Home / Heating

Back

Published: 08/04/2019

Reading time: 5 min

0

11884

In autonomous hot water systems, for multi-level facilities, the wiring has an increased length, which affects not only the period of hot water supply, but also the excessive consumption of water and energy resources due to the fact that they have to be discharged into the sewer until water of the required quality comes out of the tap. .

Such actions are simply unacceptable today, when the whole world is fighting to preserve water resources on the planet. Simple calculations show that a family with four people per year can “drain” up to 14 thousand liters of water. This problem worries the scientific potential of the EU, so they are everywhere reconstructing DHW circuits with piping an indirect heating boiler with recirculation (BKNSR).

In this area, advanced, innovative technologies are being implemented in the hot water supply system in Russia.

- 1 Recycling principle

- 2 Power calculation and equipment selection

- 3 Drazice indirect heating boiler

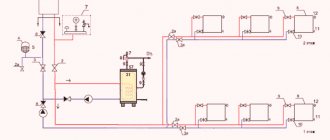

- 4 Piping diagram for an indirect heating boiler with recirculation

- 5 Installation tips

What is an indirect heating boiler

Its peculiarity is that the principle of operation is not based on heating water due to its own unit, but on heat exchange from external sources, such as fuel combustion, electrical resistance (resistance), contact with central heating, and the use of solar panels for energy processing. At its core, the boiler is a connecting link between the heart of the heating system (boiler) and all its vessels and arteries, correctly distributing the load and pressure on each branch. In this distributor, hot liquid passes through a metal spiral (coil) built into the storage tank. Heat exchange occurs through conduction between the coil and the cold water tank. A mandatory component of the boiler is thermal insulation, reminiscent in structure of a thermos to maintain the temperature inside the container, eliminating the loss of accumulated joules outside the device. The material for thermal protection is mainly polyurethane. The boiler circuit also includes a protective anode, an inspection hole, a bumper, and a submersible sleeve (for the temperature sensor).

Thanks to the heat exchanger, it is possible to heat water in a short period of time (up to 20 minutes from zero to 60 degrees). The only thing is that it is necessary to connect an indirect heating boiler with a boiler (usually gas) in order to be able to carry out such rapid heating.

Implementation

What hot water supply schemes with recirculation are possible in apartment buildings and private buildings?

Apartment buildings

To create continuous circulation of water, the DHW system needs to be looped.

In apartment buildings this is achieved as follows:

| Image | Description |

The basement is filled with cold water, hot water and heated towel rails. | There are two hot water dispensers throughout the house. The risers are connected to them one by one. As an option, only DHW risers are connected to one of the bottlings, and only risers with heated towel rails are connected to the second. |

| The riser of heated towel rails serves as a return for hot water supply | DHW risers (optional DHW and heated towel rails) are connected by jumpers on the top floor. A group can consist of 2-4 risers. An air vent (Mayevsky tap) is mounted at the top point of the jumper, allowing the air to bleed off that is preventing circulation. |

It is clear that the described water supply scheme with recirculation will not work without a pressure difference.

How it is provided:

Outside the heating season, the DHW is switched on between the supply and return lines;

Summer mode: DHW circulation between the supply and return lines

During heating operation with such a connection, the hot water supply system will represent a bypass for the heating system, catastrophically reducing the drop in the water jet elevator. Therefore, the DHW is connected depending on the temperature of the water from supply to supply or from return to return, and the difference is ensured by retaining washers installed on the flanges between the taps.

Modern elevator unit with circulation connections

If the risers are airy

What should I do if, after resetting the hot water supply system, the air pocket remaining in the risers prevents circulation and the heated towel rails remain cold?

To bleed air, use the Mayevsky valve at the top point of the jumper. However, to access it you need to get into the upper apartment via the riser, which is not always possible.

Here are simple step-by-step instructions that will help you fix the problem yourself:

- We block any of the hot water supply risers connected by a jumper;

- We open one, or better yet, two hot water taps in any apartment along this riser all the way. The air plug flies out through the mixer at the front of the water flow;

Open the faucet completely and the air will fly out of the riser at the front of the water flow

- We start the risers in normal mode.

Private houses

What hot water recycling schemes can be implemented in a private house with autonomous hot water preparation? Quite predictably, a minimum power circulation pump (from 25 watts) will be responsible for creating circulation pressure in such a system.

Circulation in the DHW circuit can be ensured by a minimum power pump

The DHW circuit must be looped along its entire length: after the plumbing fixture farthest from the water heater, the filling returns to the starting point. But the connection diagram for the water heater depends on whether it has an additional outlet for recirculation.

Diagram for a boiler with a pipe for connecting a recirculation circuit

The presence of three pipes for connecting DHW and cold water is typical for most indirect heating boilers and some storage electric water heaters.

Boiler with additional outlet for recirculation

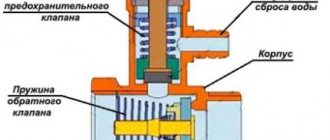

The closed circuit is supplied only with a circulation pump: since the temperature of the water in the circuit is constant after its start, the problem of thermal expansion of water does not have to be solved, and if so, a safety valve and an expansion tank are not required.

Is it possible to use a regular boiler with two outlets (for DHW and cold water) in such a scheme? Yes, but in this case the wiring will be noticeably more complicated.

Water supply with recirculation: diagram for a boiler with two pipes

A three-way thermostatic mixer is responsible for maintaining a constant water temperature in the recirculation circuit. As it cools, he mixes in hot water from the boiler;

The three-way thermostat mixer is capable of providing a constant outlet water temperature at any inlet temperature

- To compensate for the flow of hot water, cold water is supplied to the three-way mixer;

- Check valves limit the movement of water in the circuit in one direction, regardless of its flow.

Design and appearance of an automatic air vent

Connection progress for an indirect heating boiler

After choosing a circuit, it becomes clear what equipment will be required. In addition to the main devices, you may need valves, ball valves, distribution combs, valves (three-way or check).

Procedure:

- prepare the installation site (on the floor or on the wall);

- make the wiring, marking the hot/cold water outlets in red/blue;

- install a tee and a pressure relief valve, securing the connections with sealant;

- screw on the hot (top) and cold (bottom) water taps;

- connection to a power source, install a thermostat and automation;

- select heating mode;

- test the connection.

These are general guidelines needed to present the scope of work. When connecting a specific model, you must follow the instructions that come with the kit.

Hot water supply or DHW

In some low-rise buildings, hot water is connected in the same way, standing on a backwater without circulation, this explains the fact that when you open a hot water tap, cold, cooled water flows for some time. If we take the same house with 16 floors, then in such a house the hot water system is arranged differently. Hot water, like cold water, is also supplied to the house through a large pipe, and after the meter it goes into the house mains

which lifts the water into the attic where it is distributed along the risers and goes down to the very bottom into the return line. By the way, hot water meters count not only the volume of lost (consumed) water in the house. These counters also count temperature losses (gigocolors)

Temperature is lost when water passes through apartment heated towel rails, which act as risers.

