What is an indirect heating boiler

Its peculiarity is that the principle of operation is not based on heating water due to its own unit, but on heat exchange from external sources, such as fuel combustion, electrical resistance (resistance), contact with central heating, and the use of solar panels for energy processing. At its core, the boiler is a connecting link between the heart of the heating system (boiler) and all its vessels and arteries, correctly distributing the load and pressure on each branch. In this distributor, hot liquid passes through a metal spiral (coil) built into the storage tank. Heat exchange occurs through conduction between the coil and the cold water tank. A mandatory component of the boiler is thermal insulation, reminiscent in structure of a thermos to maintain the temperature inside the container, eliminating the loss of accumulated joules outside the device. The material for thermal protection is mainly polyurethane. The boiler circuit also includes a protective anode, an inspection hole, a bumper, and a submersible sleeve (for the temperature sensor).

Thanks to the heat exchanger, it is possible to heat water in a short period of time (up to 20 minutes from zero to 60 degrees). The only thing is that it is necessary to connect an indirect heating boiler with a boiler (usually gas) in order to be able to carry out such rapid heating.

Servo drive: device and principle of operation

As usual, for clarity, let’s look at the servo drive device according to the figure:

Servo drive device

As you can see, the following components are located inside the servo drive:

- Electric motor.

- A gearbox consisting of several gears.

- The output shaft by which an actuator rotates a valve or other device.

- The potentiometer is the same negative feedback that controls the angle of rotation of the shaft.

- Control electronics, which is located on the printed circuit board.

- The wire through which the supply voltage (220 or 24 V) and the control signal are supplied.

Servo control signal

Let's now take a closer look at the control signal.

The servo drive is controlled by a pulse signal with variable pulse width.

For those who don’t know what we’re talking about, here’s another picture:

That is, the pulse width (in time) determines the magnitude of the shaft rotation angle.

Setting up such control signals is not trivial and depends on the specific drive.

The number of control signals depends on how many positions the output shaft can occupy.

The servo drive can be two-position (2 control signals), three-position (3 control signals) and so on.

Connection progress for an indirect heating boiler

After choosing a circuit, it becomes clear what equipment will be required. In addition to the main devices, you may need valves, ball valves, distribution combs, valves (three-way or check).

Procedure:

- prepare the installation site (on the floor or on the wall);

- make the wiring, marking the hot/cold water outlets in red/blue;

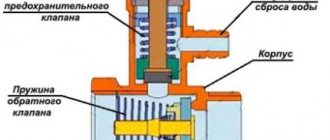

- install a tee and a pressure relief valve, securing the connections with sealant;

- screw on the hot (top) and cold (bottom) water taps;

- connection to a power source, install a thermostat and automation;

- select heating mode;

- test the connection.

These are general guidelines needed to present the scope of work. When connecting a specific model, you must follow the instructions that come with the kit.

How does a boiler work in tandem with a non-volatile boiler?

If a non-volatile boiler is used as a heating source, in order for the hot water supply to be a priority, the boiler must be located above the radiators. This is easy to do if the model is wall-mounted. The best position is when the bottom of the hot water tank is higher than the heating boiler and radiators.

In a floor-standing model, the water will heat up, but it will take much longer. In addition, the water at the bottom of the tank will remain unheated. Its temperature will not exceed the return heating level in the heating system. With this scheme, the coolant flows by gravity, with gravity acting as the driving force. There is an installation method in which a circulation pump is connected to the boiler. But this is not a solution, because if there is no electricity, the water will not heat up. Experts have developed several schemes tailored to gravity heating systems.

The trick is that the diameter of the pipe intended for the water heater circuit is taken one step larger than the diameter of the heating pipe. According to the laws of physics, the coolant will “choose” a pipe with a large diameter, that is, the boiler will be a priority.

In another method, a thermostatic head with a built-in sensor, powered by batteries, is installed in the heating system. Everything is very simple: using the thermohead regulator, you set the desired level of water heating. While the water is cold, the thermostat opens the way for water to enter the boiler. As soon as the water warms up, the coolant is directed to the heating circuit.

Strapping stages

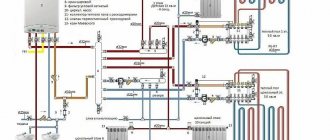

First, an installation diagram is drawn taking into account the dimensions of the room and the selected locations for all devices. After this, holes for the heating boiler and boiler are marked and drilled. If the devices are floor-mounted, then it is advisable to make a small foundation for them according to the size of the buildings.

Next, propylene pipes are cut according to size and connected to each other with tees using a soldering iron. Pumps, taps, filters are installed and everything is combined into one system. If you have additional circuits, for example, on a hot floor, then a collector is installed that evenly distributes the coolant flows.

