Are you thinking about improving your autonomous hot water system to ensure a stable hot water temperature? Agree, there is little pleasure in flushing liters of water while waiting for hot water, or getting burned when someone in the household turns on the tap while you are in the shower.

We will help you solve the problem of temperature changes, which plagues almost all users of double-circuit boilers and geysers. We'll tell you how to connect a boiler to a gas boiler. This solution will ensure the supply of hot water at a constant temperature, and the recirculation system will eliminate the need to flush the first portion down the drain.

Next, we will tell you how to implement this correctly and what connection schemes exist, highlighting their main advantages and disadvantages.

Why connect the boiler to the boiler?

Instantaneous gas water heaters - boilers and water heaters - are very economical and efficient. They instantly heat exactly the volume of water that is needed, and exactly when it is needed, without wasting energy on maintaining heat. Such efficiency and cost-effectiveness have made such equipment very popular.

However, they also have disadvantages that significantly reduce comfort during use. Considering that you pay utility bills once a month and use hot water every day, these flaws noticeably spoil the overall impression.

When several taps are opened simultaneously, the temperature of the water heated by the heater changes sharply - you can unplannedly take a contrast shower or get burned

If you live alone, you may not notice this, but in a large family this feature will cause a lot of unpleasant moments.

For any user, an unpleasant feature will be the inability to set up a thin stream of warm water - heating simply will not turn on if the pressure is too low. As a result, you will have to open the tap harder, consuming excess water and filling the sewer.

In addition, an inexpensive low-power double-circuit boiler can handle heating a small house, but it will not be able to provide hot water with high pressure. You will either have to put up with the coolness of a large jet and weak pressure of hot water, or purchase a more expensive model that will handle the water supply well, but will work for heating at a small fraction of its capabilities.

High-performance boilers, on the contrary, have problems at low pressure: their heat exchanger manages to bring a thin stream of water to a boil, and to avoid this, the boiler begins to cycle. This means that it alternates between very short periods of operation and inactivity, constantly switching on and off. As a result, the temperature of the water from the tap fluctuates significantly, and the boiler quickly exhausts its service life and consumes more gas for constant ignition.

The cheapest double-circuit boiler is capable of efficiently heating an area of about 80 square meters, but if there are more than 1 - 2 people living, the hot water pressure may be low

All these, as well as some disadvantages of a hot water supply system through a flow-through gas water heater, can be leveled out by including a boiler in such a system as a storage tank. It will always have a supply of water, uniformly heated to the desired temperature, while practically no electricity will be used to heat it.

Benefits of combining systems

Including an electric boiler in a gasified hot water system provides a number of advantages and new opportunities:

- Supply of water at a constant temperature, regardless of the number of taps open at the same time.

- Temperature stability, regardless of the pressure - even drop by drop, even with a powerful jet, the water will be hot enough, but not boiling water.

- Optimization of the system, reduction of gas, water, and sewage consumption.

- The possibility of installing a double-circuit boiler of lower power and cost - one that is enough to heat a home.

- Saving boiler life if the system is properly constructed.

- The ability to provide both heating and domestic hot water through a single-circuit gas boiler with minimal energy consumption.

- In the summer, you can turn off the gas boiler and heat the water with an electric heating element of the boiler, preserving the life of expensive equipment.

- The presence of two water heaters eliminates the inconvenience during the repair or annual maintenance of one of them.

Such a number of positive aspects will convince almost every user, because connecting a boiler to an instantaneous gas water heater solves almost all of its problems while maintaining its advantages.

Instantaneous gas water heaters are not only more economical, but also much more compact than boilers, because there is no need to store heated water

However, including a boiler in the DHW circuit also creates some difficulties - we’ll talk about them later.

Complexities and disadvantages of the solution

Firstly, the number of connections, taps and additional equipment increases, which will not add reliability to the system. Every screwed thread or tap is a potential leak that needs regular inspection and monitoring. In addition, installing an additional faucet, valve, pump and meter of pipe increases the total cost of the estimate.

Secondly, the boiler itself requires annual maintenance, and in some versions of the system it wears out much more actively than during normal operation. At the same time, no one canceled the annual heating boiler service.