With this scheme, hot water always circulates. As soon as you open the tap, the hot water is already there. The pressure in such a system is approximately 6-7 kg. on the supply and slightly lower on the return to ensure circulation.

Due to circulation, we get pressure in the riser in the apartment of 5-6 kg. and immediately we see the difference in pressure between cold and hot water, from 2 kg. This is precisely the essence of pressing hot water into cold water when plumbing fixtures malfunction

If you notice that you still have higher pressure on hot water than on cold water, then be sure to install a check valve at the cold water inlet, and at the hot water inlet you can include control valves in the system, which will help equalize the pressure to approximately the same figure as the cold one. Pressure regulator installation example

How does a boiler work in tandem with a non-volatile boiler?

If a non-volatile boiler is used as a heating source, in order for the hot water supply to be a priority, the boiler must be located above the radiators. This is easy to do if the model is wall-mounted. The best position is when the bottom of the hot water tank is higher than the heating boiler and radiators.

In a floor-standing model, the water will heat up, but it will take much longer. In addition, the water at the bottom of the tank will remain unheated. Its temperature will not exceed the return heating level in the heating system. With this scheme, the coolant flows by gravity, with gravity acting as the driving force. There is an installation method in which a circulation pump is connected to the boiler. But this is not a solution, because if there is no electricity, the water will not heat up. Experts have developed several schemes tailored to gravity heating systems.

The trick is that the diameter of the pipe intended for the water heater circuit is taken one step larger than the diameter of the heating pipe. According to the laws of physics, the coolant will “choose” a pipe with a large diameter, that is, the boiler will be a priority.

In another method, a thermostatic head with a built-in sensor, powered by batteries, is installed in the heating system. Everything is very simple: using the thermohead regulator, you set the desired level of water heating. While the water is cold, the thermostat opens the way for water to enter the boiler. As soon as the water warms up, the coolant is directed to the heating circuit.

Water intake when the supply is turned off

Most storage water heaters are closed-type and do not drain water by gravity. However, there are a number of piping additions that make it possible to draw water in the absence of pressure. These same additions make it easier to empty the tank if it is removed for maintenance.

First of all, the theory: the hot pipe of the tank reaches the very top of the container, the cold pipe is located below under the diffuser cap. The water is drained through the cold pipe, and air is sucked into the container through the long hot outlet pipe.

Storage water heater design: 1 - cold water supply; 2 - heating element; 3 - tank; 4 — hot water intake; 5 - thermal insulation; 6 - body

The simplest solution is to cut a tee into the hot outlet to the location where the ball valve is installed. Using these two taps, you can provide air to the tank and use hot water from the “cold” pipeline. But this approach is not entirely safe: if you forget to turn off the air intake valve, you risk flooding your home when pressure appears in the cold water supply system.

The problem is solved in two ways. The first is to install a check valve on the air suction valve at the hot inlet. The problem is that there is almost always a small amount of water in the high tube of a filled tank, so the system does not work very stably - the water column prevents the valve from opening even if there is a relative vacuum in the tank. You have to bleed water from the tube manually when you first open the system.

1 - tee; 2 - check valve; 3 - valve for air intake

It is also possible to install a check valve bypassing the cold supply shut-off valve. In this case, the valve is installed opposite the normal flow of water, blocking its flow into the tank when pressure is applied. As before, this task can be solved with even fewer three-way valves.

Strapping stages

First, an installation diagram is drawn taking into account the dimensions of the room and the selected locations for all devices. After this, holes for the heating boiler and boiler are marked and drilled. If the devices are floor-mounted, then it is advisable to make a small foundation for them according to the size of the buildings.

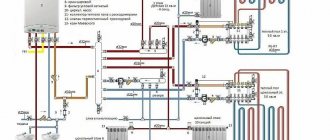

Next, propylene pipes are cut according to size and connected to each other with tees using a soldering iron. Pumps, taps, filters are installed and everything is combined into one system. If you have additional circuits, for example, on a hot floor, then a collector is installed that evenly distributes the coolant flows.

Connection diagram for a double-circuit boiler

An expansion tank and a safety complex are mandatory. When installing a safety group, you should take into account that if it works, water will flow out of it. Excess coolant goes into the expansion tank during expansion.

After all connections, water is introduced into the system and all connections are checked. If there are no leaks, then the boiler starts and the heating rate of the batteries is checked.

Why do you need a booster pump?

A booster pump is used when there is insufficient pressure in the water supply. Nowadays, most booster pumps operate when there is water supply, that is, the pump will work until you turn off the water at the mixer. This is done using a flow switch built into the pump. With the help of such pumps it is possible to pump low-viscosity, non-aggressive liquids without the inclusion of solid particles and engine oil impurities.

Specifications:

- Pressure 2 meters.

- Ambient temperature from 2°C to 40°C.

- The temperature of the pumped liquid is from 2°C to 60°C.

- Maximum system pressure 6 bar.

Installation of a booster pump.

The booster pump is installed using union nuts directly on the pipe through which cold water is supplied. The standard connection size is 0.5 inches. After installing the pump, it is necessary to remove air from it. How to do this is described in detail and with pictures in the instructions, which I strongly advise you to read before doing the installation. Let's look at an example of correct incorrect installation in the figure:

Installation example of the UPA15-90 pump Correct installation of the booster pump

It is also necessary to remember that the pump shaft must be located in a horizontal plane. If this is not done, the bearings will not be lubricated and will quickly fail! Let's look at another drawing and draw conclusions.

Maintenance.

At home, it is limited to cleaning the flow switch. If you don’t want to do this, you can install a mesh filter in front of the pump that will trap sludge. More complex repairs should be carried out at an authorized service center.

Installation instructions for the recirculation system

It often happens that plumbing fixtures are located in the house at a considerable distance from the boiler or on the upper floors. In this case, the owners of the building usually have to wait until the water that has stagnated and cooled in the pipes drains from the taps in the bathrooms to get hot water. And this, of course, is inconvenient and not particularly economical.

This situation can be corrected by assembling a recirculation system in a country house. Installation of such a network is carried out approximately as follows:

- a tee is cut into the pipe supplying hot water to the consumer as close as possible to the consumer;

- a pipe of the required length is connected to the tee;

- the extended line is connected to the boiler through the recirculation pipe;

- Next to the boiler, at the nozzle, an additional pump of not too high power crashes into the circuit.

When using such a scheme, the water in the pipes between the boiler and the consumer, after turning on the pump in the electrical network, will not stagnate and, accordingly, will be cooled. That is, residents of the house will be able to use hot water immediately after unscrewing the tap valves.

Hot water recirculation

Recirculating hot water will allow you to quickly get enough hot water. If you install a water heating boiler in your home, be sure to wire it up.

There are special diagrams that demonstrate how hot water is recirculated in the house

Thanks to recirculation, a pipeline is created through which water constantly flows and at the same time constantly heats up without having time to cool down. Because of this system, you will be able to get water as soon as you open the tap.

