Hi all! The author of the site Blogvp.ru, Vitaly, is in touch! I think you will agree that it is not a very fun experience to be left without heating and hot water on winter days. And this prospect came up several times in my house. I want to tell you how I struggled with this and what knowledge I acquired in this matter.

In my house, a gas double-circuit wall-mounted boiler ARISTON CLAS 24 FF is working to create comfort. Undoubtedly, the thing is extremely convenient; anyone who used, for example, geysers from the early nineties will understand.

But, as they say, nothing lasts forever, and therefore sooner or later, you have to deal with the refusal of technology to perform the intended work. In this article we will look at problems with pressure in the boiler, namely two types of this problem.

- When the pressure just keeps dropping.

- Cases when the pressure fluctuates, then up, then down.

- There are also cases when the pressure only increases, but more on that in another article, the link will be below.

PS - I did everything described using the example of my Ariston, but these manifestations will be common to almost any boiler. So, let's get down to business.

Setting the gas pressure of Navien boilers

To set the gas pressure of Navien boilers (Ace, Deluxe, Prime, Atmo), you will need a differential digital pressure gauge with a mm H2O scale.

A table with gas pressure values for various Navien boiler models is given at the end

1.With the boiler turned off, attach a pressure gauge to the gas pressure control fitting on the burner

2. Turn on the boiler

3. Set DIP switch 3 on the control board to the “ON” position, which will correspond to the minimum load.

4. Set the minimum gas pressure according to the table using the screw for setting the minimum pressure (Increase - counterclockwise, decrease - clockwise)

5. Set DIP switch 3 on the control board to the “OFF” position (Main state)

6.Set DIP switch 2 on the control board to the “ON” position, which corresponds to the maximum load

7. Set the maximum gas pressure in accordance with the table using the adjusting screw (Increase - counterclockwise, decrease - clockwise)

8. Turn off the boiler

9. Disconnect the differential pressure gauge hose from the gas valve fitting

10. Set the DIP switch to the “OFF” position (Main state)

11. Turn on the boiler

12. Check the tightness of the gas valve (Fitting). If abnormal noises appear, you need to check the boiler for gas leaks.

The material was prepared by an employee of heating-mtsensk.rf - Warm Home.

How to solve the pressure problem?

The very first thing to do in such cases is to check the valve. Before starting the test, make sure that the make-up valve is closed as tightly as possible. Check what happens when the gas boiler is turned off. To do this, disconnect it from the power supply. The same thing happens even when it is turned off - there is only one solution - call a service center that will replace the faucet for you. It is not recommended to replace the faucet yourself at home, as this work may require special equipment.

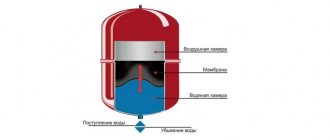

If the pressure drops only while the boiler is on, and this does not happen while warm water is being used, but only when the boiler is turned on and off, then the cause of the breakdown is most likely in the expansion tank. You can easily fix the problem yourself, at home. It is enough to find a fault by external inspection, most often it is some kind of scratch or small hole, then patch it with special glue. If the hole is large, then repairing it will require the help of specialists or a complete replacement of the expansion tank.

Navien Prime gas pressure values

| Model name depending on power | Gas type | Pressure in mm H20 | Nozzle diameter (mm) | |||

| Maximum | Minimum | |||||

| Prime-13k | Natural gas | 32 | 14 | 1,75 | ||

| Liquefied gas | 55 | 25 | 1,2 | |||

| Prime-16k | Natural gas | 46 | 14 | 1,75 | ||

| Liquefied gas | 82 | 25 | 1,2 | |||

| Prime-20k | Natural gas | 68 | 14 | 1,75 | ||

| Liquefied gas | 124 | 25 | 1,2 | |||

| Prime-24k | Natural gas | 98 | 14 | 1,75 | ||

| Liquefied gas | 160 | 25 | 1,2 | |||

| Prime-30k | Natural gas | 113 | 18 | 1,75 | ||

| Liquefied gas | 164 | 31 | 1,2 | |||

| Prime-35k | Natural gas | 107 | 18 | 1,75 | ||

| Liquefied gas | 165 | 28 | 1,2 | |||

Navien Ace gas pressure values

| Model name depending on power | Gas type | Pressure in mm H20 | Nozzle diameter (mm) | |||

| Maximum | Minimum | |||||

| Ace-10k | Natural gas | 20 | 11 | 1,75 | ||

| Liquefied gas | 33 | 17 | 1,2 | |||

| Ace-13k | Natural gas | 33 | 11 | 1,75 | ||

| Liquefied gas | 55 | 17 | 1,2 | |||

| Ace-16k | Natural gas | 43 | 16 | 1,75 | ||

| Liquefied gas | 76 | 25 | 1,2 | |||

| Ace-20k | Natural gas | 61 | 16 | 1,75 | ||

| Liquefied gas | 13 | 25 | 1,2 | |||

| Ace-24k | Natural gas | 83 | 16 | 1,75 | ||

| Liquefied gas | 164 | 25 | 1,2 | |||

| Ace-30k | Natural gas | 91 | 20 | 1,75 | ||

| Liquefied gas | 170 | 33 | 1,2 | |||

| Ace-35k | Natural gas | 82 | 22 | 1,75 | ||

| Liquefied gas | 140 | 33 | 1,2 | |||

| Ace-40k | Natural gas | 90 | 15 | 2 | ||

| Liquefied gas | 115 | 17 | 1.45 | |||

Navien Ace (Coaxial) gas pressure values

| Model name depending on power | Gas type | Pressure in mm H20 | Nozzle diameter (mm) | |||

