Most solid-state boilers have one significant drawback - the fuel in them burns out very quickly and you need to make sure you have time to put in the next portion. However, this entails irrational use of firewood, briquettes, pellets and, as a consequence, high heating costs.

The solution to this problem can be a purchased or homemade long-burning boiler with wood, which will maintain their long-term smoldering and high temperature. Certain factory models can even work without firing pads for up to 20-25 hours. In addition, they can be heated with other types of solid fuel, including waste that can be burned.

Video

- 1 Operating principle of a long-burning boiler

- 2 How does everything work?

- 3 Video - making a wood-burning boiler with your own hands

- 4 Manufacturing instructions 4.1 Chimney and reflector

Advantages and features of long-burning designs

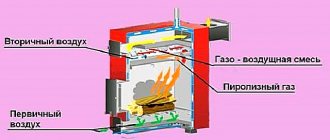

Analogs with long-burning support differ from conventional boilers by the presence of two working chambers at once. In the first of them, the stored fuel is burned directly, and in the second, the released gases are burned. Timely oxygen supply plays an important role. An ordinary fan with simple automation can be used as a device for pumping air.

Main elements of long-burning heating boilers

Among the advantages of the units it should be noted:

- minimum number of fuel fills;

- high work efficiency;

- use of various types of solid fuel;

- a small amount of soot in the pipes during operation;

- reliability of the design.

Operating principle of the modern model

Calculation of heat storage volume

A volume that is too small is ineffective, a large volume is impractical in terms of costs and loss of usable area of the room. An accurate calculation cannot be performed due to the lack of information about the heat loss of the building, especially if it is at the design stage.

However, it is possible to calculate as approximately as possible. The initial data is the boiler power and the total area of all heated premises. Calculations are made as follows:

- The heater power in kilowatts is directly related to the area. 1KW is capable of heating 10 m2. If the house is 120 m2, then the boiler should produce 12 kW. It is necessary to provide a reserve so that the equipment does not operate at maximum load (average coefficient - 1.5). It turns out that you need to install an 18 kW boiler.

- Neglecting the volume of liquid in pipes and radiators, it is assumed that every kilowatt of power is spent on heating 25 liters. coolant in the heat accumulator. Multiplying the two values, we get 450 liters. This value is not the maximum, because at the last step a power reserve of 50% was included.

The stored reserve will be enough for the coldest winter. The equipment will not operate at its maximum capacity, which means it will last a long time.

Calculation by formula

There are many complex mathematical formulas that allow you to make calculations

The simplest formula looks like this: m = Q / 1.163 x Δt,

Where:

- Q is the estimated amount of thermal energy that we can accumulate. This is the difference between the power generated by the boiler and what we need for heating;

- m – mass of water in the tank, kg. We want to calculate it;

- Δt – difference between the initial and final temperatures of the coolant, °C;

- 1.163 kW/kg – specific heat capacity of water.

Advantages and disadvantages of homemade boilers

Do-it-yourself, long-burning wood-burning boilers are becoming increasingly popular, the reason for this being the obvious advantages of such units:

- The duration of operation from one filling of the firebox with wood is 2 times longer than that of traditional boilers, and from 1 loading of coal – 3 times.

- The simplicity of the design allows you to make a boiler installation yourself, which will be much cheaper than a factory-made analogue.

- Possibility of design improvement. For example, the “trendsetter” in this direction, the STROPUVA brand, indicates in its technical specifications an operating pressure of 1.6 Bar. This is a low indicator; by strengthening the design, you can make your own solid fuel boiler with a working pressure of up to 3 Bar.

- Undemanding to the type of fuel. You can put firewood, coal, sawdust and other combustible waste into the combustion chamber. The main thing is to provide air access to it. There are also no special requirements for wood moisture content.

Craftsmen have somewhat simplified the design so that homemade long-burning boilers using coal or wood can be made at home. The change concerns the way air is supplied to the firebox. The folding telescopic structure is quite difficult to manufacture and requires additional costs.

Instead, they install a steel pipe, the length of which is 300-500 mm greater than the height of the firebox, welding a “pancake” and air diffusers at the end. The other end simply sticks out of the boiler lid; an air damper is made on it to regulate the air supply, which is turned manually. A fan is not used for injection; combustion occurs due to natural draft. Changes in the design can be traced by studying the drawings of solid fuel boilers made by yourself.

