A powerful gas boiler installed in a cottage can easily solve the problem of heating and supplying the house with hot water. But the amount of heated liquid for hygienic and household needs is limited and does not always suit the owners. To compensate for its deficiency, they install a BKN - an indirect heating boiler for a gas boiler.

Let's look at the features and functional capabilities of the storage unit, and also find out how best to use it in tandem with a gas boiler so that the result is as efficient as possible.

What is a single-circuit boiler

Single-circuit gas boilers are used to heat the coolant that fills the heating system. A single-circuit boiler does not prepare water for hot water supply. In rooms where the heated area sometimes exceeds three hundred square meters, floor-standing boilers are used. These heating devices are much more powerful than wall-mounted ones.

Wall-mounted single-circuit heating devices are most often used in high-rise apartments and can heat an area of up to three hundred square meters. These boilers are much more compact than floor-standing ones, and weigh just over 40 kilograms. The wall-mounted single-circuit boiler fits organically into the interior. Also, these wall-mounted devices are more functional than their floor-standing counterparts. The power of the most advanced models of wall-mounted single-circuit boilers is no more than 35 kilowatts.

A single-circuit gas boiler does not have any complex elements or mechanisms in its design. This boiler consists of:

- burners;

- heat exchanger;

- control unit;

- water pump;

- turbine electric motor (if the boiler has a closed combustion chamber);

- pressure gauge;

- sensors;

- shut-off valves.

Wall-mounted single-circuit boilers can be equipped with an expansion tank, which is hidden under the boiler casing. Also, the expansion tank can be part of a floor heating device, which has low power.

Installation features

First of all, you need to choose a frost-free room. The installation location is agreed upon with the regulatory services. When purchasing a device, you must ask the seller for a certificate, the presence of which will facilitate registration and obtaining permission for installation.

When choosing a location, you immediately need to think about how combustion products will be removed. You can install separate pipes or use a ready-made chimney. As a rule, heating equipment is already equipped with an exhaust system. During installation, you should be especially careful when connecting the device to the gas supply system.

The general requirements are as follows:

- It is allowed to install boilers only on load-bearing or permanent walls.

- The hood and chimney have similar dimensions.

- The system is freely accessible, which is necessary for maintenance.

- If the boiler is installed in a cabinet, then 5 cm should be left free to the top. It is also important to maintain access to the installation nodes.

When installing it yourself, you need to make sure that the equipment parameters correspond to the power of the heating system. If the wall-mounted appliance is connected to the “old” wiring, all pipes will need to be cleaned and flushed, which will prevent further clogging.

The installation process itself consists of the following steps:

- During installation, a special cardboard template is used to help make fastenings and holes for the chimney.

- Taking into account the free space for technological maintenance of the boiler, a template is attached to the wall. The places of fastenings and connections of wires are first marked on it. These marks must be transferred to the wall using a marker or colored pencil. The template can then be removed.

- Next, prepare the holes for the dowels using a drill of the appropriate diameter. Metal corners are inserted into them. It is important to choose the right dowels, taking into account the material and thickness of the wall.

- The top cover (front panel) is removed from the boiler. This makes it easier to hang the device on prepared mounts.

- Before installing the brackets, check the size of the fittings for the chimney.

- The brackets are securely fastened.

Please note that each wall has its own way of installing fasteners. This is explained by the operational characteristics of the materials, meaning the load that the partition can withstand. Electric heating convectors with wall-mounted thermostat, you will find the answer in the link.

What is a double-circuit boiler

This heating device not only heats the coolant, but is also intended for preparing hot water. A double-circuit boiler has a more complex structure than its single-circuit counterpart. The most complex device has a dual-circuit heating device, which is equipped with a three-way valve.

There are dual-circuit heating devices that are equipped with a pair of heat exchangers. One heat exchanger is responsible for heating water in the heating system, and the second heats water for water supply. The most rational design has dual-circuit heating devices that are equipped with a bithermal heat exchanger. Such a heat exchanger is two in one. Inside the bithermic heat exchanger there is another heat exchanger, which is designed to heat water for domestic purposes. But boilers with separate heat exchangers are considered more popular models.

Double-circuit gas boilers are good because they solve all the problems associated with preparing hot water for heating a room. Such heating devices are quite compact and fit organically into any interior. The design of a double-circuit heating device resembles the design of its single-circuit counterpart, which is also supplemented:

- a second heat exchanger (if the boiler design provides for this);

- 3-way valve (if the heat exchanger is not bithermic);

- inlet and outlet for the DHW pipeline.

Principle of operation

The fuel for a condensing boiler, as for a conventional gas boiler, is natural or liquefied gas. But the operation of condensing boilers is based on simple physical laws.

When natural gas burns, it produces carbon dioxide and water. The process of evaporation of a liquid is accompanied by the release of thermal energy, and the condensation of steam makes it possible to recover the energy lost during the evaporation process.

Due to this feature, condensing boilers have increased productivity and efficiency, although they consume less fuel.

Pros and cons of a double-circuit boiler

A dual-circuit heating device has many advantages. The main advantage of this device is that thanks to such a boiler you can simultaneously heat the room and use hot water. Using a double-circuit boiler will save you from additional costs that may be associated with the purchase of a boiler. Also among the undeniable advantages is the external attractiveness of dual-circuit heating devices. These boilers look aesthetically pleasing not only in the boiler room, but also in any other room.

Modern double-circuit heating devices have high efficiency, which can significantly reduce utility costs. Double-circuit boilers allow you to ideally adjust the temperature inside the room, as well as regulate the temperature of the water in the DHW pipeline.

