First steps

Ariston boilers are reliable, and testing the equipment will take a lot of time. Considering that error 104 can be caused by a problem in the heating system, it is more logical to start looking for the cause there.

A drop in flow velocity is the result of a narrowing of the circulation channel. This is caused by sediment in the cavities of the devices, deposits on the walls or the accumulation of air bubbles in the coolant. Gas formation becomes more intense the longer the Ariston boiler operates at elevated modes - a common occurrence at low temperatures outside.

How to proceed. Walk around the house, check by touch the degree of heating of pipes and radiators: the problem area is colder. Depending on the characteristics of the circuit (circuit), it is easy to make a decision - bleed the air, service the device. It is necessary to check the filters mounted in the system. They can also trigger an Ariston boiler error with code 104.

Checking the air lock in the radiator with a thermal imager

Advice . Automatic valves installed on radiators require regular maintenance. If the heating line is made of steel pipes, water treatment is not carried out, and the liquid is of high hardness - more often than recommended by the manufacturer. A clogged channel, a defective spring are the probable causes of error 104, and the Ariston boiler has nothing to do with it.

#7 2014-01-14 21:03:22

- Answers: 5 Profile

- All messages

- Reputation 0

Re: Ariston boiler - error 104

Hello. My Ariston Clas 24 FF boiler worked perfectly for 5 years, but this winter it started throwing error 104. I called a technician, he washed the heat exchangers, but the error did not go away. It throws an error periodically at different intervals - more often when I turn on hot water, but and without it too. I noticed that after flushing, when you turn on the hot water, the pressure arrow in the system jumps by 0.5. And the temperature of the hot water is at 40 degrees, and when you turn on the hot water, d40 is shown, but if hot water flows 5- 10 minutes and then turn it off, it shows C68-C70 and the temperature drops. Tell me, please.

Hardware problems

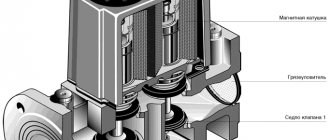

Pump

His work in Ariston boilers is specific. It operates at two speeds with powers of 55 and 80 W, depending on the mode. If only the heating is set to low (V2), when dispensing hot water it switches to V3 (high). This is necessary so that the radiators warm up better and the heat exchange in the rooms does not deteriorate. During operation, the electronic module itself switches speeds based on the room temperature, maintaining it at a user-specified level.

The causes of error 104 Ariston are caused by problems with the mechanical or electrical part of the pump. It is not difficult to verify the operability of the kinematics - the pumping device is accessible, you just need to fold back the bottom cover of the boiler.

The impeller of the Ariston boiler pump was broken!

Check what. Shaft rotation. You need to unscrew the plug (under the slot) on the pump body, first placing something like a bath to collect the leaking liquid. At the same time, accumulated air bubbles will be removed. If the screwdriver easily turns the axis, the mechanics of the pump are working properly, and the cause of error 104 of the Ariston boiler is not in it. Tight turning is the result of a problem.

Probable Causes

If no defects in the kinematic circuit are identified, the electrical circuit is tested. The task of finding the cause of error 104 in Ariston boilers is simplified if you know the structure and specific operation of the control module.

Electronic board

With its help, it is easy to determine whether the electrical part of the pump is working or not. The boiler has a blowing mode to remove air bubbles from the internal pipes and the Ariston heat exchanger. Turns on by pressing and holding (at least 5 seconds) the ESC button on the front panel. It can also be used to find the cause of error 104.

Press the ESC button on the Ariston boiler control panel

The pump starts, but its operation is cyclical: after a minute it turns off for 30 seconds. The mode lasts 5–6 minutes, the burner does not ignite. Stopping is done by pressing the button again. You need to measure the voltage at the terminals and make sure whether power is being supplied from the electronic board or not. Must be (

B): 3/4 – 220, 5/6 – 145 (with the pump running at maximum speed) or 0 (at minimum speed).

