopy.

Chimney cap with weather vane decoration

For all-round protection from blowing winds, one of the types of chimneys is used - a deflector.

Gusts of wind significantly reduce the draft in the chimney if its head does not have such a device. The deflector operates on the principle of aerodynamics, changing the direction of wind movement.

Structurally, the deflector consists of two cylinders: an upper one (in the form of a truncated cone) and a lower one, and a protective cap. Depending on the direction of the wind, the smoke comes out into one of two channels - upper or lower. The deflector is made of galvanized steel.

Varieties

The abundance of shapes and types of chimneys force manufacturers to produce caps of various shapes, styles, and sizes. In construction stores you can find the following types of products:

- Standard weather vane. Her umbrella is a pyramid made of sheet metal, attached to a drip apron using brackets.

- Four-slope weather vane. The top of such models resembles a hipped hip roof. As a rule, they are used for rectangular brick pipes.

- Wind vane with a semicircular umbrella. It is used for installation on the roofs of European-style houses. From the point of view of increasing traction, it has low efficiency, however, it looks beautiful on the slope.

- Flat weather vane. It is equipped with a flat rectangular umbrella and is used for buildings in the minimalist and modernist styles. The flat cover of the hood does not allow snow to roll off, which is why the brackets of such models experience increased load and sometimes become deformed.

- Round weather vane with a cone-shaped umbrella. They are used to protect round stainless steel pipes; such models are not equipped with a drip line.

Types of chimney caps Different types of chimney caps

Note! Wind vanes are equipped with additional functional elements: dampers, double roofs, folding doors. Don’t get carried away with elaborate details, because the main thing in choosing a deflector is durability and efficiency. An ill-conceived shape can cause noise or vibration in the pipe.

Advantages and disadvantages

The advantage of installing a cap on the chimney is:

- more aesthetic appearance of the chimney duct;

- protection of the internal space of pipes from foreign objects and various debris;

- protection of the chimney material from the effects of precipitation;

- the chimney covers part of the mouth, preventing the wind from overturning the draft.

There are not many disadvantages to installing an umbrella on a chimney, but they are quite significant:

- the product is installed in the path of combustion products exiting and serves as some obstacle to their free outflow. An incorrectly selected and installed model can reduce draft and lead to smoke in the room;

- The water vapor generated during fuel combustion exits along with the smoke through the pipe to the street and condenses, coming into contact with the cold metal of the cap, and then freezes when the temperature drops below 0º. As a result, icicles freeze on the chimney, blocking the passage opening of the pipe and preventing the smoke removal process.

How to make a visor

First of all, you need to find out the external dimensions of the head where you plan to attach the umbrella, and then sketch out a hand-drawn sketch depicting the future structure. To develop it, use simple rules:

- the dimensions or diameter of the product must be 10 cm larger than the dimensions of the pipe, so that the edges protrude 50 mm on all sides;

- slope angle of the slopes – from 30 to 45°;

- the minimum height from the chimney cut to the fungus is 100 mm, as shown in the drawing.

In addition to the traditional umbrella, there are other design options - a deflector and a rotating weather vane - “sycophant”. The first allows you to actually increase traction due to wind pressure, which creates a vacuum inside the cylindrical body, where the smoke channel exits. But in calm weather, this device not only loses its advantages, but also worsens the traction force in the pipe, creating increased resistance at the exit of combustion products.

Deflector operation diagram

For reference. The same effect is created by rotating spherical nozzles, an example of which is shown in the picture.

The attachment is beautiful, but not very effective

A semi-cylindrical weather vane, assembled from several segments and rotating on a special bearing, was called a “sycophant” due to its ability to turn with the wind. If it were not for the high price and dubious reliability of the bearing, it would be an ideal cap for any round chimney, since it successfully protects the mouth from blowing and precipitation.

Various materials are used to make chimney canopies - thin sheet steel with zinc and polymer coating, stainless steel and even copper. To make a pipe cap with your own hands, we recommend the first 2 options - galvanized or painted metal with a thickness of at least 0.5 mm.

