Double-circuit wall-mounted boilers "Baksi" - gas equipment for individual heating from an Italian company. They are compact, convenient and reliable. However, malfunctions also occur in the operation of the Baksi boiler, and it is worth finding out about their elimination in advance.

Boilers from this manufacturer have many advantages. The main advantage is cost-effectiveness. Their service life is quite long, and during operation they make virtually no noise. Using this heating device, one can also note its high performance and ease of operation. In addition, Baksi boilers are sold at affordable prices, and representatives of all segments of the population can afford them.

Baxi boiler installation instructions

Like any device, a gas boiler requires study before installation. Before installing the boiler yourself or with the help of a specialist, you should study the instructions. The boiler should be prepared for the first start-up. An experienced specialist should work at this stage, since the boiler is connected directly to gas.

At the stage of preparing the boiler for the first start-up, an experienced specialist should work

What to do

- Check that the parameters of the boiler and the parameters of the systems located in your room correspond to each other.

- Then you can connect the device.

Where is the most reliable automation for heating boilers sold? Look here.

Another interesting function is called “shower”. When used, the boiler generates hot sanitary water, which creates even greater comfort and coziness.

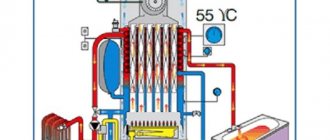

Construction of a Baxi floor-standing gas boiler

If necessary, the Baxi gas boiler can be converted from natural gas to liquefied gas. Under no circumstances do this yourself; use the services of qualified specialists.

MORA boiler and EFD-503 control units

Case from practice. Several EFD-503 units came in for repair. Such blocks are installed directly on the gas fittings and are used in boilers MORA, BERETTA, PROTHERM and others. So, specifically in this modification of the block, the error reset occurs through the closure of two contacts on the block itself, and the switching is displayed on the control panel with a button. The client says I change the blocks regularly once a year. Tired of replacing it (the price of 1 unit is approximately 10 thousand, and there are two of them in the boiler), he turned to us for repairs. In fact, faults were identified and corrected on the units provided - the units were sent back. Installation result: 1 unit works, two worked for 20 seconds, went into error and no longer work.

baxi boiler error codes

Baxi boiler error codes are known to almost all users. There are four most common: E 01, E 03, E 25, E 26 and E 35.

Gas boiler baksi and errors, unfortunately, are similar definitions to each other, but this does not mean that baksi are bad. The electronic boiler system is locked when these symbols appear on the screen.

Error E 01

Consider the baxi boiler, error e01.

This malfunction means the ignition is not working properly. It is because of this that the Baxi boiler error E 01 appears on the display. Most often it occurs when starting the boiler for the first time. Read the installation instructions carefully again, perhaps some error has occurred. Below we will name several possible reasons for the failure:

- Gas valve is not open

- The zero and phase are incorrectly observed at the stage of connecting the electric current.

- No spark or ignition electrode interference. This moment is visible to the naked eye during the pulse.

- Damage to the automated panel.

Check carefully to see if you have one of the listed errors. You can fix each of them yourself. If not, you need to seek advice from a specialist or company representative.

A more radical way is to do a hard reboot using the “reset” button.

Common error e03 on a baxi boiler

Let's now look at the baxi boiler: error e03.

This error may appear after a long time, when you are already actively using the boiler. For some users, it appears on the electronic monitor and disappears by itself. What is recommended to fix this error:

- Clean the blades thoroughly; there may be a lot of dust collected on them.

- The grease of the radiator bushing and axle on the rear of the engine has worn out. In this regard, the fan begins to spin slowly.

How much does a stainless steel pipe cost, price from the manufacturer. See here.

Branded thermostat for oventrop heating radiator. More information about the manufacturer at the link: https://prootoplenie.com/otopitelnoe-oborudovanie/batarei-radiatory/termoregulyatory.html

If nothing helps after cleaning, you need to contact a specialist.

Baxi boiler error e35 - problem with the flame control sensor.

E 35 is connected to a flame control sensor; it serves to signal the presence of fire even before the valve opens. The reasons why it may not work are varied, but the most likely of them are:

- Water or condensate gets on the electronic board located in the boiler.

- Parasitic flame. This is the name of the undying flame after the boiler is turned off. The manufacturer attributes this to insufficient tightness of the gas valve.