The disadvantages of homemade long-burning boilers largely replicate the shortcomings in the design of factory units. But there are ways to fix them:

Difficulties in manufacturing a cylindrical body. Without a rolling machine or at least a pipe bender, it is very difficult to make a round body from sheet metal. As an option, craftsmen use propane cylinders or pipes of the appropriate diameter for heating. This will add weight to the structure, since standard large-diameter pipes have a wall thickness of 5 mm or more. To make a water jacket, it is better to use thin-walled pipes.

Factory long-burning boilers are difficult to ignite when the combustion chamber is loaded to a quarter. Long-term operation of the unit is not always required; sometimes you need to heat the house a little. The boiler body is round and high; it is very difficult to fill the firebox a quarter of the way through the loading door and light it up. In homemade units, you can provide an additional door in the middle, not forgetting about its high-quality sealing.

Due to the design features, it is not recommended to load long-burning wood or coal boilers with fuel “on the go”; you must wait until the previous portion is completely burned. If you lift a load during operation and open the door to load firewood, smoke will pour out of it directly into the room. You will have to throw wood quickly and somehow, this is unacceptable. The deficiency can be treated by installing a heat accumulator, which experts recommend including in the piping of any solid fuel boiler.

In the upper position, the air supply pipe of a homemade boiler will stick out to a height equal to the height of the firebox. This should be taken into account when choosing a location for the water heating installation.

Self-production

It is quite difficult to construct a heating boiler with your own hands. The slightest inaccuracy and it will not work correctly, which can lead to tragedy. Therefore, it is necessary to carefully study the technology of their manufacture and carry out all activities very efficiently.

Shaft-type heating devices

You can create a mine or pyrolysis boiler yourself. The first operates not only on wood, but also on coal, peat or sawdust. You can immediately load up to 50 kg of firewood into its chamber.

When the chamber is fully loaded with fuel and high power, such a device will work continuously for up to 5 hours, at the lowest power (15-20 kW) - up to a day. Its efficiency is 75%. The power of such models can be adjusted automatically.

Pyrolysis model

Yellow or colorless wood gas, released under high temperature, is the heat source in the pyrolysis boiler. For such a heating device, you can only use completely dried firewood, otherwise it will not start. The pyrolysis design can also operate on pellets. Their automatic feeding into the furnace (using special augers) will be an additional advantage of the boiler. The operating time of a model of this type when fully loaded is 12 hours.

Disadvantages - high cost (you can reduce it if you make it yourself), energy dependence (the fan runs using electricity), large size. To make such a device you need:

- pipe and sheet of steel 4 mm thick;

- professional pipes, metal rods with a cross-section of 2 cm;

- electrodes;

- fan;

- fire bricks;

- automatic temperature controller;

- fasteners.

They first draw up a diagram of the future boiler with all the calculations. The most successful design of a homemade boiler in this regard, developed by engineer Belyaev, is taken as a basis. Adjustments are made to it according to the wishes of the home owner. For example, heating can be made more efficient by increasing the volume of the heat exchanger jacket.

Homemade pyrolysis devices must be installed on fireclay brick platforms specially equipped for them. After this, they are connected to the water circuit.

During the first test switch-on, they find out whether there were any errors in the boiler design. If everything was done correctly, the device can quickly switch to gas generator mode. The room will become much warmer within half an hour.

Tools and materials

A wood heating device is the safest design. Its autonomy, ease of operation, minimal risk of explosion, and the possibility of self-production are its main advantages. Its disadvantage is the regularity of adding fuel.

Homemade wood-burning boiler models can be made from the following materials and parts:

- metal barrel (volume – 200 l);

- steel sheet 3-5 mm thick (to create a firebox);

- metal pipe with a diameter of 20 mm and a wall thickness of 3 mm;

- L-shaped pipe (diameter – 20 mm);

- grate;

- doors for the vent and firebox.

Homemade models of wood-burning boilers are made using gas welding equipment and an angle grinder.

Sequence of work

Before starting work, you must carefully consider the design of the device, purchase all the necessary materials and tools.

Cut 3 circles (diameter of each 57 cm): this is the bottom, the top cover and the partition between the ash pit and the firebox. Make a hole with a diameter of 20 mm in two of them.

A strip 400 mm wide and 3600 mm long was cut from a sheet of steel, holes were cut in it for the firebox door, and below it for the ash pan. Weld the sheet together into a circle.

Weld a circle with a hole on top and without one on the bottom. Install a partition with a grate between them.

