In private homes, cottages, sports complexes and hotels, an indirect heating boiler is often used - the water heater operates without being connected to a centralized water supply. This equipment copes with heating large volumes of water, easily maintains the desired temperature and ensures an uninterrupted supply of hot flow.

In a word, if you are looking for a budget water heater to go with a single-circuit boiler, consider installing a BKN in your home. And to simplify the task of choosing, we suggest that you familiarize yourself with the criteria for purchasing a boiler, the principle of its operation and connection diagrams.

Principle of operation

The heart of any home is the heating boiler. During the cold season, it provides the home with warmth. Among the variety of models of heating equipment, two-circuit devices that heat the coolant and water in the hot water system are often distinguished. But when you turn on the tap, the equipment stops heating the rooms and directs all its energy to heating water. This is why using hot water for a long time can cause the house to freeze.

An example of connecting a double-circuit boiler Source otoplenie-gid.ru

It is much more economical and efficient to connect a water heater to the heating boiler. The operating principle of an indirect heating boiler is very simple: the equipment uses coolant energy to heat water. It is connected to the heating boiler, but when the water is turned on, even in several taps, the heating of the house does not stop. The equipment is a tank, inside of which there is a spiral-shaped tube (coil). The coolant flows through it, heating the water.

To understand what an indirect heating boiler is and what it is needed for, you need to imagine a large water tank with a tube located inside. The walls are equipped with a layer of insulation. Thanks to this, the water always remains warm. With such equipment, owners will be able to use hot water at any time.

A minimum amount of energy is spent to maintain the temperature of the liquid: the flow of heated coolant is divided: the first part is supplied to the coil, and the second to the heating system. The waste liquid is returned to the boiler for further heating. Installing an indirect heating boiler only slightly increases fuel consumption.

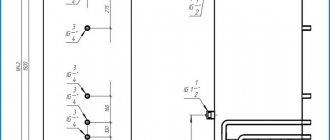

Connection diagram for an indirect heating boiler Source oteple.com

Connection on the water supply side

If the water collection points are located close to the heating tank, the connection is made according to the standard diagram presented below. Let us explain the functions of some elements:

- It is recommended to use a pressure reducer for pressure surges above 6 Bar;

- a check valve on the cold water supply prevents the tank from emptying into the water main;

- the expansion tank compensates for the increase in the volume of heated liquid;

- a safety valve set at 7 bar discharges water into the sewer if the pressure rises to a critical level;

- The drain valve is used to drain water using the method of communicating vessels.

It is important to leave the drain line filled - then when the drain valve is opened, the water will flow out according to the law of communicating vessels

Attention! Use in the piping an expansion tank designed for water supply systems and designed for higher pressure - 6...8 Bar. The container is not suitable for heating - the membrane will quickly become unusable.

When consumers are away from the boiler, it is worth installing a recirculation line with an additional pump and check valve. If your heater model does not have a separate fitting for connecting this line, simply cut the return line into the cold water inlet line.

Before starting a system with a water heater of the “tank inside the tank” type, you must first fill the internal tank with sanitary water, only then pump in the coolant and perform pressure testing. The master will tell you the details in the video:

Advantages

An indirect heating water heater is a common equipment for country houses. Its popularity is due to several advantages:

- efficiency;

- constant maintenance of high water temperature;

- heating a large volume of liquid in a short time;

- possibility of connecting several water intake points;

- if necessary, several heat sources are connected;

- work with any heating boilers.

An indirect heating boiler is a universal equipment; it can be connected to any heating boiler (solid fuel, electric, gas, combined). In this case, the coolant does not come into contact with the heated liquid. Some people exchange water for a non-freezing liquid - antifreeze. This allows you to leave the house without heating during the cold season and are not afraid of freezing and cracking of pipes.

Attention! Antifreeze in the system poses a great danger to people. If there is a small crack in the coil, toxic liquid enters the water supply system. This can lead to poisoning of people. You can use propylene glycol, which is practically safe for health. But getting it into water can also cause unpleasant consequences.

Internal structure of a water heater Source teplogalaxy.ru

See also: Catalog of companies that specialize in the installation of utilities: water supply, heating and sewerage

Positive and negative characteristics

When considering the pros and cons of indirect water heating devices, we must focus on the main advantage - saving energy resources. You will have to pay separately for gas and electric boilers. The indirect water heater receives energy free of charge from the operating heating system.

Other advantages include:

- Long service life. Heating of the heat exchanger does not form solid accumulations. Scale appears when the heating element is operating, but it is not turned on all year round, but only in the summer.

- A water heater with two heat exchangers or a tank-in-tank system is characterized by high performance.

