Let's dig into the holy of holies and find out which plastic pipes are better: polypropylene, metal-plastic or cross-linked polyethylene. And it doesn’t matter where they will be used - in water supply or heating. And each type has both advantages and obvious disadvantages. Well, let's get started

To choose the right material for a water supply system, you need to determine the conditions in which it will be used. The options may be as follows: 1. For cold and hot water in an apartment, private house 2. for oil, steam and gas heating 3. sewerage 4. basement wiring to a multi-story building 5. heating mains

Technical operating conditions will differ, and these are: temperature, pressure inside the system, mechanical load. Therefore, the plastic will be slightly different.

An opinion was formed that plastic came to us from Europe, saying that the Germans and Italians received patents, established successful production and sold the franchise first to Turkey and then to Russia. But the wise old plumbers remember that cross-linked polyethylene was produced back in the USSR at the Karaganda plastic plant in 1972.

Now water flows over plastic throughout the civilized world and this is considered the most convenient.

There are 3 main types of plastic pipes, the rest are their subspecies. Let's look at which pipes are better and where they should be installed.

Polypropylene pipes general information

Different types of material are used for cold and hot water. The fact is that ordinary polypropylene is not intended for high-temperature liquids, therefore, to prevent it from melting, it is additionally reinforced with aluminum or fiberglass. Such reinforced pipes are called reinforced and designated as D25, and simple pipes, unreinforced, respectively, D20, where D is the diameter. As you can see, about 5 mm is spent on reinforcement, and it must be taken into account that this procedure only increases the heat resistance of the pipe, but does not in any way affect its mechanical strength.

Briefly about the main thing

Cross-linked polyethylene is called due to the forced creation of transverse ligaments in the linear structure of the feedstock.

Production today is carried out mainly using only three technologies: chemical treatment with peroxide, water vapor or radiation exposure of polyethylene.

In its pure form, PEXa is most often used for the production of pipes. It is excellent for installing heated floors due to its strength and ductility. The choice of metal-plastic or cross-linked polyethylene for heated floors should definitely be made in favor of the latter based on practicality and reliability.

Installation of cross-linked propylene is carried out using fittings. They additionally perform a sealing function, which eliminates the use of additional products (flax, tapes and pastes).

Advantages

- The biggest advantage of this material is its low cost. In the Moscow region, the average price for polypropylene pipes is 60 rubles per meter, and corners cost about 20. However, despite this, end switches intended for threaded connection of pipes with metal elements are sold more expensively - 150 rubles per piece, so if in the system has many metal-plastic transitions, repairs can hit your pocket hard.

- Also a plus is the relatively simple installation. To connect a polypropylene pipe with a corner, you just need to insert them into each other and solder them - a procedure that is accessible even to a child.

General properties of plastic pipes

Often in everyday life it is customary to simplify the division of pipes into metal and non-metal. All pipes not made of steel or copper are called plastic. Indeed, in appearance, polyethylene and polypropylene products are similar and resemble plastic ones, the properties of both pipes are identical, both types:

- low melting point compared to metal ones (when heated strongly, they soften and sag);

- light weight, making them easier to transport and install.

- resistance to mechanical damage - shock, vibration;

- they are not afraid of alkaline reagents in tap water;

- do not conduct electric current;

- susceptible to destruction under the influence of ultraviolet radiation;

- cannot be bent, because break under strong tensile pressure.

A significant advantage of non-metallic products for engineering systems is resistance to organic and inorganic sediment.

The metal interacts with oxygen and salts of alkaline earth metals (hardness salts) found in water and leads to the formation of sediment, which gradually thickens, which does not threaten polyethylene and polypropylene pipes, which do not become clogged even after decades of operation, because have a smooth inner surface.

Flaws

- The main disadvantage is that the pipe has virtually no flexibility. This is especially disadvantageous if, for example, you need to assemble a complex curved line - you will need a large number of corners, which means you will have to do a lot of welding.

- Polypropylene pipes are quite bulky. To provide them with strength and a certain rigidity, it is necessary to make a large diameter, 20-25 mm. But such a pipe, of course, cannot withstand high pressure.

- "Human factor". If the installer does not pay attention during soldering, or a low-quality soldering machine is used, in general, if the person assembling the pipes somehow makes a mistake, the system may leak.

Application of polyethylene and polypropylene pipes

In practice, there is not much difference in where it is better to use polyethylene and where polypropylene pipes (if we are talking about cross-linked polyethylene). Both materials perform well in various conditions, being almost equally durable and resistant to high/low temperatures.

However, it is recommended to use both types of pipes for installation in enclosed spaces, because polymers quickly degrade when exposed to ultraviolet radiation.

If you are faced with a choice of which pipes to use for in-house engineering systems, take into account individual parameters in installation and operation. For example, cross-linked polyethylene pipes are quite easy to install using simple sealing fittings.

For polypropylene, you will need a special welding apparatus (“iron”), which must have the same diameter of melting nozzles as the pipes you have chosen.

