What is it and what is it for?

Damper (from the German Schieber - damper) is a device for completely or partially blocking the movement of gases in the chimney. It has been used since the appearance of the first Russian stoves. Made from cast iron or steel. In modern engineering it has found application both in smoke exhaust structures and in ventilation systems.

How the gate works

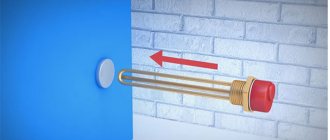

Structurally, the gate is a locking device with an adjustable valve. It is thanks to the displacement of the valve that the movement of gases in the chimney is regulated. Can be installed in chimneys of round, square and rectangular cross-section. It is a metal plate that moves inside the smoke channel in a certain way.

Gate valves can be of two types:

- Retractable. Moves in one plane back and forth.

- Rotary. Regulates air access by rotating around its axis.

In addition, valves can be manual or equipped with an electric drive. The cost of the latter is an order of magnitude higher and they are not used in chimneys.

Technical characteristics of the gate

The gate valve is a thin metal plate that is manually adjusted using a special handle. The latter is located outside the chimney pipe so that the user can manually adjust the position of the plate.

Depending on the design and type of damper, it is installed using a special metal frame, or is inserted inside the pipe and fixed with an axial rod.

The damper in the chimney performs the following functions:

- increases traction force in difficult weather conditions;

- increases the intensity of combustion in the furnace due to increased oxygen flow;

- reduces draft when there is a strong hum in the chimney during strong winds;

- saves fuel by reducing combustion intensity;

- prevents heat loss after the heater has warmed up.

To understand the purpose of this part for the chimney structure, you need to understand what a damper in a stove is. The damper provides a change in the traction force in the unit by adjusting the combustion of fuel in the firebox.

This element has an important advantage - it has low resistance relative to the remaining gas bubbles, which must be removed outside the room. When the chimney is inoperative, then the damper is completely closed. For the manufacture of gate valves for stoves and fireplaces, stainless steel is most often used - steel that is least susceptible to corrosion processes

The thickness of the metal should be one millimeter

For the manufacture of gate valves for stoves and fireplaces, stainless steel is most often used - steel that is least susceptible to corrosion processes. The thickness of the metal should be one millimeter.

This device allows you to control and regulate the draft into the smoke exhaust system. Translated from German,

gate (“schieber”) means a part that is made of a certain metal.

To eliminate these dangerous and unpleasant moments, a slide damper is installed in the smoke exhaust system. It prevents the fission of gas bubbles that should not be separated.

It is recommended to install a slide damper when heating with gas, coal, or solid fuel.

Being the main draft regulator inside the chimney, the damper regulates the combustion of fuel. To reduce the draft and reduce the intensity of the flame in the firebox, it is enough to close the slide valve. To increase traction, on the contrary, it is necessary to open it.

In fact, a gate is an ordinary metal plate that allows you to regulate traction.

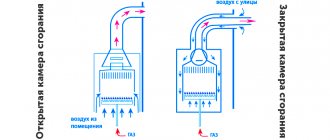

It can be installed both in single-wall and double-wall boiler systems.

As a rule, the valve is installed at the initial section of the chimney (on the first meter), since this particular section remains uninsulated.

But on the contrary, it is not recommended to install a valve on a section of a well-insulated chimney pipe. Especially when it comes to double-circuit pipes. When the metal of the inner and outer pipe expands, the gate valve may jam.

So, the main tasks of a gate valve are:

- Function of the draft regulator in the chimney.

- Partial blocking of the chimney channel section.

- Regulator of flame burning intensity in the firebox.

Types and designs

The chimney damper is available in several versions.

Retractable

It is a round or rectangular frame with a plate. The plate extends and retracts, thereby adjusting the cross-section of the chimney.

This option is most often used with brick and ceramic channels. To ensure incomplete sealing and avoid carbon monoxide poisoning, a small hole is made in the plate. The main advantage of this option is ease of installation.

Rotary throttle

A rotary or throttle valve (also known as a hog valve) is a plate made of steel or cast iron that rotates around an axis. The axis is a metal rod welded inside the chimney. Used in steel chimneys.

It is less reliable - over time, the welding fastening of the plate and axle weakens. You should avoid installing a rotary damper in the bathhouse - even when closed, this type of damper partially allows steam to pass through.

In addition, gate valves differ in material (the most common are stainless steel and cast iron) and the method of adjustment.

Differences between retractable and rotary gates

The retractable damper allows you to adjust the working cross-section of the chimney, while the rotary damper only allows you to open or close the pipe. Of course, some tricks are possible - such as securing the hog in an intermediate position in different ways, but the factory equipment does not provide for this. In addition, the rotary gate complicates mechanical cleaning of the pipe.

The hog is often installed in metal chimneys, and the retractable one is installed in brick chimneys.

Types of gate valves

Since chimneys are different, our gate valves are also different from each other. Basically, this difference lies in the form and method of functioning. There are several types of gate valves:

- A horizontal gate valve that retracts. This is the most common type of gate valve. Inside the structure there is a plate that is retractable; it is thanks to it that the cross-sectional area is regulated. Most often, this design is used for brick chimneys. To prevent the smoke channel from being blocked 100% in the closed position of the element, small holes are made in the plate. This is done for a reason, because the creation technology complies with fire safety. The peculiarity of the horizontal gate is its simplicity of design and ease of installation, as well as operating efficiency.