| Maximum | Minimum | |||||

| Ace Coaxial -10k | Natural gas | 19 | 11 | 1,75 | ||

| Liquefied gas | 33 | 17 | 1,2 | |||

| Ace Coaxial -13k | Natural gas | 31 | 11 | 1,75 | ||

| Liquefied gas | 55 | 17 | 1,2 | |||

| Ace Coaxial -16k | Natural gas | 45 | 16 | 1,75 | ||

| Liquefied gas | 82 | 27 | 1,2 | |||

| Ace Coaxial -20k | Natural gas | 70 | 16 | 1,75 | ||

| Liquefied gas | 119 | 27 | 1,2 | |||

| Ace Coaxial -24k | Natural gas | 94 | 16 | 1,75 | ||

| Liquefied gas | 152 | 27 | 1,2 | |||

| Ace Coaxial -30k | Natural gas | 93 | 21 | 1,75 | ||

| Liquefied gas | 171 | 33 | 1,2 | |||

Navien boiler error 10

This error is related to the smoke removal system of the gas boiler. Combustion products must be removed; for this purpose, the boilers are equipped with a fan. To control the operation of the fan and determine the presence of permissible draft for boiler operation, a differential relay is used, which is connected to the turbine by two plastic tubes. When the fan is running, a vacuum is created, the relay closes, and the boiler functions normally.

Reasons for error 10

may be a clogged chimney, the presence of reverse draft, or incorrect connection of the air pressure control sensor to the fan. For the latter case, you need to check that the yellow tube is connected to the bottom of the fan, and the transparent one is connected to the top, and the tubes themselves are not damaged, deformed or condensation inside.

Increased resistance in the chimney can occur due to direct gusts of wind or blockage of the chimney (bird nest or cobwebs, freezing in winter). That's right, the location of the chimney should be taken into account the direction of the winds of a particular region at the design stage and the chimney should not be installed on the leeward side of the house.

We focused on the most common malfunctions of Navien boilers, but in fact there are significantly more error codes. Methods for checking and troubleshooting are the topic of a separate article. For convenience, here is a summary table of codes with a brief description:

Faithfully, the navien boiler worked for me for seven years, heating a two-room apartment and heating water in the hot water system at two points. The apartment area is small, so the operating mode is quite gentle. But we like to include hot water.

Among the malfunctions during all this time, I changed the three-way valve - the love for cleanliness and water procedures affected it. The cause of the malfunction was an electrical microswitch whose contact plate had broken. I was too lazy to tinker with a soldering iron, so the unit was replaced with a new one. The asking price is about two thousand rubles. In addition, I removed and washed the automatic air vent a couple of times. Some kind of garbage came up. But in general, I am very pleased with the performance of the device, especially considering that it was purchased at a cost half as much as its counterparts on the market.

So, during the inspection it was found that the case was full of dust and all sorts of unfortunate insects that were sucked in by the air flow from the fan. A couple of minutes of vacuum cleaner operation, wet cleaning and complete order. Opening the combustion chamber showed that on the heat exchanger in the lower part there is a coating of red sludge from combustion products, and in the upper part there is debris and oxidation as a result of exposure to condensate from combustion products.

The combustion chamber. This is actually the boiler itself. If we compare it with classic floor-standing boilers, then in terms of power it is analogous to a boiler like Don 16 or AOGV 16, which of course will not fit in a bathroom...

To clean it, I removed the combustion chamber, carefully cleaned the heat exchanger honeycombs with a brush, washed the outside with water pressure from the tap and removed oxidation using Liqui Moli carburetor cleaner. It came in handy. I also used it to clean the automatic air vent valve installed on the circulation pump housing. Inside, the heat exchanger is practically free of contamination - there is only a small yellowish coating, which could be removed with citric acid. But this time I decided to skip this procedure. I washed the gas burner with water. A lot of dust passes through this “vacuum cleaner” and some of it, of course, settles, interfering with the normal combustion process. Monitoring the air pressure in the expansion tank showed its complete absence. An attempt to restore it showed a membrane rupture. Replacement tank. Reassemble in reverse order. Be careful not to damage the gaskets. By the way, they are all in good condition and factory lubricated. Grease had to be applied to the chimney rubber bands during assembly. Filled it with water and pressed it. That's all, the device is ready for use. After turning it on, I checked it in all modes and was pleased with the result. Costs 3,500 rubles for an expansion tank. I will give advice to those who like to save money: a failed expansion tank of a wall-mounted boiler can be left alone. To compensate for the thermal expansion of the coolant, in any convenient place you can embed and connect any simple and inexpensive tank for heating systems of suitable volume.