Making a simple round umbrella

To perform this work, you will need the usual tools - metal scissors, a drill, a hammer and a device for setting rivets. Having determined the required size of the fungus, proceed in this order:

- Screw 2 screws into the wooden strip at a distance equal to the radius of the product plus 15 mm. Get an improvised compass, with whose help mark the center of the circle on the metal and draw its outline.

- Cut the workpiece with scissors, and then draw a sector with an arc length of approximately 120 mm (the figure resembles the first piece of a round cake).

- Cut out this wedge, then forcefully align the outer edges of the circle and secure them in a vice.

- Drill 3 holes along the resulting seam and connect the ends of the part with rivets or M4 screws with nuts. The upper part of the weather vane is ready.

Drawing a circle (left) and connecting the edges of the fungus (right)

The legs for the fungus and the clamp surrounding the pipe are made of steel strips made by bending a thin sheet 2-3 times. These parts are also attached to the umbrella with rivets, which is clearly demonstrated by the master in the video:

Gable weather vane

To make this type of cap, it is advisable to use a sheet bending machine or contact the appropriate workshop for this service. In extreme cases, you will have to bend the elements manually along the line, carefully tapping the metal with a rubber hammer on a wooden block.

As in the previous version, the first step is to take the external dimensions of the brick chimney, and then calculate and sketch the pattern, as shown in the drawing. Formulas for determining the length of the sides of the elements depending on the initial dimensions of the pipe and the height of the wind vane are also given here.

Types of chimney pipe heads

Installing a cap on a chimney pipe provides the following advantages:

- protection of the chimney from moisture entering it;

- low cost of the deflector;

- preventing possible pressure drops and normalizing it inside the pipe;

- protection against chimney destruction.

The deflector is produced in various shapes, which affects its characteristics and method of application. The main types are:

- regular umbrella (head);

- cap with weather vane;

- deflector;

- cap with a hip roof.

The usual head of a chimney has the shape of a cone or a hipped roof. It is considered the best option, and its cost depends on the specific dimensions. The head with a weather vane differs from the usual one only in the presence of decorative elements.

Note! Caps (heads, umbrellas), as well as other structures, can somewhat reduce the draft and also lead to the appearance of reverse draft.

The deflector is designed to disperse flows and prevent them from entering the pipe. If it is combined with a cap, performance will be reduced. A cap with a hip roof is used to protect against precipitation (rain). It has higher strength.

The simplest version of the cap serves to protect the chimney from debris and precipitation

Manufacturing of the Grigorovich–Wolpert deflector

It is made by analogy with a conical cap:

- Two umbrellas are made and the edges are connected to each other. In the upper cone, cuts are made along the edges for attaching racks to them. The diameter of the cones is twice the diameter of the chimney pipe.

- The deflector has a width of 1.5 and a height of 1.6 times the diameter of the smoke channel. The outer cylinder is manufactured similarly to the diffuser cylinder. Having rolled the blanks, they are joined with rivets.

- The umbrella is connected to the diffuser using claws, and the entire structure is inserted into the outer cylinder.

How to choose a cap for a chimney pipe

The functions of the caps are to enhance draft, prevent destruction of brickwork, and increase the efficiency of the chimney pipe (up to 20%). Therefore, the choice of head must be taken very seriously.

At the initial stage, it is necessary to decide on the design features of the head. For a chimney, a regular cap will be sufficient, which will effectively protect against moisture and rain, and also prevent blowing into the stove.

For more complex smoke exhaust systems, the selection of a hood with a cone for spreading smoke and a built-in deflector is required. The differences between the heads, depending on the type of chimney, lie in the technology for installing the protective cap and the features of the fastening elements.

The choice of material for making the heads is also important. Copper structures are more expensive than steel ones, but they are more reliable and durable. The characteristics of zinc-titanium samples are close to those of copper and are characterized by high strength. Steel products have a service life of 10-15 years.