Connection diagram for a double-circuit boiler

An expansion tank and a safety complex are mandatory. When installing a safety group, you should take into account that if it works, water will flow out of it. Excess coolant goes into the expansion tank during expansion.

After all connections, water is introduced into the system and all connections are checked. If there are no leaks, then the boiler starts and the heating rate of the batteries is checked.

Installation instructions for the recirculation system

It often happens that plumbing fixtures are located in the house at a considerable distance from the boiler or on the upper floors. In this case, the owners of the building usually have to wait until the water that has stagnated and cooled in the pipes drains from the taps in the bathrooms to get hot water. And this, of course, is inconvenient and not particularly economical.

This situation can be corrected by assembling a recirculation system in a country house. Installation of such a network is carried out approximately as follows:

- a tee is cut into the pipe supplying hot water to the consumer as close as possible to the consumer;

- a pipe of the required length is connected to the tee;

- the extended line is connected to the boiler through the recirculation pipe;

- Next to the boiler, at the nozzle, an additional pump of not too high power crashes into the circuit.

When using such a scheme, the water in the pipes between the boiler and the consumer, after turning on the pump in the electrical network, will not stagnate and, accordingly, will be cooled. That is, residents of the house will be able to use hot water immediately after unscrewing the tap valves.

Useful qualities

The volume of the device can vary from 30 to 1500 liters, it depends on its purpose. Units with a volume of up to 200 liters are available as wall-mounted units, larger units – as floor-mounted units. As a rule, a 200-liter boiler is enough to satisfy the hot water needs of one family. The efficiency of this device is high and is about 90%.

Modern models are equipped with additional electrical elements, heating elements, or have the ability to connect them. This allows you to use them as an additional source of water heating and turn off the boiler in hot months, which significantly increases the service life of the boiler.

Installation methods and shapes of boilers

Boilers come in wall-mounted and floor-mounted versions, horizontal or vertical models. The capacity of the product, which is mounted on the wall, is naturally lower: it does not exceed 200 liters. Floor-standing devices can hold one and a half thousand liters. Boilers are mounted on the wall using standard brackets and suitable dowels. The most common boilers are cylindrical in shape.

Working pipes for connecting the system are located at the rear of the unit for convenience and aesthetic purposes. There is a temperature sensor and a thermostat on the front panel. There are models with the possibility of additional connection of heating elements if the power of the main heat source is not enough.

Schemes and rules for connecting BKN

The connection diagram and installation features of an indirect heating boiler depend on the class of the device and the heating system in the house. It is necessary to choose the right installation location, focusing on the location of the boiler, pump insertion and existing wiring. Let's try to figure out what needs to be taken into account when installing heating equipment.

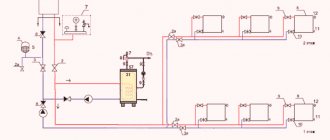

#1: Trim method with three-way valve

This is one of the most popular schemes, since when it is used, there is a parallel connection of the heating system and the BKN, equipped with shut-off valves. The boiler must be installed near the boiler, a circulation pump must be installed in the supply, then a three-way valve. This scheme is successfully used if several heating devices are used, for example, two different boilers.

A three-way valve is a kind of switch that is controlled by a thermal relay. When the temperature drops, the automation is activated, and the coolant flow from the heating circuit is redirected to the BKN (+)

Essentially, this is a priority system that ensures rapid heating of water in the boiler when the radiators are completely turned off for a while. As soon as the temperature rises to the set value, the three-way valve is activated again and returns the coolant to its previous direction - to the heating system. This piping method is useful for those who use the boiler constantly.

#2: Option with two circulation pumps

If the boiler is rarely used (for example, seasonally or on weekends) or there is a need for water whose temperature is lower than in the heating system, use a circuit with two circulation pumps. The first is installed on the supply pipe, directly in front of the BKN, the second - on the heating circuit.

The circulation pump is powered through a thermal relay, so it starts to operate only when the temperature drops below the required one. Heating accelerates when forced circulation is turned on (+)

There is no three-way valve in this scheme; the piping is equipped using simple connecting tees.

#3: Piping with hydraulic boom

This connection is used for volumetric boilers (200 liters or more) and branched heating systems with many additional circuits. An example is the heating system in a two-story house, where, in addition to a multi-circuit radiator network, heated floors are used.

A hydraulic distributor (hydraulic arrow) is necessary to simplify the layout of the heating system and avoid installing recirculation pumps on each heating branch (+)

The water gun equipment allows you to avoid thermal shock, since the water pressure in each circuit will be the same. It is quite difficult to make the piping according to this scheme yourself, so it is better to turn to professional installers.