- A model with an additionally installed heating element combines two important parameters: efficiency in winter, efficiency in summer.

- Having welding experience, you can make an indirect water heater yourself.

The downside is the complexity and high cost of installation. The first heating of the container takes a long time, but then the water temperature is constantly maintained. If there is no heating element in the summer, it is impossible to get hot water.

Flaws

Before equipping your home with a hot water supply system, you need to learn as much as possible about the indirect heating boiler: what it is, how it works, what disadvantages it has. A water heater operating in conjunction with a heating boiler has few disadvantages:

- The cost of the equipment is high, so owners need to prepare for significant expenses before installing the system.

- During the warm season, the heating boiler stops functioning, which means water heating stops. Owners need to find an alternative source of hot water.

- Water heaters have a large water capacity and impressive dimensions, so they will require a spacious room to accommodate them.

To provide people with hot water even when the heating system is turned off, manufacturers have developed a tank with a tubular electric heater (TEN). It can heat water in warm seasons.

Indirect heating boiler with heating element Source biysk.kotel-t.ru

Calculation of tank capacity

In order to calculate the required volume of the boiler, it is necessary to determine how much hot water is consumed at a time or in a short period of time.

When taking readings, be guided by the morning time, when children are getting ready for school or kindergarten, and adults are going to work. After all, at this time everyone takes a shower, washes their face, brushes their teeth, which means that the most water is consumed at this time of day. If for some reason you do not have the opportunity to take readings, then you can use the table, which shows the hot water consumption indicators for various devices.

| Name of water consumer | Water consumption, l | Average temperature of consumed water, C° | Water consumption at 60 C°, l |

| Kitchen sink | 10-20 | 50 | 8-16 |

| Bath | 150-180 | 40 | 90-180 |

| Shower | 30-50 | 37 | 16-27 |

| Sink | 10-15 | 37 | 5-8 |

| Hand wash | 2-5 | 37 | 1-3 |

Having calculated these measurements, a reserve volume of 10-15% must be added to the resulting figure. This way you will get a boiler volume that will be optimal for your family.

How to choose

The combined operation of a heating boiler and an indirect heating boiler ensures rapid heating of water at minimal cost. But you can benefit from installing such equipment only if you select the right water heater.

The main criterion for choosing equipment is the volume of the tank. It depends on the number of people taking showers and on the number of water intake points. All schemes for determining the volume of the tank are designed for the average resident of a private house. When selecting equipment, it is necessary to analyze the habits of household members and only then find the best option.

Scheme for choosing the volume of a water heater for a house or apartment Source cs11.pikabu.ru

Another important selection criterion is the material used to make the coil and the tank itself. The most efficient heating element is made of brass. It has high thermal conductivity and quickly heats water.

When producing a tank, it is necessary to ensure that the metal is protected from corrosion. The interior of inexpensive tanks is coated with enamel. But such a protective layer is vulnerable; it can deteriorate over time. Durable tanks are made of stainless steel.

Stainless steel tank with copper heating element Source i.ytimg.com

Material

The material used in the manufacture of the tank is of great importance. Currently there are 3 varieties.

Enameled tank

It is very popular due to its availability and low cost.

- May contain silver ions, but they make sense as a disinfecting element only if the design involves the use of coils.

- Otherwise, they will be useless, since the inner surface of the enameled tank will not come into contact with sanitary water, which will be used for washing.

- This material is relatively protected from corrosion, but it can still occur.

Welding seams are the most vulnerable, since they, as a rule, are not treated with a special compound, so the spread of rust often begins from them.

Stainless steel

This option is more reliable compared to the previous one, but it is more expensive and weighs a little more. However, it is also in high demand.

- It is perfectly protected from corrosion, which allows you to completely protect the structure from rust.

- Welding seams, as a rule, are also not processed, as in the previous version, so special attention is required for them.

Titanium coating

The most expensive material used to make a water heater tank. It is much better than stainless steel, stronger and more resistant to high temperatures. Otherwise the characteristics are very similar.

If you decide to use an enameled tank, you should pay attention to the presence of a magnesium anode; it will protect the surface from rust.

Connection diagram

Connecting an indirect heating boiler to a single-circuit boiler of any type is carried out according to the same schemes: with or without priority. In the first case, the coolant, if necessary, changes the direction of movement and stops heating the house, and all the energy of the boiler is directed to heating. This method allows you to quickly heat a large volume of water.

At the same time, heating of the house is stopped. But a boiler, unlike a double-circuit boiler, heats the water for a short time and the rooms do not have time to cool down.

Features of connecting an indirect heating boiler depend on the pipe material:

- polypropylene;

- metal-plastic;

- steel.