For complex chimney systems, you may need a head with additional elements - a spark arrestor or deflector

Some models have a special protective mesh that prevents debris from entering the pipe, but it slightly weakens the draft.

Principle of operation

Before making a plastic or metal chimney cap, you need to become familiar with its operating principle.

Most often, the fungus is used to protect the pipe from precipitation, debris or birds. It is also installed to catch sparks that may fly through the chimney while the stove is in use.

The operating principle of this design is quite simple. It is equipped with a protective cap that covers the smoke outlet and thus protects it.

There are also deflectors that speed up the removal of combustion products. Their operating principle is based on the law of aerodynamics. When gusts of wind collide with the deflector, an air rarefaction effect occurs. This helps to increase draft and remove smoke.

To better remove combustion products from the deflector, it is equipped with an additional cap. It is installed under the cover of the structure.

Installation technology

The main requirement of building codes is that the cap should not impede the exit of flue gases from the pipe .

To comply with it, you need to follow a number of principles:

- When the pipe is removed from the roof ridge by 1.5 meters or less, the top of the cap should rise above the ridge by at least 50 centimeters .

- When the pipe is removed from the ridge by 1.5-3 meters, the head should be on the same horizontal line .

- When the pipe is 3 meters or more away from the ridge, the head should not be below a straight line drawn from the top of the roof at an angle of 10 degrees .

- If the height of the external chimney masonry is 1.2 meters or more, then before installing the cap you need to secure the pipe with roof braces .

Most head models are prefabricated, which simplifies their installation. The general installation algorithm is standard for all additional elements: first, the main product and its additional parts are fastened, then all joints are sealed.

The head should not impede the exit of flue gases from the pipe

The lower part of the cap is installed first; it must be attached to the top of the chimney. Screws or rivets are used as fastening elements.

Next, intermediate elements and the top of the structure are installed, which are connected to each other using brackets. Rubber or silicone-based compounds are used to seal joints. Particular attention should be paid to insulating the joints of the head and chimney.

Materials for the production of smoke umbrellas

Basic requirements for the material for the chimney:

- Possibility of use at elevated temperatures. This requirement does not apply to weather vanes mounted on a ventilation duct.

- Long service life.

- Resistant to corrosion and oxidation.

Copper is used for work. Such structures will last 50-100 years, are durable and reliable. Often, when installing chimneys, hardware - fastenings - are made of copper.

Zinc titanium alloy is another popular option. The chimney will last about 50 years, and costs much less than a copper structure. For installation, dowels or long threaded nails are used.

Vanes are also made of steel - stainless or galvanized. However, in any case, the fastenings must be galvanized. Chimneys made of galvanized steel with a polymer coating are very common. The coating allows you to choose the desired color from the RAL catalog.

Why do pipes smoke?

- Wrong

pipe diameter is selected.

- Incorrect pipe length as well as height.

- If the wind increases, cold air enters the chimney. The draft becomes less as wind pressure acts on the smoke, the smoke stops leaving the chimney and, as a result, the smoke remains in the chimney.

- The chimney is clogged with soot. You cannot use any chemicals when cleaning the chimney; to clean the chimney, you must invite a specialist.

- Perhaps a brick fell from the masonry. When strong winds rise, there are cases when bricks fall from the masonry. It is necessary to remove the brick and seal the hole with clay.

- The masonry begins to crack and cold air gets into the cracks, the draft decreases, and the fireplace will smoke. All cracks must be sealed with clay mortar.

- Condensation is released, causing the oven to become damp . Reason: when the temperature of the gases released during fuel combustion decreases. Due to the soot that accumulates on the pipe walls, it reduces the thermal insulation.

- If the chimney was built incorrectly.

- If the walls of the chimney are uneven and the cross-section of the chimney is small.

- If the chimney is installed below the roof.

- When installing a chimney near tall trees and houses.

- If the chimney passes air through the brickwork.

