Here you will learn:

- Safety valve activation

- Types of safety valves

- Tips for choosing a valve model

- Is it possible to install other valves?

- How to install the valve

- Checking for serviceability

- Boiler valve adjustment

- Service

In the process of heating water in the storage tank of the water heater, its volume increases. In a closed system, according to the laws of thermodynamics, as the temperature of the substance increases, the pressure level also increases.

To control the temperature of water in boilers, manufacturers install thermostats and thermostats on their products. If these devices fail, the water in the tank will boil, which will lead to a noticeable increase in pressure and even greater heating of the liquid.

The avalanche-like course of the described process will ultimately lead to the formation of a crack in the walls of the storage tank, through which some of the hot water will pour out. The free space will immediately be filled with cold water coming from the water supply system.

This will lead to instant boiling of all the liquid in the tank, accompanied by the release of a huge amount of steam and, as a consequence, an explosion of the container, expanding under its influence.

The safety valve will not allow the pressure to exceed permissible values by discharging part of the liquid into the sewer system.

In addition to ensuring the integrity of the equipment, when critical situations arise, safety valves perform several other important functions, which include:

- preventing heated water from returning to the water supply from the boiler;

- smoothing out pressure surges in cold water at the entrance to the water heater tank, which prevents the possibility of water hammer;

- dumping excess liquid from the tank at the moment of a critical increase in temperature and pressure;

- providing the ability to drain water from the storage tank of the water heater for scheduled preventative maintenance and necessary repairs.

The valves that manufacturers currently produce can have a variety of designs. Along with the main product, the kit may include pressure gauges, various shut-off valves, etc.

When choosing a safety valve for a boiler, you should take into account the fact that the purchased device must correspond to the parameters of the hot water supply system in use in the house.

The diagram clearly shows the design of a safety valve for a water heater (boiler), all elements of which are equipped with signs with inscriptions

Why do you need a boiler safety valve?

Mounting a safety valve prevents pressure from rising above the permitted level inside the unit. Why is blood pressure rising? When heated, water has the ability to expand, increasing in volume.

- Due to the fact that the boiler is a clogged apparatus, there is no outlet for the excess volume, the taps are closed - a check valve is installed at the water inlet.

- Therefore, heating the water causes an increase in pressure. If the tank exceeds its strength limits, it can explode.

- To prevent this from happening, a check valve is installed. What if you don’t install a safety valve, but just remove the check valve?

With high and stable pressure in such pipe lines, the operation will not last long. However, it is wrong to do this and here is what causes it: the pressure in water pipes is not often constant.

It often happens that water flows from the tap in a thin stream. In this form, water from the boiler, spurred by pressure, will be released into the water supply. The shadows will be without water, they will heat the air for a short time and then burn out.

The worst thing is that when they heat up, and the increased pressure brings a lot of water, it will fall on the heated heaters, which will evaporate the water, this will cause a sharp increase in pressure, which will cause the tank to explode. The scalding water will enter the room and bring bad consequences.

Checking for serviceability

At home, you can quite easily find out whether the safety valve installed on the water heater is working properly. To do this, you just need to set the temperature regulator to the maximum value and open the hot water tap. If, after the water in the boiler has heated to the required temperature, excess liquid begins to flow out through the safety valve, then it is quite suitable for operation. If water does not flow through the valve, it is most likely faulty.

Safety valve device

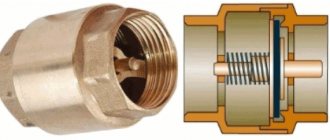

Structurally, the device accommodates a simple filling. It contains two cylinders that have a common cavity and are located orthogonally to one another.

- The larger cylinder contains a poppet-shaped valve in the middle, pressed by a spring, due to which the liquid moves one way. It looks like a shut-off valve. At the edges of the cylinder there is a thread element, due to which the device is connected to the boiler and water pipe.

- A small cylinder is placed orthogonally. From the outside, the two sides are closed with plugs, and the body is equipped with a drain pipe. This cylinder is also equipped with a bypass valve, but the direction of its action is opposite.