- Rotary gate. It also has a second name - “throttle valve”. The design is radically different from the previous version. It is made in the form of a pipe, inside of which there is a metal plate. Only it does not extend, but is located on a rotating axis. The device is equipped with a removable rotating disk, which becomes unusable over time. However, due to the rotary mechanism design, it is easy to carry out repairs and replace the part yourself. The valve is located inside the chimney pipe. The principle of operation is to rotate the plate located inside. The advantage of this gate valve design is that it is easy to operate. The home owner will not need to constantly monitor the position of the gate.

Since the second option is more difficult to implement, this chimney damper is not made by hand. Most often, it is the first option that is created – a horizontal valve. I would like to note a few more nuances. A gate valve is needed for wood-burning stoves and other heating equipment that runs on solid fuel. If we talk about gas boilers and those operating on liquid fuel, then the damper is needed more in order to protect the chimney structure from the penetration of atmospheric precipitation, debris and animals.

If we talk about installing a rotary valve for a bathhouse, then it is better not to do this. Why? During operation, the structure will partially allow steam to pass through when closed. And it is difficult to clean when open.

There are three ways to install the gate:

- Installation of the product in the fireplace insert. For this purpose, it is installed at a distance of 100 cm from the heating device (stove, fireplace, boiler), which simplifies operation.

- The pipe-to-pipe method is based on combining a gate valve with other elements of the heating system, without the use of additional fasteners.

- Installation of the valve directly in the ventilation pipe. The purpose of such manipulation is completely different. The valve is needed more to protect the channels from the penetration of foreign objects, debris, sediment and animals. This is done to protect the fan motor.

There are two options for how to proceed if you need to install a valve. The first is to simply buy a kit and carry out the installation yourself according to the manufacturer’s instructions. The second is to make a damper for the chimney yourself. We will consider options for creating both a rotary and a horizontal device.

Make it yourself or order it

The choice between a homemade or a ready-made damper should be based on the type of chimney and the degree of its readiness. So, you can install a self-made retractable structure into a ceramic or brick channel.

If we are talking about a stainless chimney that is in the process of assembly, in this case it is better to choose a finished product. The damper is usually included in the chimney system and is mounted using pipe-to-pipe technology, which I will talk about later.

In addition, it is not always possible in the store to select a product specifically for your chimney shape.

Selecting a location option

There are several ways to install a gate, each of which has both pros and cons. An important factor is what the chimney is made of. But modern masters prefer to use the three most common options:

- Installation in a fireplace insert.

- Fastening using the “pipe in pipe” method.

- Installation in a ventilation system.

The damper can be installed in the ventilation system. If the master has chosen the “pipe-to-pipe” installation type, he will not need to use special fasteners to securely fix the damper with the fireplace elements.

The location of the damper in the ventilation system completely eliminates the possibility of overheating of the fan motor during active operation. Modern manufacturers offer ready-to-install chimneys that are equipped with all the necessary devices (the slide damper is no exception). In this case, the part must be used in strict accordance with the recommendations established by the manufacturer. Otherwise, you can make a chimney damper with your own hands and at a more affordable price.

We suggest you read: What to do if concrete freezes

There are three main options for placing the damper in the chimney:

- pipe-to-pipe fastening;

- placement in a fireplace insert;

- installation in a ventilation pipe.

Brick chimney with damper

If you place a gate valve in the outlet pipe or in the furnace firebox, that is, build this element into its design, the damper is placed on a section of pipe as close as possible to the heating boiler. This guarantees ease of control and ease of turning the valve. This is explained by the fact that the handle will not touch either the portal or the cladding area. If it is located according to the “pipe to pipe” option, no additional fastenings are required for connection with other elements of the furnace.

Typically, ready-to-install chimneys are offered, which are equipped with everything necessary, including a slide valve. In this case, it is placed in the system in accordance with the manufacturer's instructions. If it is not provided for one reason or another, it is quite possible to manufacture and install this element yourself.

Do I need a damper for a chimney?

How to make a damper for a chimney. Damper chimney homemade.

Homemade stove damper in a cast iron pipe for a country stove

Making and installing a gate valve with your own hands

Required materials and tools

To independently manufacture and install any type of stainless steel gate, we will need the following tools:

- Bulgarian;

- Abrasive wheels - cutting and grinding;

- Drill;

- Tap and thread lubricant;

- Hammer;

- Pliers;

- Vise;

- Welding and electrodes;

- Kern;

- Roulette;

- Compass;

- Marker.

- Stainless steel sheet (preferably domestic brand 12×18n10t, or imported AISI304, they are more expensive, but last an order of magnitude longer).

Sheet thickness 1.5-2.5mm;

- Stainless steel tube 6mm;

- Bolts 8mm -2 pcs;

- Metal rod for the frame.

Drawing and diagrams

Before manufacturing, it is necessary to draw a drawing or diagram of the future valve.

I will give some example diagrams below:

Size calculation

You need to take measurements very carefully; a gap of even a few millimeters can cause the chimney to malfunction.