To make such a system, you need to install a recirculation pump. In this case, the flow of hot water must be directed in such a way that it constantly passes through structures that require heat. By fulfilling this condition, you will get maximum boiler efficiency.

Useful qualities

The volume of the device can vary from 30 to 1500 liters, it depends on its purpose. Units with a volume of up to 200 liters are available as wall-mounted units, larger units – as floor-mounted units. As a rule, a 200-liter boiler is enough to satisfy the hot water needs of one family. The efficiency of this device is high and is about 90%.

Modern models are equipped with additional electrical elements, heating elements, or have the ability to connect them. This allows you to use them as an additional source of water heating and turn off the boiler in hot months, which significantly increases the service life of the boiler.

What to choose for the home and what for the dacha?

Using a running hot water supply system in a residential building is impractical for many reasons. Water consumption in houses where people live permanently differs markedly from consumption in country houses, especially if not just one person lives, but a family.

The flow system is fraught with a number of disadvantages for users:

- Reduced hot water pressure due to limiters built into heating equipment.

- Unpredictable changes in tap water temperature.

- Waiting for water to flow after opening the tap.

- High consumption of electricity or gas, depending on the type of system chosen.

However, for a summer residence, a flow system will be the optimal solution. After all, the need for hot water is not so high, the cost of such a system is much lower, and its dimensions are more compact.

There is also another important advantage - if when using a water heating tank you need to wait for water after turning on the equipment, then users of flow-through systems are free of this problem.

A flow system is better for a summer residence, the use of water heating tanks is better for a home, but there are exceptions. For example, when one person lives in a house or when people live in a dacha not occasionally, but permanently. Therefore, each case must be considered separately.

Schemes and rules for connecting BKN

The connection diagram and installation features of an indirect heating boiler depend on the class of the device and the heating system in the house. It is necessary to choose the right installation location, focusing on the location of the boiler, pump insertion and existing wiring. Let's try to figure out what needs to be taken into account when installing heating equipment.

#1: Trim method with three-way valve

This is one of the most popular schemes, since when it is used, there is a parallel connection of the heating system and the BKN, equipped with shut-off valves. The boiler must be installed near the boiler, a circulation pump must be installed in the supply, then a three-way valve. This scheme is successfully used if several heating devices are used, for example, two different boilers.

A three-way valve is a kind of switch that is controlled by a thermal relay. When the temperature drops, the automation is activated, and the coolant flow from the heating circuit is redirected to the BKN (+)

Essentially, this is a priority system that ensures rapid heating of water in the boiler when the radiators are completely turned off for a while. As soon as the temperature rises to the set value, the three-way valve is activated again and returns the coolant to its previous direction - to the heating system. This piping method is useful for those who use the boiler constantly.

#2: Option with two circulation pumps

If the boiler is rarely used (for example, seasonally or on weekends) or there is a need for water whose temperature is lower than in the heating system, use a circuit with two circulation pumps. The first is installed on the supply pipe, directly in front of the BKN, the second - on the heating circuit.

The circulation pump is powered through a thermal relay, so it starts to operate only when the temperature drops below the required one. Heating accelerates when forced circulation is turned on (+)

There is no three-way valve in this scheme; the piping is equipped using simple connecting tees.

#3: Piping with hydraulic boom

This connection is used for volumetric boilers (200 liters or more) and branched heating systems with many additional circuits. An example is the heating system in a two-story house, where, in addition to a multi-circuit radiator network, heated floors are used.

A hydraulic distributor (hydraulic arrow) is necessary to simplify the layout of the heating system and avoid installing recirculation pumps on each heating branch (+)

The water gun equipment allows you to avoid thermal shock, since the water pressure in each circuit will be the same. It is quite difficult to make the piping according to this scheme yourself, so it is better to turn to professional installers.

#4: Using coolant recirculation

Recirculation is useful when there is a circuit that requires a constant supply of hot water - for example, a heated towel rail. If it is connected to the heating system, the coolant will constantly circulate, and the dryer will function and at the same time serve as a heating device.

The use of recirculation has one big advantage - you don’t need to wait for the water to heat up to the desired temperature, it will always be hot (+)

But this scheme also has disadvantages. The main one is an increase in fuel costs, because constant heating of the water cooled in the circuit is required. The second disadvantage is mixing water in the boiler. Typically, hot water is located in the upper part, and from there it flows to the water supply points, where it is mixed with cold water, as a result of which the outlet temperature is slightly lower.

There are models of boilers with built-in recirculation, that is, with ready-made connections for connecting a heated towel rail. But it’s cheaper to buy a regular tank using tees for connection.

#5: System for working with a non-volatile boiler

A distinctive feature of this scheme is the installation of the boiler at a higher level than the boiler and heating appliances. Preference is given to wall-mounted models that can be hung at a height of 1 m above the floor.

Floor-standing models specifically within this scheme are inferior to wall-mounted ones in heating speed and quality. The water temperature is much lower (about the same as in the return pipeline), therefore, the supply of hot water is less (+)

The non-volatile type of heating is based on the application of the laws of gravity, therefore, the coolant will circulate even when the electricity is turned off. In normal mode, you can connect circulation pumps.

Installation principle

If you need to mount a tank with a capacity of up to 200 liters, this can be a wall-mounted product. For its fastening, special kind of brackets are provided, which must be located on flat and strong vertical surfaces. Conventional plasterboard partitions are of little use for mounting even such a “light” storage device. You need to choose between saving on the arrangement of interior space and saving on the boiler. Floor-standing units are preferred to meet the needs of large households; sometimes they even install products with a capacity of over a thousand liters and allocate a special boiler room for them.

In private homes, you can limit yourself to indirect heating boilers that accumulate from 250 to 300 liters of water. The exact choice of capacity must be made taking into account real and projected needs. When connected to a double-circuit boiler equipped with a built-in pump, the boiler automation itself takes over the coordination of the valve operation based on signals from the thermostat

This is very important because a double-circuit heating device, unlike a single-circuit heating device, must supply hot liquid both to the heating system and to the hot water supply circuit

If you install a three-way valve, the water heater will have an advantage in the system compared to the heating circuit. This approach is acceptable when a large capacity tank is installed. Please note: this connection method is also practiced when forced to use hard water, which complicates the normal use of the hot water system. Although, of course, it would be much more correct to take care of softening the incoming coolant. But sometimes you have to adapt to it against your will.

Problems may arise due to the fact that significant consumption of hot water can complicate the functioning of this circuit. In this case, the method of obtaining heat, including using a pellet or other solid fuel boiler, is not significant. And this is where the boiler comes to the rescue, smoothing out fluctuations in two circuits. Thanks to it, even intensive coolant consumption has little impact on people’s daily lives. Installers must consider which function will have the highest priority.