However, most often, error E 35 corrects itself after rebooting the boiler.

Error E 25

According to the manufacturer, this malfunction indicates that the maximum temperature has been exceeded. Here you should pay attention to the heating circuit temperature sensor. But first check the following:

- Pump. If error E 25 occurs, it may be blocked.

- It is likely that the heating system is completely or partially aired.

- The filters in the heating system itself are clogged and, as a result, there is insufficient coolant circulation.

- The heating temperature sensor in the device is broken.

The error does not clear

Sometimes users and specialists who carry out diagnostics cannot reset the error and conclude that the control unit is faulty. The main reasons why the error may not be reset:

the error cannot be reset until the fault has been eliminated (for example, lack of pressure in the boiler)

poor contact between the reset button and the control board (often seen on Vaillant TEC boilers)

the reset order is broken (in some cases you need to hold Reset for a certain time)

A malfunction of the information board (display board) is rare, but possible.

At the same time, when the user’s board is changed, everything works because there is no error on it. Everything will work until the next error appears, and if the reason is not figured out, they will replace a working board every time.

From practice, we often received serviceable units for repair that simply had not cleared the error. It is often impossible to convince (especially specialists) that there is a possibility of a problem with the error reset. “We know everything, we can do everything, 20 years of experience - we checked everything, the error does not reset - the control board is faulty!”

The main advantages of Baksi boilers

- Size: the boilers are so compact that they fit into any room;

- Savings: unlike other boilers, they save up to 35% of gas while remaining very efficient;

- Modulation: the boiler itself determines when it can save, thereby automatically reducing energy consumption;

- Boilers can be installed in cascade;

- Silent;

- Possibility of smoke exit through the wall, without installing a special chimney;

- Environmental friendliness: air emissions are significantly reduced.

- The weight of the boiler is 98 kilograms, and the dimensions are 950/600/650. The dimensions of Baksi are almost 4 times smaller than those of the same boilers from other manufacturers.

Incorrect connections are often encountered, which leads to errors in Baxi boilers

Baxi has a fairly wide range of boiler models to suit the different needs and capacities of your premises. After installation, even a child can use this boiler. The electronic panel is simple and accessible without studying the instructions.

The main reasons for the failure of Baxi heating equipment:

Twenty years ago, a boiler was considered a simple device whose main purpose was to generate heat. Today, the requirements for heating equipment have changed dramatically. Now the boiler unit must be able to maintain a comfortable temperature automatically, prepare hot water in the required quantity, be energy efficient, environmentally friendly and safe. Baksi gas boilers not only meet all modern conditions, but also, in some respects, exceed them. For example, boiler units of the Baxi Luna–3

,

NUVOLA

,

ECO

have a built-in self-diagnosis system and many integrated safety devices and sensors that ensure maximum reliable and safe operation. And yet, during the operation of the boiler, it becomes less productive, and its reliability decreases.

This happens due to the influence of 4 main factors:

- natural gradual wear of parts;

- contamination of surfaces with salt deposits and carbon deposits;

- features of the operation of heating equipment in our country - our heating season lasts longer, so the load on the equipment is higher;

- low quality engineering systems.

Noticing and eliminating all problems as early as possible means saving yourself from breakdown of boiler equipment and expensive repairs of the baxi boiler. During regular service inspections, our engineers not only carry out all the measures prescribed by the manufacturer, but are also ready to eliminate all shortcomings and errors made during installation of equipment by third parties and carry out a complete modernization of the heating system.

Certified service is the key to efficient operation of equipment for many years:

Many years of experience of specialists from the authorized E-Tech service center have shown that it is the non-compliance of operating conditions with established standards, as well as the requirements of equipment manufacturers, that is the most common cause of failure of even the most advanced equipment. For example, according to statistics, one of the most common causes of breakdowns of Baxi Main

is poorly prepared water and low-quality fuel;

Baxi AMPTEC

- power surges that disable automation. Baksi specialists tried to neutralize some of the negative factors in advance by equipping all models of boiler units with a reliable safety control system and adapting them to work in Russian conditions. However, identifying most defects in the boiler piping and their neutralization falls on the shoulders of specialists providing service.