#4: Using coolant recirculation

Recirculation is useful when there is a circuit that requires a constant supply of hot water - for example, a heated towel rail. If it is connected to the heating system, the coolant will constantly circulate, and the dryer will function and at the same time serve as a heating device.

The use of recirculation has one big advantage - you don’t need to wait for the water to heat up to the desired temperature, it will always be hot (+)

But this scheme also has disadvantages. The main one is an increase in fuel costs, because constant heating of the water cooled in the circuit is required. The second disadvantage is mixing water in the boiler. Typically, hot water is located in the upper part, and from there it flows to the water supply points, where it is mixed with cold water, as a result of which the outlet temperature is slightly lower.

There are models of boilers with built-in recirculation, that is, with ready-made connections for connecting a heated towel rail. But it’s cheaper to buy a regular tank using tees for connection.

#5: System for working with a non-volatile boiler

A distinctive feature of this scheme is the installation of the boiler at a higher level than the boiler and heating appliances. Preference is given to wall-mounted models that can be hung at a height of 1 m above the floor.

Floor-standing models specifically within this scheme are inferior to wall-mounted ones in heating speed and quality. The water temperature is much lower (about the same as in the return pipeline), therefore, the supply of hot water is less (+)

The non-volatile type of heating is based on the application of the laws of gravity, therefore, the coolant will circulate even when the electricity is turned off. In normal mode, you can connect circulation pumps.

Useful tips and tricks

An indirect heating tank is a new technology, however, many users who use this type of hot water preparation are happy to share their tips and recommendations:

It is important to initially correctly select the heating power of the BKN, taking into account the number of users and water use mode. For calculations, SNIP water consumption standards and a maximum heating temperature of up to 65C are used. The productivity of the BKN is limited by the thermal power of the boiler unit; initially, heating equipment is selected with a margin of 30-50%. Pre-select the type of installation on the wall or on the floor; there should be enough space for maintenance and repair, as well as for placing an expansion tank with a volume of at least 10% of the working tank of the reservoir. The correct ratio of the power of the BKN and the boiler is chosen, for example, if the boiler unit has a power of 10-15 kW, it is not advisable to set the volume to 200 liters, because while the water is heating up, the temperature in the heating circuit of the house will cool down. It is better not to skimp from the beginning and purchase a “tank-in-tank” type unit design, which is the most efficient in operation and easy to maintain; it only requires annual cleaning from dirt and scale. Before purchasing, you need to check the useful volume of the tank; usually, it is 20-35% less due to the internal heat exchanger. Before mounting the BKN model on the wall, study the manufacturer's passport; usually the device is installed so that the cold water is at the bottom

If the tank is accidentally turned over, the coil will overheat, and the natural circulation of cold and hot media will be disrupted, which is unacceptable.

It is important to initially correctly select the heating power of the BKN, taking into account the number of users and water use mode

These simple tips will help novice BKN users perform professional installation and fine-tuning, guaranteeing a stable supply of heated water, ensuring the operation of systems and devices in the specified mode, preserving system elements from premature wear and saving money on unforeseen repairs.

Connection features

An indirect heating boiler is a storage tank, inside of which one or more tubular heat exchangers are located. The hot coolant from the boiler circulates through the coil and heats water in sufficient volume for domestic and economic needs.

The principle of operation of the water heater is simple; difficulties arise during installation and wiring of heating equipment.

Therefore, it would not be amiss to find out the specifics of connecting a water heating device before starting work:

- The closer the boiler is located to the boiler, the more efficient the heat exchange from the heating system occurs.

- The installation of the water heater must be carried out in accordance with the manufacturer’s recommendations - wall-mounted models are attached to the wall, floor-standing models are installed on the floor.

- The flow of cold water should be supplied through the lower pipe, and the intake of hot water through the upper, then the recirculation point will be in the center of the container itself.

- The pipes for the coolant inlet and outlet should “look” towards the heating device. The movement of hot water or antifreeze along the coil should be from top to bottom.

Compliance with these simple rules guarantees the efficient operation of the boiler-boiler system, the efficiency of the heater will reach its maximum and there will be enough hot water for all consumers.

Advantages, disadvantages, types of equipment

What is so good about this boiler? The most important thing is that the water in it can be heated without unnecessary costs. That is, you will not have to pay additionally for electricity or gas, unlike the same direct heating boilers, which have special heating elements such as burners in their design. The KN boiler uses the ready-made resource of the heating system in the house.

Indirect heating water heater

This aspect also allows us to talk about a reduced load on the electrical network in the house. At the same time, the boiler’s performance is quite high, it is safe and can serve for many years without complaints, because its internal part is even protected from contact with running water. Water from such a boiler is supplied to the consumer as soon as it is needed.