- If the room is poorly ventilated.

- Rain, snow.

- When it's warmer outside than in the building.

- When you light it for the first time when the chimney is frozen.

Is there a difference between weathervanes, chimneys and umbrellas?

Chimney caps are a general term for chimney caps. This is the name given to protective devices placed on the pipes of fireplaces, stoves, gas or diesel boilers that exhaust waste gases with smoke.

An umbrella is a broader concept. Umbrellas are suitable for both chimneys and ventilation outlets, exhaust ducts, and sewers. Their design and purpose are the same.

The caps of weather vanes are complemented by weather vanes - devices by which the direction of faith is determined. Otherwise, they are identical to smoke chambers.

An umbrella-deflector is installed on the chimney to increase draft. It increases the efficiency of the heating system, simultaneously protecting it from snow, rain, wind, debris, and other troubles.

All devices look like exhaust pipe hoods with a gable, hip, pyramidal or conical visor. The name changes only because of a slight difference in purpose.

Causes of breakdowns and their elimination

There are three types of work and troubleshooting:

- Preventive maintenance

- Major renovation.

- Partial renovation.

Prevention is carried out to remove soot. No professional help needed. It is necessary to monitor all parts of the stove, clean it from soot and ash.

The stove smokes and burns poorly. It is necessary to check the draft of the stove and whether the fuel is suitable for this particular stove.

- Poor heat output from the stove . It is necessary to check how tightly the vent and the firebox door close; you need to use a special tourniquet.

- Strong draft , all the heat will go outside and the room will not warm up.

- If there is good draft , the gases will escape through the chimney and carbon monoxide will not form.

- The oven does not warm up . There are cracks in the chimney. The cracks need to be sealed. The main channel is narrowed; the narrowed channel needs to be disassembled.

- No traction. Clean the pipe using a weight. If this method fails to clean, you will have to disassemble the chimney to clean it. If the soot is from resin, then you need to light a fire in the chimney and clean it using this method; there are also chemicals.

- The stove begins to smoke . This problem occurs when the stove is constantly fired. It is necessary to disassemble the stove and repair the internal masonry of the chimney. The riser is clogged. It is necessary to disassemble the chimney closer to the clogged riser and clean it. From strong wind. Install the deflector.

- If wet spots appear on the pipe . This is the formation of condensation. Line the pipe with glass wool, do not heat the stove with raw wood or fuel, make the firebox larger, and make the entire chimney pipe much shorter.

- If after heating the stove for a long time and it still does not heat up, it is necessary to clean the chimney of soot.

- If cracks appear , then you need to cover them with a clay solution.

- After not heating for a long time , the traction will disappear. This means that there is cold air in the pipe. You need to set fire to a piece of paper, and there will be traction again.

Choice of coverage

To ensure that the chimney lasts longer and is not exposed to the negative effects of the external environment, it is covered with a special layer. In addition, such processing increases the decorativeness of the structure.

Main types of coverage:

- Powder paint. Non-toxic, has a wide range of shades. Provides surfaces with increased strength. The advantages include ease of application and high drying speed. Gives the metal surface thermal insulation properties. Resistant to deformation and bending.

- Pural. Service life 30 years. The coating does not fade in the sun, is not subject to mechanical stress, and withstands temperature changes. Very plastic and highly durable, not susceptible to chemicals in precipitation. You can choose either a solid color or a textured one.

- Polyester. Beautiful coating with a noble shine. Durable and wear-resistant, does not peel off, does not fade in the sun. Resistant to high humidity and temperature changes. Will last from 5 years.

- Plastisol. Corrosion resistant, decorative, plastic and durable. It beats other coatings in that it is capable of self-healing - small cracks are healed while maintaining tightness. Service life – up to 20 years.

Arguments against installing a cap

Familiarizing yourself with them makes it difficult to make a final decision, but you should be aware of them. Only complete information makes it possible to make the optimal choice, taking into account the maximum number of different factors.

