When building a water supply and heating system in a house, equipment such as a double-circuit boiler and a water heater - an indirect heating boiler is widely used. I would like to clarify that these are two completely different systems and therefore such equipment is not intended for them to work together to heat cold water for the heating system.

However, an indirect heating boiler is used in a hot water supply system to quickly additionally heat water in taps to the desired temperature, which can be taken from a double-circuit boiler, so they must be connected in the correct way, without making common mistakes.

The difference between a double-circuit and single-circuit boiler

To implement heating systems in the house, single-circuit boilers are installed based on heat exchangers of various types.

But there is a method of combining the heating and water supply system in the house through another heating boiler - a much more functional one, called a double-circuit boiler.

The main difference between double-circuit boilers and single-circuit boilers is their ability to heat not only the coolant - water (while burning gas or other energy resources for which they are intended) for the heating system, but also supply it to the consumer for his own domestic needs, ensuring the process of water supply in the house . And usually for these purposes, double-circuit boilers are made automatic. The operation of such a boiler is monitored by automation (water heating and gas consumption sensors with microprocessors). As soon as the boiler receives a command to request water into the water supply system, it immediately switches its mode to this task from the heating system, since it is its priority - at a higher level.

The maximum temperature that can be set on a hot water boiler is + 60 degrees Celsius, otherwise the automation will work and burns are possible.

Wall-mounted gas boilers are the most widely used, since gas is the cheapest heating material and walls are best suited for their placement and use, although other varieties are not uncommon.

Subtleties of installing system components

Having decided on the method of connecting a gas boiler and an electric boiler, you need to carefully think through and draw up a wiring diagram, and then proceed with installation.

Stage #1 - connecting a gas boiler

This stage should be entrusted to professionals: like any other gas equipment, only professionals certified by the gas service have the right to connect a gas boiler. This is due to the fact that even minor errors in installation and configuration are fraught with serious consequences.

It is quite possible to get confused in the variety of outputs of a double-circuit boiler, and if you start an incorrectly connected boiler, expensive equipment may fail

If a water supply or sewer leak threatens you with a puddle, a maximum of a couple of centimeters of water on the floor, then an error in connecting a gas boiler threatens a fire, explosion or poisoning by combustion products.

We reviewed installation diagrams for a double-circuit gas boiler in this material.

Stage #2 - boiler installation

An electric boiler operating in conjunction with a gas boiler is connected in the same way as for standard use. The only difference is that not cold water is supplied from the water supply, but hot water from the boiler.

When planning a hot water supply scheme with a boiler and boiler, be sure to set the latter’s thermostat to a lower temperature than in the boiler

Step-by-step instructions for installing a boiler are discussed below:

- You need to punch two holes in the wall for dowels at the same distance as the boiler mount.

- Then hammer the dowels into the holes, screw the hook-brackets into them almost all the way, and turn them with the hooks straight up. Fasteners are usually included with the boiler and are designed to support its weight when filled with water.

- Hang the tank on the hooks, check that they fit exactly into the grooves.

- Make water connections to the boiler and taps using plastic, metal-plastic pipes or flexible hoses. Install a ball valve at each connection for easy maintenance of the boiler.

- Make a branch from the safety valve into the sewer using a thin tube. You can neglect it, but then you will need to tighten the locking screw, provide a container into which a small amount of water can drain, and check the operation of the valve manually every 2 weeks.

- Connect to the electrical network - this procedure is performed through a dedicated grounded line - a separate cable stretched from the meter. Regardless of whether the boiler will be plugged into an outlet or connected directly to a cable, you will need to install a circuit breaker for additional protection.

- It is also important to take care of high-quality insulation, because the room may be damp.

Installing the boiler and boiler is the main, simplest and most important part of the work, but this is only the beginning. For their effective interaction, it is necessary to perform the piping according to a pre-selected pattern. We will talk about the elements of such schemes further.

Stage #3 - connections and additional equipment

The first thing any water-related system should begin with is installing a filter to clean it.

Installing a mechanical water purification filter will prevent small solid particles from entering the heating and water supply system and extend the life of the equipment

When choosing a filter, remember that the better it purifies water, the longer the boiler, boiler, and all other equipment will last. Otherwise, small particles from the water settle on the walls of the coil and tank, form scale on the heating element of the boiler, contribute to the destruction of the tank and lead to rapid failure of all parts of the system - from the boiler to the faucet in the kitchen.

However, it is also not worth choosing the most expensive filter that purifies tap water to drinking state - it is too expensive and irrational. A filtration system with 2 – 3 levels of mechanical purification of varying degrees, from coarse to fine, will be quite sufficient.