Our engineers are ready to undertake the entire range of servicing of the heating system based on the Baxi boiler. Before starting direct maintenance work (cleaning work surfaces, replacing spare parts for baxi boilers, etc.), E-Tech center specialists will conduct comprehensive diagnostics and determine the entire range of factors that negatively affect the operation of heating equipment. During the service, the automation will be calibrated, allowing you to set the most effective operating mode. After carrying out the maintenance, our specialists will draw up a Certificate of Completion of Work, which will indicate faults that require separate repairs, and will also record recommendations for operating the boiler. Modern technical support and our own spare parts warehouses allow us to carry out work of any complexity and level of responsibility in a short time and with maximum efficiency.

Today, a gas autonomous heating system is quite popular; it is used not only by owners of country houses, but also of apartments located in multi-storey buildings. This can be explained by the positive qualities of modern devices, ease of installation and operation, which is confirmed by many reviews from experienced specialists and consumers.

Analysis of errors and malfunctions of Baxi gas boilers

Almost any buyer of Baxi wall-mounted gas boilers, sooner or later, encounters some malfunctions and breakdowns of the device. Experts strongly recommend carrying out gas boiler maintenance at least once a year: flushing the heat exchangers, cleaning off accumulated scale, checking the functionality of the sensors before the start of the heating season.

However, modern heating equipment tends to break down over time, which will require repair or replacement of spare parts. Let's consider one of the most popular brands in Russia - this is the Baxi gas boiler, its malfunctions and errors are displayed on the control panel under special codes under the symbol "E", which is an abbreviation for the English word "Error" - error.

Let's consider the main malfunctions that a user of a Baxi gas boiler may encounter when there is no hot water and why the boiler does not heat the water, the pressure drops, the burner of the Baxi Main Four 240F or Baxi Eco Four 24F and other models does not turn on or ignite.

We will analyze all the errors of the device according to the instructions, the reasons for their occurrence and methods for eliminating the problems that arise on our own or by specialists.

Display of the Baksi gas boiler

Italian wall-mounted double-circuit and single-circuit gas boilers are equipped with an informative digital display, which displays not only information (symbol “A”): the temperature of the water in the heating system or in the DHW circuit, or setting parameters (symbol “F”): operating modes and warnings, but also errors under codes “E”.

If the “R” symbol appears on the display, this means that a malfunction has occurred and you can try to fix this problem yourself. To do this, press the “R” button and hold it for several seconds. If this does not help, then it is better to immediately call a specialist gas specialist to your home.

However, let's take a closer look at the error codes that we may encounter when operating the Baxi boiler.

Error E01.

This is one of the most common errors that occur when operating Baksi brand gas boilers. It signals that there is no ignition in the device, as a result of which the boiler does not turn on.

Baxi Error E01

2. The flame electrode or the wire leading to the ignition unit may be faulty.

3. Gas valve or electronic board is faulty. Check all connections between them.

Error E02.

Another common error under the symbol “E02” indicates to us that the safety thermostat of the Baxi boiler has tripped. Usually this error is displayed when the boiler does not heat the water in the heating system well.

1. Check whether the pump impeller is blocked when there is no coolant circulation.

2. The main heat exchanger may be clogged and requires cleaning.

3. It is also necessary to check the limit thermostat connector and the NTS temperature sensor of the heating system at the boiler inlet.

4. A faulty electronic board may also be the cause of error E02.

Error E03.

This error indicates that parameter F43 was incorrectly set when setting up the boiler, which leads to an error in the configuration of the electronic board. To change settings, press and hold two buttons simultaneously for at least 6 seconds:

This malfunction can occur in two cases:

— no ignition; — the flame broke out.

1. It is necessary to check the integrity of the connections between the ignition unit and the flame sensor, as well as between the board and the gas valve.

Malfunctions and causes of their occurrence

The good thing about boilers is that if problems arise, you can handle the repairs yourself, without having to call in specially trained people. True, it is acceptable to do this only if the malfunction is typical and can be eliminated according to the diagram. For those who have never had the opportunity to repair gas equipment, it is better not to repair Baksi boilers with your own hands, but to call a specialist. Typical unit malfunctions include the following:

- the burner does not light or constantly goes out;

- ignition does not work;

- there is a knocking sound in the combustion chamber when the boiler is operating;

- exceeding the permissible temperature inside the device;

- the maximum water temperature becomes lower;

- the occurrence of loud noise during operation;

- failure of temperature or pressure sensors.

