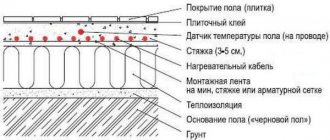

Correct installation of a heated floor is a strictly defined sequence of steps for installing the screed, laying the heating system itself, finishing the finishing layer and much more. However, in order for such floors to serve for a long time and delight the owner, it is necessary to use additional materials during installation. For example, to prevent the screed from cracking during operation, and also to reduce heat loss, it is necessary to use a rather unremarkable invention in the field of construction. A damper tape for a heated floor is necessary so that the result of the entire work exceeds expectations.

Damper tape for heated floors

Why do you need a damper tape for heated floors?

Damper tape (DL) is a rolled material for laying along indoor walls when creating a concrete screed. The main location is a corner joint between the wall and the floor in a rough state, but is mounted along the perimeter of the entire surface.

A huge number of companies are engaged in the production of expansion strips, which independently regulate the production of the size range of the product. Therefore, there are no standard norms for parameters.

Despite this, damper tapes with the following indicators are most often found on sale:

- width – from 80 to 150 mm;

- bay length – 100, 50, 30, 20, 15 and 10 m;

- thickness – from 3 to 10 mm.

The widest strips are needed for dry screed and heated floors, and 100 mm for one- or two-layer screed.

The name came to us from Germany. Translated from German (Dämpfer) means shock absorber or muffler. Therefore, by definition, the action of the damper tape is aimed at preventing vibrations and compensating for linear expansions in concrete (when it changes in volume due to temperature changes).

During this process, the screed is subject to cracking due to the high pressure on the walls, but the damper tape is compressed, so the floor covering does not deform.

Other features:

- if temperature fluctuations occur again during further operation, the damper tape returns to its original state, so the screed does not crack;

- If the tape is not used, then not only the concrete coating suffers, but also the upper floor covering, and additionally the finishing on the walls.

What is required when installing an infrared floor

To install infrared heated floors, you will need the following materials, parts and devices:

- Polysol is a thermal insulating substrate that prevents excessive energy consumption when the heating system is turned on.

- Bitumen insulation for thermal insulation of places where the film comes into contact with clips and wires and protection from electric current.

- Clips for connecting wires to IR film.

- Power cable and wires for connecting to the network.

- Heat-shrinkable sleeves for connecting power cables and underfloor heating wires.

- Thermal sensors and thermostats for automating the switching on and off of power supplied to the floor.

- Installation box for thermostat unit.

- Metallized self-adhesive tape for connecting the thermal insulation layer to sheets of IR film and for securing the cable.

When purchasing a film IR heated floor, you need to determine the requirements for its heating. If the floor will serve as an additional source of heat, you can choose a model with a power density of about 150 W/m². If the heated floor is the main source of heating the room, then the specific power should be at least 250 W/m². With stone flooring, the power should also be greater,

Purpose of damper tape

During the use of thermal insulation structures, constant heating and cooling of the floor covering occurs, which is why both the rough base and the finishing suffer. This leads to damage to the materials, which is why the coatings have to be changed again.

Damper tape, why is it needed and is it needed at all?

To prevent destruction, a damper tape is additionally installed. This applies to a greater extent to water-heated floors, but when installing an electrical cable system, experts also recommend using tape.

It is needed for the following purposes:

- laying a leveling screed (wet and especially dry, in which expanded clay backfill and flooring with a hard coating are used);

- pouring self-leveling compounds with an organic and mineral base;

- installation of water and electric heated floors;

- placement around the perimeter of the room during the construction of blind areas (so that the gap between the base and the blind area does not deform).

If expansion joints are present, a special type is used - T-shaped. And when using a heated floor, to create a thermal gap, the edge tape is mounted on the area of the doorway.

There are situations in which it makes no sense to install a damper tape:

- a simple type screed on a rigid, stable base;

- the presence of thermal insulation along the entire perimeter with a height below the level of the concrete screed;

- thin-layer leveling screed made of quick-hardening mortar and self-leveling floor without heating (if the thickness is no more than 10 mm).