Navien Atmo gas pressure values

| Model name depending on power | Gas type | Pressure in mm H20 | Nozzle diameter (mm) | |||

| Maximum | Minimum | |||||

| Atmo-13 | Natural gas | 75 | 40 | 1,3 | ||

| Liquefied gas | 127 | 71 | 0,92 | |||

| Atmo-16 | Natural gas | 110 | 40 | 1,3 | ||

| Liquefied gas | 184 | 71 | 0,92 | |||

| Atmo-20 | Natural gas | 76 | 18 | 1,3 | ||

| Liquefied gas | 127 | 32 | 0,92 | |||

| Atmo-24 | Natural gas | 108 | 18 | 1,3 | ||

| Liquefied gas | 185 | 32 | 0,92 | |||

Which tap needs to be turned on the boiler to increase the pressure in the system (cm)?

Gas double-circuit boiler Ariston.

Before starting, you need the pressure sensor to show 1.0 - 1.15 bar.

Mine shows 0.5 bar.

How to increase the pressure in the system?

Looking at the diagram of a heating gas boiler, it is not difficult to guess which valve is responsible for the pressure in the heating system. Of course, the fact that your pressure gauge shows 0.5 bar is a very low pressure for normal operation of the boiler. The fact that the instructions say 1.0-1.15 bar is the minimum. Considering that I seem to have the same boiler, I want to show you a close-up of the control panel, namely the pressure gauge scale.

Please note that the red stripe is right up to number 3. And don’t look at the fact that my blood pressure is low. I haven't turned on the heating yet. What I want to say. The minimum pressure should be 1.15 bar and the maximum 3.0 bar. Therefore, I am always for the golden mean. Try to keep the pressure around two. As soon as it drops below two, open the tap number 16 in the diagram (feed tap). In my boiler, this tap is made of blue plastic (if you look under the boiler, you can see it). Especially for you, I put my phone “under the skirt” of the boiler and took a picture of what the feed tap looks like.

Navien Deluxe gas pressure values

| Model name | Gas type | Pressure in mm H20 | Nozzle diameter (mm) | |

| Maximum | Minimum | |||

| Deluxe-13k | Natural gas | 30 | 11 | 1.75 |

| Deluxe-16k | Natural gas | 43 | 16 | 1.75 |

| Deluxe-20k | Natural gas | 65 | 16 | 1.75 |

| Deluxe-24k | Natural gas | 89 | 16 | 1.75 |

| Deluxe-30k | Natural gas | 95 | 19 | 1.75 |

| Deluxe-35k | Natural gas | 97 | 18 | 1.75 |

| Deluxe-40k | Natural gas | 90 | 13 | 2 |

How does a Navien boiler work?

The Navien wall-mounted double-circuit boiler operates on the basis of the APS mechanism, which guarantees stable combustion and reduces gas costs. The mechanism controls the amount of gas that penetrates the burner, ensuring total combustion of fuel, reducing its consumption.

Interesting materials:

What to do if a cat pees in your shoes? What to do if your cat constantly bites? What to do if a cat jumps on the curtains? What to do if a cat jumps on the table? What to do if your cat always sheds a lot? What to do if your cat sheds a lot? What to do if the cat is seriously poisoned? What to do if a cat sharpens its claws on the wallpaper? What to do if your cat scratches the wallpaper? What to do if your cat scratches?

Navien Deluxe Coaxial gas pressure values

| Model name | Gas type | Pressure in mm H20 | Nozzle diameter (mm) | |

| Maximum | Minimum | |||

| Deluxe-13k | Natural gas | 28 | 11 | 1.75 |

| Deluxe-16k | Natural gas | 41 | 16 | 1.75 |

| Deluxe-20k | Natural gas | 63 | 16 | 1.75 |

| Deluxe-24k | Natural gas | 85 | 16 | 1.75 |

| Deluxe-30k | Natural gas | 92 | 19 | 1.75 |

What to do?

There are several main features that must be adhered to if there is a pressure drop in the system:

- A decrease in water atmosphere indicates problems with the boiler and the entire heating system. How to increase the values when the pressure gauge indicates that the system is below normal? It’s simple – you just need to use the refill valve to add the required amount.

- If after this there is also a drop in atmosphere, there is clearly a hole somewhere that needs to be repaired urgently. It is advisable to seek help from a specialist, since further independent movements can only worsen the condition.

- Be sure to inspect the entire heating in a circle. Sometimes there are situations when the pressure level is increased and as a result the joints or seams of the pipes diverge - a minimal leak appears. Over time, the pressure gauge needle drops. If such a problem is discovered, it must be corrected as soon as possible.

- If nothing is found, it is better to invite a specialist who will check the functionality of the expansion tank and fully diagnose every meter of the structure.