- Using a tape measure, measure the dimensions of the internal section of the channel;

- Add 20-30 mm to the obtained result - you get the outer size of the frame;

- Do not forget to make an opening in the finished valve to release gas;

- The position of the welding holes should be accurately marked.

We summarize the dimensions for the rotary gate in the table:

Automation for boiler control

The modernized control system greatly facilitates the use of domestic and industrial boiler equipment.

The main components of the control unit are:

- blower fan;

- controller;

- draft regulator;

- circulation pump.

Additionally, they can be equipped with water level sensors, fuel level and consumption sensors, pressure recorders, safety valves, as well as an alarm that is triggered if the temperature level exceeds the permissible installation range (25-50 ⁰C).

Principle of operation

The automation for heating devices works simply and clearly:

- controls the blower;

- controls the entire volume of air entering the combustion chamber;

- ensures optimal combustion mode.

Unlike previous models, in the new improved devices there is no need to constantly open the ash pan door manually and monitor the temperature using a thermometer. For this they have a draft regulator. This is a very convenient energy-dependent device that automatically opens and closes the door in accordance with the temperature of the water contained in the container.

Instead of a standard damper, a fan controlled by a controller is installed. Its task is to supply exactly as much air to the combustion chamber as is necessary for full and safe operation.

The preferred coolant temperature level is adjusted using a controller with a screen and remote control. In order to maintain the temperature in accordance with the climatic conditions of the street, you can install an additional system with remote controllers and outdoor air sensors.

The fuel is ignited using an electric glow element built into the burner.

Advantages and disadvantages of use

A small number of sensors and instruments keep the combustion process of any type of solid fuel under control, maintain the temperature set by the owner and guarantee safety.

The most important useful functions and advantages of using automation include:

- rational and economical consumption of solid fuel;

- increasing the performance of the heating device;

- ensuring safe operation;

- no need for independent combustion control;

- increasing the interval between scheduled technical checks of the device;

- constantly maintaining the temperature in the heating system at the required level;

- automatic shutdown of the boiler in case of failure of any of its parts - based on a signal from sensors.

Automated systems also have disadvantages, but they are minimal:

- high price, which directly depends on the number of available options;

- the need to purchase an uninterruptible power supply due to the energy dependence of the control unit.

Installation features

- When installing the gate at the stage of laying brickwork, the frame is placed at a height of 6-8 rows from the base of the pipe;

- The frame should stand straight, without blocking the outline of the chimney;

- In stainless steel chimneys, the valve is installed using the “pipe-to-pipe” technology. It is necessary to coordinate its dimensions with the diameter of the channel;

- An important nuance - the damper is installed on an uninsulated section of the chimney;

- The height from the firebox to the damper should not exceed 1 m (for metal channels);

- Pipe height from the floor to the valve - 1.8 - maximum 2 m (for brick);

- The damper in the grooves should move freely;

Device, classification and requirements

A chimney or chimney is a special channel used in various buildings to remove volatile combustion products of solid fuels. It is usually a straight pipe of round cross-section, as this allows for maximum draft and minimal accumulation of soot on the walls of the chimney pipe.

Various requirements apply to the gas exhaust system, such as:

- Good traction;

- Availability of thermal insulation;

- Easy installation and maintenance;

- Long service life;

- Corrosion resistance;

- Smoothness of the inner walls;

- Fire safety;

- Aesthetic appeal;

When choosing a chimney for a solid fuel boiler, you should take into account the temperature of the combustion products. Depending on this parameter, you should select the material of the chimney pipe

Modern manufacturers produce modular chimneys from materials such as:

- stainless steel;

- ceramics;

- plastic;

- glass;

Photo 1: External installation of a chimney in a country house

The temperature of the flue gases at the outlet of the TT boiler can reach 600 degrees Celsius. Therefore, a steel and ceramic chimney is quite suitable for use in conjunction with a ZOTA solid fuel heating boiler. The use of glass and plastic chimneys is not allowed, since these materials are designed for significantly lower gas temperatures.

Separately, it is worth noting the classic brick chimney. The aggressive environment that arises inside such a structure quickly renders it unusable. That is why they give way to more modern devices.

Most often, stainless steel is used as the material for the manufacture of chimney pipes. The use of steel gives such a device a number of undeniable advantages:

- has low weight compared to brick;

- easy to install and assemble;

- does not require foundation construction;

Photo 2: Installation of a ceramic chimney in a country house

Stainless steel chimneys according to the type of construction are divided into the following types:

Single wall

Such chimneys are a regular steel pipe. The advantage of this design is its low cost. The main disadvantage is the formation of condensation on the inner surface and, as a consequence, its freezing at sub-zero temperatures.

Double-walled (or double-circuit)

The design of such a chimney is a “pipe-in-pipe” design. A smaller diameter pipe is placed inside the main pipe, and the space between them is filled with heat-insulating material. The advantage of this design is the presence of thermal insulation that protects the chimney from the formation of condensation, but the disadvantage is that the price of such devices is much higher.

The chimney design in the form of a sandwich pipe has recently gained particular popularity. This design is a chimney assembled from individual meter-long pipes, the joints of which are equipped with heat-insulating material.