At what height to trim

In general, the damper tape is needed for the screed, so you can safely cut it to the edge with the concrete slab. But the finishing materials laid on it also have thermal expansion. They are mounted with this in mind - leaving an empty space between the edge and the wall. This gap is usually 1 cm in size. So if you have a 10 mm thick edge installed, it does not need to be trimmed. In this case, the required technological gap will be maintained automatically.

The buffer tape for floor screed must be continuous

So, the damper tape can be cut flush with the concrete slab, or at the level of the finished floor, or not cut. What is not allowed is for it to be below the concrete level.

Basic properties

In addition to the action described above, the damper tape keeps the liquid solution from spreading. It reduces heat loss, since there are no gaps between the joints, so this energy is directed not outside the building, but inside. Experts note that without the use of DL, heat is consumed 10% more.

What properties does the expansion tape have:

- soundproofing - thanks to polyethylene foam, sound is poorly transmitted;

- resistant to low and high temperatures - the material can withstand from -40°C to +80°C (it can even be installed under steam systems);

- moisture-resistant and waterproof - if a pipe breaks in a water-heated floor system, at the joints and all places where the tape is located, water will not leak out;

- resistant to chemicals - it is not affected by alkali and other chemical compounds included in concrete and other solutions;

- elastic - after compression, the tape freely takes its reverse shape, and with new temperature changes it is able to shrink again;

- impenetrable to ultraviolet radiation - direct sunlight does not change the characteristics.

The raw materials from which DL is made are biologically inert, and therefore do not form a nutritious and favorable environment for mold fungi and other pathogenic microorganisms.

Introduction

So, what is damper tape for? The main functions of this tape are fully revealed by the translation of its name - muffler, shock absorber . This is an edge film designed to reduce vibrations that occur in the design of the heating coating. It is worth noting that damper products, in addition to absorbing vibration effects , compensate and at the same time slow down more serious processes that can have very unpleasant consequences for a warm coating. In particular, this applies to expansion of the screed , which occurs for the following reasons:

- During heating, the cement base, like other solid structures, tends to expand , and when cooled, on the contrary, to shrink. Of course, against this background the edges of the base also move ;

- The monolithic base is an effective transmitter of sounds that come from heating pipes;

- In addition, the screed absorbs vibrations from any movements on the floor covering.

Return to content

What is the damper tape for heated floors made of?

To make shock-absorbing construction tape, industries use foamed polyethylene, which is divided into 2 types - synthetic rubber and polyester (densely woven polyester fibers). Their chemical formulas are different, but their properties are identical.

Damper strips can be stitched or unstitched. The former are cheaper, the latter are more expensive.

Many property owners, unlike professional builders, prefer to use scrap materials during rough work, trying to save their budget. The following materials are used for this:

- Wooden slats. To install them, would-be craftsmen wrap the wood with plastic film. This option is considered unacceptable, since the wood becomes moldy and rots over time, and easily allows moisture and cold air from the street to pass through (because there is no close contact with the wall and floor). This design does not at all correspond to the characteristics of the DL.

- Styrofoam. Its thickness is from 10 to 15 mm. The material insulates well, but does not take the shape of recesses, corners, protrusions, etc., and therefore does not fit tightly to the surface. Another disadvantage is that the foam does not withstand mechanical stress, so it breaks and crumbles.

- Roll insulation. Usually they buy options made from foamed polyethylene or similar raw materials. This is also not the best option, since insulation materials do not have soundproofing, waterproof and other properties to the same extent as damper tape. The reason for this is the different density of the material.

- Extruded polystyrene foam. It can act as an expansion compensator, but not as a damper, since it has a low level of elasticity.

The best option for replacing the damper tape is the following:

- rubber;

- polyethylene backing for laminate;

- penofol;

- old linoleum.

Experts say that the compensating tape has no equivalent (100%) analogues.