Connecting indirect heating boilers to a single-circuit boiler can be done using a pair of pumps. Then, with their help, water flows are distributed through two pipelines. It is usually assumed that the hot water supply circuit will come first. The operation algorithm of the boiler in conjunction with a single-circuit device is also adjusted accordingly. To prevent liquid flows of different heating levels from changing each other’s basic parameters, both pumps must be preceded by a return valve. Hot water is supplied exclusively from the boiler.

Connection features

An indirect heating boiler is a storage tank, inside of which one or more tubular heat exchangers are located. The hot coolant from the boiler circulates through the coil and heats water in sufficient volume for domestic and economic needs.

The principle of operation of the water heater is simple; difficulties arise during installation and wiring of heating equipment.

Therefore, it would not be amiss to find out the specifics of connecting a water heating device before starting work:

- The closer the boiler is located to the boiler, the more efficient the heat exchange from the heating system occurs.

- The installation of the water heater must be carried out in accordance with the manufacturer’s recommendations - wall-mounted models are attached to the wall, floor-standing models are installed on the floor.

- The flow of cold water should be supplied through the lower pipe, and the intake of hot water through the upper, then the recirculation point will be in the center of the container itself.

- The pipes for the coolant inlet and outlet should “look” towards the heating device. The movement of hot water or antifreeze along the coil should be from top to bottom.

Compliance with these simple rules guarantees the efficient operation of the boiler-boiler system, the efficiency of the heater will reach its maximum and there will be enough hot water for all consumers.

General principles

The procedure for piping a boiler means connecting it to the heating system and the water supply line. The productivity of the water heating system directly depends on the quality of the work.

That is why the installation of a boiler should not be carried out using arbitrary technology, but in compliance with the following mandatory principles:

- Water supply is through a pipe in the lower zone of the boiler.

- Hot water must be drawn in through a pipe at the top of the equipment.

- The recirculation point should be in the center of the boiler.

- The coolant enters the boiler tank from top to bottom - through a pipe in the upper zone. And to exit, that is, return to the system, through the lower zone.

Boiler design

If all four principles are followed, the water dispensed in the upper zone of the boiler will always be hot, which will allow you to achieve maximum equipment efficiency.

Let's look at the specifics of different strapping methods.

Common installation mistakes

During installation or during the commissioning process, you should try to avoid a number of mistakes:

- The boiler and boiler are installed far from each other. Their installation should not only be done as close to each other as possible. But, to simplify installation, the pipes are positioned correctly.

- Incorrect connection of the pipeline with the coolant.

- Incorrect installation of the circulation pump.

Proper installation, adjustment and configuration guarantee a stable hot water supply and allow all systems and devices to operate normally. This will prevent wear of parts and save on premature repairs.

Additional water system improvements

To create an additional level of comfort and improve the performance of the water supply system, additional improvements can be made, such as:

- additionally take care of disconnecting the water heater from the system by installing ball valves in case of need for its maintenance, breakdown or simply shutdown to reduce energy costs;

- installation of additional heated towel rails that will be warm all year round;

- carrying out additional thermal insulation of pipes from the water heater to the water supply systems to reduce heat loss;

- installing the water heater as close to the water supply points as possible, otherwise you will have to drain cold water from the taps in order to wait for hot water. In this case, it is necessary to install a recirculation pump for more efficient and economical use of cold water drained from the tap into the hot water supply system to the water heater - to reduce its consumption and economical use, so as not to drain it into the sewer. Calculations indicate water savings per year for a family of 4 people at the level of 15,000 - 000 liters.

The results of these improvements:

- savings (on water, on gas - since the boiler will rarely turn on, on electricity);

- always warm water on taps;

- the service life of the main boiler increases, since the boiler will turn on less often and operate less often, so all components will last much longer.

How to choose an indirect heating boiler

In principle, choosing a BKN is very similar to choosing a conventional storage boiler. But let's briefly repeat the main points.

Volume is the very first thing to choose. Let's simplify your task: on average, 1 family member should have 40-80 liters of water. There will be no problems with selecting a model of suitable capacity. Today, the indirect heating boiler market offers models with volumes from 200 l to 1500 l.

Water flow through the heating circuit - be sure to look at this characteristic from the model data sheet.

The value of this characteristic should be no more than 40% of the total volume of water that passes through the heating boiler.

The material of the tank and thermal insulation - you understand, the best choice for the tank is stainless steel. It is better to choose polyurethane foam or mineral wool as insulation - they have the best heat-insulating properties.

Experts do not recommend choosing models with foam thermal insulation. It doesn't hold heat very well.

Malfunctions

What problems in the operation of the water supply system can the apartment owner eliminate on his own? Here are some of the most typical situations.

Valves leaking

Description: leakage along the stem of screw valves.

A typical leak location is shown by an arrow.

- Reason: partial wear of the oil seal or wear of the rubber O-ring.

- Solution: open the valve knob all the way. In this case, the thread on the rod will tighten the seal from below, and the leak will stop.

Crane noise

Description: when you open a hot or (less often) cold water tap, you hear a loud noise and feel the vibration of the mixer. Alternatively, your neighbors faucet could be the source of the noise.

A noisy neighbor's faucet can become a source of a lot of negative emotions.

Cause: a deformed and crushed gasket on the screw valve in the half-open position causes a continuous series of water hammers. Its valve closes the seat in the mixer body at intervals of a fraction of a second. In hot water, the pressure is usually noticeably higher, so the effect is more pronounced.

Solution:

- Shut off the water to the apartment;

- Turn out the problematic valve housing;

- Replace the gasket with a new one;

- Use scissors to remove the chamfer from the new gasket. The removed chamfer will prevent the valve from beating in a turbulent stream of water in the future.

Replacing the gasket on the screw valve

The photo shows a ceramic crane box

Cold heated towel rail

- Description: The heated towel rail in your bathroom has cooled down and is not heating up.

- Reason: if the water supply scheme of a residential apartment building uses continuous circulation of hot water, the air remaining in the jumper between the risers after water is discharged (for example, for inspection and repair of shut-off valves) is to blame.

- Solution: go up to the top floor and ask your neighbors to bleed the air from the jumper between the DHW risers and heated towel rails.

If for some reason this cannot be done, the problem can be solved from the basement:

- Shut off the DHW riser passing through your apartment, to which your connections are connected;

- Go up to the apartment and open the hot water taps all the way;

- After all the air has come out of the riser through them, close the taps and open the tap on the riser.

If a vent is installed on the riser, it can be diverted directly from the basement

Immediately after the end of the heating season, the difference between the lines of the route may be zero

Boiler recirculation diagram

Recirculation of water in the DHW system is necessary in order to provide hot water to any point in the system without additional spillage. To do this, a circuit is installed through which water from the boiler passes throughout the entire system, and then returns back to the boiler. Recirculation is carried out using a small pump that operates completely silently. This system helps maintain a stable temperature of hot water anywhere in the house.

