What is indirect heating, and how to implement it yourself? The operating concept is the same as that of thermal power plants (CHP). In the process of solving the main problem (operating steam generators), “extra” thermal energy appears. It can be irresponsibly released into the atmosphere, or used to organize heating for the neighborhood.

The indirect heating unit works the same way. We take a heat source (which exists regardless of your need to extract additional benefit from it), and “take away” part of the thermal energy from it.

In this way, residents of communal apartments without hot water supply obtained hot water (mainly for washing dishes, sometimes for taking a shower). To do this, in collaboration with neighbors, we made an indirect heating boiler with our own hands. The solution is simple, but requires at least a gas torch for welding pipes. Or the unit was manufactured using the “left” method at the main place of work (usually a factory or repair shop).

The simplest heat exchanger

A homemade heater looks like this:

A larger diameter shell is welded onto the central heating pipe. The result is a sealed vessel with hot coolant flowing inside it. On opposite sides of the outer pipe (in fact, this is a boiler), flanges are installed for supplying (draining) cold water. When the coolant is hot enough, the water in the boiler heats up quickly. After which the top tap can be opened and the hot water supply can be used until the hot water is replaced by cold.

If we leave aside the legality of re-equipping the collective heating network (there is hardly any serious liability for this), the system works effectively. Hot water is conditionally free, minus one-time investments in materials, and a bottle of strong drink for the welder.

If you install such a instantaneous water heater with your own hands in a private household, there will be no conventional problems.

The only limitation is the volume of the outer container. In real time, the water will not heat up; the reserve of thermal energy in the heating pipe is too small. Therefore, the system works cyclically: heating - use - heating. The higher the diameter ratio (or the longer the pipe), the greater the supply of hot water. Accordingly, the longer it will take to warm up.

Another serious drawback: in the summer (with the heating turned off) such heaters do not work.

DIY assembly and connection instructions

The boiler is assembled after preparing all the components.

Holes are drilled in the tank: for the water filling tap, coolant inlet and outlet. If you decide to install a heating element, then a hole is also made for it at the bottom.

- Next, a coil is installed in the container, and the tubes are passed into the holes using special adapters, which it is advisable to weld into the boiler body. Other options are possible, but the main thing is that the holes are sealed hermetically.

- The legs are welded to the bottom (if provided).

- A heating element is installed if this was planned.

- Then the coil is connected to the heating system circuit, according to the diagram.

- A pipe for cold water supply and a tap for heated water are connected. You can immediately make connections to water collection points - to the kitchen and bathroom.

Thermal insulation

To keep the water warm for a long time, the container is thermally insulated. For it, foiled mineral wool or polyurethane foam is used. The boiler body must be completely covered in thermal insulation material - the efficiency of the device will directly depend on this. To make the insulation look neat, you can place a casing made of thin sheet metal (for example, galvanized) on top of it - you get something similar to a sandwich pipe. A visual example is in the first picture of the article.

The principle of operation of a wood boiler

Wood boiler

Another type of indirect heating water heater is wood-burning titanium, which will only require the cost of creating a supply of solid fuel. This boiler has a samovar design and operates autonomously from all power sources, so it is ideal for installation in a private home.

The principle of operation of a titanium boiler

To build such a device with your own hands, you must first build a stove, which will heat the water inside the tank. Such a boiler can have a round or square tank, and it can be installed either on a small stove made of brick or on a stove like a potbelly stove welded from a piece of metal pipe of a sufficiently large diameter.

The second option is more complicated due to the fact that sections of metal will have to be cut out of the pipe to install firebox and vent doors in these places. In addition, using welding inside the pipe, you need to strengthen the brackets for laying the grate. The bottom and top of the stove pipe are welded with solid sheets of metal. A round hole is made in the upper part, a chimney pipe is welded into it, which will pass directly through the container with water and heat it to the desired temperature.

The tank must also be welded to the furnace lid.

If you decide to make the stove out of brick, the boiler tank can be either round or square. The top of the stove is covered with a metal panel, into which a chimney pipe is also welded. Next, a container without a bottom (water tank) is hermetically welded to the upper metal plane of the furnace.

The chimney, after passing through the water tank, is discharged to the street.

Two or three pipes with valves must be welded into the tank: for water inlet, for outlet to the mixer tap and to the shower.

Water can enter the boiler either from the main line or be filled in manually. In addition, a water storage tank can be installed above the boiler, from which water can also flow into the heating tank.