There are two relays in the power circuits (RL 03 and 04). They are not mounted on the board of the Ariston boiler: only the circuit of radio components and conclusions are on it. But for the convenience of identifying the cause of code 104, measurements can be carried out here by applying probes to the corresponding points. The presence of voltage indicates the serviceability of the relay, the absence of voltage indicates a problem (broken winding, burnt contacts). To eliminate error 104, Ariston will have to be changed.

Ariston boiler control board

Advice . In the purge mode, the regularity of pump startup is controlled. Turning on every other time is a sign of problems with the relay supplying 220V power. It's better to put another one right away.

Electrical part of the pump

If power is supplied to the terminals, no defects in wires or contacts are detected - there is a problem with the winding of the device. The probable cause of error 104 is an interturn short circuit, which reduces the rotation speed of the axis. It is impractical to eliminate such a defect in a workshop - the pump is replaced with a working sample. For Ariston boilers, they are sold in specialized stores.

Advice

Sensors

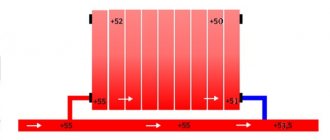

The diagrams are designated NTC 1 and 2. They respond to a rapid increase in the temperature of the liquid passing through the Ariston boiler. With an increase of 20 0 C per second, a signal is sent to the electronic board, generating error 104.

Their testing is carried out by measuring the resistance when the power to the unit is turned off, when, in addition to code 104, others (103, 105) are also displayed, depending on the selected mode. In the user manual there is tabular data on R: if the values do not match, the sensor is changed.

Heat exchanger

The last “object” to identify the cause of error 104. If the measures taken do not give a positive result, the device is dismantled and serviced. Poor quality of liquid (water, “anti-freeze”) leads to the accumulation of salt deposits, tiny fractions of dirt, and rust on the walls of the cavity. The Du narrows, the circulation speed drops, and the Ariston boiler overheats.

Advice . It is impossible to carry out high-quality maintenance of the heat exchanger on your own. And although there are enough recommendations on thematic websites, it is better to take it to a service workshop. For 2-3 days you will have to switch to a backup heat generator, but until the end of the season, error 104 will not occur for this reason. You cannot quickly remove scale from the device on your own: you will have to wait until it softens when the inside is filled with an aggressive composition. And then rinse thoroughly, under pressure. In any case, the Ariston boiler is taken out of service, and the time costs are almost identical.

On a note . To minimize the risks of reducing the flow rate and stopping the Ariston boiler with error 104 during the heating season, you need to prepare for it. This code is caused by a number of factors, and in the off-season all elements of the circuit must be serviced, not just the unit. Radiators especially need this, which many people forget.

#6 2010-11-04 21:39:14

- Answers: 3 Profile

- All messages

- Reputation 0

Re: Ariston boiler - error 104

You can hear the motor running by the sound of rotation, especially if you put a screwdriver on it, and on the other side to your ear (the kitchen on the blunt side). But if instead of the sound of rotation you hear a 50Hz hum, it means the pump is jammed.

You also need to understand that alarm 104 occurs how many seconds after the burner is turned on!

Last edited by SASHOK (2010-11-04 21:41:41)

Ariston Class - overheating of the main heat exchanger. Main causes and ways to eliminate them

Any gas boiler is a heating installation in which the thermal energy from gas combustion is transferred to the coolant through a heat exchanger located above the burner. In order for the heating system as a whole to work efficiently, water must constantly circulate throughout the circuit, that is, there must be a flow of coolant through the heat exchanger. The cooled water entering the boiler is heated, circulation is provided in most cases by the boiler pump.

Obviously, if the circulation stops, the water in the heat exchanger will quickly reach boiling point, and the pressure in the closed system will increase. This situation is unacceptable, and therefore the boilers provide protection against overheating and constantly monitor the circulation of the coolant and the temperature at the outlet of the heat exchanger.