The reasons for the malfunction of the Baksi boiler may be as follows:

- water getting inside the boiler;

- insufficient quality of the coolant used;

- weakening or sudden change in gas pressure;

- power surge in the network;

- initial inaccuracies in equipment installation.

Decoding

The factory interpretation of error E25—reduced coolant circulation—does not provide a complete understanding of the essence of the problem. In the instructions for various models of the Baxi boiler, the emphasis is on blocking the pump. But this is not the only reason such a fault code appears on the display.

p, blockquote 2,0,0,0,0 —>

Error e25 indicates an intense increase in temperature in the heating circuit. This parameter in Baksi units is determined by the difference in readings from sensors installed at the inlet and outlet of the boiler heat exchanger. When it grows at a speed above 1 0 C/sec, the operation of the unit is blocked by the protection circuit. A decrease in fluid circulation is caused by several factors, therefore there is no clear recommendation for eliminating error E25. The algorithm of actions given in the article will allow you to figure out the reason for the appearance of this fault code in a short period of time.

p, blockquote 3,0,0,0,0 —>

The meaning of error E01

Code e01 is one of the most problematic. Indicates the absence of a burner flame, although in fact there may be one, but of low intensity. In any case, the ionization sensor does not detect it - the control board gives a command to block Baksi - the boiler stops due to an emergency signal. Therefore, the cause of error e01 must be sought in external factors or elements of ignition and flame control.

p, blockquote 5,0,0,0,0 —>

* The recommended algorithm of actions described below, based on the principle from simple to complex, is identical for all Baksi gas boilers, regardless of modification.

Method for finding the cause of error E01

Step 1 - testing the gas line

With an autonomous gas supply, the gearbox may freeze or break down. There is no need for a specialist here - problems are solved independently.

p, blockquote 7,0,0,0,0 —>

The user can determine the pressure level from the same plate. It is necessary to light all the burners without exception and evaluate the intensity of the flames and their stability. Perhaps the gas holder or cylinder group has reached its limit on the supply of “blue fuel”. Alternatively, the main filter is excessively dirty. Often, its banal cleaning eliminates the E01 Baxi error.

p, blockquote 8,0,0,0,0 —>

Step 2 - troubleshooting the boiler

In practice, some “craftsmen”, on the advice of so-called experts bend the electrode to increase the intensity of the spark. This is absolutely not allowed! The size of the gap is indicated in the documentation for the Baxi boiler; you just need to find the corresponding section in the instructions and bring everything back to normal. But it is not the electrode pin that should be bent (it is fragile), but its fastening element.

In fact, this is all that the user can do to restore the functionality of the Baksi boiler when error E01 appears on the display. It is also caused by other malfunctions: in the diode bridge, ignition unit, gas fittings (valve), electronic board elements (capacitors, relays). But testing such boiler components and eliminating problems is the job of a professional. At home, the control module is not checked or repaired: only in a specialized workshop.

p, blockquote 10,0,0,0,0 —>

On a note!

The new Baksi board costs between 8,300 and 10,100 rubles (depending on the boiler series). Its diagnosis and restoration at a service center costs approximately 3,400 – 3,800 rubles. for 2018

Design and operating principle

The best option for apartments is a wall-mounted double-circuit boiler. Such models are produced in several series, differing in power, smoke removal system and type of gas burner. For apartments, it is recommended to choose a device with forced exhaust. Calculating the power is simple - divide the square footage of the living space by 10. You will get the required boiler power in kW.

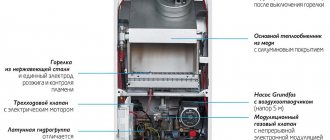

Small boilers of the Main series with a bithermic heat exchanger, to the tubes of which copper plates are spot welded. This increases efficiency. The design includes an expansion tank and a circulation pump. Filtration of incoming water is provided. The heat exchanger is installed on top of the firebox.

The combustion chambers of Baksi boilers are made of metal and covered on the outside with a heat insulator.

The system operates in the same way as all gas boilers. The signal from the thermostat goes to the pump, which creates a vacuum in the return. Water under low pressure (less than 0.45 bar) enters the heating system. Ignition occurs automatically.

