Heating equipment is a special niche in the household appliances market, which has its own leaders. And one of these is the domestic company BaltGaz, which has conquered the Russian buyer and consumers from the CIS countries with equipment produced under the Neva Lux brand. Today, the manufacturer is demonstrating considerable success in the niche of water heating equipment and gas boilers. And one of the most popular models brought to the market by BaltGaz is the gas boiler Neva Lux 8224. It is this unit that will be discussed below.

Advantages and disadvantages

Gas boilers have a number of important advantages.

- Modern design. These heating boilers have a beautiful and neat appearance, as evidenced by many consumer reviews.

- Low price. According to most experts, this heating equipment will be affordable for almost anyone.

- Good performance. Such units can operate stably even when the gas and water pressure is too low.

- Safety. This equipment is equipped with a multi-level security system.

- Ease of control. To set the desired mode, you just need to use the remote control to select the temperature you need on the monitor.

- Possibility of heating on two wings. Neva gas boilers can be used to heat a house with two branches.

Despite this list of positive qualities, Neva gas boilers also have some disadvantages.

- Presence of noise. Often, during operation, such a device makes extraneous sounds.

- Possibility of breaking screen buttons. Some users noted that a short time after purchase, these units experienced a breakdown of the button that is responsible for switching the temperature mode. After that, it had to be purchased additionally and installed at a separate price.

e2

Error e2. Ignition failed, check the following:

- Open the shut-off valve on the gas pipeline; if you are using liquefied gas, the cylinder may be empty. There is a breakdown in the gas line, contact the gas service.

- The spark plug is broken, replace it with a new one.

- There is a fault in the electrical circuit of the spark plug. Using a multimeter, test the contacts for an open or short circuit.

- There is insufficient distance between the spark plug and the burner section, set the gap to 5 mm.

- Dust accumulation on the spark plug, clean it from deposits and degrease it.

- Disturbance in the electrical ionization circuit. To check, do the following: while the device is operating, remove the wire from the spark plug. The boiler operation should stop and 01 will appear on the monitor.

Then connect the wire back and hold down the K6 and restart keys, after which the device will turn on. The flame is detected by the principle of monitoring the ionization current. Its measurements are carried out using a microammeter, alternately connecting ionization candles into the circuit.The optimal value is from 3 to 5 microamps. A possible reason for the decrease is its leakage or insufficient connection, incorrect connection (swap the spark plug and ionization plug).

- Insufficient distance in the ionization candle and separation by the burner. Set it in the 3mm range. Ionization candles for boilers Neva Lux

- The ignition transformer has failed. Replace it with a new one.

- Damage to the electrical circuit in the ignition transformer. Check it for breaks and check the integrity of the connectors.

- Burner block clogged. Clean it.

- There is a malfunction in the electrical circuit of the fuel supply regulator. Check the circuit with a multimeter and test the controller board. Repair if you find a break; if the board is faulty, purchase a new one.

- The electronic board is broken. Needs to be replaced.

The most popular boilers of the Neva Lux series

Under the Neva brand, modern luxury class gas boilers are produced, which eliminate the shortcomings of previously produced models. The design has been changed, modern automation has been installed, but the price of the products is less than models of Western companies with similar parameters. Other models of domestically produced gas boilers can be found in our article “Russian-made gas boilers: varieties and properties.”

Model Neva luxury 8618

For Neva Lux gas boilers, the price depends on the model. Single-circuit models are cheaper, double-circuit models are more expensive. For example, one of the most popular models in this series, the gas boiler NevaLux 8618, is in demand due to its low price and the following qualities and capabilities:

- small dimensions;

- all models are adapted to Russian conditions;

- the boiler is equipped with a circulation pump manufactured by the Neva company, which facilitates the installation of the boiler into the installed heating system;

- DHW is organized by connecting an indirect heating boiler;

- if necessary, a fan is connected for forced smoke removal;

- connection to a room thermostat is provided.

The popular single-circuit gas boiler Neva Lux 8618 for wall installation is intended only for heating, but if necessary, organizing hot water supply is possible using an indirect heating boiler. The model has the simplest possible design with non-volatile automation. The price of this boiler is the lowest of the entire model range.

Model Neva luxury 8224

The wall-mounted gas boiler Neva Lux 8224 is designed for heating rooms up to 250 m2. The boiler is equipped with a unique water-cooled combustion chamber. High accuracy of temperature setting is ensured by a special microprocessor. In terms of their parameters, Neva boilers are not inferior to foreign models, the only difference that the gas boiler Neva Lux 8224 has is the price, reviews of many owners confirm this.

This model has two heat exchangers. A plate heat exchanger is used for hot water supply, and a copper heat exchanger built into the Neva Lux gas boiler of this series is used for the heating circuit.

For the popular gas boiler Neva Lux 8224, reviews found on the Internet fully confirm the excellent consumer qualities of the device. Many reviews emphasize that the Neva Lux 8224 gas boiler has a relatively low price and high performance. This is a wall-mounted double-circuit model, which is designed to heat rooms up to 240 m2. The unit provides hot water supply (DHW).