The reasons for poor circulation can be different, here are the most popular ones:

The circulation pump does not work (or the rotation speed is not sufficient)

pipelines, filter elements or heat exchanger are clogged

the control board is faulty (the pump does not change speeds)

In Ariston boilers, this control occurs through NTC temperature sensors. In such sensors, the resistance decreases with increasing temperature.

Flame and ignition control (errors 5**)

Problems can arise in both open and closed combustion chambers. Although it must be admitted that there are few types of faults here compared to other components of a gas boiler.

Error No. 501. No flame when igniting.

This situation can happen for many reasons:

- No gas. You need to check the supply tap. It must be open.

- The system will not turn on if the voltage between the neutral and the grounding conductor is more than 10 V. The current leakage must be eliminated.

- The ionization electrode has failed. Before changing it, you need to check the quality of the connection to the motherboard.

- The power of smooth ignition has lost. You need to adjust this parameter according to the instructions for the specific model.

- Main control board faulty.

Error No. 502 : Registration of flame before activating the gas valve. It often occurs in the absence of a ground loop. If it is made according to the standard, then you need to perform the same steps as for error No. 309.

If the house did not have grounding, then it will have to be done for a gas boiler. Moreover, according to all the rules, otherwise the protective mechanisms will block the heating from starting

Error No. 504. Flame loss on the burner if it occurs at least 10 times during one cycle. It is necessary to check the gas pressure, the exhaust of combustion products and the gas valve.

Description of Ariston overheating errors

Error 103 - the rate of temperature rise at the NTC 1 sensor (supply pipe - on the left at the outlet of the heat exchanger) is more than 7 degrees per second. First, error 1P1 may appear, if after restarting the boiler the situation repeats - an accident with error 103. Temperature changes are monitored continuously every 100 milliseconds except for the first four seconds after starting the burner.

Error 105 – the temperature difference on the NTC 1 or NTC 2 sensors is more than 55 degrees. It is checked constantly while the burner is running, and also within 7 seconds after switching off. Error 1P2 may appear first; if the situation repeats twice within four minutes, error 105 will appear.

Error 106 – supply temperatures are greater than the return pipe temperature + 10 degrees. It is checked constantly; error 1P3 may first appear.

Error 107 - similar to 106: the supply temperature is greater than the return pipe temperature + 30 degrees.

The presence of actual overheating on the heat exchanger, as a rule, cannot be confused with anything - it is a characteristic crackling sound due to the boiling of water inside. Overheating may be accompanied by the release of water through the emergency valve - because the pressure increases.

Temperature zones

It is also necessary to monitor temperature zones. If the display shows errors with codes 701-707, then this is probably overheating or a malfunction of the temperature sensor on one of the circuits.

Error code 701 - Supply temperature sensor error (zone 2)

Short circuit or open circuit in the electrical circuit of the flow temperature sensor (zone 2).

Error code 702 - Return temperature sensor error (zone 2)

Short circuit or open circuit in the electrical circuit of the return temperature sensor (zone 2).

Error code 703 - Supply temperature sensor error (zone 3)

Short circuit or open flow temperature sensor (zone 3).

Error code 704 - Return temperature sensor error (zone 3)

Short circuit or open return temperature sensor (zone 3).

Error code 705 - Water temperature sensor error

Short circuit or break in the electrical circuit of the hydraulic temperature sensor.

Error code 706 - Overheating error in zone 2

Overheating in temperature zone 2.

Error code 707 - Overheating error in zone 3

Overheating in temperature zone 3.

Checking NTC temperature sensors

If there are no signs of actual overheating, you should first check the temperature sensors themselves. They are checked by measuring the resistance at the contacts. To do this, you need to turn off the boiler, remove the connector from the sensor and measure the resistance at the terminals. The obtained values should be compared with the table values, and if there are significant discrepancies, you need to buy a new NTC sensor and replace it.