Of course, the equipment has disadvantages. This is, first of all, high cost - it costs more than a direct heating boiler. It is also worth understanding that the water in it takes longer to heat up, but it also stays hot longer. And such a boiler takes up a lot of space; it’s better to place it in a separate room. And one more main drawback - in the summer, in order to heat the water, you will have to start the heating boiler.

When installing a hot water system in a private home, the owner often has to decide which is better - an indirect heating boiler or a double-circuit boiler

On a note! There are several types of indirect heating boilers. Let's see how they differ from each other.

Table. Types of KN boilers.

| View | Description |

| With built-in control | Such heaters are connected to boilers that do not have controls. They are usually equipped with a special sensor that allows you to control the water temperature, and also allow you to accurately control the inclusion and shutdown of the liquid supply to the so-called coil - the coolant circuit. It is easy to connect such a boiler - you just need to connect the supply and return water from heating the house, as well as connect the supply of cooled liquid and the distribution of heated hot liquid. |

| Without built-in control | Such tanks are usually connected to a system equipped with an automated boiler. During installation, it is important to think about installing the temperature sensor and install it in the housing, then connect it to the boiler. |

| Wall | As you might guess, such a boiler is mounted on the wall. It is usually small in size, so it will not heat up a lot of water. It is important to understand that a boiler is not a lightweight structure, and the wall on which it will be mounted must be strong. |

| Floor | This option is placed on the floor and comes in a variety of sizes and capacities. It is rarely used in residential buildings - such a boiler can more often be seen in industrial premises. They put him in a separate room. |

| Vertical | The most common option, as it allows you to intelligently save space in the room. But such a boiler does not have a large capacity. |

| Horizontal | This is usually a fairly large boiler that will hold a lot of water. Often used in enterprises. |

Using an indirect heating boiler and an electric boiler

On a note! It is important to understand that the smaller the boiler, the faster the water will heat up in it. Although modern designs sometimes make it possible to heat a large volume of water in a very short time.

How is the boiler power selected?

Common installation mistakes

During installation or during the commissioning process, you should try to avoid a number of mistakes:

- The boiler and boiler are installed far from each other. Their installation should not only be done as close to each other as possible. But, to simplify installation, the pipes are positioned correctly.

- Incorrect connection of the pipeline with the coolant.

- Incorrect installation of the circulation pump.

Proper installation, adjustment and configuration guarantee a stable hot water supply and allow all systems and devices to operate normally. This will prevent wear of parts and save on premature repairs.

How to choose an indirect heating boiler

In principle, choosing a BKN is very similar to choosing a conventional storage boiler. But let's briefly repeat the main points.

Volume is the very first thing to choose. Let's simplify your task: on average, 1 family member should have 40-80 liters of water. There will be no problems with selecting a model of suitable capacity. Today, the indirect heating boiler market offers models with volumes from 200 l to 1500 l.

Water flow through the heating circuit - be sure to look at this characteristic from the model data sheet.

The value of this characteristic should be no more than 40% of the total volume of water that passes through the heating boiler.

The material of the tank and thermal insulation - you understand, the best choice for the tank is stainless steel. It is better to choose polyurethane foam or mineral wool as insulation - they have the best heat-insulating properties.

Experts do not recommend choosing models with foam thermal insulation. It doesn't hold heat very well.

Compatibility with heating equipment

Indirect heating boilers work without problems with any heating system that supplies hot water - as long as its power is sufficient. As noted above, solid fuel boilers that operate on all available types of fuel are an excellent option. However, devices running on gas, electricity or liquid fuel will also be quite effective.

The installation of the tank itself is not very complicated, but the connection diagram for an indirect heating boiler is no different in simplicity. When choosing a model with controls, there will be no special problems, but with simplified products you will have to tinker so that the boiler working in conjunction with them can work with both heating and water supply.

Boiler recirculation diagram

Recirculation of water in the DHW system is necessary in order to provide hot water to any point in the system without additional spillage. To do this, a circuit is installed through which water from the boiler passes throughout the entire system, and then returns back to the boiler. Recirculation is carried out using a small pump that operates completely silently. This system helps maintain a stable temperature of hot water anywhere in the house.

Among the common recycling schemes, there are several main options:

- Installation of a three-way or servo-motorized valve. This method is used for wall-mounted and floor-mounted boiler models. Two pipes (two circuits) are connected to the boiler. One circuit is intended for heating, the other for hot water. The water heater in this system acts as the main coolant. When the water temperature drops, a servo-driven or three-way valve is used, which begins to work to heat the water. The heating is turned off at this time. After heating the water to the desired temperature, heating is resumed;

- Installation of two circulation pumps in one system. With this scheme, one of the pumps is designed to recirculate hot water through the heating system, and the other - through the boiler circuit. This system initially ensures normal water temperature in the boiler, and then in the heating system. A feature of this scheme is the presence of a thermostat and a mode switch, which allows you to turn off, if necessary, one of the systems;

- Application of a hydraulic arrow. It is used if there are more than two circuits in the house (heating, hot water, heated floor). This scheme is aimed at heating water, due to which all circuits are heated. This system has a significant drawback - when analyzing water. The coolant may not be able to meet the needs of all people at the same time.