Photo 3: Stainless steel chimney sandwich design

Special requirements are placed on the wall thickness of a steel chimney. When used in conjunction with TT boilers, the wall thickness of the chimney should be 1 mm or more.

Ceramic chimneys are also used to remove combustion products from a solid fuel boiler. Like steel, they are resistant to high temperatures and aggressive environments. The thickness of their walls is much greater (1.5 cm), and therefore they are much heavier and require installation on a foundation. Also, ceramic chimneys must be strictly vertical. The presence of various bends is excluded. This feature in some cases makes the installation and installation of such a chimney impossible.

Frequent errors and problems during installation

- Installation of a valve in an insulated area. Under the influence of thermal expansion, the damper may jam;

- Installation of a cast iron part in a metal chimney (cast iron weighs a lot);

- Using too thin steel or stainless steel with a low nickel content for the manufacture of valves. Such a product quickly deforms under the influence of hot gases and can burn out;

- Installation of a gate with a non-smooth surface;

- Installation of a valve without a hole for carbon monoxide release;

- Installation of handles that do not allow monitoring the position of the valve (applies to rotary elements).

Installation in a brick pipe

The process is practically no different from the standard assembly of a finished kit. If installation work is carried out by a professional on a brick pipe, then the steps will be as follows:

- Laying down to the last layer of brick.

- Forming a pillow from clay, which cools slightly until it is soft and can be fixed.

- Laying the gate, accompanied by the application of slight pressure to place it in the clay mass.

- Re-placement of clay on the top layer and formation of a new brick row,

- Wait for it to dry and check the operation of the installation (if necessary, you can remove excess clay).

- Covering the resulting cracks.

If the pipe has already been installed, the technician will need to further disassemble it and only then proceed with the steps described above.

Knowing how to make a damper valve in a steel chimney pipe will allow you to entrust all the work to a specialist and not waste unnecessary nerves. And studying and becoming familiar with the main technologies, nuances and features of this process guarantees a high-quality installation check, ensuring the uninterrupted functioning of the smoke damper and the safe stay of people in a bathhouse or private house.

Features of gate maintenance

The gate, made of stainless steel, is usually polished to perfect smoothness. Soot settles on it poorly, but still settles. Therefore, it must be cleaned periodically.

The horizontal valve can be cleaned simply by pulling it out to the maximum and applying a special solution. Rotary - cleaned through the chimney with a special plastic brush. You should also ensure that the damper moves freely along the guides. It is allowed to periodically lubricate them with an anti-corrosion compound.

How to light a boiler

The most difficult thing in cycling is not to ride, but to start and finish the movement. It’s the same in the operation of a boiler - the most difficult thing is to light it. Do not expect that lighting the boiler will take you little time: you will have to allocate about an hour for this procedure.

Firing a wood-burning boiler is a responsible task

The beginning of the firebox is removing the ash and preparing the boiler for operation. After the ash pan and combustion chamber are cleaned, you can proceed to kindling.

Warming up the boiler firebox and chimney

For your own comfort and proper startup of the boiler, you need to warm up its firebox and chimney. If the heating device is not equipped with a forced smoke removal system, in order for the fuel to start burning, it is necessary to create draft. The formation of thrust is based on Archimedes' law: heated gases become lighter and tend to “float”. For their movement and removal, heating devices that burn fuel are equipped with a chimney.

Boiler diagram. Photo from the site www.viessmann.ru/

The design of the boiler is such that the path for smoke is difficult: in its path there is a heat exchanger and a complex convective surface, which reduces the speed of movement of combustion products. And the chimney pipe is usually located horizontally, which also makes it difficult for smoke to move. Therefore, if the boiler is not heated up, combustion products look for the easiest way. And most often the smoke begins to seep into the room.

In some cases, the vertical part of the chimney is equipped with a firebox (a small firebox used to warm up the chimney) with a door, by opening which you can burn a small amount of flammable fuel (for example, paper) directly in the chimney itself. When used, the heating element warms up the inside of the chimney duct.

If this possibility is not provided, then kindling is placed in the firebox - crumpled paper, birch bark - something highly flammable. On top of the kindling are chips and splinters, then logs of small thickness. The combustion chamber must be filled with firewood to no more than half the calculated volume.

At the moment of kindling, you need to open the chimney damper and the blower valve, ensuring the flow of air for combustion.

There is advice before starting the fire to open the window in the boiler room, if there is one: do not forget that the physical and chemical process of combustion requires oxygen.

How to properly heat a boiler with wood

To burn a kilogram of wood, about 5 cubic meters of air are required. If the air flow into the boiler furnace is from the boiler room, then it is necessary to arrange supply ventilation - especially if the boiler room does not have windows or they are sealed (with double-glazed windows).

After laying the logs, the kindling is ignited. When a stable combustion appears, the firebox door must be closed and the filling should be allowed to burn out.

Output to design power

As soon as the combustion chamber and chimney have warmed up sufficiently, you can proceed to the main stage of boiler operation. To do this, repeat the kindling process using well-burning materials. Now the main load of firewood is already complete, in order to fill the combustion chamber, according to the instructions for the device.