Other breakdowns

In addition to those described above, the following codes may appear:

Another reason may be that the turbine blades have worked too hard, stuck to the housing, this can interfere with rotation, replace the blades or the turbine itself.

The second reason in this situation may be the NTC sensor; to check its functionality, measure the resistance at its contacts with a multimeter; if it is unstable, replace the sensor with a new one. If the safety valve is leaking, the gaskets may be worn out, replace them.

NTC sensor

How to determine the error code if the device does not have a display or does not have a dial, such as on the Ariston BS II 24FF model? This device is equipped with indicator lights, thanks to which you can determine the breakdown. So, for example, if the 90 indicator and the crossed out water drop icon are on, this means that the boiler has overheated and is blocked. To eliminate this, you need to check the pressure switch and its connection to the board.

Checking the circulation pump

A common cause of poor circulation in closed heating systems is a faulty circulation pump. This device has two parts - electrical and mechanical. The electrical part is a plastic box in which the starting capacitor is located. The main characteristic of a capacitor is its capacity. In most circulation pumps of wall-mounted gas boilers, the capacitance of the condenser is 2-2.5 microfarads (the exact value is indicated on the capacitor itself). Therefore, you should first check this value using a tester. If the capacity is significantly lower than the nominal value, you will need to buy a capacitor and replace it.

For example, an Ariston Clas boiler with a Wilo pump worked unstably and gave error 104 with a capacity of 0.15 microfarads, and an Ariston Egis boiler worked normally with a capacity of 1.15 microfarads. Therefore, in each specific case the situation may be different and depend on the parameters of the heating system as a whole. It is advisable to buy a starting capacitor for a gas boiler with exactly the same characteristics and rating as was installed; an error may affect the service life of the pump.

To check the mechanical part, the pump will have to be removed. But keep in mind that this may require sealing. After dismantling the pump, it is inspected for mechanical damage, the presence of deposits - check how freely the impeller rotates. It is better to entrust this process to a qualified specialist. It is not always possible to repair the circulation pump.

#3 2010-09-18 08:34:03

- Answers: 3 Profile

- All messages

- Reputation 0

Re: Ariston boiler - error 104

Yes, the fact of the matter is that I set the pressure to 0.6 and 1 and 1.5 bar, but to no avail.

The air vent, as I understand it, is opened by a red cap on the pump, but there is no effect. And the automatic air removal function somehow works incomprehensibly: I hold ESC for 5 seconds, P1- appears on the display, as described in the instructions, but after that nothing happens. After a couple of minutes, the boiler goes into standby mode again. An attempt to ignite again results in error 104 .

Last edited by Legba (2010-09-18 08:38:44)

Ariston control board malfunction and repair

The control board in Ariston boilers can also cause overheating. Many models have circulation pumps with a speed switching function. Speed switching is carried out as necessary - if the temperature difference between the return and supply pipe coolant is more than 20 degrees (factory value) - the second speed of the pump is switched on, if less - the pump operates at the first speed to save energy and resources. To do this, two switching relays are installed on Ariston electronic boards: one controls turning the pump on and off, the other controls speed switching. Accordingly, if there is a malfunction and the speeds do not switch, the boiler will generate overheating errors in certain operating modes. To solve this problem, it is enough to repair the Ariston board.

Analogue relay JQX 118F

Attention! I found an analogue of the JQX 118F pump speed switching relay.

This is a Finder relay (Not China) relay number 43.41.7.024.2000 There is some stock of these relays, so if anyone needs it, write to me by email, I will send it. The address is on the “My Services” page

Relay Finder

About the pump power relay

Of course, relay RL04, which supplies the main power to the pump, may also be associated with a pump control malfunction - This is a typical case.

I once repaired a boiler for a friend of mine. It was in the summer, the heating was turned off, but they complained that in DHW mode the boiler either worked or didn’t, they also went into defense, although I don’t remember what error code it gave, but I remember for sure that at that time the RL 04 relay had to be replaced, which supplies power to the pump. Its contacts burned out and it turned on the pump every other time. Replacing the relay solved the problem.