Is it possible to replace it with something?

To save money, the damper tape can be replaced. Suitable for this:

- wooden slats;

- strip of plywood;

- trimmings of linoleum and polymer materials;

- Styrofoam;

- wooden strip wrapped in plastic film - allows you to remove the strip. Without film, wood is difficult to remove. In most cases, it remains and takes on the pressure of the screed.

There is a lot of criticism of these materials from experts. But it is baseless. After all, the damper can simply be removed and the gap closed with a plinth.

Advantages and disadvantages

Professional craftsmen and ordinary self-taught people prefer to work with damper tape, as it has many advantages. Namely:

- a high degree of elasticity allows the material to take the required shape (even if there are irregularities, chips, etc.);

- it does not crumble, crack, or break (under mechanical or other influence);

- resistance to chemical elements makes it possible to use solutions of any composition;

- protects walls from mold;

- it is quickly, easily and simply installed, thanks to which a beginner can cope with the task;

- maximum set of properties (absorption of vibration, noise, reduction of heat loss, etc.);

- environmental friendliness - foamed polyethylene does not contain toxins;

- small rodents do not feed on these raw materials, so there are no problems with storage and operation;

- characteristics do not change for several years;

- creates tightness;

- wide range of applications;

- withstands significant loads;

- versatility - can be installed not only indoors, but also outdoors.

The damper tape has no disadvantages, except for the only unpleasant moment - the cost is too high.

If the film is missing

If the vibrations, which are perceived as extraneous noise, have a small amplitude, then during the thermal increase of the screed with no gaps from the wall to the concrete base, there is a possibility of strong stress, which inevitably results in cracks and all kinds of chips. Moreover, such unpleasant phenomena can occur both in the screeds and in the wall. Accordingly, a damper edge strip is required not only to provide sound insulation (however, this task is very significant), but also to protect the heated floor from premature destruction.

Return to content

Varieties

There are 2 types of damper tape, depending on the location area - edge (installed only along the walls) and inter-circuit T-shaped (installed when screeding in expansion joints with a floor area of more than 6 square meters, in door openings and near heating circuits when laying heated floors ).

There are other varieties that differ from each other in different indicators.

Standard

The second name is straight. It is a strip, most often made of polystyrene, on which there is no adhesive base. During installation, the technician needs to lay the damper upright against the wall and secure it. The masters consider these two disadvantages to be the main ones. The third drawback is poor sealing.

The main advantage is the lowest cost, the purpose is to compensate for the expansion of the concrete composition.

How a standard damper tape is attached to the surface:

- landing on polyurethane glue;

- fixation with double-sided tape;

- pressing with a dry backfill mixture or solution;

- small nails (if the surface allows, for example plasterboard);

- liquid nails.

Self-adhesive

Unlike the previous version, one of the sides of the tape is equipped with an adhesive base, which is hidden behind a protective film.

Advantages:

- convenience and speed of installation;

- does not budge after sticking;

- average price;

- no need to buy fasteners.

Flaws:

- you need to press it hard against the wall;

- Do not attach to uneven surfaces or dirty walls.

To prevent the sticky layer from becoming covered with dust during operation, remove the protective film as needed.

With a skirt

This is a damper tape with a peplum. Consists of 2 parts along the entire length:

- First. It is made of polyethylene foam, so it is dense. They put it against the wall.

- Second. Made of dense polyethylene, therefore thin. Mounted to the floor.

Skirt tape is produced in 2 types:

- with adhesive base;

- without glue (construction tape is used for fastening).

It is recommended to install it when installing a warm water floor, since the thin part (basque or skirt) is intended to increase the level of tightness, so that in the event of an accidental burst of pipes, water will not flow into the joints.

An additional advantage is high-quality sealing and maximum ease of installation. Among the disadvantages are the high cost (accordingly, the self-adhesive version is more expensive than the adhesive-free version) and the pointlessness of use in electric heating systems.