Expert advice

Where to install the damper on the chimney

There are 3 options for placing the damper relative to the chimney:

- Placement in the firebox of a fireplace or stove;

- Fastening according to the “pipe to pipe” principle;

- Installation in a ventilation pipe.

Let's consider the first 2 options:

- By placing the valve in the furnace firebox or in the outlet pipe

In this case, the damper is located at a height of no more than 1 m from the firebox, on an uninsulated section of the pipe. This location is convenient for adjusting the damper.

Applicable for metal chimneys. This installation option does not require additional fasteners. When purchasing a ready-made system, you should install the valve strictly according to the manufacturer’s instructions.

How to adjust traction

Adjusting the draft using a slider is quite simple. By changing the position towards increasing the gap, we increase the flow of air to the fire and the flame flares up stronger. Reduce the gap - traction decreases. The valve is closed after the flame has completely died out - this way the oven cools down much faster.

The latest boiler models are made with built-in automatic baffles. All other heating units require the mandatory installation of a damper.

Types of gate valves

There are two main types of gate valves - sliding and rotary (throttle). The design features are clear from the name: the first type works due to the perpendicular movement of the metal plate relative to the chimney pipe.

We recommend that you read: How to make a spark arrestor for a chimney with your own hands?

To increase draft, the damper is moved back and almost completely extends beyond the chimney, and to reduce the flow it is pushed back into the pipe.

Retractable gate

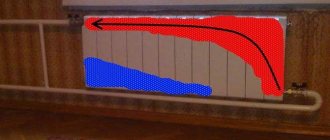

The most popular damper for a retractable type chimney. It compares favorably with other varieties in terms of reliability and ease of use. The retractable gate is a plate with a smooth, even surface, in which there is a special longitudinal hole. It runs along the grooves in the chimney.

This type of valve is installed strictly horizontally. To change the draft force in the chimney, it is enough to move the damper in the desired direction, increasing or, conversely, reducing the cross-section for the pipe.

This option is suitable for steel pipes, but is more suitable for stoves made of brick. Its installation does not require special knowledge or significant effort.

Some models provide a small cut-out area. This ensures the safety of the structure: even if this valve is completely closed, the movement of carbon monoxide in it will continue.

Rotary gate

Another type is a rotary gate. It is a plate made of metal, which is fixed in the central part of the guide by welding.

Dimensions and principle of operation of the rotary gate

Its main portion is located in the inside of the chimney, but the tip should always remain outside. Against the background of rotation of this plate relative to its own axis, the draft in the chimney is regulated.

The disadvantage of this type is the need for fastening by welding. It is this place that is the weak point of the design: the damper will open if the fastening becomes loose.

The rotary gate is characterized by low reliability. But this indicator may vary depending on what it is made from. Most often it is used for installation in steel chimneys. It is also installed in cases where there is not enough space to extend the classic valve.

Cast iron gate

Cast iron dampers have found quite wide application in various types of stoves and fireplaces. The disadvantage of such products is their significant mass. At the same time, cast iron itself has been used for a long time in the production of valves for furnaces. This is explained by its high reliability, durability and strength.

Model range of cast iron gates

Steel type gate

A gate unit made of stainless steel is not the cheapest option. But the design is characterized by high quality and excellent performance characteristics. Its advantages are as follows:

- maintaining furnace efficiency;

- small weight;

- long service life;

- not subject to metal corrosion;

- prevents soot accumulation.

These gates may have different designs depending on the characteristics of the furnace. They are relevant for chimneys made of steel or brick.

About firewood

As mentioned above, the quality of the fuel is of great importance. Both for the efficiency of heating equipment and for increasing its service life. This is especially true for firewood - a very unstable type of fuel. The efficiency of the boiler depends on the uniform supply of fuel, which is equalized in its calorific value. This is most important for modern technological heating devices, burdened with automation.

Firewood differs in its technical qualities - humidity, specific heat of combustion. That is why manufacturers of boiler equipment insist on choosing high-quality fuel.

Pellets and fuel briquettes are more efficient fuel for a wood boiler

The simplest way to achieve this requirement is to choose artificial “logs” - pellets, fuel briquettes.

You can read in more detail about the differences between firewood and their varieties in the article Pros and cons of various types of solid fuel for boilers: wood and its derivatives.

The manufacturer's recommendations, as a rule, indicate what length of logs are suitable for a particular firebox model. There are boiler options that can accommodate meter-long logs in the combustion chamber.

Log log discord

- Birch firewood

Birch has dense wood, so it burns hot and produces a lot of heat - 3750 kcal, even if the wood is damp. It is highly flammable. But when such firewood burns, especially damp wood, tar is released - a substance useful in medicine, cosmetology or for protecting surfaces from rotting, but extremely harmful to the insides of the boiler.

Soot on the boiler heat exchanger

- Alder firewood

Burning alder wood produces virtually no soot. Moreover, burning alder wood helps clean the chimney. Alder is flammable, burns well and produces a sufficient amount of heat - 2100 kcal.

- Aspen firewood

Burning aspen, like alder, cleans the chimney. But such firewood itself produces a little heat when burning - up to 1650 kcal.