Rehau cross-linked polyethylene pipes

This is a relatively new and very popular development among middle- and high-income customers. These pipes, marked with the abbreviation PEX (read: PECS), are made from a special modified form of polyethylene, which is called cross-linked. The crosslinking process is quite complicated, so it is only worth saying that as a result the material acquires increased temperature resistance, that is, it does not melt under the influence of hot environments.

There are 3 types of PEX pipes, distinguished by heat resistance - these are PEX-a, PEX-b and PEX-c. The first are the best, since they have a higher degree of cross-linking, the second are average, the third are suitable only for low-power water supply systems, and they usually do not last long.

Internal differences

Let's try to understand the differences in the properties of cross-linked polyethylene and polypropylene by turning to the features of their structure:

- PEX polyethylene is produced by cross-linking linear macromolecules of polymerized ethylene to obtain a three-dimensional mesh-cellular structure:

- The strong intermolecular bonds formed in this process give the material high resistance to mechanical, chemical and thermal loads.

- Such connections, even at the casting stage of the product, give it a shape that will then be very difficult to change.

- PEX is the densest of all types of polyethylene with a rating of 940 kg/m3.

- Polypropylene is a polymer of propylene hydrocarbon that has an unstable crystalline structure, which gives it both high tensile and tensile strength and high ductility. He:

- There can be three types depending on the spatial direction of the branches of the molecules (methyl groups),

- It has a “breathing” structure that can allow gaseous substances to pass through,

- It is a much less dense material than any other type of plastic, with a density ranging from 850 to 900 kg/m3.

Advantages

- PEX pipes have a significant advantage over polypropylene pipes - they can bend and keep their shape. This greatly simplifies their installation, especially in geometrically complex systems. But there is also a type of non-plastic PEX that, with any bending, immediately returns to its original form. Such pipes are cheaper, but if you need to make an angle, they have to be fixed with special fasteners. The first ones are marked as FLEX (read as flex), and the second ones Stabil (stable).

- They can withstand quite high temperatures - up to 95 degrees.

- A lower diameter than that of polypropylene pipes - the water flow rate and pressure that the PLP pipe can withstand with a diameter of 25 mm, PEX duplicates with a diameter of only 16.

- Simple installation, without the so-called “human factor”. To connect two sections of the pipeline, you just need to crimp the ring with pliers and twist it until it stops. That is, it is basically impossible to make a mistake here that could lead to a leak.

What is rehau and why cross-linked polypropylene does not exist

Or here is a video we received from our client whose polypropylene heating pipes that were walled up in the walls leaked.

On the plumbing services market you can find offers for installing batteries of various types. All specialists, of course, have different opinions and each one also has his own approach to work - especially among universal finishers, the so-called “jacks of all trades”. They are in polypropylene, they love you... Well, because you can buy a soldering iron for polypropylene for 800 rubles and install the pipes first! Understand correctly - this is not about the fact that polypropylene pipes are a complete waste, but no, they are an excellent material, but you need to know where and how to use them. That is, you can’t use polyk everywhere, and certainly not inside the screed. That is, we will talk about the wrong choice of pipes for hidden connections and the consequences that will come out a few years later exactly after the warranty expires and how to choose the right pipes that will not delight us with such sad surprises. The fact is that the most common mistake when installing radiators with hidden connections is the incorrect use of polypropylene pipes. Which, according to technology, are prohibited from being hidden inside the screed. However, it is widely used by general craftsmen - that is, not by plumbing specialists.

The picture shows a polypropylene leak at the welding site.

Judging by the picture, you can understand that such a collective farm installation of a heating radiator was not carried out by a professional plumber, but by some kind of generalist finisher - a jack of all trades. As you can see the result of the work is obvious! Now you not only need to redo the radiator piping, but also destroy the walls and floor... sad...

This leads to the following consequences.

The figure below will show what a polypropylene pipe looks like in cross-section after it has been removed from the screed after a catastrophe with a leak inside the floor, which is usually discovered after the neighbors from below knock on your door. This does not happen immediately after starting the system, but after about 3–5 years of operation.

This drying out of a polypropylene pipe or its embrittlement is well explained in the video below. Where the author documents the opinion of many management companies that plastic pipes should not be installed on the heating system of an apartment building.

Let's look:

The first rule of high-quality apartment renovation is not to skimp on engineers. You cannot trust engineering work, such as plumbing or electrical work, to a plasterer, even if he showed you a soldering iron for polypropylene. The presence of a soldering iron and even the ability to weld polypropylene pipes does not mean anything.

If you are making repairs in a new building, then you need to approach the issue of choosing a plumber very carefully and under no circumstances agree to install polypropylene pipes if these pipes, whether water or heating, are hidden inside the walls as in the figure below.

The collective farm is a voluntary business!