I also purchased this type of relay with a small reserve on Aliexpress. This was a relay from the well-known manufacturer OMRON, relay type G5NB-1A-E, it works flawlessly!

Important!!! When choosing a relay, pay attention to the fact that the relay power supply is 24 volts, they come with a lower supply voltage, this is important! The link to the relay had to be removed because the seller apparently ran out of them. But you can easily find them by entering the name of the relay on Alika. True, they usually sell them in small quantities.

But, I’ve already found someone who doesn’t sell much.

Don’t waste your money on cheap relays, there are known cases (one serviceman shared) when some installed relays from some unknown manufacturer, unfortunately I don’t remember the name, and they literally caught fire, thereby causing irreparable damage to the boiler circuit board.

Boiler overheating - annual maintenance

Overheating can also be associated with the presence of actual problems with circulation due to high hydraulic resistance: clogging of the heat exchanger and filter elements. To do this, you need to carry out full maintenance of the equipment with flushing of the heat exchanger. These operations should be done periodically - according to the manufacturer's regulations - once a year before the start of the heating season. This will avoid unexpected difficulties. If the boiler has been in operation for several years and has not been serviced, then very often a comprehensive service can eliminate the problems that have arisen.

Code 103

The error is due to the coolant heating too quickly, which can be caused by the following reasons:

- airiness of batteries;

- thermostat malfunction;

- problems with the board.

If such an error occurs, you can try to bleed air from all existing batteries. In most cases, this will fix the problem. If after such actions the code continues to be displayed on the display, then the problem is deeper and cannot be done without the help of specialists.

Hardware problems that can lead to error 104

Fault code 104, according to the manufacturer's instructions, indicates poor circulation or insufficient coolant.

Ariston boilers have an automatic system for checking the circulation and heating of the coolant at the moment of release from the heat exchanger, which protects the device from overheating.

Control is performed by temperature sensors NTC1 (supply to the central heating circuit) and NTC2 (input from the central heating circuit). NTC devices are thermistors, the resistance of which decreases with increasing degree of heat of the coolant.

When the rate of increase in readings on NTC1 or NTC2 is more than 20 degrees per second, and fault code 104 occurs.

In real life, this breakdown looks like this: after switching on, the burner ignites, after a few seconds the gas boiler makes the characteristic crackling sounds of rapidly evaporating water, then the boiler clicks, the installation turns off and switches to emergency mode with error code 104.

In models BS 24 ff, cf the red light 90 gr is on. together with the indicator (crossed out flame), this indicates overheating of the equipment. When the yellow indicator (chimney) in the 24 ff heater flashes simultaneously with the 40 or 50 g indicators, this means a lack of coolant or insufficient circulation.

When trouble code 104 appears, the manufacturer recommends that you first reboot the equipment to make sure that it is not a system self-diagnosis failure.

Let's find out how to enable restart - to do this, press the "Reset" or "Reset" button on the control panel.

If after a reset the boiler does not function normally, then the self-diagnosis indicates a real defect.

The most likely causes of equipment damage: either problems in the heating pipes, or problems in the device itself - clogged coarse filter, damage to the pump, electronic board, sensors, heat exchanger.

Problems with the heating system

If the pressure meter transmits inflated data, or heat transfer decreases, this demonstrates problems in the heating structure: blockage in the pipeline, the formation of air locks, a violation of the tightness.

Blockages appear due to the penetration of dirt into the pipes, layers of rust and scale. Detecting the location of a blockage is a very labor-intensive task; for this, methods of measuring the heat of pipes and an acoustic method are used, in which the pipeline is tapped and listened to.

To flush pipes, a hydraulic method is used, or the blockage is broken through using a wire with a brush attached to the end.