The choice of method of heating water and heating, as well as methods of its recirculation through the boiler, must be carried out in accordance with clear calculations of all consumers and the power of the coolant. Among the main schemes, boilers with three-way or servo-actuated valves have an advantage.

What is a servo and how does it work?

Let's start with a definition. A servo is an electric motor controlled through negative feedback.

In this case, the negative feedback will be a shaft angle sensor, which stops the shaft movement when the desired angle is reached.

To visualize the servo drive, look at the picture below:

Servo drive for three way valve

Step-by-step strapping in gravity systems

The water heater is installed in networks of this type in such a way that it is located above the radiators. Therefore, for gravity systems, they usually purchase not floor-mounted, but wall-mounted suspended boilers.

The correct installation of water heaters in networks with natural coolant circulation includes the following steps:

- the supply from the boiler is connected to the boiler coil using a pipe of a larger diameter than in the heating system;

- then the heating system supply is cut into this segment between the boiler and the water heater;

- between the boiler and the resulting branch, a thermostatic head with an attached sensor, powered by batteries, is mounted;

- the boiler is connected to the boiler by a return pipe;

- a line for discharging cooled coolant from the radiators is cut into the return pipe;

- An expansion tank is installed closer to the boiler on the return line.

When using this scheme, water is heated due to the difference in the cross-section of the supply pipes of the boiler and the heating system. The water heater in this case is a priority. As soon as the water in the boiler warms up to a certain temperature, the sensor is triggered and the pipeline is closed. As a result, water begins to flow into the heating system.

Wiring a solid fuel boiler with an indirect heating boiler

Connecting a water heater with a solid fuel boiler solves two problems at once:

- obtaining hot water supply;

- obtaining a method for discharging coolant in the event of an accident.

Due to the fact that such a system places a thermostatic valve on the battery, comfort increases. But there is a danger of the boiler overheating. The same threat arises during power outages. If a boiler of increased capacity is installed, this process does not pose any danger. Because excess heat is spent on heating water in the water heating tank. Accordingly, for the normal operation of this system, a boiler with natural ventilation is needed.

See the following video for one of the options for connecting a solid fuel boiler to a boiler.

General requirements

In order for the piping system of a single-circuit boiler with a boiler to work normally, without interruptions and emergency situations, the following requirements must be met:

- At the outlet of the boiler, an expansion tank with a volume of at least 10 percent of the boiler is installed. (not to be confused with an expansion tank for heating). It plays the role of a neutralizer during the thermal expansion of water.

- Be sure to install ball valves on all pipes that lead to the tank. They will be needed for repair or preventive maintenance of circulation pumps, three-way valves or other elements of the system.

- A boiler is considered safer during operation if it is equipped with a thermostat to prevent excessive overheating. In the basic configuration, such water heating devices are equipped with safety valves that release steam from hot water and prevent rupture of the tank body.

How to choose an indirect heating boiler

The main parameter of such a device is its usable volume. The numerical value of this parameter is influenced by many factors:

- the number of residents of the house consuming hot water;

- residents' habits;

- their mode of life, etc.

Based on “such parameters” it is difficult to determine the exact value of the volume. Therefore, when calculating the volume, take approximately 80 liters per resident. The range of volumes for devices of this type is quite wide: from 200 to 1500 liters. However, choosing a heater with a significant reserve volume is unprofitable, since energy costs will increase. And the device itself “increases in price” as its volume increases.

The second important parameter is the coolant flow through the heating circuit (data from the device data sheet). As a percentage, it should not be more than 40% of the total flow through the heating boiler.

You should also pay attention to the material from which the container is made and the quality of its manufacture. Heaters with a stainless steel tank have the greatest longevity and price

An important point may be the ability to dismantle the internal heat exchanger for cleaning.

Thermal insulation should be polyurethane foam or mineral wool.

The name of the heater manufacturer and the “geography” of its production, along with the listed factors, play a significant role in determining the price.

The choice is yours! The modern heating engineering market is saturated with offers of a wide range of parameters.

Selecting a KN boiler

The choice of such a unit as an indirect heating boiler must be approached with all responsibility and, first of all, ask yourself the question: “Will it be convenient to use such a device?”