The cap may interfere with draft

This warning has the right to exist only in one case - the cap is set very low, the size of the cracks around the perimeter is smaller than the diameter of the chimney pipe. This happens very rarely; no one deliberately covers the chimney with a cap.

The cap can only interfere with draft if it is set too low

Condensation may freeze on the cap and partially or completely block the hole

Unfortunately, such cases happen quite often. It all depends on the climatic conditions of the area where the building is located, the efficiency of the boiler and the physical characteristics of the fuel. If everything is clear with the first factor, then the last two should be discussed in more detail.

- Building codes and regulations strictly regulate the temperature of gases leaving the chimney. It should not be less than +120°C, only under such conditions the appearance of condensation is excluded. But modern heating boilers have a very high efficiency, which means that the maximum amount of thermal energy is transferred to the heat exchanger, and accordingly, the gas outlet temperature is low. Not a single boiler can withstand the recommended values; all of them heat the interior, not the street.

Condensation in the chimneyConclusion - condensation will be not only on the cap, but also on that part of the chimney where the temperature is below the established standards. This should always be taken into account when attempting to cover chimneys with additional elements.

How to eliminate condensation in a chimney

- The amount of condensate depends on the type and characteristics of the fuel. If the boiler is fired with wet wood, then the condensate will have to be collected daily in ten-liter containers, but if with high-quality natural gas, then it is almost completely absent.

If the stove or fireplace uses solid fuel, it is important that it is dry

Conclusion. Make the decision to install a cap taking into account the factors described above; they have a decisive influence on traction performance and can cause extremely dangerous situations.

Caps burn out quickly and have to be replaced frequently

If the products are made of low-quality metal that is not protected from corrosion, then yes, their service life does not exceed 3–5 years. But today, either galvanized or alloyed sheet steel is used for such purposes. The service life of high-quality stainless steel is practically unlimited.

Stainless steel caps have a long service life

Calculation of the chimney design

When making a chimney, it is very important to carry out the correct design calculations. If you make a mistake, the “cap” will not cope with protection during snow or rain.

What to consider when calculating:

- The size of the cap must exceed the size of the chimney. Otherwise, the chimney will not be able to effectively perform its functions.

- A drainage drip is required. It organizes the discharge of sedimentary water onto the roof and then into the gutter.

- It is important to equip the weather vane with a ventilation duct, which will serve as a barrier to the condensate that forms from entering the pipe.

- If the house has a fireplace or stove, the weather vane will need a plate - a second bottom. It will protect the structure from burning, condensation, and the formation of icicles. Various materials are used for its manufacture: for stoves it is best to choose galvanized metal, and for chimneys with a high temperature of exhaust gases, copper is preferable.

- When calculating the slope, it should be taken into account that the resulting surface should have an angle of 40 degrees or more. Otherwise, a snow cap will form on the chimney in winter. However, a very large angle is also unacceptable - smoke from the chimney will not be able to escape freely.

- The efficiency of the entire structure depends on the correct calculation of the light opening.

All these six conditions must certainly be met, otherwise the smoker will not be able to perform the tasks assigned to it.

Recommendations from experts

It is not recommended to install a deflector on the chimney pipe of gas equipment. Since low gas temperatures in winter can lead to the horizontal part of the chimney outlet freezing, and the deflector helps to intensify this kind of tendency.

Experts do not recommend weather vanes, since their rotating elements fail quite quickly. In winter, due to the formation of condensation, they become covered with ice, which leads to loosening of the pipe masonry. Therefore, the best option for chimneys are canopies.

An example of a “smart” deflector with a rotating hood

Which design of visor to choose depends on the cross-section of the pipe. For example, for a round chimney, most often the canopy is of an identical shape, but for a rectangular structure it can have a large number of types.

Manufacturing technology of the Tsaga deflector with drawing

Manufacturing drawing of the Tsaga deflector.