Weld the pipe and the barrel together according to the “one inside the other” principle. Install a firebox with a blower underneath. Connect all elements by welding.

Attach an L-shaped piece of pipe to the top of the barrel: it will connect the heating container and the chimney. When water heats up in a barrel, it forms steam, which will freely escape into the chimney, thereby preventing the pressure in the boiler from increasing.

Install pipes at the top and bottom for cold water inlet and hot water outlet.

Hang the doors on the firebox and vent.

Install the structure on a foundation made of refractory bricks.

Such a device heats using firewood, pellets or peat, tightly packed inside the firebox.

Even the simplest model of a wood-burning boiler requires care and attention when making it yourself

Choosing the type of solid fuel boiler

How to understand which boiler will be optimal for servicing a particular heating system? Obviously, you need to decide on the type of fuel, the required power of the unit and the features of its design, installation process and subsequent operation, as well as the features of the connected heating system.

Among the materials that can be used as solid fuel, the most widely used are:

- coal;

- peat briquettes;

- pellets;

- firewood;

- sawdust and other combustible production waste.

Types of solid fuel for heating boilers in the photo

In order to increase the profitability and efficiency of the heating system, it is possible to manufacture a universal unit that can work with various types of fuel.

The choice of the type and design of the heating boiler directly depends on what fuel you are going to use, the required performance of the heating system, as well as the place where it will be installed. The following modifications of solid fuel heating units are suitable for self-production:

Equipped with a steel or cast iron heat exchanger, they can be used for both heating and hot water supply. The efficiency of such boilers is about 85%.

- Pyrolysis

They ensure separate combustion of fuel and the volatile gases released, thereby significantly increasing the efficiency and, consequently, the cost-effectiveness of the heating system.

- Pellet

The efficiency of this type of heating boiler reaches 90%. Their main advantage is the high degree of automation of work processes, and the disadvantage is the complexity of the design.

- Long burning

They are able to operate continuously throughout the entire heating season, requiring fuel loading once every few days, which distinguishes them from classic solid fuel boilers.

Heating installation in a private house with a wood-burning boiler

Wood-burning boilers with a water circuit for heating a private house are connected to an existing heating system with forced or natural circulation of coolant. During installation work, the requirements of PPB and SNiP are met.

Another important issue taken into account during connection is the need to accommodate large fuel storage. The boiler burns 10-15 cubic meters of wood per season. The storage must be dry, accessible, spacious and safe.

Where can a wood boiler be installed?

A wood-fired hot water boiler for heating a private home can be installed anywhere, provided that it meets the technical and fire safety requirements. General recommendations regarding the choice of premises for a boiler room are:

- For the needs of a boiler room in a private house using wood, use any technical room that meets the following requirements: ceiling height of at least 2.2 m, area 8-12 m². There is supply and exhaust ventilation and lighting.

- You can install a wood-burning boiler in the basement, provided that the room is dry and heated. Compliance with these conditions will extend the service life of steel heat generators.

- A wood-burning boiler for heating a private house with water heating is installed on a solid foundation. If you connect a cast iron unit, you will need to make a concrete foundation.

- To prevent accidental fire when laying firewood, the wooden base, in the direction of opening the fire door, is covered with a metal or asbestos-cement sheet.

- The firewood storage is located in an adjacent room.

- The boiler is installed in a place convenient for maintenance. All components: the water treatment and filtration system are given free access.

- Modern heating of a private house with a wood-burning boiler often requires connection to the electrical network. Be sure to install a voltage stabilizer and an uninterruptible power supply. Automation is connected directly from the switchboard, through automatic devices and RCDs.

- The chimney is installed in compliance with fire safety requirements during installation. All heating elements, when passing through floor slabs and roofing sections, are insulated. I install a spark arrestor on the head of the pipe. Chimney options are discussed here.

The main requirement for operating a wood-burning boiler is compliance with safety regulations. Modern models are equipped with a multi-level security system that prevents smoke in the room and boiling of the coolant.

Heating schemes for a private house with a wood-burning boiler

Heating in a private house using a wood boiler can be done in different ways. The choice of wiring diagram largely depends on the design of the boiler and the parameters of the room. All options can be divided into several classes, according to the following features:

Coolant movement - forced heating systems use circulation pumps to create pressure in the water circuit. The disadvantage of the solution is its dependence on energy. Systems with natural circulation use the ability of a liquid to expand when heated. The coolant moves along the circuit by gravity. The disadvantage of the solution is the high requirements regarding compliance with slopes and angles. A professional installer can properly install heating to the radiators.