Among the common recycling schemes, there are several main options:

- Installation of a three-way or servo-motorized valve. This method is used for wall-mounted and floor-mounted boiler models. Two pipes (two circuits) are connected to the boiler. One circuit is intended for heating, the other for hot water. The water heater in this system acts as the main coolant. When the water temperature drops, a servo-driven or three-way valve is used, which begins to work to heat the water. The heating is turned off at this time. After heating the water to the desired temperature, heating is resumed;

- Installation of two circulation pumps in one system. With this scheme, one of the pumps is designed to recirculate hot water through the heating system, and the other - through the boiler circuit. This system initially ensures normal water temperature in the boiler, and then in the heating system. A feature of this scheme is the presence of a thermostat and a mode switch, which allows you to turn off, if necessary, one of the systems;

- Application of a hydraulic arrow. It is used if there are more than two circuits in the house (heating, hot water, heated floor). This scheme is aimed at heating water, due to which all circuits are heated. This system has a significant drawback - when analyzing water. The coolant may not be able to meet the needs of all people at the same time.

The choice of method of heating water and heating, as well as methods of its recirculation through the boiler, must be carried out in accordance with clear calculations of all consumers and the power of the coolant. Among the main schemes, boilers with three-way or servo-actuated valves have an advantage.

Operation and mode of operation

After assembly and performance testing, the recirculation system is put into operation. It works continuously.

Some users, trying to save energy and equipment life, turn off the system at night or during a long absence.

This is a completely effective solution, but you will have to get up early in the morning to start the movement of water and raise its temperature. However, you can spend a little money and install a control unit. It will automatically stop the circulation and restart it according to the set program.

In private

For a private home, continuous circulation operation is recommended. This is especially important if the house uses an independent sewer system.

Discharging excess water will require frequent pumping of the receiving tank, which will require extra costs and add to your worries.

In a multi-story

DHW recirculation in multi-storey buildings works automatically, without the participation of residents. The system is configured in such a way that all controls are located in the basement (in the boiler room) and do not require outside intervention.

All maintenance, repairs and other work are carried out by employees of the management company. This is convenient for apartment residents, as it relieves them of worrying about the condition of the equipment.

Step-by-step strapping in gravity systems

The water heater is installed in networks of this type in such a way that it is located above the radiators. Therefore, for gravity systems, they usually purchase not floor-mounted, but wall-mounted suspended boilers.

The correct installation of water heaters in networks with natural coolant circulation includes the following steps:

- the supply from the boiler is connected to the boiler coil using a pipe of a larger diameter than in the heating system;

- then the heating system supply is cut into this segment between the boiler and the water heater;

- between the boiler and the resulting branch, a thermostatic head with an attached sensor, powered by batteries, is mounted;

- the boiler is connected to the boiler by a return pipe;

- a line for discharging cooled coolant from the radiators is cut into the return pipe;

- An expansion tank is installed closer to the boiler on the return line.

When using this scheme, water is heated due to the difference in the cross-section of the supply pipes of the boiler and the heating system. The water heater in this case is a priority. As soon as the water in the boiler warms up to a certain temperature, the sensor is triggered and the pipeline is closed. As a result, water begins to flow into the heating system.

Electric and diesel heat generators

Connecting a diesel fuel boiler to the radiator system is identical to piping gas-using installations. Reason: a diesel unit operates on a similar principle - an electronically controlled burner heats the heat exchanger with a flame, maintaining the set coolant temperature.

Electric boilers, in which the water is heated by heating elements, an induction core, or through the electrolysis of salts, are also connected directly to the heating. Automation located in an electrical cabinet connected to the network according to the electrical diagram provided is responsible for maintaining temperature and safety. Other connection options are shown in a separate publication on the installation of electric heating boilers.

Wall-mounted mini-boiler rooms equipped with tubular heaters are intended only for closed heating systems. To work with gravity wiring, you will need an electrode or induction unit, which is tied according to the standard scheme:

If you look at it, there is no need for a bypass here - the boiler will not work without electricity either

Wiring a solid fuel boiler with an indirect heating boiler

Connecting a water heater with a solid fuel boiler solves two problems at once:

- obtaining hot water supply;

- obtaining a method for discharging coolant in the event of an accident.

Due to the fact that such a system places a thermostatic valve on the battery, comfort increases. But there is a danger of the boiler overheating. The same threat arises during power outages. If a boiler of increased capacity is installed, this process does not pose any danger. Because excess heat is spent on heating water in the water heating tank. Accordingly, for the normal operation of this system, a boiler with natural ventilation is needed.

See the following video for one of the options for connecting a solid fuel boiler to a boiler.

Problems

Circulation in a water supply system is a process that is quite easy to disrupt. In the next section of the article, we will analyze typical problems that can lead to a stop in circulation and the associated cooling of hot water risers and heated towel rails in an apartment building.

Airlock

- Symptoms: after turning off the hot water, one riser or a group of risers has cooled down. The neighbors' pipes are still heated.

- Reason: air lock in the ring jumper. A pressure drop of 0.2 atmospheres is not enough to force it into bottling.

- Solution: expel air through the vent at the top of the jumper. If this is not possible (for example, due to the absence of residents on the upper floor), you can pass the riser through the basement or water fittings in the apartments.

To do this you need:

- Shut off one of the problematic hot water risers with a tap or valve in the basement;

- If there is a vent on this riser, open it and wait for the air to escape;

The hot water riser is equipped with a vent that allows it to be bypassed from the basement

- If there is not a waste pipe on the riser, but a plug, you can open hot water to capacity on one or two mixers in any apartment located along the same riser;

Air can be expelled from the riser through any mixer connected to it

- After bleeding the air, open the valve or tap at the base of the riser.

Closed valve

- Symptoms: when drawing water, the riser heats up from above due to the hot water supply being inserted into it. It is obvious that water flows to the liner through the ring jumper.

- Reasons: after turning off the riser, the faucet or valve remained completely or partially closed.

- Solution: go down to the basement and open the shut-off valves on yours and the adjacent DHW risers all the way to failure.

With an open ball valve, the handle is always directed parallel to the axis of the body

Valve valve separation

Symptoms: water enters the line through the ring jumper from above. A screw valve is installed at the base of the DHW supply riser in the basement. The arrow on the valve body is directed towards the hot water supply.

The arrow on the screw valve body indicates the only possible direction of water flow

- Causes: valve valve separation from the stem. This happens if you try to open an incorrectly installed shut-off valve of this type, overcoming the water pressure on the valve.

- Solution: replacing the valve with a ball valve (on a steel riser, in this case, you have to change the flow to a longer one), installing a new screw valve in the correct position (with an arrow in the direction of flow).

The riser valve in the photo has been replaced by an assembly with a ball valve

No difference in the heating main

In houses with open heating, the hot water circulation system often stops immediately after the end of the heating season. Symptoms: Cold heated towel rails throughout the house. The reason is that local Heating Networks completely eliminate the difference between the threads of the heating main.

Why is this being done?

The fact is that the heating season begins when the temperature outside is +8 °C or higher for at least five days in a row. Even if after stopping the heating there is a new frost, the heating will not be turned on, since on a city scale, restarting it is associated with colossal costs.