Malfunctions of the gas boiler Neva Lux

The simplest single-circuit and non-volatile model Neva Lux 8618. It completely lacks electronics. A simple Neva gas boiler is very reliable.

The most common faults characteristic of this boiler are the following:

- very low level of gas pressure in the line;

- low pressure due to the presence of air in the circuit;

- burner flame goes out;

- mechanical damage to the boiler or heating circuit.

The presence of a control unit with a microprocessor in the Neva Lux 8224 model allows for self-diagnosis of faults that arise during the operation of the gas boiler. The electronics installed on the Neva Lux double-circuit gas boiler displays faults on the display in the form of an error code.

e1

Error e1.

This malfunction indicates low fluid pressure in the heating circuit. The reasons may be as follows:

- The heating circuit has become airy or the pressure has dropped to its minimum point. Increase the fluid pressure in the system, remove air from the heating circuit.

- The bypass valve is installed incorrectly or is faulty; to check, follow these steps: set the boiler to heating mode, then close the shut-off valve to the heating circuit.

The bypass should redirect the liquid not into the heating circuit, but pass it through the bypass line (at the same time it will heat up). And, if it is faulty, replace it with a new one, installing all the taps in the position in which they were before the check. - Pump failure. It is necessary to remove it from the device, disassemble it, wash it, and clean it of accumulated deposits. If this does not work, replace it.

- There is a breakdown in the electrical circuit of the pressure sensor.

Using a multimeter, test the circuit for an open; if found, repair it. DHW sensor Visually check all contacts and connectors. If this does not give the expected result, replace it with a working device. Occurs often in Neva Lux 2073. - A slow-moving rod or sticking of the measuring device rod in the heating circuit, the cause could be a failure of the membrane on the flow sensor.

To begin, remove this sensor from the device, turn the boiler (pump) on and off, in a similar way you can remove the boiled rod. If this does not work, check the condition of the membrane; if it is worn or deformed, replace it. - There is a malfunction in the flow sensor, or the integrity of the connecting wire is broken. Perform an electrical circuit check and also check the connections of the controller board connectors. If the problem persists, replace the flow sensor. Typical for the Neva Lux 2083 model.

- Failure in the electric motor of the three-way valve. Repair is not possible, complete replacement is necessary.

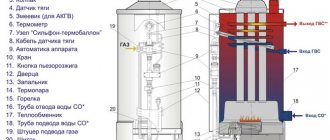

Design features

Neva gas boilers are single-circuit or double-circuit equipment that has an open or closed combustion chamber. Each of these devices has a built-in thermostat. It controls the temperature of the coolant.

The operation of such units can be generated with a thermostat, which will make it possible to accurately set the temperature regime. The burner of this device has automatic equipment used to control the flame.

Each Neva boiler is equipped with a pressure gauge (a device for measuring gas and liquid pressure). Install it on the device panel. With a significant increase in temperature, the pressure in the system increases. Heating appliances from this company can operate stably even at low water and gas pressure.

These gas boilers have a screen with which you can set the required temperature. Thanks to the display, the operation of blocks and nodes is monitored. It comes with a special control panel. In one set with the device itself there is an expansion tank, a circulation pump and a detailed diagram that contains a complete description of how to install the device.

Review of the Lux boiler line

The range of boilers is represented by two basic modifications: Lux and Turbo. If we talk about the Lux series that is already well known to consumers, it can also be divided into two categories:

- Neva Lux double-circuit mounted gas boilers have a closed or open combustion chamber and a bithermic heat exchanger. Requires connection of a coaxial or classic chimney. The heating of the coolant is controlled using “smart” automation with high precision. The maximum distortion from the set temperature is no more than 1%. Another significant difference that Neva Lux 2-circuit wall-mounted gas heating boilers have is the ability to connect two heating systems at once. There are outlets for heated floors. Independent control of coolant heating is carried out for each heating system.

Wall-mounted single-circuit gas heating boiler Neva Lux - works exclusively for heating the house. Modification to provide domestic hot water is allowed by connecting an indirect heating boiler. High efficiency is achieved through the use of a modulating burner, which changes the combustion intensity depending on the selected temperature regime. Conversion to liquefied gas is possible. Neva single-circuit atmospheric wall-mounted gas boilers are especially popular due to their low cost, ease of maintenance, and the absence of volatile components subject to voltage surges.

Connecting a thermostat significantly reduces gas consumption and ensures that the automation operates in a completely autonomous mode. The control unit will independently adjust the heating of the coolant, depending on the degree of heating of the room.

The company's new product is the Turbo boiler

Neva Turbo boilers are, in fact, a modified version of the already familiar Lux modification, taking into account the shortcomings of previous versions. The models have the following technical characteristics:

Turbo boilers are energy-dependent. The boiler is powered by connecting to a regular 220 V mains voltage. For stable operation, you will need to install a UPS and a generator.

Ease of maintenance and operation

It is enough to connect the installation to the heating and power supply system and start heating your house or apartment. In practice, provided the heating system is already ready, all work takes about 3-4 hours.