Often there is a lever on the valve - due to it, the drain can be forced to open.

Installation and adjustment of the safety unit

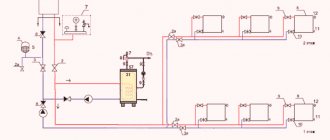

Anyone can install a safety valve on a boiler without the help of a plumber. The correct installation diagram indicates that the safety unit is attached to the cold water inlet pipe of the water heater. Below are taps, filters and other piping elements.

The valve is installed on the water heater in the following sequence:

- The safety valve is installed directly on the cold water inlet pipe going inside the water heater. Often a detachable adapter is placed between them - “American” for ease of dismantling during maintenance.

- Fum tape is wound onto the threads of the pipe or adapter to seal the connection. The safety assembly is screwed on so that the arrow on the body is directed towards the boiler.

- When screwing the safety valve onto the water heater, you need to stop when you feel a stop. On cheap models there is no mounting fuse. The part is screwed four turns. You can't turn it anymore. The thread of the pipe will close the channel of the fitting for draining the water.

After installation, it is worth looking inside the housing from the check valve side. Inside the hole you can see the seat and the locking mechanism plate itself. To check the functionality, press the plate with a finger or pencil. It should move inward, and when released, return to its original place.

When the entire circuit is assembled, begin adjusting the security unit:

- The water heater is filled with water, voltage is applied and the thermostat is set to the maximum temperature. You have to wait until complete heating occurs, and the automation will turn off the heating element.

- Drops of liquid should appear from the fitting. If they are not there, turn the adjusting screw until a positive result is obtained.

- After adjustment, use the lever to bleed some water from the tank, after which the mechanism is returned to the closed state. The drip from the fitting will stop. A new portion of water will flow inside the tank. The heating element will heat it up, and the liquid will again begin to drip from the fitting.

- The mechanism, adjusted to the maximum temperature, will always work when the permissible limit is exceeded. Now you can set a lower operating temperature on the regulator, for example, 50–60°C. When this threshold is reached, liquid will not drip from the fitting.

The safety group is checked for functionality of the forced drain lever and operation at maximum temperature once a month. If the adjusting screw is missing and the mechanism does not operate according to the required parameters, the part is replaced.

Working principle of safety valve

The device operates according to a very simplified method. Being under the pressure of water from the pipes, the poppet valve opens slightly and water flows into the heater tank.

When the tank is full and the pressure in it exceeds the external pressure, the valve will close.

- Subsequently, when the water begins to gradually disappear, its amount will gradually be replenished.

- The second valve has an even more intense spiral and is required for even greater pressure in the water heater tank, and it will increase as the water heats up.

- When the pressure reaches the limit level, the spring will close and the hole will open, allowing excess liquid to escape through it. As a result, the pressure will level out to normal.

Service

During use, depending on the intensity of hot water consumption, it is necessary to flush the safety valve for the boiler from scale, rust fragments from pipes and other foreign matter in the water. To do this, you just need to sometimes open the emergency discharge channel of excess liquid using a lever.

This mechanism should not be used to empty the water heater. Particles settling at the bottom of the tank passing through the bleed spring will get stuck and interfere with its further normal operation.

By following all the rules for using the water heater and ensuring that the safety valve is working properly, you will confidently and safely use hot water.

Types of safety valves

The protective valve to the boiler will be able to operate in normal and unusual conditions. Conventional safety valves are similar in appearance, but differ only in the external elements responsible for their suitability for operation.

Let's look at product variations:

- A product with a release lever secured with a screw;

- Lever model without screw. They make it possible to check the performance of the device every month;

- The valve with screw has a long fitting of a non-linear figure. The hose can be easily put on it and there is enough protrusion to tighten the clamp;

- The model without a screw has a short fitting with a thickening on the edge. It will be difficult to pull the hose onto this product and fix it;

- A relief valve without a forced pressure relief flag - an option with a threaded cap. If necessary, it can be unscrewed and cleaned from various blockages;

- A valve without a flag is a non-dismountable type. This is the simplest of the options, but the advantage is the low price.