(Click to enlarge) First, you need to decide on the dimensions of the outer and inner girth pipe. Measurements must be accurate.

The outer diameter of the stove hood fits tightly onto the chimney pipe.

The main parts are made in proportion to the internal diameter:

- the inlet pipe is placed on the pipe;

- the outer cylinder is a diffuser, its size should be approximately 30% larger than the internal diameter of the pipe;

- cover, its size should be about 90% of the pipe diameter.

In order to correctly calculate the dimensions of the deflector, a table is provided.

Please note: although the installation of a deflector or nozzle may be simple, the proportion must be maintained, and if this is disturbed, the expected result of traction will be lost. . A drawing is made on paper to match the shape and dimensions of the cap. The patterns are applied to a metal surface and cut out with metal scissors. The resulting parts must be bent according to the design and connected with rivets. The finished parts of the deflector are assembled in the workshop, and at a height they are only fixed above the pipeline.

- A drawing is made on paper to match the shape and dimensions of the cap.

- The patterns are applied to a metal surface and cut out with metal scissors.

- The resulting parts must be bent according to the design and connected with rivets.

- The finished parts of the deflector are assembled in the workshop, and at a height they are only fixed above the pipeline.

Please note: it is correct to install the smoke shaft at a height of up to 2 meters above the roof level. Remember that work carried out at height requires special care and compliance with safety regulations.

Advantages of installing a chimney

The positive effect of an umbrella placed on a ventilation or chimney pipe will be as follows:

- rain moisture or snow will no longer get inside;

- an umbrella with wind protection for the chimney will prevent smoke and exhaust gases from blowing back into the room;

- Birds will not build a nest inside the chimney, and mice or other pests will not get in;

- the brickwork of the pipe will remain intact longer;

- a design of an unusual shape or color will decorate the roof, which is especially important if the pipe spoils the view;

- by choosing a suitable deflector, you can increase draft and heating efficiency;

- You will need to clean the chimney less often.

If the hood is placed over a pipe installed to remove odors from a country toilet, septic tank or sewer, then due to increased draft, ventilation will become more efficient.

DIY chimney canopy

The first example of attaching a visor

You need to take 4 metal rods, they will make racks.- out of a titanium sheet , but with such a margin when bending the sheet. It should be larger than the hole in the chimney.

- The rods must be heated and flattened and holes must be made for fastening.

- The made rectangle must be secured to the racks, preferably with rivets.

- The titanium sheet must be bent in the form of an arc. They can be inserted into the chimney, but the posts must be in close contact with the walls of the chimney.

- At the last stage, the canopy must be secured to the chimney with self-tapping screws.

Second fastening example

- M5 bolts and nuts and secure the racks that are located in the lower cylinder.

- The upper cylinder must be attached to the lower cylinder.

- You need to attach the cone cap with rivets. All this can be assembled yourself by welding.

- For everything to work out, you need to take into account the diameter of the pipe and what size the visor will be.

Step-by-step description of the installation process

It is very important to take a responsible approach to installation, since it depends on it whether the chimney will perform its functions. Otherwise, there is a risk that it will simply become a decoration for the roof.

It is important that the assembly conditions comply with safety regulations. You should work in shoes with soft soles so as not to damage the roofing material. Wear a thick robe, gloves, and prepare a fastening for the safety rope.

Sequencing:

- Prepare holes in the apron for fasteners. Diameter – from 5 mm, pitch – 15 mm.

- Place the weather vane on the chimney and secure it. Using a form, drill holes in the chimney.

- Remove the chimney.

- Place dowels under the screws into the holes.

- Install the weather vane on the pipe so that the holes match and secure with self-tapping screws.

For additional fastening strength, it is recommended to install a steel clamp and crimp it. To check the reliability of installation, tap with a hammer along the perimeter of the apron, this will help to understand whether there is any displacement under loads; you should also press with your own weight on the cap.

For reliability, metal surfaces are covered with a protective coating selected depending on financial resources, conditions of use and decorative properties.