- Pine firewood

They burn well and quite hotly (3800 kcal), but pine wood is resinous and a lot of soot is formed during combustion.

Firewood in the storage meter

- Spruce firewood

Spruce firewood is comparable in quality to pine, but has a slightly higher specific heat of combustion - 3900 kcal, and is also less resinous.

- Poplar firewood

Poplar burns hot, but burns out quickly.

- Firewood from apple and pear trees

Firewood from fruit trees - apple or pear - has dense wood, which means it produces a lot of heat, burns and smolders for a long time. But these species are usually grown for their fruits, so such firewood is not common. Another feature: the trunks of pear and apple trees are clumsy, the logs are difficult to prick, and the logs are knotty and difficult to pack tightly in the firebox.

- Oak, beech, ash firewood

Oak, beech, and ash are dense wood; when these species burn, a lot of heat is released - up to 3600 kcal. The disadvantages of oak or beech firewood include their rarity on sale and the difficulty of splitting and heating a boiler with them.

Considering the described qualities of wood as fuel, a good owner stores different types of firewood: some so that it flares up easily, others so that it burns long and hot, and others so that it can periodically clean the chimney of soot.

We increase the efficiency of the boiler with a chimney draft stabilizer

Have you ever thought about how you can reduce heat emissions through the chimney of a solid fuel boiler and use it for its intended purpose instead of heating the street? Surely many are now thinking about a damper or a water jacket wound around the chimney. However, there is a simpler and more elegant solution to save up to 20% of fuel through the use of an automatic chimney draft stabilizer. So, let's figure out what it is and how it works.

Signs of proper chimney operation

As you understand, the chimney, namely the draft it creates, is the only variable beyond our control. If we take into account the fact that draft depends on many factors (wind direction, ambient temperature, atmospheric pressure), it is not surprising that draft exceeds the minimum required norm throughout most of the heating season. This, in turn, means that a huge amount of the heat generated is simply released into the air.

During normal operation of the chimney, the speed of movement of gases inside it must correspond to the standards specified in the passport of the solid fuel boiler. The normal operation of the chimney is indicated by the yellow color of the flame with golden tongues. In the case of excess draft, the speed of movement of gases inside the pipe increases, as evidenced by the light yellow, close to white, color of the flame, and the humming inside the pipe during operation of the boiler.

Features of using a chimney draft stabilizer in a TT boiler

The stable operation of a solid fuel boiler directly depends on timely adjustment of the combustion intensity inside the chamber. The optimal functioning of such devices is ensured by the presence of stable draft in the chimney. A special chimney draft stabilizer automatically mixes cold air into the chimney, reducing the temperature and speed of movement of gases inside the pipe. This, in turn, allows you to use the burned fuel as efficiently as possible, without affecting the correct operation of the boiler. A correctly configured regulator significantly increases the efficiency of burning wood or coal and increases the service life of the boiler.

As a rule, a chimney draft stabilizer is installed on the chimney pipe, half a meter from the heating device. Since the principle of its operation is based on a system of perfectly balanced “weights”, it should be located exclusively indoors in order to exclude the influence of weather factors on its operation. Next, it is necessary to indicate the correct adjustment of the unit.

To do this, open the instructions for the boiler, find the model we need and look at the “minimum draft” parameter. We set the value on the regulator equal to or one step higher than the one found (for example, 22 Pa). At this point the installation can be considered complete.

Now, regardless of the weather, your boiler will use the maximum possible amount of heat, while continuing to burn as normal.

However, there are several options for placing the device:

- Installation of the connection between the boiler and the smoke exhaust system at the same level. However, the distance should not be less than 40 cm from the floor surface;

- Placement 50 cm above the junction of the heat generating unit with the chimney.

The choice of method depends on the design features of the boiler room and chimney, as well as on the personal preferences of the owner of the premises.

Advantages of a traction stabilizer

The chimney draft stabilizer is universal, i.e. can be used with any heat generating unit. Including in heating systems with condensation-type devices, in which the temperature of the burned gases is below the “dew point”. Due to the fact that the stabilizers are made of stainless steel, they can operate at operating temperatures up to 500˚C. They are quite easy to install in a minimal area and adjust. In addition, the following advantages of installing a draft regulator can be noted:

- Effective reduction of heat loss;

- Economical use of fuel;

- Increased safety and service life of the chimney system;

- Increasing the level of air flow circulation;

- The ability to operate the chimney in different conditions (forced and natural draft);

- Alignment of the fuel combustion process inside the chamber;

- No burning smell and no release of harmful compounds both indoors and outdoors;

- Installation is allowed even on an old chimney for connection with new boilers.

Probably many owners of solid fuel appliances, having heard about a chimney draft stabilizer, thought about a damper. A damper is a small damper that covers the chimney to contain heat inside the firebox. As sad as it is to say this, this solution is ineffective. Since when the damper is closed, the speed of gas movement in this section of the chimney simply increases. However, the volume of exhaust gases per unit time remains practically unchanged.

Adjusting the temperature of a solid fuel boiler

The efficiency of a heating system depends on a uniform temperature supply. And if in gas and liquid fuel boilers this issue is resolved by continuous fuel supply, then in solid fuel boilers there is no such possibility. And the solid fuel itself, when burned, releases its temperature unevenly: at the beginning and end of combustion, the portions of firewood are smaller, in the middle of the process – more.