These heating devices are not without several disadvantages, the list of which includes:

- turning off the heating at the time of dispensing hot water;

- relatively low productivity in preparing hot water.

What is an indirect heating boiler

Today, more and more people are resorting to using indirect heating boilers. This useful device allows you to use the heat of a gas boiler more efficiently. In winter, when the heating system is turned on, the indirect heating boiler operates from this system, and in summer, when the boiler does not operate for heating, such a boiler operates from an electric heating element or the boiler is switched to summer mode (if settings allow).

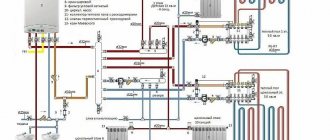

Heating of water in an indirect heating boiler does not occur in a direct way, but in a kind of incidental way. Inside such a boiler there is a fairly large coil, inside which coolant from the heating system circulates. Thus, the gas boiler heats the water in the indirect coil, which circulates in the heating system with the help of a pump, and the heat exchanger heats the water that is in the boiler. This type of water heating for the DHW main is recognized as the most cost-effective.

The casing of this boiler is mainly made of steel sheet, and its inner part is made of stainless steel. Between the outer and inner parts of an indirect heating boiler there is a special material that almost does not conduct heat. The design of such a boiler is very similar to the design of a thermos.

As a rule, an indirect heating boiler is installed near the heating boiler. The heated coolant must pass through the boiler first. The water in such a boiler will always be hot, and several hot water sampling points can be connected to this boiler at once. Hot water is heated in an indirect heating boiler without damaging the operation of the heating system.

In most cases, such a boiler is equipped with a highly efficient heat exchanger, which is made of special steel. More expensive indirect heating boilers are equipped with heat exchangers made of brass. The boiler heat exchanger has the shape of a long spiral, which allows you to very quickly heat the water to the temperature that the water in the heating system currently has.

Advantages and disadvantages of heating with an electric boiler

The main advantage of the scheme is simplicity. Almost any craftsman can assemble such a structure, since for this purpose neither special qualifications nor complex tools are required. Another advantage is the low price. Most often, electric water heaters for heating are sold at lower prices than electric boilers. Thanks to this, when creating a heat supply system for small objects, you can save significantly. In this case, you can get a very reliable, highly functional system that can be controlled via modern communication lines, for example, Wi-Fi. That is why it integrates well into the Smart Home program.

The disadvantages of using water heaters include:

- Low power.

- The heating element is constantly in working condition, which leads to rapid wear. To guarantee, you need to choose devices with 2 or more heating elements.

Pros and cons of a single-circuit boiler and BKN

A boiler that produces hot water by indirect heating is often used in conjunction with a single-circuit heating device. This tandem has both advantages and disadvantages. The main advantage of such a boiler is that this device practically does not require any maintenance and financial costs throughout its entire service life. An indirect heating boiler does not overload the electrical network with excess load, which is very important for those regions where voltage sags are observed.

An indirect heating boiler, which works together with a single-circuit gas boiler, is very convenient to use. Such a boiler uses water efficiently, since it does not require draining a large amount of water until hot water flows. Such a boiler heats water very quickly, and several mixers can be connected to this device, which can be located in different places in the house or apartment.

The heat exchanger of an indirect heating boiler operates under conditions that completely eliminate the formation of scale. The design also prevents the formation of harmful microorganisms inside the device. An indirect heating boiler does not require periodic cleaning and can operate for more than ten years without any maintenance.

The heat exchanger of the indirect heating boiler has special protection against corrosion. This protection very effectively protects these boiler elements from stray currents that occur in water mains.

Indirect heating boilers have several minor disadvantages, the list of which includes:

- higher cost than their electric counterparts;

- indirect heating boilers are larger than conventional boilers;

Using a single-circuit boiler and a conventional boiler

Along with indirect heating boilers with single-circuit gas boilers, conventional boilers are also used. Conventional electric boilers are slightly cheaper than indirect heating boilers, but are significantly inferior to them in many parameters. A conventional electric boiler takes much longer to heat water and this device requires regular maintenance.

It is advisable to clean the electric boiler from scale once a year, and also periodically change the anode, which serves as protection for the electric heater. An electric boiler also needs reliable power supply, and an independent electrical line must be laid to this device. Also, this water heating device seriously loads the electrical network - in general. Therefore, it is better to use an electric boiler in rooms where the electrical wiring has a safety margin.

Rating of the TOP 15 best floor-standing gas boilers for a private home for 2021-2022

| TOP 5 best floor-standing gas boilers by price/quality for 2021-2022 | ||

| 1 | Lemax Premium-16 | Find out the price |

| 2 | Siberia 11 | Find out the price |

| 3 | BAXI SLIM 1.230 iN | Find out the price |

| 4 | Lemax Premium-10 | Find out the price |

| 5 | MORA-TOP SA 20 | Find out the price |

| TOP 5 best single-circuit floor-standing gas boilers | ||

| 1 | Buderus Logano G124 WS-32 | Find out the price |

| 2 | Lemax Premium-20 | Find out the price |

| 3 | Siberia 17 | Find out the price |

| 4 | Ferroli Pegasus D 32 | Find out the price |

| 5 | Viessmann Vitogas 100-F GS1D883 | Find out the price |

| TOP 5 best double-circuit floor-standing gas boilers | ||

| 1 | Lemax Premium-30B | Find out the price |

| 2 | Navien GA 23KN | Find out the price |

| 3 | Lemax Premium-25B | Find out the price |

| 4 | Vaillant ecoCOMPACT VSC INT 266/4-5 150 | Find out the price |

| 5 | Pechkin KSGV-20 | Find out the price |