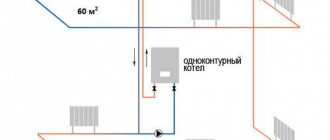

The image above shows an option for installing a sectional radiator using the collective farm method. Firstly, because a sectional heating radiator was chosen for hidden connections rather than a monolithic one with a decent bottom connection. And the second thing that catches your eye is the laying of pipes in an overlap - one through the other (so that the pipes cut each other under the screed, soft insulation will not save..) The second is heating with pipes made of polypropylene under the screed. This is exactly the case when at first everything is fine, all the work is handed over, the customer accepts the work and sleeps peacefully for the first three years. Enjoying the new renovation of the apartment and never dreaming that the pipes under the screed are vibrating, either expanding or contracting in size depending on the temperature of the coolant. Slowly loosening the welded joints hidden deep inside the screed and hello to the neighbors below.

This occurs due to the high temperature expansion of polypropylene pipes. Google to help - “coefficient of thermal expansion of polypropylene pipes” Well, for example, they soldered all the pipes and when they turned on the heating and the pipes got hot...

Of course, if you turn off the heating, the pipes will fall back into place, and the radiator branch will again take its normal appearance. So the principle is clear? It is obvious what happens with polypropylene pipes during thermal expansion and contraction when it cools and heats up again. Such vibration is not weak and can loosen any connection, especially if it is in a screed protected by soft thermal insulation - which does not protect the pipe in any way. For example, such expansion compensators are installed on hot water supply risers.

An expansion compensator is not needed on a cold water riser. In the case of installing heating radiators with open-laying polypropylene pipes, namely open, this is the correct use of polypropylene pipes. Expansion compensators are installed by competent plumbers in the design of the radiator piping.

Well, that is, the principle is clear - the pipe has room to move during expansion, the expansion itself is not noticeable to the eye if, as mentioned above, thermal expansion compensators are taken into account in the design. And if there is nowhere, then here..

But this has already been discussed above, and in order not to be repeated, it’s time to move on to the question of the correct - hidden laying of pipes inside the floor or walls. For this purpose, Swedish engineers from the company “Uponor” or the old name “Wirsbo” developed a special material called cross-linked polyethylene or simply cross-linked or PEX.

Who sews it and with what? The fact is that the technology of cross-linking polyethylene is achieved at the molecular level using special irradiation of ordinary polyethylene, after which the polyethylene molecules begin to have a special molecular memory that they - the polyethylene molecules - acquired after this very irradiation. Now this is not just a pipe made of “Pert” type polyethylene, but a highly reliable “PEX” type pipe made of molecularly cross-linked polyethylene, which remembers its original state at the time of irradiation and always strives to return to this state, no matter what loads it is subjected to. Watch a video about how a man abuses a pipe by breaking it and heating it with a burner and it returns to its original state.

And this is the polypropylene pipe that we discussed above. (cracked from stress..)

Well, that is, the difference between pipes for hidden installation inside the walls and under the screed is obvious. The stitching is intended specifically for high-quality internal lining, and the polyester is intended only for external lining. Do not confuse this when communicating with a plumber and check with the appropriate questions the master for his competence. Here is an option for the correct replacement of a heating radiator in the Tsvety residential complex in Nizhny Novgorod on Sakharov Street.

The expansion coefficient of pipes made of sieve polyethylene is even higher than that of polypropylene, but this is not scary because it does not bunch up at the seams inside the screed as described above, but simply walks or fidgets inside a special rigid corrugation. Which is required when installing heating pipes inside the screed. Sometimes, during a major renovation of an apartment in a new building, there is a need to move the heating radiator. Often this is necessary in order to move the heating radiator to a glazed loggia or to the wall in order to free up space from the balcony partition and make the loggia or balcony an extension of the room.

To move a radiator in a new building, a special press tool from “Rehau” or “Uponor” is required. Such a tool costs about 100 thousand rubles. Therefore, the finisher cannot have it. And connecting collective farms under the screed. Working with cross-linked polyethylene requires a special installation tool, which is not cheap, so not every plumber has it in stock. In connection with this, you may receive proposals such as to fake threaded connections and switch from cross-linking to poly, reject them immediately. This issue was discussed in detail above. Such a collective farm should end up in a way that you know what will lead to.

For those plumbers who have tools for working with cross-linked polyethylene pipes, the cost of moving a heating radiator to a balcony or wall starts from 4,500 rubles. Not cheap, but of high quality in compliance with all SNIPs for the installation of hidden pipelines.

Braided pipes are laid so that the cross-linked polyethylene pipe can move freely as it expands and contracts inside the protective jacket; all turns are made for this purpose as smooth as possible without sharp corners and pipe clamps inside the protective jacket.

It is also necessary to properly insulate all joints so that the main cross-linked pipe does not come into contact with the concrete screed in any way, in order to avoid chafing and destruction of the pipe after a certain period of operation, to the point of complete destruction and leakage. Competent plumbers from the Trubservice Nizhny Novgorod company carried out work on moving heating radiators and heated towel rails with hidden connections inside the walls made of cross-linked polyethylene in all districts of Nizhny Novgorod and in almost all new residential complexes. Such as Julieverne, Flowers, Seventh Heaven, Water World, and Residential Complex South. For reference, we provide prices for all types of work on borrowing and moving heating radiators throughout Nizhny Novgorod.