The pros and cons of the unit are described above. In this section, we will note several aspects that you need to know in order to understand whether you need to buy it. They will also help you choose the most suitable KN boiler option. To what extent will the purchase of such equipment be justified? The fact is that it makes sense to buy such a device if the water flow in the house or room is large enough and is at least 1.5 l/min. For comparison, this is exactly the water consumption observed in large families of 4 or more people.

The presence of such a boiler will certainly increase energy costs if it is connected to an electric boiler.

The volume of the boiler is also an important aspect. So, you need to calculate and take into account the hot water needs for your family. It must be selected taking into account the parameters of the room where it will be installed.

The materials from which the boiler is made also matter. So, those made of stainless steel will allow you to heat the water up to 90 degrees. In enamel, the temperature should be lower. But very heated water can always be diluted with cold water, which means that the efficiency of even a small tank in a boiler that warms up the water very much will be higher

It is also important to choose a boiler that will not rust.

The power of the heating boiler itself should also be taken into account. It should be enough to heat not only the unit, but also the heating system.

The pump for loading equipment should also be optimal

The operating instructions for the equipment will help you choose which one is suitable - it usually contains all the numbers you need to focus on.

The time for heating water will play a decisive role for many, so this point should also be taken into account. So, on average, it takes about 2 hours to heat 100 liters of water. But some models of tanks heat water faster - for example, a stainless steel tank will heat the same amount of water in 20-30 minutes.

The material for thermal insulation inside the unit can be represented by foam rubber, mineral wool or polyurethane foam. Foam rubber is found in cheaper models.

You can organize a constant uninterrupted supply of hot sanitary water in a private house using an indirect heating boiler

It is also better to buy boilers that have some protection elements - safety valves, thermostats, etc. Don’t be lazy and refuse to fill out the warranty card in the store when purchasing. The boiler is expensive, and it would be a shame to purchase it and find out that the quality of the product is inadequate. And it is difficult to change such equipment without a warranty.

Manufacturing of an indirect heating boiler

The process of assembling a water heater may vary depending on the type of design, but in most cases, equipment for gas and electric boilers is manufactured in the following sequence:

- Two holes are drilled in a pre-prepared cylinder using an electric drill with a crown attachment. One hole will be located in the lower part and used for supplying cold water, the other - in the upper part for discharging hot water.

- The resulting holes are cleaned, fittings and ball valves are installed in them. Then another hole is drilled in the lower part, into which a tap is installed to drain stagnant water.

- To make a coil you will need a copper pipe with a diameter of 10 mm. It is better to make a spiral bend using a pipe bender. If such a tool is not available, then you can take any round piece - a large diameter pipe, a log, a barrel, etc.

- The coil is being manufactured according to the previous calculations. The ends of the heat exchanger are bent in one direction at a distance of 20–30 cm. To mount the coil, two holes are drilled in the bottom of the cylinder. Threaded fittings are installed and welded into them.

- Before installation, the coil is lowered into a bucket or large container with water and blown out. If the structure is sealed, then the coil is lowered into the cylinder, aligned with the inlet and outlet openings and welded.

- If the cylinder was cut in the middle, then an anode is mounted in the upper part. To do this, a hole is drilled into which a threaded nozzle is screwed in, and a magnesium anode is mounted into it. If the container is assembled from three separate parts - bottom, lid and central part, then the anode can be installed at the last stage.

- Thermal insulation material is installed on the outside of the boiler. It is best to use spray polyurethane. Before application, all pipes are protected with thick polyethylene and cloth. If funds are limited, then you can use regular polyurethane foam, which, after hardening, is wrapped in reflective insulation.

- Fastenings for hanging on brackets are welded to the back of the boiler. For floor-standing boilers, support legs made of angle steel or reinforcement are welded to the bottom of the equipment.

At the final stage, fittings and taps are screwed on and the top cover is mounted. If possible, you can not weld the lid, but make clamping fasteners from steel wire with a cross-section of 3 mm.

When making a boiler for use with solid fuel boilers, instead of a copper coil, a U-shaped steel pipe is used, which is mounted at the bottom of the device. From the side of the furnace or boiler, the pipe is connected to the outlet pipe. The pipe is taken out from the boiler and connected directly to the chimney.

Calculation of the main parameters of the boiler

Before you begin searching for material and directly manufacturing, you will need to calculate the minimum volume of the tank and the working length of the heat exchanger.

Volume and shape of the tank

The volume of the water tank directly depends on the number of residents permanently residing at the place where the equipment is installed. It is believed that a person uses up to 80 liters of water per day. For the calculated value, it is recommended to take 45–50 liters per person. If the norm is exceeded, the water in the tank will stagnate, which will certainly affect its quality.

The shape of the tank is selected taking into account the pressure in the plumbing system. If the pressure is low, then the use of homemade boilers with a square tank is allowed. If the pressure in the system is high, only equipment with a rounded bottom and top can be used.