However, residents of a separate house may well, having access to a heating point, turn the heating back on. To do this, you just need to open a couple of so-called house valves (after the water jet elevator) or taps. But in the absence of a difference, this will not lead to the resumption of circulation in the heating system, and, therefore, to unpaid heat consumption.

At the end of the heating season, the DHW circulation may stop for some time.

Unfortunately, there is no reasonable solution for this scenario. All you can do is wait a couple of weeks. As soon as truly spring weather sets in, the circulation-providing difference will return.

How to choose an indirect heating boiler

The main parameter of such a device is its usable volume. The numerical value of this parameter is influenced by many factors:

- the number of residents of the house consuming hot water;

- residents' habits;

- their mode of life, etc.

Based on “such parameters” it is difficult to determine the exact value of the volume. Therefore, when calculating the volume, take approximately 80 liters per resident. The range of volumes for devices of this type is quite wide: from 200 to 1500 liters. However, choosing a heater with a significant reserve volume is unprofitable, since energy costs will increase. And the device itself “increases in price” as its volume increases.

The second important parameter is the coolant flow through the heating circuit (data from the device data sheet). As a percentage, it should not be more than 40% of the total flow through the heating boiler.

You should also pay attention to the material from which the container is made and the quality of its manufacture. Heaters with a stainless steel tank have the greatest longevity and price

An important point may be the ability to dismantle the internal heat exchanger for cleaning.

Thermal insulation should be polyurethane foam or mineral wool.

The name of the heater manufacturer and the “geography” of its production, along with the listed factors, play a significant role in determining the price.

The choice is yours! The modern heating engineering market is saturated with offers of a wide range of parameters.

Selecting a KN boiler

The choice of such a unit as an indirect heating boiler must be approached with all responsibility and, first of all, ask yourself the question: “Will it be convenient to use such a device?” The pros and cons of the unit are described above. In this section, we will note several aspects that you need to know in order to understand whether you need to buy it. They will also help you choose the most suitable KN boiler option.

To what extent will the purchase of such equipment be justified? The fact is that it makes sense to buy such a device if the water flow in the house or room is large enough and is at least 1.5 l/min. For comparison, this is exactly the water consumption observed in large families of 4 or more people.

The presence of such a boiler will certainly increase energy costs if it is connected to an electric boiler.

The volume of the boiler is also an important aspect. So, you need to calculate and take into account the hot water needs for your family. It must be selected taking into account the parameters of the room where it will be installed.

The materials from which the boiler is made also matter. So, those made of stainless steel will allow you to heat the water up to 90 degrees. In enamel, the temperature should be lower. But very heated water can always be diluted with cold water, which means that the efficiency of even a small tank in a boiler that warms up the water very much will be higher

It is also important to choose a boiler that will not rust. The power of the heating boiler itself should also be taken into account.

It should be enough to heat not only the unit, but also the heating system

The power of the heating boiler itself should also be taken into account. It should be enough to heat not only the unit, but also the heating system.

The pump for loading equipment should also be optimal

The operating instructions for the equipment will help you choose which one is suitable - it usually contains all the numbers you need to focus on.

The time for heating water will play a decisive role for many, so this point should also be taken into account. So, on average, it takes about 2 hours to heat 100 liters of water. But some models of tanks heat water faster - for example, a stainless steel tank will heat the same amount of water in 20-30 minutes.

The material for thermal insulation inside the unit can be represented by foam rubber, mineral wool or polyurethane foam. Foam rubber is found in cheaper models.

You can organize a constant uninterrupted supply of hot sanitary water in a private house using an indirect heating boiler

It is also better to buy boilers that have some protection elements - safety valves, thermostats, etc. Don’t be lazy and refuse to fill out the warranty card in the store when purchasing. The boiler is expensive, and it would be a shame to purchase it and find out that the quality of the product is inadequate. And it is difficult to change such equipment without a warranty.

Manufacturing of an indirect heating boiler

The process of assembling a water heater may vary depending on the type of design, but in most cases, equipment for gas and electric boilers is manufactured in the following sequence:

- Two holes are drilled in a pre-prepared cylinder using an electric drill with a crown attachment. One hole will be located in the lower part and used for supplying cold water, the other - in the upper part for discharging hot water.

- The resulting holes are cleaned, fittings and ball valves are installed in them. Then another hole is drilled in the lower part, into which a tap is installed to drain stagnant water.

- To make a coil you will need a copper pipe with a diameter of 10 mm. It is better to make a spiral bend using a pipe bender. If such a tool is not available, then you can take any round piece - a large diameter pipe, a log, a barrel, etc.

- The coil is being manufactured according to the previous calculations. The ends of the heat exchanger are bent in one direction at a distance of 20–30 cm. To mount the coil, two holes are drilled in the bottom of the cylinder. Threaded fittings are installed and welded into them.

- Before installation, the coil is lowered into a bucket or large container with water and blown out. If the structure is sealed, then the coil is lowered into the cylinder, aligned with the inlet and outlet openings and welded.

- If the cylinder was cut in the middle, then an anode is mounted in the upper part. To do this, a hole is drilled into which a threaded nozzle is screwed in, and a magnesium anode is mounted into it. If the container is assembled from three separate parts - bottom, lid and central part, then the anode can be installed at the last stage.

- Thermal insulation material is installed on the outside of the boiler. It is best to use spray polyurethane. Before application, all pipes are protected with thick polyethylene and cloth. If funds are limited, then you can use regular polyurethane foam, which, after hardening, is wrapped in reflective insulation.

- Fastenings for hanging on brackets are welded to the back of the boiler. For floor-standing boilers, support legs made of angle steel or reinforcement are welded to the bottom of the equipment.

At the final stage, fittings and taps are screwed on and the top cover is mounted. If possible, you can not weld the lid, but make clamping fasteners from steel wire with a cross-section of 3 mm.

When making a boiler for use with solid fuel boilers, instead of a copper coil, a U-shaped steel pipe is used, which is mounted at the bottom of the device. From the side of the furnace or boiler, the pipe is connected to the outlet pipe. The pipe is taken out from the boiler and connected directly to the chimney.

Installation process

Installation of a recirculation piping is one of the stages of assembling a hot water supply and heating line. Usually, it is carried out simultaneously with the installation of the boiler, assembly of the heating circuit and other work.

It is recommended that assembly be entrusted to experienced personnel who have the necessary skills and training. However, sometimes home owners assemble the system themselves.

Tools and materials

To assemble the recirculation loop you will need:

- a welding machine of one design or another (depending on the type of water pipes);

- device for cutting pipes (grinder, electric saw, jigsaw);

- a set of plumbing windings, Unipack type thread paste;

- set of fittings, adapters, fasteners.

In addition, you will need tools to install load-bearing elements:

- hammer drill with drills;

- impact electric drill, etc.

Necessary equipment

To install the line you will need the following devices:

- pipes and fittings (different types are used, from copper to metal-plastic);

- circulation pump;

- shut-off valves (valves or ball valves, three-way valves, check valves, etc.).

