Here you will learn:

- Optimal indicator

- Peak values

- Pressure drop in the heating circuit

- Increase in pressure in the heating circuit

Closed heating systems are becoming more and more common. The process of their installation is fine-tuned to the smallest detail. Nevertheless, users still have questions about their operation. A typical example of this is the pressure indicator in the heating circuit. In this review, we will tell you what pressure should be in a closed-type heating system and how to deal with its surges and drops.

Optimal pressure values for private houses

In a system without liquid coolant, the pressure is normal for the atmosphere - 0.1 MPa or 1 Bar.

The overall indicator is formed based on the following components:

- Hydrostatic pressure - created by the coolant and when the boiler is not working, is formed by the pressure of the water column. In an open system, a special reservoir is mounted at the top - an expansion tank. Based on its filling level, the height of the heating circuit will be measured.

- Dynamic pressure - created in closed networks by a pump for circulation and convection (heating and cooling directly affect the volume of water). Such indicators often differ in places where pipes of different diameters are connected, the location of shut-off valves and many other points.

General values affect the rate of circulation of the energy carrier in the pipes, direct heat exchange in different parts of the heating circuit, and also with increasing pressure, the efficiency of the heating network increases, because the resistance in the system decreases.

Stable operating pressure and optimal, according to the accompanying technical documentation, indicators for the equipment make it possible to reduce heat loss and guarantee that remote areas of the house receive energy with almost the same temperature indicators as during heating in the boiler.

Theoretically, any value is possible for it, as long as it can withstand heating equipment with boilers and radiators. There is a completely reasonable and justified interest in the issue of working pressure.

These are the maximum indicators that can be viewed in the technical documentation of the equipment. According to established standards, for a private home the optimal pressure is up to 3 Bar, although individual units have a lower limit.

Norm

For an autonomous heating system in a private home, a pressure of 0.7 to two atmospheres is considered normal.

The specific value is calculated during design, depending on the characteristics of the equipment, the characteristics of the heating network, and the number of floors. An indicator above two atmospheres is considered critical. If the pressure reaches three atmospheres, an accident will occur. The connections will become leaky and the system will fail.

A prerequisite that gives grounds to consider the pressure normal is the necessary difference between the indicators in the forward and return pipes. It should be from 0.3 to 0.5 atmospheres.

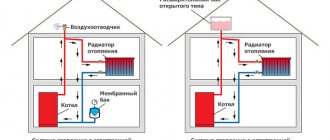

Closed and open types of heating circuit

Before making any calculations, you need to figure out which system is installed and what the main differences are. So, the main thing is the presence of an expansion tank (helps to collect excess liquid) in an open heating network and the tightness of the system in a closed one.

The membrane inside the vessel in the last type of heating system divides it into 2 compartments. One is filled with air, and the other is connected to a common line. This design allows you to remove excess liquid as its volume increases during heating. And when the water cools and decreases in volume, it will help make up for the shortage.

- The expansion tank is installed at the top of the heating circuit, for example in an attic or other special room at a height, connected to the heating system riser, and on the other side to a drain that protects in case of overflow.

- To create an open-type network with a pressure of 1 Bar, the tank must be installed at a height of 10 m from the minimum. For an average power of 3 Bar (usually standard boilers) you will need a height of more than 30 m.

- This is precisely the reason for the more frequent choice of open-type heating systems for low-rise buildings. The operating pressure in them in rare cases is higher than the usual hydrostatic pressure even when heated, which means that it is not necessary to install additional fuses other than the equipped drain.

Remember, normal operation of an open-type system is ensured by installing the boiler at the lowest level of the heating circuit and the tank at the highest.

The pressure in a closed system is much more affected by changes in water temperature and safety valves must be installed. Usually for a two-story building they set it at 2.5 atm. In a small house the limit of 1.5-2 atm is maintained.

Where and at what approximate cost is it sold, what else should I consider when purchasing?

You can buy pressure gauges in stores that specialize in heating and water supply. Prices depend on the manufacturer and model. The simplest ones cost around 300-500 rubles.

We should not forget about the adapters that will be required if the thread diameter is different. They cost about 100-150 rubles.

There are models with connecting tubes . Their price can reach several thousand rubles. But usually they are installed only on the equipment itself.

To avoid buying a broken pressure gauge, you need to carefully inspect it. Firstly, the case must be undamaged. Secondly, the needle must be at zero. In addition, you should pay attention to the year of manufacture.

Some people cannot tell the difference between a water and an air pressure gauge. Indeed, outwardly they are absolutely identical, but in structure the difference is huge. Therefore, before purchasing, it is better to check with the seller for what purposes the device is used .

Why monitor pressure while heating your home?

The difference in pressure when water is supplied and when it moves in the opposite direction reflects how efficiently a particular system operates.

A small one indicates that the coolant successfully passes through the pipes and the rooms receive the proper amount of energy, and an increase in this difference with a large difference signals an increase in the resistance of the area, a reduced flow rate and excessive cooling.