A system for regulating the intensity of fuel combustion, that is, the supply of air necessary for combustion, helps to partially solve this problem.

Thermostatic draft regulator

The boiler doors have seals, so air enters under the grates through the lower damper. The amount of opening of this blower flap is controlled by a thermostatic draft regulator .

Thermostatic draft regulator. Photo from cotlix.com

The required temperature is set on it, and the regulator itself is mechanically (by a chain) connected to the blower door. If the temperature is insufficient, the regulator slightly opens the blower door; if it is too high, it closes it.

You need to understand that a solid fuel boiler is a very inert device, and the draft regulator controls the combustion process with a large error. Therefore, the entire heating system must be designed taking this feature into account.

Fan and controller

A smoother adjustment of the combustion process is possible using a fan that pumps a specified amount of air into the firebox. The number of revolutions of the device blades is regulated by a controller that takes into account the readings of the temperature sensor and the value of the temperature set by the user.

Shiber

A damper is a damper on a chimney, otherwise called a throttle. The damper is installed after the boiler and blocks the chimney channel. Whether it needs to be installed or not depends on the equipment model. Some types of boilers are equipped with a damper as standard; in other cases, manufacturers may recommend installing an additional damper in the chimney.

The damper allows you to increase the efficiency of the heating device by partially blocking the chimney and reducing the rate of removal of heated combustion products. How much to open or close the damper can only be determined experimentally, because it depends on the outside air temperature, humidity, atmospheric pressure, wind direction and strength.

Properly selected heating equipment, and most importantly, its effective use, will bring warmth into the house, and the owners will only need to supplement it with home comfort.

>

Gate, valve. Is it necessary and which one to choose! Adjusting the draft of boilers and furnaces

Good day to all!

The damper is used mainly for direct combustion boilers and stoves, including sauna stoves, to regulate draft! It can also be used to shut off the chimney after the end of combustion in the firebox, in order to retain the heat of the stove (boiler), so that the heat does not escape into the chimney through the natural draft of the chimney!

The damper is usually installed immediately after the boiler or furnace, but there are other installation options, for example, on a higher floor or even in the attic. More than one gate can even be installed! All this will help keep the heat in the house from ventilating.

And also rotating, with an external handle

According to safety rules, both gate options must be designed so that when they are completely closed, a small passage remains in the pipe. This passage is required in order for the carbon monoxide that is still being formed to evaporate, which is very dangerous if it gets into the room! Here it is written about the dangers of carbon monoxide!

Such holes are enough for carbon monoxide to evaporate, but such holes do not create the draft that would contribute to the rapid evaporation of heat! You should not neglect these rules and install “blind” valves. this can really be very dangerous for your life!

Also, sometimes the gate needs to be covered a little when there is a strong wind outside! This is especially true for not very tall chimneys that are not equipped with a wind deflector! The fact is that a strong wind can lead to such a process as reverse draft, that is, the wind through the chimney pipe can inflate the boiler, and you may not immediately know about it! That’s why you should partially cover the gate! Of course, it’s best to install a wind deflector at the very top of the chimney in advance!

Most modern boilers equipped with draft regulators or automatic equipment with an air supply turbine almost never require draft adjustment with a damper, since the supplied air is adjusted by the specified devices. However, this will not save, again, from accidental reverse thrust! Don't forget about this!

How does a solid fuel wood boiler work?

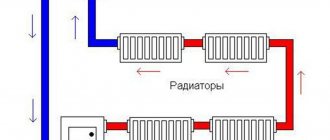

The boiler works as follows:

- As a result of burning wood in the hearth, a certain amount of heat is released, which varies for different species.

- The heat is used to heat the water tank located above the fireplace.

- Water circulates through the pipeline from the tank to the radiators and vice versa in a closed loop. Circulation can be natural (when the pipes have a slight slope) or forced using a circulation pump.

- Combustion products are discharged through the chimney to the street. In order for the draft to be normal, the height of the vertical part of the chimney is three or more than three meters.

- The combustion intensity is regulated by the firebox and chimney dampers.

The heating unit is equipped with a safety system for emergency pressure relief in case of overheating. Otherwise, the operation of the boiler becomes dangerous.

Universal boilers Stropuva

- Coal.

- Pellets.

- Wood waste.

- Firewood.

The Stropuva universal solid fuel boiler, according to research and consumer reviews, can be classified as one of the most economical types of heating equipment produced by the Stropuva company.

The use of wood waste only is not permitted. With each fire, you will need to add a small amount of high-quality solid fuel. Stropuva universal dual-fuel coal-wood boilers require regular maintenance.

In practice, it has been proven that it is better to use coal for a combination boiler. This type of fuel significantly increases the battery life from one load, as well as the efficiency of heat transfer. In normal mode without extreme loads, the unit can operate for up to 130 hours. Firebox capacity 220 kg. It is not allowed to add coal during combustion.

Installation and operation of Stropuva boilers

When installing and connecting, you must adhere to the basic rules that apply to all solid fuel units. The housing contains two outlets for supply and return of coolant, and connections to the central heating of the house.