The easiest way is to connect the equipment to polypropylene communications that are not sewn into the walls. In this case, the technician will have to cut the pipe, install tees, and use couplings to connect the pipes going to the boiler.

To connect to hidden polypropylene communications, it is necessary to additionally install pipes going to the pipes in the walls.

There is no technology for concealed installation of metal-plastic water supply systems, so the connection will be identical to the connection of polypropylene open communications.

Correctly installed indirect heating boiler Source www.o-vannoy.ru

Determining the efficiency of a new water heater

How to start using your new boiler economically and correctly? Experts focus on determining its energy efficiency when purchasing.

General rules

Before purchasing equipment, the user needs:

- compare the energy efficiency of expensive and budget models in the store to establish the return on investment of the equipment;

- clarify that the energy efficiency class includes efficiency, losses per hour during heating and maintaining temperature, circulation. Information is indicated in the manufacturer's booklet;

- take into account the displacement of the container, the operating speed of the heating element, the type of installation to clarify the total costs.

Interesting to know! On European boiler models, energy efficiency has been indicated since 2013, on American ones - since 2009.

Calculation of annual operating costs

For calculations, you will need information about the energy efficiency class, type and cost of the coolant. Further calculations are performed using the formula:

- for gas models, the number of days per year is multiplied by energy efficiency and the cost of a cubic meter of gas;

- for electric boilers, the number of days per year is multiplied by energy efficiency and the cost of kW/hour.

Interesting to know! The DOE test for water heaters takes into account cold (15 degrees) and hot (60 degrees) temperatures and determines the unit's performance for a family of 3 as 240 liters per day.

Heating element power as a saving factor

The greater the power of the heating element, the faster the water will heat up. Keep in mind that in houses with a single-phase wiring diagram, from 7 to 10 kW of power are allocated. A high-performance water heater will lead to increased load on the network, huge energy costs and tripping of circuit breakers.

Video description

Connecting the boiler in the video:

When installing a water heater, you must first choose the correct location in accordance with the requirements:

- Quick access to water supply connections for quick repair work.

- Proximity of communications.

- Availability of a strong load-bearing wall for mounting wall-mounted models. In this case, the distance from the fasteners to the ceiling should be 15–20 cm.

Options for placing a water heater Source legkovmeste.ru

Installation of a boiler for heating

Installation of a heat supply circuit using a water heater as a heating source is performed as follows:

- Select a location and prepare it for installing the water heater. The site must have a flat horizontal surface measuring at least 1x1 m.

- The foundation for structures with a volume of more than 200 liters is made of concrete, reinforced with reinforcement.

- The water heater structure is installed in a strictly vertical position.

- I am installing an electric circulation pump.

- Perform pipe piping. The outlet of the water heater for heating is connected to the electric pump, and the input is connected to the return line.

- Shut-off and control equipment and security system monitoring sensors are installed.

- The device is connected to the power supply through a separate panel with a machine and an RCD.

- After assembling the circuit, perform hydraulic pressure testing of the heating system and check the functionality of the electrical heating circuit of the heating element.

Boiler for electric heating - service instructions

Servicing electric boilers in heat supply systems is no different from performing the required operations for servicing a heating element device. The heating boiler will work well if you adhere to the following rules:

- Monitor the integrity of the installation’s thermal insulation monthly.

- Observe the temperature difference of the coolant; it should not exceed 15-20 C.

- Monitor the tightness of pipe connections for leaks.

- Every year before the heating season, perform system maintenance by flushing the internal circuit and replacing gaskets.

- They monitor the operating parameters of the electrical network; if there are frequent failures in the electrical lines, you need to install a stabilizer to preserve the electronic control unit.

To select the heating power from the boiler, the calculation is 1 kW per 10 m2 of heated room. This formula is well applicable in systems located in the central climatic region of Russia. Next, you will need to decide on the minimum tank volume. Provided that the minimum level of storage capacity is 5 kW and the temperature difference between forward and return water is -20 C, the volume of the tank will be:

V=5/20=0.25 m3 or 250 l

Possible mistakes

When connecting an indirect heating boiler, people make several common mistakes:

- The main mistake is the incorrect placement of the water heater in the house. The device installed far from the heat source requires pipes to be laid to it. This leads to increased costs. At the same time, the coolant going to the boiler cools in the pipeline.

- Incorrect connection of the cold water outlet will reduce the efficiency of the device. It is optimal to place the coolant inlet at the top of the device, and the outlet at the bottom.

To increase the service life of the system, it is necessary to correctly connect and then perform periodic maintenance of the equipment. It is important to clean the pump and maintain its performance.

Option for correct placement and connection of a water heater Source opt-953360.ssl.1c-bitrix-cdn.ru