T-shaped

It is advisable to install this type in large rooms when there are too few deformation voids along the walls, which is why the expansion of concrete is not compensated. Therefore, after installing the T-shaped material and subsequent pouring, an expansion joint is formed.

It is usually produced with an adhesive base; the cost is high, but it is fully justified.

Notched

The model is designed specifically to improve installation conditions and speed up this process. It is a tape that has tearing lines along its entire length. This makes it possible to quickly remove protruding areas after pouring the concrete mixture.

The cost is high due to these cuts, but many users believe that there is no point in overpaying for this, since you can make tear lines yourself using a sharp or stationery knife.

L-shaped

It differs from other options in that slots are made on the surface of the tape, allowing it to be bent in the shape of the letter L. Feature - when installing, keep in mind that the short edge is laid on the floor, and the wide edge is laid on the wall.

The main advantage is the highest damping and sealing properties, but the price leaves much to be desired.

How to install and secure

The edge damper tape is laid out along the perimeter of the walls. If the tape has an adhesive strip, there are no discrepancies. We unfold it so that the glue faces the wall. If there is no adhesive strip, the shiny side should be turned towards the wall, release the film (if any), lay it out on the floor. We do not stretch the tape, we lay it loosely. Those with skirts can generally wrinkle a little, otherwise the skirt will be stretched. In the corner on the floor, fold the release of the plastic film into a triangle. There's no point in trying too hard to post it. Just to avoid coattails.

When laying, the damper tape is not stretched. The skirt is straightened on the floor

In general, everything is simple. The manufacturers themselves roll the material so that it is convenient to install. Material for right-handed people has been rolled up. That is, we place the roll on the floor, secure the edge and then roll it out from left to right. If two pieces are connected, an overlap of about 5 cm is needed.

You can attach the damper tape to the wall using staples, glue, tape or... Not at all

The quickest and easiest way to attach the damper tape to the walls is with staples from a construction stapler. You can use liquid nails, double-sided tape. The question is not fundamental. You don’t have to fasten it at all, but then when laying concrete and during further work, you will need to make sure that the damper tape does not fall.

At what height should the fasteners be installed? The best option is in the middle of the width of the tape. In any case, not higher than the planned finished floor line. In most cases it is cut off, so it will be easier if the fasteners are installed lower. It is not necessary to trim off the excess, but it seems more “aesthetically pleasing.”

Laying damper tape for water heated floors

When installing damper tapes, especially when laying a warm water floor, it is important to take into account some nuances, so that the work will be done efficiently. There is no difficulty in this, so even an inexperienced layman can cope with the actions.

Useless damper tape or floor screed in an apartment with your own hands, that is, poured screed

At what height should I trim?

Since the damper tape is intended for concrete screed, it is recommended to cut it to the edge with the floor slab. When finishing materials are laid on the concrete slabs of a building, thermal expansion also occurs, so builders leave a gap between the wall and the edge.

The average size of this void is 0.9-1.2 cm. In such cases, the edge is set to the same thickness and is not cut off. Based on this, the cutting height is the level of the concrete slab or finishing. The main thing is that it is not lower than concrete.

How and with what to prune correctly?

If it is necessary to cut the damper tape or any material replacing it, 2 methods are used. Namely:

- First. It is considered optimal, since the strips are smooth, cutting the material is convenient and quick. To do this, take a wooden board. Fold the tape in 2-4 layers and place it on the board. Place a long ruler on top, along which you cut with a sharp knife.

- Second. Not very convenient and slow. To do this, take the scissors in one hand and the tape in the other. Cut by hand.

If you are cutting rolled materials that are too wide, be sure to first measure the required distance from the edge and draw a line along which you need to cut.

Preparing for work

The first thing the master does is prepare the base for the tape. To do this, do the following:

- Apply starting and finishing putty to the walls, since this is problematic to do after installing the tape.

- Install door and window trims.

- Prepare the subfloor.

- Lay waterproofing material.