The filter is installed at the very beginning of the chain, before connecting the water supply to the boiler. Be careful with the direction of flow - it is usually indicated by arrows on the body.

During operation, do not forget to regularly change the filter cartridges, otherwise they cease to perform their function and may negatively affect the water pressure.

The second obvious and necessary equipment is ball valves. You need a lot of them, they are placed at each connection: in front of the filter, at the boiler inlet and outlet, on both boiler connection pipes, at each outlet from the hydraulic needle, in front of each water tap.

This number of cranes ensures safety and comfort of operation. At some point, every part of the system will require preventive maintenance, and possibly replacement, and the ability to turn off just that will be very important.

Expansion tanks are installed to compensate for pressure drops in the water supply or heating circuit caused by changes in water temperature - for safety

When organizing DHW through a boiler, an expansion tank is usually not required: in the event of a critical increase in pressure, the boiler safety valve will operate. But if the heating circuit is installed separately, such protection will not be superfluous.

In addition to the listed devices, as well as the hydraulic comb discussed above, check valves are installed on the pipelines, which do not allow the flow to reverse even when the pump is turned off, safety and three-way valves, and, if necessary, a pressure reducing valve to reduce pressure.

What is an indirect heating boiler

An indirect heating boiler is a hot water tank. Instead of a heating element, it contains a special coil inside, which acts as a heat exchanger. Hot coolant from the boiler or heating system flows through the coil.

The boiler is covered with heat-insulating material. Externally it looks like a barrel. It is equipped with an automatic thermostat that determines the temperature, and a pump that circulates and heats warm water in it.

What is a single-circuit boiler

Of the two existing types of boilers, differentiated by the number of built-in heating circuits, the single-circuit one differs in that it is endowed with only one useful function - heat supply to the batteries to increase the room temperature. Its design itself is not capable of supplying hot water to the tap, so the role of the mixer in this case is reduced to zero. Boilers are electric (heating heating elements, induction, electrode) and gas, which is due to different methods of heating, power, and consumption.

The electric boiler has the following nomenclature: a central tank that performs the function of a heat exchanger, tubular heating elements (heating elements), inlet and outlet pipes in the lower part of the body, a circulation pump for circulating water in the system, a thermostat, and indicators. In the induction boiler, instead of heating elements, there are coils that are driven by electromagnetic induction; the outlet pipe with hot water is installed on the top cover of the structure. Electrode boilers operate, respectively, through poles of a closed electrical circuit (anode and cathode) installed in parallel, generating electrical voltage and heat generation.

A gas single-circuit boiler is equipped with a heat exchanger, a combustion chamber for incoming fuel from a gas burner, a three-code valve, a circulation pump, an expansion tank, and a valve for connecting to the gas supply line.

All modern models of single-circuit boilers include, in addition to the water inlet and outlet pipes, pipes for connection to external water heating units. Thus, the possibility of synthesizing a single-circuit boiler with an indirect heating boiler to create a multifunctional heating and hot water supply system for a home is realized.

Features of a double-circuit boiler

A double-circuit boiler is intended not only for the implementation of a heating system in the house (circuit 1), including heated floors, ceilings, etc., which is its priority, but also for the water supply system in the house (circuit 2), (washbasin, shower, kitchen sink). As soon as the boiler receives a request for water supply, it immediately stops heating water in the heating system and opens the valves and automation for heating water for the water supply system, i.e. switches to circuit 2.

The usual capacity of a double-circuit boiler for a water supply system is 12-13 liters of water per minute.

In some cases, the given power of a double-circuit boiler may not be enough for such consumer requests - at increased loads, when both taps and showers are used at the same time. In addition, the temperature of the hot water in the taps will be slightly different from the temperature of the water in the heating system.

In these cases, it makes sense to use in the water supply system an indirect heating boiler with a single-circuit boiler instead of a double-circuit one, or a water heater that has its own pump with additional capacity.

Principle of operation

The main element of the boiler is a heat exchanger made of steel or brass. It has a large surface area and is located inside a tank coated with paint. To prevent rapid decrease in water temperature, thermal insulation or casing is provided.

One of the main parts of this device is the magnesium anode. It is needed to slow down the corrosion process, which extends the life of the boiler.

The device is equipped with a safety valve and a thermostat that protect it from sudden increases in pressure. If protection is not structurally provided, then it is installed during piping of the water heater. The process of heating water is quite simple: the hot coolant in the coil heats its walls, after which the heat from the metal is transferred to the cold water in the container.