Boilers with a storage tank of square and rectangular shape can only be used in water supply systems with low operating pressure

The fact is that increased pressure contributes to the occurrence of bending forces on the walls of the tank, so a square or rectangular tank can become deformed. A container with a round bottom is more resistant to deformation due to better streamlining.

Heat exchanger power and length

In vertical indirect heating models, a copper coil is usually used as a heat exchanger, located between the inlet and outlet.

Boiler coil made of copper pipe

For DIY production, it is best to use a copper pipe with a diameter of 10 mm. This product can be easily bent by hand without using any tools. When using a metal-plastic pipe, it should be taken into account that the heating temperature of the coolant should not be more than 90 °C, otherwise the pipe will be deformed and the joints will leak - this will lead to mixing of water in the tank.

The length of the pipe required for the manufacture of the coil is calculated by the formula L = P / (3.14 ∙d ∙∆T), where:

- L—pipe length (m);

- d—pipe cross-section (m);

- ∆Т – temperature difference between heated and cold water (оC);

- P is the power of the heat exchanger for every 10 liters of water (kW).

According to experts, for every 10 liters of water there should be at least 1.5 kW of thermal energy. Taking this into account, you can calculate the length of the pipe for making the coil.

For example, let’s calculate the material for a coil that will be installed in a boiler with a capacity of 200 liters. The temperature of cold water supplied to the container will be 15 oC, and after heating it is necessary to obtain water with a temperature of 80 oC: L = 1.5 ∙20 / (3.14 ∙0.01 ∙65) ≈ 15 m.

Table: length of copper heat exchanger for boilers with a capacity of 50–200 liters

| Storage tank volume, l | Equipment power, kW | Heat exchanger length, m | Boiler tank diameter, m | Coil diameter, m | Number of turns |

| 200 | 30 | 15 | 0,5 | 0,4 | 12 |

| 150 | 22,5 | 11 | 0,5 | 0,4 | 9 |

| 100 | 15 | 7,5 | 0,4 | 0,3 | 8 |

| 50 | 7,5 | 4 | 0,4 | 0,3 | 5 |

The number of turns of the coil depends on the method of bending and the distance between the elements. Typically, the coil is positioned so that the distance between the coils and the walls of the tank is at least 10–12 cm. The distance between the coils should not be less than 5 cm. The calculated values for storage tanks of various volumes can be seen in the table above.

If an indirect type boiler needs to be equipped with a tubular electric heater, then the power is calculated based on the fact that to quickly heat 50 liters of water, a heating element with a power of at least 1.5 kW is required. In addition, any combi boiler must be equipped with a thermostat.

Installation diagram with two pumps

Another common scheme for connecting an indirect heating boiler is using two pumps. In this scheme, two separate, parallel to each other, circuits are configured: heating and the boiler itself - each of them is equipped with its own recirculation pump.

Priority in this system is given to the boiler circuit, so the boiler system pump is mounted in front of the heating pump. A mandatory component of the circuit is a check valve, which prevents the two water flows from mixing and ensures the correct distribution of liquids along the circuits. Also, it cannot do without the already familiar temperature sensor, which sends signals to the valve, thereby controlling the operation of the pumps.

Installation diagram with two pumps

The piping scheme for a boiler device with two pumps is best suited for systems with two separate heating boilers. Each of them must have independent power and provide heating of the liquid in separate circuits: one boiler must be responsible for general heating of the home, and the second for heating boiler water for domestic use. In this case, the circuit functions as follows: when the water in the boiler tank cools to the lower level, the coolant flow is switched to heat it, and after reaching the programmed temperature it returns to the main heating circuit.

This type of piping is valued due to the rapid heating of water: due to the speed of operation of the equipment, when switching heating to the boiler circuit, the coolant in the main heating system will not have time to cool down.

Installation principle

If you need to mount a tank with a capacity of up to 200 liters, this can be a wall-mounted product.

For its fastening, special kind of brackets are provided, which must be located on flat and strong vertical surfaces. Conventional plasterboard partitions are of little use for mounting even such a “light” storage device. You need to choose between saving on the arrangement of interior space and saving on the boiler. Floor-standing units are preferred to meet the needs of large households; sometimes they even install products with a capacity of over a thousand liters and allocate a special boiler room for them. In private homes, you can limit yourself to indirect heating boilers that accumulate from 250 to 300 liters of water. The exact choice of capacity must be made taking into account real and projected needs. When connected to a double-circuit boiler equipped with a built-in pump, the boiler automation itself takes over the coordination of the valve operation based on signals from the thermostat

This is very important because a double-circuit heating device, unlike a single-circuit heating device, must supply hot liquid both to the heating system and to the hot water supply circuit

If you install a three-way valve, the water heater will have an advantage in the system compared to the heating circuit. This approach is acceptable when a large capacity tank is installed. Please note: this connection method is also practiced when forced to use hard water, which complicates the normal use of the hot water system. Although, of course, it would be much more correct to take care of softening the incoming coolant. But sometimes you have to adapt to it against your will.