Installation of damper tape together with a water system - step-by-step instructions

After the preparatory work, proceed to installing the heated floor and damper tape. Proceed sequentially:

- Bring the roll to the edge of the wall and unroll it as you work. Attach it to the wall and floor so that in the future the concrete screed will be 1-2 cm below the top edge of the strip.

- Fix the tape and press at the adhesion points.

- Lay thermal insulation boards over the floor surface. Place them close to the wall so that the tape is pressed.

- Lay heat distribution plates for heated floors in 2 cm increments.

- Install the coolant pipes into the grooves of the plates. Start the process from the collector supplying water. Follow the generally accepted pattern - laying along all external walls in increments of 15 cm, then like a snake inward in increments of 20 cm.

- Spread the waterproofing film on top.

- Now lay down the gypsum fiber sheets.

- Cover with finishing floor covering.

If you plan to make a concrete screed, then do not place gypsum fiber, but immediately fill it with mortar.

Helpful installation tips

All about damper tape for heated floors in 1 minute

There are many nuances and tricks that experienced craftsmen know about. If you're new to this, use these tips:

- To improve adhesion (adhesion of the material to the surface), roll the roller along the entire length of the tape, especially in the area with the adhesive base;

- Before installation, treat the surfaces with a primer, which will eliminate dust and enhance adhesion;

- At the junction of the 2 ends of the tape, use the overlapping method for a length of 10-15 cm;

- If you use a damper with a skirt, be sure to level the polyethylene along the floor and overlap it in the corners;

- Trim off any leftovers with a very sharp knife;

- The edges can not be cut, but hidden under the baseboard;

- Try not to make a large number of joints in the damper tape - this reduces the level of tightness;

- Don't leave any gaps.

How to fill the seam?

Since the damper is a consumable item, many people prefer to remove it. In this case, there will be gaps that are important to fill with something, otherwise debris and dust will collect in the voids and insects will breed.

Experts recommend 2 optimal options for filling the gaps:

- silicone-based sealant is an excellent way, since the material is quite elastic, but the “pleasure” will be expensive;

- polyurethane foam is inexpensive and flexible, but it leaves an unaesthetic appearance (be sure to cut off the remains).

General principles of application

Mounting tape for heated floors is used for the following purposes:

- neutralizing temperature fluctuations,

- absorption of various types of vibrations,

- as a supplement to retain heat and improve waterproofing,

- compaction and filling of excess intermediate areas,

- installation of expansion joints and seals for joining areas.

What does underfloor heating tape look like?

Rules for choosing expansion tape

There is a huge variety of damper tape on sale, so a person who does not have experience in the construction industry has difficulty understanding what exactly the choice is based on.

In reality, it's simple:

- decide in advance what width of the product you need and calculate the length based on the area of the room - do not forget about the extra centimeters for overlap;

- buy a product that has sealed packaging - this applies to models with an adhesive base;

- inspect for any deformations - if there are any, then the seller violated the conditions during storage, so such material will not fully comply with its functionality;

- if you buy an open roll version (without glue), check the surface - it should be clean;

- check the density of the coil winding - unscrupulous sellers can secretly unwind part of the tape;

- In self-adhesive products, delamination of the material is unacceptable;

- choose products from well-known brands and trusted manufacturers;

- do not hesitate to ask to see the certificates to make sure that they are not fake;

- pay attention to the thickness along the entire length - it cannot be different;

- if the model has notches, then the line should be perfectly straight.

Check the cost of identical products in different places - if somewhere you are offered a price that is an order of magnitude lower than that of competitors, beware - it may be counterfeit.

Installation features

The developer may have a question about how to attach the damper tape and when to do it. Installation is carried out before pouring the screed, but after installing the waterproofing. As a rule, film and any other waterproofing on the sides is lifted and placed on the walls, in which case the buffer tape is installed on top of it.

The installation method depends on the type of product. If it has an adhesive layer, everything is simple: place the roll with the sticky side to the wall and, gradually unrolling it and removing the protective layer, glue the strip to the base, slightly pulling it so as not to falsify. If there is a film release (“skirt”), it is spread on the floor, folded at the corners into a triangle.