If such a water heater is installed in the bathroom, it will not only provide hot water, but also heat the room.

Anyone who has used geysers or flow-through heaters powered by electricity is familiar with the situation that when the tap opens, you have to wait a while for hot water to flow. When installing an indirect heating water heater, this factor is completely eliminated - by opening the tap, you can immediately get heated water.

Compared to water heaters running on gas or electricity, this type of boiler will help you save on energy.

Improved design

How to improve heat transfer? That's right, it is necessary to increase the contact area. Of course, the material of the inner pipe is also important; a copper pipe transfers heat much more efficiently. But in this design, the emphasis is on saving, so we make an indirect heating boiler with our own hands from steel.

To improve the heat transfer coefficient, several schemes can be used:

- We have already considered the classic version.

- The “U” shape with the same overall length improves the performance by almost half.

- Double "U" guarantees twice the efficiency

Important according to paragraphs 2 and 3:

Thermodynamics is not a linear science. With an increase in the exchange area in such imperfect structures as a “pipe-in-pipe” boiler, the efficiency changes differentially.

- Creation of additional volume due to the formation of a kind of “fold” in the outer pipe. Allows more secondary heating water to be stored.

- The coil significantly increases the length of the device, while maintaining unchanged dimensions.

- The so-called “turbo” circuit. The complex design of the primary pipe (with the coolant) increases the time it takes for heat to pass through the outer shell.

Useful tips from professionals

There are a number of important nuances, without knowledge and compliance with which connecting the boiler to the water supply will be incorrect. You should know that the hot water supply system does not need to be equipped with any additional elements, with the exception of a shut-off valve. It is installed on the boiler pipe.

The cold water pipe is installed after preliminary installation of the tee. The tap for draining excess cold water from the water heater cuts into the side outlet of the splitter. A return valve and a shut-off valve are also connected to the tee. The latter is connected to the water supply.

How to drain water from a water heater

When connecting the tank to the water supply, do not do the following:

- open the protective window when the heater is on;

- test an empty boiler. The tank must first be filled with water, otherwise the heating element may burn out;

- drain the water without first turning off the heater;

- equip the water heater with parts from other boilers. The exception is the same models, as well as tanks with compatible spare parts.

Large storage systems

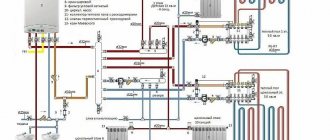

We found out what the main disadvantage of the “pipe-in-pipe” water heating element is. Indirect heating takes too long. Since increasing heat transfer is difficult, you can use a larger container to heat water. Then you can “conjure” the heat exchanger. The best option in the illustration: a coil inside a wide body.

The design is a tank of the required capacity (50, 100, 200 liters), inside of which there is a coil (the longer, the more effective the heating). The heat source does not matter: usually it is the room heating circuit. The water in the sanitary (internal) tank warms up quite quickly. The only problem is the uneven distribution of heat. A “cold” area remains at the bottom of the container. Despite the correct selection of heated water (receiving pipe from above), the cold area does not allow the entire volume to warm up.

When making it yourself, it is recommended to use a stainless steel tank and a copper coil. The additional costs will be offset by the high efficiency of the system.

Moreover, materials are not in short supply. The tank will fit from an old activator-type washing machine. A copper tube is sold at any plumbing store.

Another option: “tank in tank”. If you are faced with the question of how to make a boiler with your own hands, take a closer look at this diagram.

The internal container (in which indirect heating will occur) is selected with corrugated walls (preferably). This means there is a larger heat exchange area. And the primary heating water flows through an external point. If you cooled a pan of hot compote in a bowl of cold water, the principle of operation of the heater is clear.

Of course, such a system is more difficult to implement, but the efficiency will be higher.

DIY boiler body from a gas cylinder

The body of the product is made of steel. The walls can be thin, since the water temperature should not exceed 70 degrees. A homemade boiler can be made from a gas cylinder or a plastic barrel. To clean the tank, you will need to weld a large flange on one end. But this is not a prerequisite.

Required holes in the housing:

- Heating connections;

- Hot water supply;

- Hot water circulation;

- Supply of tap fluid;

- heating element and magnesium anode;

- Temperature sensors.

The heat exchanger can be located below or along the entire surface of the internal structure. The hot water outlet is located at the top, and a little lower there is a pipe for circulation. Cold water is supplied from below. The heating element must always be in water, so it is mounted at the bottom. Temperature sensors occupy a place in the middle of the structure.