The output power increases smoothly with increasing temperature. When it reaches the set value, the operating mode will switch from heating to modulation. When the temperature drops, the thermostat will command the inlet valve to open and the water will be heated again.

If the burner shuts down due to excess power immediately after startup, then restarting is allowed after three minutes.

Baksi device

Hot water supply works like this. Water is supplied through a three-way valve that shuts off the heating main and enters the secondary circuit. There it is heated and supplied to the taps for personal use.

But no matter how problem-free the Baksi is, it also sometimes breaks down.

Troubleshooting

If the flame is not powerful due to incorrect operation of the gas valve, the pressure in the system must be adjusted. This must be done in accordance with the requirements of the instructions. The diode bridge often fails. Then what is required is not repair, but complete replacement.

"Baksi" fee

If the coolant is not heating well, check the pressure at the outlet of the gas valve. Change the position of the regulator and try to start the boiler again. That's all the repairs.

If there are deviations in the sensor readings, they need to be changed.

When the temperature in the DHW is unsatisfactory, check the functionality of the three-way valve. Wait until the water has cooled completely, then close the heating taps, and then turn the heater back on to hot water supply mode. If the heating starts heating up, the valve is faulty. It needs to be replaced.

When strong pops are heard at the moment of ignition, the reasons for what is happening are as follows:

- Gas supply pressure too low.

- Increased distance from the nozzle to the igniter (due to improper transportation).

In such cases, the gap needs to be adjusted. It should be within 4-5 mm. Open the front panel, unscrew the screw securing the electrode, remove the electrode, bend it a little and put it in place.

Baxi Slim 2.230i - 2.300i.

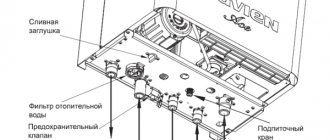

12. Bleeding air and unblocking pumps

12.1. BLEEDING AIR

Before turning on the boiler the first time , it is necessary to loosen the plug on the automatic air vent. To automatically remove air from the heating system , the plug must always be left slightly unscrewed . _ _ _ _ _ _ _

When filling the system for the first time, it is necessary to remove any air pockets that may have formed in the system. To perform this operation, proceed as follows: · Close the gas valve. · Open the front panel of the boiler. · Set the mode switch (position 1, Fig. 1) to the “winter” position. · Set the DHW water temperature regulator (position 3, Fig. 1) to the maximum value, and the heating circuit water regulator to the minimum value (position 2, Fig. 1) (with this position of the regulators, only the boiler circulation pump works) and wait until it locks boiler (the boiler block indicator lights up due to unsuccessful ignition (8)). · With the system circulation pump running, loosen the plug covering the pump shaft to allow air to escape and open the manual air vent located under the DHW circuit pump. · Alternately set the heating circuit water temperature regulator to the maximum value, and the DHW water temperature regulator to the minimum value (with this position of the regulators, only the boiler circulation pump works). · With the boiler circulation pump running, loosen the plug covering the pump axis. · Re-tighten the pump plug.

If necessary, repeat the above operations several times. It is recommended to collect water flowing out of the boiler during these operations.

12.2. UNLOCKING PUMPS The boiler has a pump blocking protection function. If the user does not use the boiler for 24 hours, the pump is automatically turned on for one minute. This function works if the power supply is connected to the boiler and the mode switch (position 1, Fig. 1) is not set to position (0). However, if after the boiler is idle or when turning it on for the first time, you need to unlock the pump, just remove the plug covering the pump axis, insert a screwdriver and turn the pump rotor several times to unlock and put the pump into operating mode.

13. Adjustments on the main electronic board

“ OFF” position switches means: T.RISC range of regulation of water temperature in the heating circuit 30-85°C GPL boiler operating mode on methane gas T-OFF minimum time between two boiler starts in the heating circuit is 3 minutes. POMPA pump post-circulation time in heating mode is 3 minutes from the moment the room thermostat is turned on D. POMPA switch must always be set to ON position

“ON” position switches means: T.RISC range of regulation of water temperature in the heating circuit 30-45°C GPL operating mode of the boiler on liquefied gas T-OFF minimum time between two turns on of the boiler in the heating circuit is 10 seconds POMRA pump post-circulation time in heating mode equals 4 hours from the moment the room thermostat is turned on

Note: the above-described switching must be done with the device disconnected from the supply .