Installation of L-shaped tape Source o-builder.ru

Having finished gluing one roll, the second is mounted overlapping, starting the beginning of the second strip 5 cm from the end of the first.

If there is no adhesive strip, you first need to determine the front and back sides. The reverse side is usually smoother and shiny, and it is pressed against the wall.

Rigid fastening is not necessary - the strip can simply be pressed with the solution during its installation. But this is very inconvenient: you have to constantly make sure that it does not fall or bend under the screed, otherwise the whole point of why the damper tape is needed is lost.

Therefore, choose one of the most convenient fixation methods:

- shoot with a stapler, the staples of which easily fit into the wooden base;

- drill the dowel with nails;

- glued with double-sided tape, liquid nails or other adhesive.

Popular brands

Among the most popular types there are not only global foreign brands, but there are also Russian products that meet all requirements and standards. Professionals usually purchase models with impeccable quality:

- Knauff FE with skirt. It is of high quality, but for 40 meters of length, 100 mm wide and 8 mm thick you will have to pay at least 850-900 rubles.

- Energofloor from Energoflex with peplum. Like the previous version, it has improved quality indicators, and due to its worldwide popularity, it has the same cost. With a width of 100 and a thickness of 10 mm, for a roll of 11 meters they ask for about 450 rubles.

- Kermi. Self-adhesive tape 25 m long. Thickness 8 mm, width 160 mm, cost – 870-900 rubles.

- Oventrop. Adhesive-based, has a perforated line, but is intended for ordinary concrete screed. A roll 25 m long, 120 mm wide and 10 mm thick costs about 800 rubles.

- Upon arrival. The self-adhesive damper is 50 m long, 150 mm wide, and 10 mm thick. For such a roll you need to pay 3500 rubles.

- Tilit Super. Domestic high-quality product with a protective apron on one side. Roll length 25 m, width 100 mm, thickness 10 mm, price 900-940 rub.

- Thermoflex. Another Russian product, which is considered economically profitable, since for 50 meters you can pay only 1200-1300 rubles. The width is 100 mm, thickness is 6 mm, but the product is of the standard type (without adhesive base).

This is only a small part of high-quality damper products, but there are also types that cost 2-3 times less. Experts do not recommend using them when arranging flooring, since after 3-4 years they will need to be replaced.

Everyone has the right to decide for themselves whether to lay damper tape for underfloor heating or not, but based on modern requirements for the construction of residential buildings, this must be done. The main thing is to clearly decide on the choice, learn how to install it yourself, and, if necessary, consult with specialists.

What can be used to make a damper tape for a screed?

Selection of engineering devices

The choice of product largely depends on the size of the room and the number of thermal circuits when installing the heating system. It is easiest to use a device with a self-adhesive side. It attaches quickly, does not require the use of additional adhesive solutions, and even a beginner can handle the job.

If it is necessary to make additional expansion joints in the room, then it is better to use a T-shaped product. Craftsmen use a regular strip without an adhesive layer in those rooms where there is no need for additional protection from moisture or thermal insulation.

It is important to pay attention to the cost of the compensation tape:

- Self-adhesive imported Kermi tape costs approximately 900 rubles per package, the footage of which is 25 meters.

- Domestic edge strip. Its price is 160–300 rubles per 20 meters.

- Uponol self-adhesive, made in Switzerland, costs about 3.7 thousand rubles for 50 meters.

- German products from Oventrop have prices ranging from 800 to 3 thousand rubles.

Cost is often the determining factor when choosing the presented device. But you shouldn’t buy too cheap options, they won’t last even a few years. Not every owner will agree to redo the heated floor every 2-3 years.

Many companies are engaged in the selection of engineering equipment; all aspects of each case are taken into account when calculating. Specialists calculate the relevance of all materials, equipment and fittings existing on the market. This helps analyze the cost of each section of the network.