A metal pipe is welded to the holes that work with water and sensors. The diameter of all pipes must be the same. A large tube is provided under the anode; a cover, bolt and anode are mounted on it.

Before buying a boiler, you need to ask the seller for a certificate that confirms its quality

The heat exchanger is secured with a clamp or nuts. The first option is considered more reliable. It is not necessary to install a drain. For these purposes, you can use a tee, which is mounted on the liquid supply.

General rules for the manufacture of indirect heating boilers

- A heat-insulating shell is required. Otherwise, the heated water will rapidly cool through the outer walls. The best option is to install the working container in a larger barrel and blow out the gap between the walls with construction foam.

- You can wrap the container in thermal insulating building materials, although it doesn’t look as aesthetically pleasing (but it’s inexpensive). If the boiler is located in the boiler room, you can save money.

- The inner pipe (if a coil design is used) must be corrosion-resistant. Once the structure is assembled, access for maintenance will be difficult.

- When using electrochemical pairs (for example, aluminum tank + copper tube), the connection flanges must be insulated with neutral gaskets.

- It is advisable to install an inspection window in the wall of the outer tank through which cleaning or maintenance is carried out.

Installation procedure

Installation of an indirect heating boiler, in which the coolant is supplied through a coil, begins with its installation. A thread is cut at the ends of the coil, onto which a lock nut is screwed, and then they are inserted into the prepared holes in the tank so that the lock nuts have a stop.

The threaded part of the coil should extend beyond the surface of the tank. Rubber gaskets are put on them, and threaded couplings are screwed on top of them. As a result of these manipulations, the coil is securely fixed, and it becomes possible to connect it to the heating system.

The next stage of work is to connect the tank to cold water and drain the hot water tap to the required location. The final part of the installation will be insulating the water heater, but before that you should check the tightness of all connections.

This way you can provide your home with enough hot water at minimal cost. The cost of purchased materials will cost a small amount, especially if you compare it with industrially manufactured models. The price of a factory-made boiler starts from 20 thousand rubles for models from Drazice OKC.

We have selected eight more useful articles for you, see below.

- How to weld polypropylene pipes: instructions and tools

- Copper pipes and fittings for water supply - quality guarantee for 200 years!

- PVC pipes and fittings for water supply: product descriptions, current prices and installation

- How to install water pipes in a private house with your own hands

- Have you decided to install a new faucet in your kitchen? We'll show you how to do it right

- Which pipes are best to choose for water supply in a private house?

- Installation of the washing machine and connection to the water supply

- Let's figure out how to increase the working pressure in the water supply system: reasons for the decrease and solutions

Similar articles:

- Indirect heating boiler device and principle of operation

- Heating element for a washing machine: tips for choosing, instructions for replacing it yourself

- Do-it-yourself garage stove, homemade stoves and manufacturing diagrams

- Do-it-yourself pipe bender for profile pipes, homemade options

Available materials

We have already talked about stainless steel tanks from old washing machines. However, finding such a blank is not easy. A discarded 100 liter propane tank can be an excellent donor. It doesn’t hold pressure (that’s why it was written off), but it will still serve as a water tank. Of course, a gas cylinder boiler must be thoroughly cleaned (especially from the inside) and painted with high-quality waterproof enamel.

No industrial equipment is required for production. All you need is a grinder and a welding machine. The upper part is cut off, then heating fittings are formed in it.

If you have free access to other materials, you can make the heater even from stainless steel sheets. You can see how to make an indirect heating boiler with your own hands in the video (watch below).

Perhaps the aesthetics suffer, but the quality and durability of the manufactured heater is no worse than the factory one.

- We already know that in the warm season, when the heating boiler is not working, indirect heaters remain out of business. In this case, an electric heating element built into the tank as a backup element will help.

- Another option for obtaining hot water in the summer is to install a second heat exchange circuit connected to solar heating systems.

- As a result, you can assemble a 3 in 1 heating system. From a heating boiler (regardless of the type of fuel), from an electric heating element and from solar energy. If two of the three energy sources disappear, you will still be able to provide your home with hot water.

Preparing the tank for water heater assembly

To make an indirect type boiler, you can use a new or old gas cylinder. This container is made of thick stainless steel 3-4 mm thick and is perfect for working with hot water.

Before assembling the heating structure, you will need to carefully prepare the cylinder. To do this, the product is cut in half using a grinder. The inner surface of the container is cleaned using an angle grinder with an appropriate attachment.