Problems may arise due to the fact that significant consumption of hot water can complicate the functioning of this circuit. In this case, the method of obtaining heat, including using a pellet or other solid fuel boiler, is not significant. And this is where the boiler comes to the rescue, smoothing out fluctuations in two circuits. Thanks to it, even intensive coolant consumption has little impact on people’s daily lives. Installers must consider which function will have the highest priority.

Connecting indirect heating boilers to a single-circuit boiler can be done using a pair of pumps. Then, with their help, water flows are distributed through two pipelines. It is usually assumed that the hot water supply circuit will come first. The operation algorithm of the boiler in conjunction with a single-circuit device is also adjusted accordingly. To prevent liquid flows of different heating levels from changing each other’s basic parameters, both pumps must be preceded by a return valve. Hot water is supplied exclusively from the boiler.

Design features of an indirect boiler

The indirect type boiler is a tank made of stainless steel. The inner walls of the container are covered with a special material, which not only protects the surface of the water heater from corrosion processes, but also reduces the concentration of harmful bacteria and microorganisms.

Diagram of an indirect type boiler with a single-circuit coil

Otherwise, a boiler of the simplest design consists of the following components:

- heat exchanger - a spiral pipe or smaller tank. Depending on the volume of the tank, it can be located in its upper and lower parts;

- inlet pipe - a fitting at the bottom of the device for supplying a pipe with cold running water;

- outlet pipe - fitting for connecting the hot water outlet pipe;

- magnesium anode - additional protection of the tank walls from corrosion processes;

- internal thermometer - a device for measuring the temperature of heating water;

- thermostat - a device that prevents equipment from overheating;

- control unit - rotary knob with divisions for setting the heating temperature;

- thermal insulation - a layer of insulating material that helps maintain the desired temperature of the heated water;

- outlet - valve for draining stagnant water;

- revision - a large diameter hole intended for maintenance, repair and modernization of the boiler.

The design of new tank models may differ slightly and have a number of modifications from manufacturers, but in general, any indirect type boiler consists of the listed elements.

Operating principle of the boiler

An indirect type boiler is part of the heating system and is connected directly to a gas, electric or solid fuel boiler, which heats the coolant using the energy released when fuel is burned.

The coolant circulates through the DHW system and passes through a heat exchanger located in the indirect heating boiler. Due to the release of thermal energy from the hot coolant, the cold water that fills the device’s tank is heated. From it, heated water is transported through an outlet through a pipe to the bathroom, kitchen and other rooms with plumbing equipment.

An indirect type boiler can work with any type of heating boiler

When the heating boiler is turned off or switched to an economical operating mode, the coolant quickly cools down. Thanks to the design of insulating the tank walls with urethane foam, the water in the tank cools very slowly. This allows you to use the entire volume of warm water for several more hours.

Features of operation, troubleshooting

The walls of a properly functioning boiler are at room temperature, the device does not make noise, does not consume electricity beyond what is specified in the passport, and warms up in 20–30 minutes.

Prolonged heating indicates that scale or debris has accumulated in the tank. The problem is solved by mechanical or chemical cleaning. Both require draining the water and dismantling the tank.

For the first, the boiler is disassembled, the walls and heating elements are cleaned manually. No disassembly is required for dry cleaning.

The removed storage tank is turned over, a solution of citric acid or anti-scale agent is poured into the cold water inlet pipe, and the boiler is left in this form for several hours. Then the cleaning liquid is drained, the container is mounted in place and washed with water.

A hot boiler body indicates depressurization of the container due to microcracks. It is impossible to fix the problem yourself; repair or replacement of the device is required.

Connecting the boiler to a gas boiler

For the proper functioning of the boiler with a gas boiler, it contains a temperature sensor. For them to work together, a three-way valve is connected. The valve regulates the flow between the main circuit and the DHW circuit.

To a single-room gas boiler

For such a connection, a piping with two pumps is used. It is this that can replace the circuit with a three-way sensor. The main thing is to separate the coolant flows. In this case, it would be more correct to say that the two circuits operate synchronously.

To a double-circuit gas boiler

The main components of this connection scheme will be two magnetic valves. The bottom line is this - the boiler is used as a buffer. Cold water comes from the water supply network. The DHW inlet valve is closed. If you open it, water will first flow from the buffer, which is the boiler. The buffer contains heated water, the consumption of which is regulated by the capacity of the boiler and the set temperature.