Source of the article: https://otopleniye-sam.ru/12.194_razblok_nasos_baxi_slim_2.230.php

Maintenance and cleaning

If the system is heavily clogged, the temperature drops and the efficiency of the boiler sharply decreases, which leads to a deterioration in the microclimate in the house and excessive gas consumption. To extend the life of a Baxi Main boiler or another model, as well as to maintain high efficiency, it is necessary to periodically clean the heat exchanger using a special device and cleaning fluid.

Video: flushing the Baxi Main boiler

Repair and maintenance of boilers when error codes e01, e03, e10 appear can be done with your own hands. More complex faults that involve complex adjustments or replacement of elements require calling a gas equipment specialist. In addition, it is better to contact a service center if the boiler is under warranty, since independent repairs will void it.

Main components and principle of operation

The Baxi line of gas boilers includes a number of models that differ in volume, type of installation, and functionality. However, the principle of their operation is generally similar.

The most popular boiler models:

- Baxi Luna (Baxi Luna);

- Baxi Slim (Baxi Slim);

- Baxi Main four (Baxi Main for);

- Baxi Main 24 fi (Baxi Main 24 fi);

- Baxi Nuvola (Baxi Nuvola);

- Baxi EKO four (Baxi Eco for, Baxi Ecofor).

According to the type of installation, gas boilers are divided into wall-mounted and floor-mounted.

The wall heater is fixed using special brackets in any convenient place, which makes wall-mounted models very popular. Chambers with a closed combustion chamber, for example, Baxi Main 24 fi, have increased efficiency and environmental friendliness in a small size.

The volume of coolant in the heat exchanger depends on the model, in the most powerful it reaches 80 liters. In terms of functionality, models can be single-circuit - for heating, or double-circuit - in addition to the heating system, they also supply the hot water circuit.

They can operate both on natural main gas and on liquefied gas from cylinders, making it possible to install them in non-gasified areas. The boilers are completely volatile and require connection to an alternating voltage network.

Operating principle of gas heating equipment:

- Sensors analyze the temperature in the room, and when the minimum value is reached, they send a signal to turn on the circulation pump.

- The pump turns on, creating a vacuum in the return pipe, and the heated water enters the heating system.

- The microprocessor sends a signal to ignite the burner at low power, it gradually increases, and the coolant is heated to a temperature specified by the user.

- Then the boiler operates in modulation mode - it maintains the temperature within the specified limits, turning on when it drops.

At any of these stages, a malfunction may occur, which the boiler notifies using coded errors.

Possible malfunctions of the Baxi Main for, Baxi Main 24 fi, Baxi Eco for boiler:

- the burner goes out immediately after switching on or during the heating process (error codes e01, e04);

- ignition of the boiler is impossible;

- overheating occurs (error code e02);

- The water pressure in the system drops (error code e10);

- extraneous noise is heard during operation;

- there is popping noise in the combustion chamber;

- the coolant does not heat up to the set temperature;

- One of the sensors fails (different error codes may appear).

The most common causes of certain malfunctions, according to service center specialists, may be:

- improper installation of the heating system;

- errors when connecting the boiler to the electrical network;

- water getting into the circuit board, burner or electrical part of the boiler;

- low quality of network water or other coolant;

- sudden drop in gas pressure;

- The network voltage drops or increases unacceptably.

The resulting malfunctions can be easily eliminated by adjusting the boiler, but sometimes it is necessary to call a specialist to replace boiler parts.

If you are not confident in your skills in setting up gas equipment, it is better to contact a service center. Incorrectly performed repairs can lead to complete failure of the boiler!

Positive Features

Malfunctions of the Baksi boiler, of course, sometimes occur, but it still has more positive features - automated operation, environmental friendliness, reasonable cost, ease of operation, and maximum adaptability to difficult conditions. The last feature is relevant for Russia.

Because the equipment is automated, it can operate for a long time according to a specific program. This is convenient for country cottages in which the owners do not live permanently, but from time to time. When such boilers operate, carbon dioxide is released into the air, which is absorbed by plants. This indicates the environmental friendliness of such devices. The manufacturer has made sure that the buyer repairs Baxi boilers as rarely as possible. The main faults and solutions are described below.

During the manufacturing process, equipment is equipped with protective chips that are capable of leveling out voltage fluctuations in the network.