Indirect device

Functions of a water heater in a water supply system

An indirect water supply boiler is a buffer tank that does not force the boiler to switch to the water supply mode from the heating mode at a low water consumption of 1..3 liters and smoothes out all its temperature differences at the beginning and end of its consumption.

For this purpose, it makes sense to install a membrane expansion tank with a volume of up to 10 liters , so that water flows into the taps and showers from the water heater first due to the pressure of the expansion tank and does not turn on the main heater for these purposes, increasing energy savings. It will only start when there is a large consumption of hot water into the system.

If there is no water heater in the system, when you turn on hot water, you may not get it, since sometimes you have to wait a long time until the process of restarting the main boiler is completed and the process of heating it in the circuit takes place.

In addition, the water heater can also serve as a backup source of hot water during the period of preventive maintenance of the main boiler for its maintenance - often in the summer.

The mechanism of operation of an indirect heating boiler, which is mounted on a wall or on the floor, can be described as follows: there are two tubes for inlet and outlet, often installed at the bottom. Cold water enters the boiler from below. The heated water for heating is taken from above. The tank is heated through a coil, which acts as a heat exchanger. Hot coolant from the boiler flows through the coil.

Boiler installation tips

It is important to install the boiler in accordance with current standards and rules, then the system will work for a long time and without failures. During the installation process, you must follow the following recommendations:

- Ground the boiler.

- To eliminate possible water hammer, a hydraulic accumulator should be provided on the output line.

- Provide for the possibility of connecting the boiler to an outlet if the gas boiler suddenly fails.

- Install shut-off valves on the supply and return lines of the container so that, if necessary, you can disconnect it.

- To heat the water faster, it is recommended to install the boiler as high as possible than the radiators.

- It is better to install it near a gas heating boiler.

The connection diagram of the boiler to the gas boiler is selected depending on the existing conditions and operating features of the system. In this regard, they think through all the nuances in advance and make the right choice. The best option is a system that consumes little gas and is maximally efficient.

Connecting the indirect heating boiler and boiler

It is important that the correct boiler power is selected to heat the water to the required temperature - otherwise the boiler will not provide enough heating for the water supply system.

According to the mind, there is no need to use the capabilities of the second circuit of a double-circuit boiler when heating an indirect heating boiler. It is necessary to tie the operation of the primary circuit to simultaneous operation with heating and hot water heating. To do this, it is necessary to connect the boiler and boiler through the distribution manifold. The collector will act as an intermediary and will distribute the hot coolant throughout the heating system and indirect heating boiler. All this will be heated by a double-circuit boiler.

In order to avoid overspending on heating hot water, you must connect your own pump to the boiler circuit. It is necessary to purchase an external thermostat for the boiler. The remote thermostat must be connected to the pump so that it turns the pump on and off.

When the boiler cools down, the thermostat will signal the pump to turn on. The boiler will begin to heat up. Having reached the desired temperature, the thermostat will signal to turn off.

This scheme for connecting a double-circuit boiler and an indirect heating boiler cannot be called ideal, but it allows you to heat normally hot water. The best and most economical solution would be to purchase a single-circuit boiler with a boiler connection function. Such a scheme would not have to be fenced off.

Types

Manufacturers of water heating devices do not skimp on developing cutting-edge models, having correctly taken into account the public interest in autonomous heating and hot water supply devices for private homes that emerged several years ago.

Currently, there are two types of single-circuit heating devices:

- floor;

- wall-mounted

Floor-standing options are more powerful, but their placement requires separate rooms in the form of an extension. Wall-mounted water heater – compact, small-sized, installed on the wall. That is why the first of these models became widespread among owners of country and city private houses, dachas and cottages, and wall-mounted boilers found their admirers in urban areas.

Both boilers have a simple and understandable design, attractive appearance, and a high degree of safety. You only need to form your own opinion about which ones are better depending on the tasks they face. Sometimes it is more profitable to purchase a single-circuit wall-mounted unit with less power, but which is enough for a full-fledged heating system at home, and make a simple connection to connect the wall structure to a column used to heat cold water for your own needs (the column can be electric or gas). The hose tying kit can be purchased separately.

Additional water system improvements

To create an additional level of comfort and improve the performance of the water supply system, additional improvements can be made, such as:

- additionally take care of disconnecting the water heater from the system by installing ball valves in case of need for its maintenance, breakdown or simply shutdown to reduce energy costs;

- installation of additional heated towel rails that will be warm all year round;

- carrying out additional thermal insulation of pipes from the water heater to the water supply systems to reduce heat loss;

- installing the water heater as close to the water supply points as possible, otherwise you will have to drain cold water from the taps in order to wait for hot water. In this case, it is necessary to install a recirculation pump for more efficient and economical use of cold water drained from the tap into the hot water supply system to the water heater - to reduce its consumption and economical use, so as not to drain it into the sewer. Calculations indicate water savings per year for a family of 4 people at the level of 15,000 - 000 liters.