Air jams are formed as a result of air entering the pipeline for the following reasons: when water is heated, air dissolved in it creates air bubbles; air accumulation occurs due to a decrease in pressure, leaks, and repair processes.

After finding the plug by tapping (the sound increases in the problem area), the air space is eliminated using air collectors or air bleed valves.

Air locks also lead to a decrease in pressure in the heat exchanger, which will result in error code 108.

In most cases, leaks occur due to corrosion, which leads to both leaks and complete rupture. If you do not have the skills to properly install heating pipes, you should contact a specialist.

Coarse filter clogged

Ariston CLAS, GENUS, ALTEAS models have a built-in mesh filter. It is advisable to monitor its condition on a regular basis; if it becomes clogged, the bearings quickly wear out and cooling deteriorates.

To verify the cause of the breakdown, you should perform several manipulations:

Pump failure

To check the circulation mechanism, unscrew the release screw on it, after placing rags or rags under it to prevent moisture from getting on the board. This will make it possible to see whether the shaft rotates after starting the equipment.

You can also turn off the power and try to turn the shaft manually with a screwdriver by inserting it into a special wide slot. If the shaft rotates manually but does not start when the device is turned on, check the supply voltage of the mechanism. If there is 220 watts on the chip, most likely the cause of the heater defect is damage to the part.

Ariston installs 2 types of pumps, with modulation and two-speed WILO: if the modulated one has become unusable, then only replacing the element will help, but the two-speed one can be repaired by changing the rotor and impeller assembly. A rotor from WILO RS25/6 is suitable for these purposes.

Electrical part of the pump

The circulation pump has two rotation speeds: V2 (55 W) – central heating mode and V3 (80 W) – hot water supply mode. Consequently, it is activated by 2 relays, the first supplies 220 V power, the second regulates the speed of rotation of the shaft.

To check the functioning of both relays, the heater should be started in the “Purge” mode; this mode is configured by pressing the ESC button for more than 5 seconds. Next, we measure the alternating voltage: at the 3rd and 4th terminals there should be 220 V, and at the 5th and 6th - 0 V or 145 V. If the required voltage is not available, the corresponding relay should be replaced. When there is voltage at the 3rd and 4th terminals, but the unit does not turn on, try making a jumper between pins 5 and 6.

If power is supplied to all terminals, a possible cause of the defect may be an interturn short circuit. This problem can only be eliminated by completely replacing the component part.

Peculiarities

The demand for heating equipment of this brand in our country is due to the high quality of the products. A Russian resident always chose a more reliable product, although somewhat more expensive. In addition, boilers from Ariston have a very affordable price. With proper use, they can last about 20 years or more, which makes such a purchase very profitable.

Another advantage that has affected the popularity of Ariston equipment is a wide range of models. You can find a boiler based on your preferences and requirements.

As a rule, all heating boilers are divided into four types:

- gas;

- electrical;

- liquid fuel;

- solid fuel.

In this article we are talking about gas boilers. So let's take a closer look at their subspecies.

First of all, gas heaters are divided by the number of circuits.

- Single-circuit boilers. Simple, therefore more reliable and cheaper technology. It is aimed exclusively at heating rooms, without the ability to heat water. Consists of one heat exchanger, circulation pumps and expansion tanks.

- Double-circuit boilers. Suitable for those who want to have hot water in their home, but do not want to purchase additional equipment. Inside, such boilers have two heat exchangers. Moreover, their sizes practically do not differ from the sizes of single-circuit boilers. The water in the hot water circuit is heated by water from the heating circuit circulating through the heat exchanger. This technique is more complex and therefore less reliable.

All gas boilers require air flow.

Depending on how it is provided, heaters are divided according to the type of combustion chamber.

- In boilers with an open chamber, oxygen enters from the room where they are located. Such equipment has low productivity, but is demanding on the organization of conditions: the room must be equipped with good ventilation and a chimney through which combustion products will be removed. In this case, it is necessary to strictly observe fire safety rules. The advantages of such boilers include reliability and low noise level during operation.