The circulation pump should be low-power. It is only needed to create a slight pressure to move the flow. Models that are installed in a heating system cannot be used.

The choice of pipelines is dictated by operating conditions and personal preferences of the owner. For example, to install copper (brass) pipes you will need to solder connections, which requires a torch, solder and an experienced craftsman.

You can use compression fittings in combination with polyethylene or metal-plastic pipes. This does not require the use of complex equipment, but is only suitable for DHW systems with low operating pressure.

Algorithm of installation actions

The circulation loop is assembled in stages:

- marking walls or other load-bearing surfaces in accordance with the developed scheme;

- installation of load-bearing elements (brackets, clips, clamps);

- cutting pipes along the length of routing sections;

- serial line connection, connection of fittings and adapters;

- connection of mixing units, circulation pump, shut-off valves;

- connecting the return line to the boiler.

When assembling complex lines, some deviations from the given scheme of work are possible. As a rule, additional elements are added or control devices are connected.

Installation diagram with two pumps

Another common scheme for connecting an indirect heating boiler is using two pumps. In this scheme, two separate, parallel to each other, circuits are configured: heating and the boiler itself - each of them is equipped with its own recirculation pump.

Priority in this system is given to the boiler circuit, so the boiler system pump is mounted in front of the heating pump. A mandatory component of the circuit is a check valve, which prevents the two water flows from mixing and ensures the correct distribution of liquids along the circuits. Also, it cannot do without the already familiar temperature sensor, which sends signals to the valve, thereby controlling the operation of the pumps.

Installation diagram with two pumps

The piping scheme for a boiler device with two pumps is best suited for systems with two separate heating boilers. Each of them must have independent power and provide heating of the liquid in separate circuits: one boiler must be responsible for general heating of the home, and the second for heating boiler water for domestic use. In this case, the circuit functions as follows: when the water in the boiler tank cools to the lower level, the coolant flow is switched to heat it, and after reaching the programmed temperature it returns to the main heating circuit.

This type of piping is valued due to the rapid heating of water: due to the speed of operation of the equipment, when switching heating to the boiler circuit, the coolant in the main heating system will not have time to cool down.

Circulation of hot water in the boiler

A DHW circulation pump is used to move water from the boiler through the pipes and in the opposite direction; it is prohibited to use a pump for the heating system. The pump is constantly connected to the network and consumes little electricity, about one hundred watts per hour.

The operation of the pump has no effect on the speed at which water flows out of the tap. It only ensures its movement from the boiler and back.

In a system with DHW recirculation, a heated towel rail is connected in series to the pipeline circuit. This connection ensures that the heated towel rail is heated even when the heating system in the room is turned off, but the hot water system is turned on.

Certain models of boilers are equipped with an electric heating element. This is very convenient when the gas is turned off or the boiler is undergoing maintenance, since then this boiler is able to function as a storage electric water heater.

The pipeline supplying cold sanitary water to the boiler system must be connected through a safety group, which must be equipped with:

- Shut-off valve.

- Check valve.

- Safety valve.

- The expansion tank of the hot water supply system, and it must have the required volume.

If in summer there is no need to heat the air dryer, then you should disconnect the circulation pump from the electrical network, and also close the ball valve on the circulation pipeline. When installing a hot water supply system, you need to keep in mind that all plumbing fixtures that consume hot water must be connected to the hot water supply branch, while the heated towel rail and circulation pump are mounted on the return pipeline. If the system is not installed in this way, then when using hot water, the heated towel rail and the air in the room where it is located will heat up.

A system with hot water circulation and a boiler is the most convenient and comfortable for users, but at the same time it costs an order of magnitude more than a simple system.

Did you like the material? Give us a thumbs up and subscribe to our feed! Every day we publish new and interesting materials with our original videos!

Design features of an indirect boiler

The indirect type boiler is a tank made of stainless steel. The inner walls of the container are covered with a special material, which not only protects the surface of the water heater from corrosion processes, but also reduces the concentration of harmful bacteria and microorganisms.

Diagram of an indirect type boiler with a single-circuit coil

Otherwise, a boiler of the simplest design consists of the following components:

- heat exchanger - a spiral pipe or smaller tank. Depending on the volume of the tank, it can be located in its upper and lower parts;

- inlet pipe - a fitting at the bottom of the device for supplying a pipe with cold running water;

- outlet pipe - fitting for connecting the hot water outlet pipe;

- magnesium anode - additional protection of the tank walls from corrosion processes;

- internal thermometer - a device for measuring the temperature of heating water;

- thermostat - a device that prevents equipment from overheating;

- control unit - rotary knob with divisions for setting the heating temperature;

- thermal insulation - a layer of insulating material that helps maintain the desired temperature of the heated water;

- outlet - valve for draining stagnant water;

- revision - a large diameter hole intended for maintenance, repair and modernization of the boiler.

The design of new tank models may differ slightly and have a number of modifications from manufacturers, but in general, any indirect type boiler consists of the listed elements.

Operating principle of the boiler

An indirect type boiler is part of the heating system and is connected directly to a gas, electric or solid fuel boiler, which heats the coolant using the energy released when fuel is burned.

The coolant circulates through the DHW system and passes through a heat exchanger located in the indirect heating boiler. Due to the release of thermal energy from the hot coolant, the cold water that fills the device’s tank is heated. From it, heated water is transported through an outlet through a pipe to the bathroom, kitchen and other rooms with plumbing equipment.

An indirect type boiler can work with any type of heating boiler

When the heating boiler is turned off or switched to an economical operating mode, the coolant quickly cools down. Thanks to the design of insulating the tank walls with urethane foam, the water in the tank cools very slowly. This allows you to use the entire volume of warm water for several more hours.

Calculation of the main parameters of the boiler

Before you begin searching for material and directly manufacturing, you will need to calculate the minimum volume of the tank and the working length of the heat exchanger.

Volume and shape of the tank

The volume of the water tank directly depends on the number of residents permanently residing at the place where the equipment is installed. It is believed that a person uses up to 80 liters of water per day. For the calculated value, it is recommended to take 45–50 liters per person. If the norm is exceeded, the water in the tank will stagnate, which will certainly affect its quality.

The shape of the tank is selected taking into account the pressure in the plumbing system. If the pressure is low, then the use of homemade boilers with a square tank is allowed. If the pressure in the system is high, only equipment with a rounded bottom and top can be used.

Boilers with a storage tank of square and rectangular shape can only be used in water supply systems with low operating pressure

The fact is that increased pressure contributes to the occurrence of bending forces on the walls of the tank, so a square or rectangular tank can become deformed. A container with a round bottom is more resistant to deformation due to better streamlining.

Heat exchanger power and length

In vertical indirect heating models, a copper coil is usually used as a heat exchanger, located between the inlet and outlet.