The results of these improvements:

- savings (on water, on gas - since the boiler will rarely turn on, on electricity);

- always warm water on taps;

- the service life of the main boiler increases, since the boiler will turn on less often and operate less often, so all components will last much longer.

What does tank size matter?

The shape of water heaters can be cylindrical or cubic and, depending on the volume, they have different sizes. The tank capacity can range from 80 to 1500L, the user must select the tank according to the need. The dimensions of the container are also significant for installation conditions, since wall placement is allowed only for models up to 200 liters; the rest are placed on the floor. Wall-mounted tanks are equipped with mounting devices, while floor-mounted tanks are equipped with support elements. It is worth considering that cubic boilers are more compact and take up less space.

Expert recommendations

If greater productivity is needed, you should pay attention to remote hot water tanks. Such boilers, whose capacity can reach 500 liters, can be connected to heat generators that have this ability. This indicates that the equipment must have inlet pipes, and inside there must be a circulation pump necessary to service the hot water circuit. The power of the boiler must correspond to the capacity of the boiler, otherwise the water temperature will never reach normal levels.

The nuances of strapping

Despite the fact that the harness is selected individually, there are several general provisions that must be adhered to:

- The boiler for schemes with natural heating circulation is installed below the level of the radiators.

- The base for installing floor-standing units must be made of non-combustible materials.

- Boiler rooms are equipped with ventilation and lighting.

- The boiler unit is connected with the inclusion of a coaxial chimney.

- After assembling and installing the unit and smoke ventilation systems, a safety group is installed: a control pressure gauge, a pressure relief valve and then an air vent.

- The expansion tank is installed between the hydraulic switch and the boiler unit.

Connecting a wall-mounted boiler

This type of boiler allows installation on the wall in the kitchen. Structurally, it is made in such a way that the necessary piping has already been carried out by the manufacturer, and its elements are supplied as a kit. Depending on the type of unit, they can be single or double circuit, so the number of pipes for piping may differ.

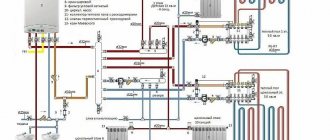

Wiring a wall-mounted gas boiler

Algorithm for piping a double-circuit gas boiler:

- Remove the plugs from the pipes.

- Install a strainer on the return line to remove dirt and suspended solids.

- A filter is installed to purify water from hardness salts; it can be installed on the common tap water inlet.

- When piping a wall-mounted gas boiler, shut-off and control valves with detachable connections, for example, “American” ones, are installed.

- The cold water pipes are located on the left side relative to the center of the boiler, and the hot water pipes are located on the right.

- The boiler is connected to the gas mains with the involvement of a certified specialist; the final approval of the boiler will be issued by a representative of Gorgaz after a test run of the boiler equipment.

- When piping a double-circuit gas boiler, the threaded gas connections are sealed only with tow.

- Install a special filter on the gas shut-off valve.

- The boiler is connected to the gas main with a corrugated hose and a union nut with a paranitic gasket.

Connecting a floor-standing gas boiler

This scheme requires a separate room to house the boiler, since floor-standing models are large and often have an open firebox design that works with natural circulation through the gas-air path. The scheme also includes a pump for coolant circulation, especially for piping a double-circuit gas boiler and for a multifaceted heating level: number of floors, different types of heating - radiator and “warm floor”.

The circuit for dual-circuit heating (heating and domestic hot water) consists of 5 pipes: 1 - gas, 4 - water coolant. The first is connected to the burner device with a ball valve.

Connection diagram for water coolant when piping a floor-standing gas boiler:

- Heating boiler inlet;

- heating boiler output;

- DHW heat exchanger inlet;

- DHW heat exchanger output.

The distribution of water flows is automatic, performed by a three-way valve, hydraulic arrow or balancing valves.

For piping a floor-standing gas boiler with extensive heating networks and a long distance, it is recommended to connect 2 collectors with an autonomous pump, for example, one for low-temperature coolant up to 50 C for a “warm floor” system, and the other up to 90 C for conventional radiators.

To reduce the temperature, the manifold can be equipped with a mixer or a three-way valve with a servo drive installed between the supply and return on the comb. Sensors allow you to set different temperatures in the circuits.

Thus, in order to properly tie the boiler, you will need not only experience in installation work, but also strict compliance with state operating rules and the requirements of the manufacturer.