After installation, there is no need to worry about the safety of the station. The sequence of operation of the automation completely eliminates the possibility of gas leakage and the creation of an emergency situation, even if an unplanned power outage occurs.

The main differences between Neva boilers

The Turbo modification provides economical gas consumption and, subject to proper operation, fully pays for itself within a few years.

Calculation of power and temperature of a warm water floor

Russian wall-mounted gas double-circuit boilers Neva provide consumers with maximum comfort when switching to autonomous heating and hot water supply. This equipment is intended for use in multi-apartment residential premises and country houses. For the production of boilers, modern materials are used, as well as high-quality components from the best European suppliers. The company's designers conduct a constant scientific research, testing prototypes of new models on an experimental one before launching into mass production.

Thanks to this, it is possible to correct all the shortcomings, improve the manufacturability of production and, which is important for gas equipment, increase the degree of its reliability. The domestic manufacturer BaltGaz has implemented two design options in Neva Lux gas double-circuit boilers. Thus, in the boilers of the 72 series, as well as in the BaltGaz 18 DBF boiler, a single bithermal heat exchanger is installed to work with heating and hot water circuits

This decision made it possible to reduce production costs, which had a positive effect on the pricing of these products. In addition, the products of the 72 series provide precise temperature control with a tolerance of 1 0 C. The models of the 82 and 86 series use a traditional layout with two heat exchangers - copper for the heating circuit and plate for the hot water supply circuit. The entire line of double-circuit boilers, with the exception of the Nevalux-8624 model, is equipped with a closed combustion chamber. In addition to the above, Nevalux gas double-circuit boilers are distinguished by thermal performance and minor design details:

- Nevalux-7211 - thermal power 11 kW, bithermal heat exchanger, maximum heating area - 110 m2

- Nevalux-7218 - thermal power 18 kW, bithermal heat exchanger, maximum heating area - 180 m2

- Nevalux-7224 - thermal power 24 kW, bithermic heat exchanger, maximum heating area - 240 m2

- BaltGaz 18 DBF - thermal power 18 kW, bithermal heat exchanger, maximum heating area - 180 m2

- Nevalux-8624 - thermal power 24 kW, copper heat exchanger (heating) and plate heat exchanger (DHW), maximum heating area - 240 m2

- Nevalux-8224 - thermal power 24 kW, copper heat exchanger (heating) and plate heat exchanger (DHW), maximum heating area - 240 m2

- Nevalux-8230 - thermal power 30 kW, copper heat exchanger (heating) and plate heat exchanger (DHW), maximum heating area - 300 m2

wall-mounted boilers

Wall-mounted gas boilers are in great demand among consumers who have a house or small cottage. This is due to the advantages of this type of equipment. Thus, the wall-mounted boiler has small external dimensions, due to which the equipment can be installed indoors with minimal loss of space. The equipment does not make noise during operation and is capable of stably performing assigned tasks, regardless of operating conditions. Many users choose the Neva Lux double-circuit gas wall-mounted boiler for installation in the heating systems of their homes, the advantages and main technical characteristics of which will be discussed below.

The lineup

The manufacturer's product line includes several wall-mounted Neva Lux models with compact dimensions, the power of which varies from 12.7 to 30 kW.

The model is initially intended for use in apartments and small houses with an area of up to 110 square meters. m. This unit has two circuits and a closed chamber, with a power of 12.7 kW. Equipped with a bithermal heat exchanger and an electronic ignition system. Capable of heating up to 9 l/min when using DHW. The use of a common heat exchanger led to a reduction in cost while maintaining functions. Features low gas consumption.

Heater diagram Neva Lux 7218

- The power of this double-circuit heater with one bithermic heat exchanger is 18 kW. Designed for living space up to 180 sq. m. It features a more powerful pump, as a result of which the heating rate of hot water reaches 14 liters per minute.

- A double-circuit boiler with one bithermal heat exchanger is designed for rooms with a heating area of up to 240 sq. m. m.

- It differs from the above model by connecting a remote control, an outdoor temperature thermostat and a personal computer. There are two heat exchangers, one of which is copper and the other is made of steel plates. Designed for 240 square meters of area. Runs on liquefied gas. Equipped with a closed chamber, cooled by water and a forced smoke removal system.

- This double-circuit model with an open chamber is intended for use in heating systems of apartments and houses with a total area of up to 300 sq. m. m. Equipped with one bithermic heat exchanger.

- Neva Lux 8624. This model, with a power of 24 kW, is equipped with two heat exchangers and an open combustion chamber. The Italian electronic board is adapted to our conditions.

As you can see, along with proven budget models, the manufacturer supplies their updated versions at a higher price. The firebox of the latter (the designation begins with an eight) was water-cooled. The heat exchanger for heating water is made from tubes of increased diameter, which slows down the appearance of scale.

The external cladding is made of metal-plastic. Three layers - primer, galvanization and enamel - reliably protect the boiler from corrosion. They feature improved control panels.