It is mandatory to install an overheating protection system. If necessary, install circulation equipment.

A check valve and a coarse filter must be installed in the boiler piping. For the universal and pellet models, you will additionally need to purchase and install an air manifold.

The chimney is located on the rear side of the housing. It is recommended to install the chimney using insulated sandwich pipes.

Cleaning of carbon deposits is necessary after each fuel burnout. This is done through a special hatch located at the bottom of the boiler.

Kindling is carried out as follows:

- The air damper opens and the draft regulator is fixed in the raised position using a cable.

- Firewood is laid in layers. As a rule, large logs are placed in the center of the firebox, small ones at the edges.

- The top layer is filled with sawdust and wood chips. It will not be possible to add firewood until the already stored fuel has burned out, due to the internal structure and operating principle of the unit. Therefore, it is immediately necessary to fill the firebox completely (with the exception of the first kindling).

- The reason for the lack of draft may be the accumulation of soot in the smoke exhaust manifold, as well as insufficient heating of the chimney. Therefore, it is recommended to leave the damper open until the wood burns. This will provide good traction and reduce the formation of condensation.

Stropuva boiler piping diagrams

Stropuva boilers were able to truly solve the problem of autonomy of solid fuel equipment. Of course, they also have their drawbacks, but their choice is the optimal solution when heating a private home with no possibility of gasification.

How to heat a solid fuel boiler with wood

Before you start heating, you need to light it properly, but if you do not pay attention to this, smoke can begin to enter the house. Different types of wood are best suited for different stages of the process, and the size of the wood is also important in this case.

Which firewood to choose

It is recommended to heat well-dried wood, and its varieties are worth dwelling on separately.

Birch - gives a lot of heat, burns for a long time, but during the combustion process a large amount of tar remains on the walls of the chimney.

Alder gives off heat one and a half times less than birch, but leaves virtually no soot. Suitable for ignition as it ignites easily.

Aspen also does not emit soot and little heat; It is advisable to use it also as a lighter.

Pine burns hot, but contains a lot of resin and soot. Spruce firewood burns hotter than pine firewood and produces less soot.

Poplar, releasing a lot of heat, burns very quickly.

Apple and pear give a lot of heat, good coals, but knotty and difficult to chop.

Oak, ash and beech are dense and hard, prickly. When burning, they release a lot of heat and produce a little soot. They don't sell often.

Taking into account the above properties, firewood is selected both for ignition and for direct heating of the boiler.

Correct sequence of actions

The process begins with cleaning the ash pan and then igniting it. Over time, this step may take about an hour. The purpose of lighting is to heat the hearth and fireplace to create sufficient draft. The complexity and duration of the process are determined by the shape of the chimney and the presence of horizontal sections inside it.

Crumpled paper, bark, and small shavings are used as firewood. Then put thin logs. After ignition, firewood is gradually added to half the firebox load. During the cooking process, the fan and chimney fins are wide open to ensure good air flow. It is also advisable to open the room's windows to increase the flow of fresh air. After the flame has ignited well, the dampers are closed halfway.

Once sufficiently warmed up, they begin to perform full burns, with their burning rate depending on the type of wood and the location of the shock absorbers.

To automate the control process, draft thermostats and fans with controllers equipped with a temperature sensor are used. These devices make it possible to significantly simplify temperature control and increase the efficiency of the boiler.

Source – https://mr-build.ru/newteplo/kak-polzovatsa-siberom-na-tverdotoplivnom-kotle.html

Operating principle of a coal boiler

There are several types of coal boilers:

- direct combustion. The fuel simply burns in a firebox, limited at the bottom by a grate. Underneath there is an ash chamber. The generated heat is communicated to the coolant passing through the heat exchanger;

- pyrolysis. The action is based on the ability of organic fuel to decompose when heated without access of air to combustible gases (gas generation or pyrolysis). The firebox is divided into two chambers. In one, gas generation occurs, in the other, the resulting mixture of gases is burned. The air supply to both chambers is controlled automatically;

- long burning.

Long-burning boilers are divided into two subtypes:

- top combustion. The firebox of increased volume has an elongated upward shape. The fuel is ignited from above, air is supplied strictly to the combustion zone. Due to this, the fuel charge is burned longer than in a direct combustion boiler;

- with forced air supply. It is pumped by a fan through an air duct. When the desired coolant temperature is reached, the controller turns off the blower and the air duct is closed with a damper (lowers under its own weight when the fan is turned off). After the coolant has cooled, the fan starts again and ignites the smoldering coal.

Modern coal boilers are equipped with an electronic control unit and an automation system that makes the heater’s operation safe and efficient.

For regions with unstable power supply, non-volatile boilers are produced, the automatic operation of which is ensured by thermogenerators, thermocouples, bimetallic plates and lever systems.

Advantages and disadvantages

Like any engineering solution, a gate has a number of advantages and disadvantages.

Pros:

- Possibility of traction control;

- Fuel economy;

- Dampers help retain heat.

Minuses:

- The devices make it difficult to clean chimneys;

- If installed incorrectly, the gate may jam and negatively affect the movement of gases;

- To make the correct adjustment, you must have some knowledge in the field of smoke exhaust systems.