Thirdly, such an advantage of gas systems as compactness is lost: in conjunction with a boiler, even a small double-circuit boiler, connected correctly, will require a lot of space.

In addition, the services of another specialist will be required who will correctly wire the equipment and install the heating and plumbing.

Important Buyer Tips

The experience of specialists involved in the development of heating systems powered by natural gas and conducting tests, including in our climatic conditions, will allow you to make the right choice. Just follow the tips below:

- When purchasing a small-sized boiler, be sure to look at the lower power value. If it slightly exceeds the calculated value, then it is worth purchasing a thermostat in addition. It will save money on equipment operation in the long term, and will also significantly increase the service life by reducing the number of equipment starts.

- The heat exchanger is known to suffer from one serious ailment, the deposition of salts and lime. To avoid this, in conditions of “hard” water, you should take equipment with bithermic heat exchangers. If the water undergoes pre-treatment, the so-called “softening”, then it is better that the heat exchanger is separate; in the first case you will reduce the formation of lime, and in the second you will save money.

- In the case of spruce, the house area is large, and the consumption of hot water is also high due to the large number of points of its consumption, it would be more advisable to purchase such a wonderful thing as a boiler. In some double-circuit boilers it is already present, but if not, then it must be added. The boiler will allow you to increase the consumption of hot water several times, so you will not experience a shortage of it.

Information!

It is important to remember that gas boilers are mostly designed to work with a central gas pipeline, but if there is no such thing, and it is necessary for the equipment to operate on liquefied gas, then be sure to notify the seller during setup and installation, use only the services of a qualified specialist, not expose yourself and your loved ones to unnecessary risk

Also, if there is a need to connect such things as heated floors, ventilation and other third-party circuits to the boiler, it is important to entrust the calculations and selection of components to a specialist. When purchasing a boiler, you should take care of purchasing and installing an automated control system in your home. Automatic controls will not only more than pay for themselves in the long run, but will also significantly reduce the cost of heating premises

They work on the principle of adjusting and regulating the boiler power during daily operation. By purchasing an automated control system once, you can save about 20% on fuel, which will definitely affect your wallet.

The issue of heating a living space and providing hot water requires maximum responsibility and care. It is necessary to buy a wall-mounted gas double-circuit boiler with a boiler in specialized stores and centers with mandatory preliminary consultation. Otherwise, inattention and frivolity can lead to accidents and disastrous consequences. Only qualified specialists and consultants can guarantee the correct operation of such delicate equipment throughout its entire service life.

Options for interaction between boiler and boiler

Connecting an electric boiler to a gas heating boiler is a very non-standard solution, caused mainly by the desire to reduce the cost of installing the system.

The main option for improving the quality of hot water supply from the boiler is to connect an indirect heating boiler, with a heating pipe coil inside or layer-by-layer heating

Such a system does not use electricity at all to heat water, but it is expensive to install and does not make it possible to save hot water by turning off the boiler. Therefore, skilled craftsmen have learned to use ordinary electric boilers, which are essentially a huge thermos with a built-in boiler and thermostat.

Scheme #1 - through a three-way valve

This option of connecting a gas boiler and boiler through a three-way valve is perhaps the simplest, most obvious and common. It allows you to organize hot water supply even from a single-circuit gas boiler, saving on electricity.

The essence of the method is that an installed tee valve with a thermostat redirects the flow of hot water either to the DHW circuit or to the heating circuit. It is controlled by the automatic boiler: as soon as the water in the tank reaches the set temperature, the valve turns off the supply of hot water to it. At the same time, the boiler is almost constantly working for heating, and during the short period that the water in the boiler is being replaced, the batteries do not have time to cool down.

However, if you have a large family or a huge Jacuzzi bathtub, you will need a high-power boiler to run the system efficiently. Otherwise, after using a large volume of water, the house will become noticeably cooler, and hot water will begin to flow into the radiators only after the boiler has been filled. Thus, water supply is a priority in such a scheme.