Before assembling the boiler, the cylinder must be opened and the inner surface cleaned

After this, the inside of the cylinder is washed, dried and coated with nitro primer paint. This work must be carried out without fail, otherwise after putting the boiler into operation, the heated water will smell like gas.

When using a tank from other metal containers, preparation is carried out according to a similar scheme.

Electric indirect heater

The use of heating elements does not apply to indirect heating methods, since there is direct contact of water with the primary heat source. An exception is the induction water heater. The liquid receives energy virtually, as it were, without touching the internal thermoelement. In fact, it is not in the design at all.

A do-it-yourself instantaneous water heater is made according to the principle of induction hobs. Only instead of a pan of water, a metal pipe is heated.

The main advantage of the system is that heating occurs not due to direct thermal contact with a source of electrical energy, but with the help of eddy currents. Losses on the heat transfer coefficient are minimal, efficiency tends to 100%. At the same time, both the metal pipe and the liquid itself are heated (if it is sufficiently thermally conductive). In addition, flow-through induction heaters are significantly safer than boilers with a traditional electric heater: there is no contact of water with an element connected to the electrical network.

The disadvantage is obvious: heating requires an electrical connection. That is, the option of indirect heating using a wood-burning (gas) boiler does not work. The room must be electrified.

Important nuances

For good boiler operation, the number and location of heaters in the tank is important. It is recommended to fix them one above the other, at the same distance from each other and from the bottom. According to physical laws, warm water rises, flows to the back wall, smoothly falls, and is replaced by an even hotter stream.

Constant movement helps maintain the temperature and heat the entire volume evenly.

Number of heating elements

The number of heating elements in the boiler depends on their power and the desired performance of the device. The standard value for household heaters is 2 kW. They use 3 such elements (6 kW in total) to heat water with a volume of 300 liters to 100° in 3 hours. Based on this, you can calculate how many heating elements are needed for a homemade water heater. The more there are, the faster the device copes with the task.

If you are going to consume hot water in large quantities, then it is better to make a model with two heating elements.

Volume of the tank

According to statistics, a resident of an apartment uses 100-400 liters of water every day. When making a boiler, you need to take into account the number of people who will use it and the frequency of use. The minimum capacity of the container is 30 liters. You need to remember that the larger the water heater, the longer it takes to heat up.

Other details

Safety should be considered during the manufacture of the device and its operation. Helpful Tips:

- If the water circulates naturally in the boiler, you need to install a temperature sensor, which will turn off the heating element if it overheats.

- It is safer to connect the device not to an outlet, but to a separate line with a cable of increased cross-section.

- Exposed wires must be insulated and the entire structure grounded.

- The minimum distance from the device to the ceiling is 30 cm, and to the floor - 80 cm.

- If the connection is to a central water supply system, it is necessary to install a safety valve that reduces the pressure.

Device diagram and operating principle

Using a high frequency generator (tens of kHz), alternating current is generated in the induction coil. According to the laws of physics, at this moment a magnetic field with a constantly changing vector appears. Random eddy currents arise in a conductor exposed to a magnetic field. The molecules begin to move chaotically and the material quickly heats up.

With the help of such an inductor you can even heat a metal workpiece red-hot. Since water is flowing through the pipe, there is no excess heating.

The generator can be borrowed from a hob (induction, of course), or you can make it yourself.

Another donation option is an inverter welding machine.

Although, given the simplicity of the electrical circuit, many home craftsmen make similar generators from available radio elements.

Selection of capacity

A reservoir or storage tank basically has almost any size and volume. Another sign depends on the number of consumers and the standard consumption of hot water. For the most part, hot water consumption is about 50-70 liters per consumer, as a result of which the approximate volume of the tank for a family of four is approximately 200 liters.

How to calculate the volume of produced BKN

According to rough calculations taken into account when designing a private house, an average family of 4 people spends an average of 280 liters per day. For normal water supply to a family, you will need a 200 liter boiler. If you plan to use hot water only for showering and washing, 100-120 liters will be enough. containers.

To calculate the approximate needs for domestic hot water, use the following table:

Approximate water consumption (l)

Water consumption from the boiler (l)

When calculating the volume of the boiler, another factor is taken into account. If you plan to install a mounted BKN, then its capacity is limited to 150-160 liters, which is due to the load on the wall. If a larger volume is required, install a floor-mounted boiler.