These types are suitable for water heaters with a volume of 50-60 liters. For large-capacity boilers, you will need other options with built-in additional devices: a ball valve or a pressure gauge that controls the pressure.

These devices have a fitting for draining water with a factory thread, so the fasteners are durable. The mentioned options offer high quality and reliability, which is why they are expensive.

Classification by tank volume

There are various models of water heater check valve valves that are suitable in volume for the following boilers:

- small ones are installed on tanks up to 50 liters;

- middle valves are mounted on boilers with a volume of 50–200 liters;

- tanks with a capacity of more than 200 liters are equipped with large valves.

Valve designs of small and medium sizes are characterized by not very high pressure ratings and low prices. Therefore, replacing failed shut-off equipment of these types is not difficult.

In large tanks, water heater check valves are installed, the pressure of which is rated at 7 bar. Such equipment is equipped with a special nozzle for connection to the water supply system.

How to choose a safety valve

Water heaters come to retail outlets with a built-in safety valve. Therefore, when purchasing a new product, especially from a brand, you do not need to worry about the device.

The need to purchase appears when the following occurs:

- The valve is broken or worn out;

- The fuse was lost during a move;

- I received a used boiler without piping parts.

Having examined the boiler model, it will not be difficult to select a new part. In the instructions for use you can find the numbers for the highest pressure; they must correspond to the engraved numbers on the casing of the new device.

The thread size must correspond to the dimensions of the fitting and the cold water pipe. To install the device on a pipe, you will need a linen thread or a rubber gasket when using a bending liner.

Rules and standards

The use of safety valves is regulated by national and industry standards, operating rules and technical instructions.

For pressure vessels, the following regulatory documents apply:

- (PB 03-576-03). Safety rules for pressure vessels and installations.

- "Boiler & Pressure Vessel Code" American standard.

- GOST 24570-81 National standard for safety valves.

Systems protected by emergency valves, in the event of abnormal operation or an accident, pose a significant threat to industrial and public safety. Therefore, their design, configuration, installation, and operation are supervised by authorized bodies that monitor compliance with the requirements of rules and standards at all stages of the equipment life cycle. In the Russian Federation, this is entrusted to Rostekhnadzor.

Safety valve mounting options

Installing a safety valve is considered one of the steps to install a boiler. For this you will need: a polypropylene pipe, a safety valve, a fitting, a drain tap and a coupling with a union nut.

You will also need polypropylene fittings to move the water supply line to the wall.

- The more sophisticated security option is not used all the time. Some installers believe that only this valve is needed.

- This is an economical installation package. If splitters and other fittings are not used, the device is fixed to the boiler tube.

- All that remains is to drain the water through the hole in the device. To this end, take a bendable plastic tube of the required size.

- One edge of the tube is pulled onto a small tap pipe, the other is pulled into the drainpipe.

- Unprudent homeowners place a straw in a bucket or jar, but this is the wrong decision.

Such a container will only help against leakage of drops. If there is an accident, the volume of water coming from the tube will increase and there will not be enough dishes.

The best solution is to lead the drainage pipe into the sewer through an overlay into a tee or an individual entrance.

With release handle

One of the most common types of check valves that are equipped with water heaters is a valve with a release handle. Let's talk briefly about its structure and principle of operation.

The design of a check valve with a release handle has the following elements: a body, a water release fitting, a forced pressure release handle, a safety valve spring and a check valve spring.

Under the influence of water pressure, the spring of the check valve is compressed, as a result of which the poppet valve rotates and allows water access to the tank. Once enough water has been collected, the check valve returns to its original position.

The release handle is needed to, if necessary, forcefully relieve pressure inside the system. As soon as the pressure exceeds the permissible maximum, a safety valve is activated, through which excess water is discharged, thereby normalizing the pressure.

Photo of a safety valve for a water heater

Operating rules

- It is not allowed to install shut-off mechanisms in the area between the safety valve and the entrance to the boiler.

- The safety valve must be fixed at a distance of no more than 2 meters from the entrance to the water heater.

- Using a flexible drain tube made of clear material will allow you to check the operation of the safety valve by visual inspection alone.