When connecting the boiler thermostat as a servo drive for a three-way valve, set the temperature on it at least 10 degrees lower than what the boiler produces

Also, a bypass can be organized through a three-way valve, then under given conditions it will direct the flow of hot water back to the boiler instead of radiators and other elements of the heating system. This will add security and ease of maintenance to the system.

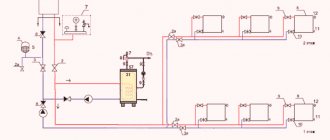

Scheme #2 - through two independent pumps

Next, we’ll look at how to independently connect a boiler to a double-circuit gas boiler using a circuit with two circulation pumps. This system is the most difficult to install, but is also quite convenient to use. Thanks to the constant circulation of water in both circuits, hot water will flow from the tap immediately, it will not need to be flushed, and the heating also works constantly, regardless of the use of hot water.

One pump is required to move water through the heating circuit. In this case, the system is closed, special additives can be added to the liquid to extend the service life of the equipment - it will not enter the water supply. Almost all double-circuit boilers are equipped with automation, and this pump is built into them. If your boiler does not have it, or you use a separate single-circuit boiler and a gas water heater, installing such a pump is necessary for high-quality heating.

The second pump provides recirculation in the hot water supply system. It is installed after all water intake points, and after it the water, slightly cooled after passing through the pipeline, returns to the boiler to repeat its path until someone opens the tap.

In indirect heating boilers, a separate input is provided for connecting recirculation, but in electric tanks such an input is very rare

The recirculation supply is connected through a three-way valve at the inlet to the boiler, where the cold water supply is usually connected, and in the case of a connection with the boiler, already heated water.

Scheme #3 - through a hydraulic arrow

A hydraulic distributor is necessary to equalize the speed and pressure of water in different circuits so that the boiler and pumps can operate smoothly. Essentially, it is a reservoir with two or more inlets and outlets through which the streams can either pass in parallel, independently if their pressure is the same, or mix until balance is established.

Instead of a ready-made, factory-made hydraulic switch, sometimes at the boiler outlet they install a section of pipe 2-3 times larger in diameter, into which taps of normal diameter are cut into various devices. At the same time, if the system is overloaded, and the pressure of hot water that the boiler produces is not enough, water from the return line, which has already cooled down somewhat, is mixed into the supply line.

If, on the contrary, the boiler’s performance is excessively high, part of the hot liquid is immediately returned to the boiler without entering the heating and water supply circuits.

Thanks to the hydraulic distributor, the electric boiler can be connected to both a single-circuit and a double-circuit boiler. The separation of circuits can be done through this system, and it will also help replenish the used volume of water. It is best to allocate a separate circuit for each type of equipment: boiler and water supply, radiators, heated floors, etc.

The main disadvantage of a multi-circuit hydraulic system is that it takes up a lot of space and is quite complicated to design, install and debug.

However, by installing such a system, you will ensure long and uninterrupted operation of the equipment throughout the house, and you will also be able to control each circuit, up to complete shutdown, separately.

Scheme #4 - connection with instantaneous boiler

Sometimes the equipment is installed in such a way that all the water heated by the boiler goes directly into the boiler, and from there it is routed for water supply and heating. At the same time, when someone opens the tap and the pressure in the system drops, it is replenished by supplying cold water to the boiler, along with the return line or instead of it.

This scheme is the simplest. It provides high-quality hot water: the water will always be hot, immediately and at the same temperature.

But it has a number of disadvantages:

- Due to the constant flow of water, a boiler that is not designed for this mode of operation will quickly wear out.

- The temperature of the water in the hot tap will be the same as in the radiators - that is, almost boiling water.

- When using large volumes of water, the air temperature in the house may decrease.

The positive aspects of this solution may be a small amount of additional equipment, as well as undemandingness to the boiler parameters.

If an electric boiler is installed with a gas boiler as a flow-through boiler, there is no point in overpaying either for volume or for additional functions: only the quality of the tank is important

When connecting the boiler according to this scheme, do not forget to set the relay to a low temperature or even to a minimum so that the heating element does not try to heat the water more than the boiler does.

Otherwise, the heating element will work constantly, providing heating and consuming hundreds of kilowatts of electricity.

Features of connecting BKN

KN boilers can be connected in different ways, but there are still general principles for performing such work.