- How fast will be the water flow and heat exchange between objects in different parts of the system, possible heat losses, and the efficiency of the network directly reflects the total pressure indicator.

- Maintaining it is essential for the efficient operation of the heating circuit throughout the building. The stability of the values will reduce heat loss and ensure rapid distribution of the coolant to all corners of the house, practically matching the temperature obtained during heating.

Large differences in a long heating supply line, where there are many radiators with thermostatic valves, can be regulated using automatic limiters.

It is necessary to create excess pressure in closed systems for:

- Ensuring forced movement of liquid in pipes;

- Monitoring the condition of the network using a pressure gauge in order to replenish or repair it in a timely manner;

- Under pressure, faster heating occurs.

Homeowners are interested in the second item from this list - the device’s measurement readings, so that it is clear how serviceable and efficient the entire heating circuit structure is.

Top 3 models

There are a lot of pressure gauge models, but there are 3 most popular ones:

- The Watts F+R250 is a good meter with a ½ inch fitting. Measuring range - from 0 to 6 bar. The body is made of coated ferrous metal. But the diameter is 100 mm, so it is not suitable for everyone. Price - about 900 rubles.

- Itap 483/1/4 - the body of this pressure gauge is made of ABS plastic, but this does not mean that it is worse. The connection size is ¼ inch, so in some cases an adapter may be required. It can measure pressure up to 10 bar and its diameter is 63 mm. Price - approximately 400 rubles.

- Tim Y50T-10bar - from the name it is already clear that the pressure gauge is intended for systems in which the pressure does not exceed 10 bar. The plastic case with a diameter of only 50 mm allows it to be installed even in the most difficult to reach places. The diameter of the fitting is ¼ inch. Price - from 110 to 150 rubles.

If you choose these models, you don’t have to worry about breakdowns and service life. This also includes the accuracy of measurements.

Causes of pressure drop in the heating system

Jumps after the start of the heating season 2-3 weeks later require careful inspection to identify possible problem areas. Pressure loss can be caused by contamination, small cracks, extensive wear, possible defects of the equipment manufacturer, as well as a defect in the expansion tank.

Among the common reasons:

- A leak. It is necessary to check the threaded connections; perhaps there is too little sealant, or the welding technology for polypropylene pipes was violated;

- Air. After starting the system for constant heating, it needs to adapt. At first, such a decrease in pressure is the norm, but it can be adjusted by replenishing the coolant, it will increase to the required level

- New aluminum batteries. Contact of radiators with water will initiate the oxidation reaction. It will end after the entire area has been oxidized and the situation will stabilize.

Having identified strong pressure drops, it is worth consulting with a specialist, because the reasons can be different. The engineer will diagnose the heating system, check how well and accurately the pressure gauges, air vents, and fuses work.

Modern heating equipment is equipped with special sensors that respond not just to a pressure surge, but to changes in the temperature of the energy carrier.

Any problems in the operation of heating in a private household not only bring discomfort and costs for repairing equipment, but often people can be injured or the building itself can be damaged. It is important to be attentive to the system and competent during control.

What it is?

A pressure gauge is a device for measuring pressure.

When the heating pressure drops, the equipment stops working. Moreover, air begins to accumulate. If the pressure exceeds the norm, this can lead to a rupture at some point in the system.

To set up equipment and troubleshoot problems in a timely manner, you must always monitor the indicators . This is precisely what pressure gauges are used for. They are used not only in heating, but in general in any systems where pressure needs to be controlled.

They look quite simple: a plastic case, a dial and a connecting tube.

There is a membrane or spring inside. When pressure is applied to them, they are deformed, and the needle deviates to a certain point. Electronic options are less common, but they are also installed .

Bars, atmospheres or pascals are used for measurement. 1 bar = 0.99 atmospheres, but there are too many pascals, so megapascals are used more often. 1 megapascal = 10 bar.

Photo of the best heating system for a home

Instrument verification

Verification is a series of operations that are performed to confirm the correct operation of measuring instruments.

Usually its validity period is 2 years , although it all depends on the manufacturer. If the pressure gauge is working properly, leave it.

Obvious damage includes a broken case and an arrow that does not change position. Special equipment for testing at home is almost never used, since it is easier to simply replace the pressure gauge.

Leak test

To check the tightness of pipelines, a procedure called pressure testing is performed.

Its essence is as follows:

- A pressure tester - a pump with a pressure gauge - is connected to the emptied system through a special pipe.

- Air is pumped into the system until its pressure exceeds the operating pressure in the heating system by 20%.

- The system is left under pressure for several hours. If it falls, then the system is leaking. Leaks can be detected by the hissing of air or by applying soap foam to the connections.

Pressure testing of heating systems of private houses, with a relatively small volume, can be performed using inexpensive manual pressure testing machines.