- Boilers with a closed combustion chamber are less reliable, but more efficient. They are also not so demanding on the arrangement of the room and are practically not harmful to the environment. Their operation is based on a special burner and fan. With the help of the latter, air is taken in and combustion products are removed. However, keep in mind that the fan makes a lot of noise when operating.

Heaters can also be divided according to the type of their placement.

- Wall-mounted. Due to their compact size, they are most often purchased for placement in apartments. They are light in weight and easy to install. They usually have a closed combustion chamber and are easy to handle, which ensures additional demand. Wall-mounted boilers are not very powerful, but they are enough to heat a residential apartment.

- Floor-standing. They have increased power. But in size and weight they are noticeably superior to their wall-mounted counterparts. The price is also slightly higher. Such boilers are usually used for heating rooms and buildings with a large area.

Whatever level of reliability the boiler you choose has, it is unlikely that you will be able to avoid errors in operation. Fortunately, most modern units are equipped with control sensors and a self-diagnosis system.

The first ones will stop the boiler in order to prevent more serious breakdowns. In addition, the sensors will block all functions of the unit. You will have to fix the problem to remove the blockage. The second will notify you of a problem that has arisen by highlighting an error code on the display.

They are divided into two types:

- problems that the user can fix with his own hands;

- breakdowns, for which you should contact specialists to correct them.

You can find all code values on the Internet or in the instructions for your specific model. Next, we will talk about the most common errors that occur in the operation of Ariston boilers.

Useful video on the topic:

Failure of the electronic board

Also, heater failure may be associated with the control board itself. You can try to measure the voltage output to the pump.

To do this, remove the connector, set the tester to measure voltage, turn on the device, reset the error by pressing the Reset button. If there is no voltage, the device is broken and does not supply voltage to the pump, but the heater comes into action and boils. A new board needs to be installed.

Failure of sensors

NTC sensors may be faulty. In models BS 24 ff, cf, when they break down, the yellow indicator light (chimney) lights up simultaneously with the 60, 70 or 80 g indicators.

To check their serviceability:

Air supply and flue gas removal (errors 6**)

The system for supplying air and removing flue gases generated during the operation of a gas boiler can be natural or forced. Therefore, some errors may not occur for different devices. But we'll look at them all.

Error No. 601. The draft thermostat is triggered when the contact is broken or the smoke exhaust thermostat is internally damaged. It is also possible that the air vent system is clogged.

Error No. 602. The same thing, only for VMC type combustion chambers.

Error No. 604. The Hall sensor is faulty (it needs to be replaced) or the speed of the fan blades is low (it needs to be cleaned or also replaced).

Error No. 607. The contacts of the controlling pneumatic relay were closed before the fan turned on. This detail confirms that there is sufficient draft before ignition. To eliminate early closure, you need to carefully remove the pneumatic relay and blow out its tubes, removing dirt or condensation. If this does not help, the part will have to be replaced.

The air relay is connected to the exhaust chamber with a silicone tube. Sometimes there is a condensate trap there. If the problem is with the pressure switch, then first you need to check the integrity of the tube

Error No. 610. Thermal fuse contacts are open. This part needs to be replaced.

Error No. 612. Same as error No. 604, but on early Ariston models.

Code 502

Code 502

Indicates a leak when a flame appears when the gas supply valve is closed. If an error is displayed on the display, but in fact there is no flame when the gas supply is closed, then the problem is in the ionization electrode, which gives incorrect signals to the board, from where this error actually “pops up”.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

Be sure to check the serviceability of the gas supply valve on the pipe to eliminate the possibility of a leak.

Code 501

Code 501

When igniting, there is no flame or the flame disappears quickly. There are several reasons:

- There is no gas supply, the valve on the pipe is closed.

- The ionization electrode has oxidized or moved away from the board.