The unit must be placed only on a flat surface or suspended on a solid brick or concrete wall

Fastening is done using anchors.

It is important to comply with all pressure requirements throughout the entire system - it should not exceed the parameters optimal for the boiler. The tank should always be located slightly higher than the heating boiler itself - this will ensure faster heating of the water. So it’s better to put it on a small podium

At the same time, the BKN should not be placed too far from the boiler directly. The water inlet and outlet pipes from the boiler must always be oriented towards the boiler itself during installation.

To properly connect a boiler, you need to know the basic principles of connecting such devices. It is important to take into account that the coolant water must enter the boiler tank from above, and the cooled liquid must exit from below.

Subtleties of installing system components

Having decided on the method of connecting a gas boiler and an electric boiler, you need to carefully think through and draw up a wiring diagram, and then proceed with installation.

Stage #1 - connecting a gas boiler

This stage should be entrusted to professionals: like any other gas equipment, only professionals certified by the gas service have the right to connect a gas boiler. This is due to the fact that even minor errors in installation and configuration are fraught with serious consequences.

It is quite possible to get confused in the variety of outputs of a double-circuit boiler, and if you start an incorrectly connected boiler, expensive equipment may fail

If a water supply or sewer leak threatens you with a puddle, a maximum of a couple of centimeters of water on the floor, then an error in connecting a gas boiler threatens a fire, explosion or poisoning by combustion products.

We reviewed installation diagrams for a double-circuit gas boiler in this material.

Stage #2 - boiler installation

An electric boiler operating in conjunction with a gas boiler is connected in the same way as for standard use. The only difference is that not cold water is supplied from the water supply, but hot water from the boiler.

When planning a hot water supply scheme with a boiler and boiler, be sure to set the latter’s thermostat to a lower temperature than in the boiler

Step-by-step instructions for installing a boiler are discussed below:

- You need to punch two holes in the wall for dowels at the same distance as the boiler mount.

- Then hammer the dowels into the holes, screw the hook-brackets into them almost all the way, and turn them with the hooks straight up. Fasteners are usually included with the boiler and are designed to support its weight when filled with water.

- Hang the tank on the hooks, check that they fit exactly into the grooves.

- Make water connections to the boiler and taps using plastic, metal-plastic pipes or flexible hoses. Install a ball valve at each connection for easy maintenance of the boiler.

- Make a branch from the safety valve into the sewer using a thin tube. You can neglect it, but then you will need to tighten the locking screw, provide a container into which a small amount of water can drain, and check the operation of the valve manually every 2 weeks.

- Connect to the electrical network - this procedure is performed through a dedicated grounded line - a separate cable stretched from the meter. Regardless of whether the boiler will be plugged into an outlet or connected directly to a cable, you will need to install a circuit breaker for additional protection.

- It is also important to take care of high-quality insulation, because the room may be damp.

Installing the boiler and boiler is the main, simplest and most important part of the work, but this is only the beginning. For their effective interaction, it is necessary to perform the piping according to a pre-selected pattern. We will talk about the elements of such schemes further.

Stage #3 - connections and additional equipment

The first thing any water-related system should begin with is installing a filter to clean it.

Installing a mechanical water purification filter will prevent small solid particles from entering the heating and water supply system and extend the life of the equipment

When choosing a filter, remember that the better it purifies water, the longer the boiler, boiler, and all other equipment will last. Otherwise, small particles from the water settle on the walls of the coil and tank, form scale on the heating element of the boiler, contribute to the destruction of the tank and lead to rapid failure of all parts of the system - from the boiler to the faucet in the kitchen.

However, it is also not worth choosing the most expensive filter that purifies tap water to drinking state - it is too expensive and irrational. A filtration system with 2 – 3 levels of mechanical purification of varying degrees, from coarse to fine, will be quite sufficient.

The filter is installed at the very beginning of the chain, before connecting the water supply to the boiler. Be careful with the direction of flow - it is usually indicated by arrows on the body.

During operation, do not forget to regularly change the filter cartridges, otherwise they cease to perform their function and may negatively affect the water pressure.