Boiler coil made of copper pipe

For DIY production, it is best to use a copper pipe with a diameter of 10 mm. This product can be easily bent by hand without using any tools. When using a metal-plastic pipe, it should be taken into account that the heating temperature of the coolant should not be more than 90 °C, otherwise the pipe will be deformed and the joints will leak - this will lead to mixing of water in the tank.

The length of the pipe required for the manufacture of the coil is calculated by the formula L = P / (3.14 ∙d ∙∆T), where:

- L—pipe length (m);

- d—pipe cross-section (m);

- ∆Т – temperature difference between heated and cold water (оC);

- P is the power of the heat exchanger for every 10 liters of water (kW).

According to experts, for every 10 liters of water there should be at least 1.5 kW of thermal energy. Taking this into account, you can calculate the length of the pipe for making the coil.

For example, let’s calculate the material for a coil that will be installed in a boiler with a capacity of 200 liters. The temperature of cold water supplied to the container will be 15 oC, and after heating it is necessary to obtain water with a temperature of 80 oC: L = 1.5 ∙20 / (3.14 ∙0.01 ∙65) ≈ 15 m.

Table: length of copper heat exchanger for boilers with a capacity of 50–200 liters

| Storage tank volume, l | Equipment power, kW | Heat exchanger length, m | Boiler tank diameter, m | Coil diameter, m | Number of turns |

| 200 | 30 | 15 | 0,5 | 0,4 | 12 |

| 150 | 22,5 | 11 | 0,5 | 0,4 | 9 |

| 100 | 15 | 7,5 | 0,4 | 0,3 | 8 |

| 50 | 7,5 | 4 | 0,4 | 0,3 | 5 |

The number of turns of the coil depends on the method of bending and the distance between the elements. Typically, the coil is positioned so that the distance between the coils and the walls of the tank is at least 10–12 cm. The distance between the coils should not be less than 5 cm. The calculated values for storage tanks of various volumes can be seen in the table above.

If an indirect type boiler needs to be equipped with a tubular electric heater, then the power is calculated based on the fact that to quickly heat 50 liters of water, a heating element with a power of at least 1.5 kW is required. In addition, any combi boiler must be equipped with a thermostat.

Connecting the boiler to a gas boiler

For the proper functioning of the boiler with a gas boiler, it contains a temperature sensor. For them to work together, a three-way valve is connected. The valve regulates the flow between the main circuit and the DHW circuit.

To a single-room gas boiler

For such a connection, a piping with two pumps is used. It is this that can replace the circuit with a three-way sensor. The main thing is to separate the coolant flows. In this case, it would be more correct to say that the two circuits operate synchronously.

To a double-circuit gas boiler

The main components of this connection scheme will be two magnetic valves. The bottom line is this - the boiler is used as a buffer. Cold water comes from the water supply network. The DHW inlet valve is closed. If you open it, water will first flow from the buffer, which is the boiler. The buffer contains heated water, the consumption of which is regulated by the capacity of the boiler and the set temperature.

All-season operation of heated towel rails.

In order for heated towel rails to be constantly hot, they must be included in the recirculation system. Consistently, one after another. This will not lead to a significant increase in the hydraulic resistance of the route or any noticeable cooling of hot water at consumers. Simplified, it looks like this: Since there are a great variety of heated towel rails, I will not describe how to connect a heated towel rail. I can suggest that while they are not installed, before finishing, you can install jumpers made of pipes instead of them. The connection diagram for heated towel rails shown in the figure allows you not to worry about the accumulation of air in the upper part of them. Air will be expelled through the hot water taps when any of them are opened.

Types and selection of devices

In addition to tanks of a simple design, there are also boilers of a more complex design, which allow you to realize some wonderful functions when integrated into the heating system.

One of the most popular functions is the use of a boiler as a heat accumulator. This is especially important for electric heating with an unstable power supply or when working at daily rates. Devices with heat accumulator mode have a significant capacity (more than 300 liters) and reliable thermal insulation.

Boilers with a recirculation system that provides instant supply of hot water to the mixer are considered more expensive. They have three pipes for connecting to the hot water system: one for supplying cold water and two for flowing hot water. Circulation is carried out by a small built-in pump. Boilers of this type are less economical, but with their help you can organize a small heating circuit, for example, to install a heated towel rail.

Some boilers have a “tank-in-tank” design; the name speaks for itself. The outer tank contains the coolant of the heating system, and the inner tank contains heated tap water. The advantage of this design is that water heats up very quickly, but due to the complexity of the device, such boilers are much more expensive than conventional ones.

Indirect heating boiler “tank in tank”: 1 - cold water inlet; 2 - hot water outlet; 3 - central heating input; 4 — internal tank made of stainless steel; 5 - central heating output

Installation of coil and heating element

Next, we proceed to the manufacture of the coil - we recommend choosing a copper tube, since copper bends easily and resists corrosion well. The recommended tube diameter is 10-20 mm. To calculate the length, we will use a special formula l=P/π*d*Δt, where l is the length of the tube, P is the thermal power of the coil, d is the diameter of the tube in meters, Δt is the temperature difference. Thermal power should be 1.5 kW per 10 liters of water. The temperature difference is calculated by subtracting the supply water temperature from the coolant temperature.

Let's try to calculate using an example in which we have a copper tube with a diameter of 0.01 m and a tank of 100 liters. The required thermal power of the coil is 15 kW, the inlet water temperature is +10 degrees, the coolant temperature is +90 degrees. Using the above formula, we find out that the length of the coil should be approximately 6 meters.

Wrap the copper pipe around the plastic pipe. The rate of heating of the water in the tank will depend on the number of turns of the resulting spiral.

To make a coil, we wind a copper tube on some base, for example, on a plastic sewer pipe. Winding with force is not necessary, otherwise removing the coil from the base will be problematic. Finally, we solder fittings to the coil - with their help we connect to the fittings inside the tank. At this point, the work with the coil is completed, and all we have to do is install a heating element at the bottom of our homemade boiler, cutting it in in a convenient way.

Combined indirect heating water heaters are designed in such a way that the heating elements are located in the lower part, from where the heated water can rise upward, gradually mixing. As for the coil, it is advisable to unfold it a little and install it so that the water is heated throughout the entire volume - this will ensure faster heating.

Types of systems

Those users who use geysers and various types of boilers to obtain hot water are very familiar with a lot of problems that arise during their operation: you need to wait some time until the water heats up to the desired temperature, if you turn on hot water in the kitchen and bathroom at the same time, then her temperature will drop. An indirect boiler eliminates these problems: the water coming from it always has a constant temperature, no matter where it is supplied. Such water heaters can be of several types.

- The most common is the design with a coil, which is installed inside the tank and hot water circulates through it. Cold water entering the container comes into contact with the coil and heats up to the set temperature.

- Another option is when the coil is mounted along the walls of the container, and not in its center.

- If there are two containers - large and small, then the smaller one is inserted into the larger one. Water circulates between them: hot water is pumped into the small one, and cold water is pumped around it for heating.

The operating principle of such water heaters is simple; in order to clearly understand the operation of the system, there is a detailed diagram.