Do you need to check through the viewing window whether the flame appears at all or there is no spark? Specialists can fix the problem.

Coolant circulation in a combined (branched) heating system

Let's start analyzing the coolant circulation with a complex system - then you will understand simple circuits without problems.

Here is a diagram of such a heating system:

It has three circuits:

1) boiler – radiators – boiler;

2) boiler – collector – water heated floor – boiler;

3) boiler - indirect heating boiler - boiler.

Firstly, it is necessary to have circulation pumps (H) for each circuit. But this is not enough.

For the system to work as we want: the boiler is separate, the radiators are separate, we need check valves (K):

Without check valves, let’s say we turned on the boiler, but the radiators “out of the blue” began to heat up (and it’s summer, we just needed hot water in the water supply). Cause? The coolant went not only to the boiler circuit, which we now need, but also to the radiator circuits. And all because we saved on check valves, which would not allow coolant to pass where it was not needed, but would allow each circuit to operate independently of the others.

Even if we have a system without boilers and not a combined one (radiators + water heated floor), but “only” branched with several pumps, then we install check valves on each branch, the price of which is definitely less than reworking the system.

Causes of poor coolant circulation

There may be no coolant circulation in the heating system for the following reasons:

- insufficient power of the circulation pump (or pumps, if there are more than one). For this reason, the coolant simply does not reach the radiators furthest from the boiler, so they are cold (or slightly warm, which still doesn’t make it any easier). There are several articles and videos on how to select the power of a circulation pump in the section on heating calculations;

- check valves are not installed. Usually their absence is “painful” for complex systems with several circuits. Check valves are used to ensure that the coolant moves along the desired circuit and in the desired direction (read more below);

- system contamination. It happens that the pipes are clogged along the entire diameter - what kind of circulation is there! There is only one way to treat this: replacing the pipes. This is exactly the case when the best treatment is prevention. And “prevention” should be carried out at the stage of installation of the pipeline and radiators. First, make sure that no debris gets inside the pipes. To do this, after first making sure that there is nothing inside, we close the ends of the pipes with something before installation. For example, it is convenient to use simple plastic bags. Secondly, there may be debris in the radiators. Even new ones! So we check and get rid of it;

- pipe diameter is too small. Small pipe diameter - high hydraulic resistance - the pump is not able to “push” the coolant throughout the pipeline - there is no circulation in the heating system (well, or it is so bad that it’s the same as if it doesn’t exist). Again, at the design stage it is necessary to calculate the hydraulic resistance;

- accumulation of air in the system (airing). Air, of course, is not garbage, but air pockets will also prevent the coolant from circulating freely. Air locks may appear due to violations of the rules for installing the heating system. Getting rid of air is simple - install an automatic air vent at the highest point of the system and Mayevsky valves on the radiators.

Code 109

Code 109

The error appears when the system pressure is critically high (more than 3 bar). This is possible in the following cases:

- Excess fluid in the system.

- Airy batteries.

The problem can be solved by forcibly draining some of the water from the heating system, as well as bleeding air from all existing batteries.

Problems starting with the number 2 appear only in those models that have two circuits working for heating and water heating.

Code 209

Exceeding the maximum permissible temperature in the water heating tank, which happens when the thermostat itself malfunctions, as well as a sharp decrease in water pressure in the system.

The boiler is blocked, after which you can try to restart it. Frequent repetitions of this error are a signal that it is necessary to test the thermostat board and replace it if necessary. Problems in this category can arise both when there is a power surge in the network or when the contacts of working elements deteriorate. All codes start with the number 3.

Code 103-107

Code 103-107

Errors in this range are associated with an increasing temperature difference in the supply and return pipelines.

There are several reasons for this:

- batteries are airy;

- pump is faulty.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

When this code occurs, the boiler operation is blocked automatically. The search for causes is sometimes complicated by problems with the central temperature sensor, which records false readings.