The second obvious and necessary equipment is ball valves. You need a lot of them, they are placed at each connection: in front of the filter, at the boiler inlet and outlet, on both boiler connection pipes, at each outlet from the hydraulic needle, in front of each water tap.

This number of cranes ensures safety and comfort of operation. At some point, every part of the system will require preventive maintenance, and possibly replacement, and the ability to turn off just that will be very important.

Expansion tanks are installed to compensate for pressure drops in the water supply or heating circuit caused by changes in water temperature - for safety

When organizing DHW through a boiler, an expansion tank is usually not required: in the event of a critical increase in pressure, the boiler safety valve will operate. But if the heating circuit is installed separately, such protection will not be superfluous.

In addition to the listed devices, as well as the hydraulic comb discussed above, check valves are installed on the pipelines, which do not allow the flow to reverse even when the pump is turned off, safety and three-way valves, and, if necessary, a pressure reducing valve to reduce pressure.

Common installation mistakes

The manufacturer, referring to SNIP standards, requires during installation to insulate cold water/hot water supply pipes with a layer of 20 mm and a thermal conductivity of 0.030 W/m2. At the same time, both the pipe and all components are insulated.

They suffer without insulation and a cold water network, being a place where condensation accumulates en masse, creating unsanitary conditions. Another common mistake is installation without an expansion tank, especially for tanks with a volume of 200 liters or more.

List of other violations:

- The electrical cable is routed in a high-temperature area or on sharp metal surfaces.

- The procedure for connecting to the water supply system specified in the diagram by the manufacturer has been violated.

- The vertical/horizontal level of the installation is broken.

- There is no ground loop for the heater.

- The power supply parameters do not meet the requirements of the manufacturer specified in the passport data.

Before starting the device, you must carefully inspect the circuit; any, even the smallest mistake in the installation can become fatal during its operation, so every self-respecting owner should know how to connect the boiler correctly.

Alternative solutions for DHW through a boiler

As we have already mentioned, instead of an electric boiler, hot water supply from a gas boiler can be organized through an indirect heating boiler.

They come in different structures:

- with a coil-battery inside, from which the water is heated;

- a tank in a tank, where the internal tank from the water supply is washed and warmed with water from the heating system;

- layer-by-layer heating, where cold, hot water and heating return are mixed.

Each of these types has its own characteristics, but they are all more expensive than electric boilers and more bulky.

Read how to connect an indirect hot water boiler to a gas boiler in a separate article on our website.

A faucet with automatic electronic temperature control will always allow you to use water at the desired temperature. The thermostat will independently regulate the water supply from the hot and cold water supply pipes

In addition, the problem of temperature changes can be solved by installing a mixer with a thermostat: it will supply evenly heated water by mixing with different amounts of cold water. Such a mixer is not cheap, but installing it is often easier than re-equipping the entire heating and hot water system.

How does a double-circuit boiler with a biothermal heat exchanger work?

A bithermal heat exchanger is a coil made of a coaxial pipe. To simplify somewhat, these are two pipelines inserted into one another.

The coolant moves through the external volume, and water for the hot water circuit moves through the internal volume. This heating method significantly changes the quality of the boiler’s operation - efficiency increases, the amount of hot water increases and allows you to satisfy the needs of a large family.

However, a bithermal heat exchanger has a significant drawback - the complexity of organizing the internal space of the tube makes washing much more difficult.

All lime deposits, which quickly appear on the inner surface of the pipe, must be periodically removed, otherwise it will completely block the cross-section of the heat exchanger.

In addition, as the thickness of the lime layer increases, the heating efficiency decreases - the deposits begin to act as a heat insulator. The user has to increase the gas supply to adjust the boiler operating mode.

CAREFULLY! As a result, the heat exchanger quickly fails due to excessive heating outside and a large amount of scale inside.

Not all service centers perform flushing of such a heat exchanger, and the design of some boilers is such that it is easier to change than to dismantle and reinstall the same unit.

The disadvantage of bithermic heat exchangers relates entirely to operational issues. From an efficiency point of view, this design is very successful and allows you to increase the volume of hot water available for simultaneous delivery without loss of temperature in the heating circuit or the DHW itself.