One and two pipe scheme. The single-pipe system involves connecting each battery in series. The water circuit feeds each radiator, after which the coolant returns back to the boiler. The disadvantage is that heat transfer deteriorates the further away from the boiler. A two-pipe system does not have this disadvantage. A supply and return pipeline is connected to each radiator. This scheme ensures uniform heat supply to each heating point.

A liquid heating system connected to a wood-burning boiler requires proper planning and execution of work in strict compliance with all existing building codes. The heating layout in a two-story house is especially carefully planned. Setting up a security group is required.

When installing circulation pumps. Additionally, a voltage stabilizer and an uninterruptible power supply are connected.

Modern wood-burning boilers are economical, safe and easy to control, and are successfully used as an alternative to gas equipment.

Calculation of power and temperature of a warm water floor

Water jacket

The principle of operation of a solid fuel boiler implies the presence of double walls in its firebox: in the interval between them they are filled with coolant. This design is called a water jacket. As the fuel burns, the liquid in the water jacket heats up. This leads to the appearance of heat flows that lift the hot coolant to the upper part of the container. From here, hot water flows into the heat pipe. After the liquid passes through the entire heating circuit and gives off heat to the home, it returns back in a cooled state. For these purposes it has a lower pipe.

To speed up the circulation of water inside the heating system, special pumps are installed on some solid fuel boilers. However, most models are produced for open heating systems. This refers to schemes where the coolant moves not due to a running pump, but due to a slight slope of the pipeline. This is explained by the simplicity, reliability and efficiency of inertial systems. In addition, they are completely independent of the availability of electrical energy. Thanks to this, they can be used in remote areas deprived of the benefits of civilization.

Two-pipe scheme

Two-pipe heating system

Of all modern heating schemes, the two-pipe one is considered the most efficient. It is based on a closed loop where all the components of the structure are connected. Its operating principle is quite simple: the coolant gradually reaches the desired temperature and begins to spread throughout the battery. Here the process of energy exchange between the liquid inside and the manufacturing material is already taking place. Thus, the coolant completely releases thermal energy and returns to the main boiler. Then the process is repeated. The two-pipe design was created in order to avoid the disadvantages of the single-pipe design. In this case, the equipment includes the work of two main parts:

- A heat supply pipe through which water circulates into the battery;

- To remove heat through which the liquid returns to the boiler.

Due to this scheme, it is possible to achieve maximum efficiency.

Types of two-pipe system

Drawings of solid fuel boilers for long burning

Long-term operation of the device with a heat exchanger on one batch of firewood is ensured by a special design:

- increased capacity of the fuel chamber - holds 2 times the volume of the bookmark;

- non-standard direction of ignition - firewood burns vertically downwards.

The fire engulfs the top layer of fuel. Due to the dosed supply of air flow, an even, low flame is formed. The lower volume of the bookmark gradually heats up as the wood burns out.

Classical

In standard drawings, a heat generator is installed in the shape of a cylinder. The rectangular body is not suitable for classic long-burning boilers.

The equipment works as follows:

- the combustion chamber is filled with wood and lit from above;

- in the process of burning the fuel, a load with a hole for air circulation is lowered onto it through a telescopic pipe;

- oxygen enters the firebox through the chimney under the influence of natural draft or fan;

- There is no heat exchanger in the classical scheme; water for heating is heated directly.

In addition to firewood, peat or coke is used for kindling.

Photo 1. Classic long-burning solid fuel boiler with wood in the combustion chamber and no heat exchanger.

Pyrolysis

In gas-generating appliances, firewood smolders more slowly. Combustible smoke is released, which enters a separate zone and generates additional thermal energy. The design includes:

- Loading chamber. The process of pyrolysis combustion of fuel takes place in it.

- Afterburning compartment. This is where the gas burns.

- Heat exchanger. Performed in the form of a “shirt”. Inside the heat exchanger, water is heated for subsequent release into the network.

- Air supply device. Provides the flow of primary (into the furnace) and secondary (into the afterburning chamber) flow.

- Throttle valve. To adjust the speed and volume of oxygen at the stage of the first ignition of fuel.

- Devices for controlling the temperature and power of equipment.

The two chambers are separated by a fire-resistant ceiling with a nozzle and holes. The rate of heating of water inside the heat exchanger depends on the secondary air flow.

Photo 2. Pyrolysis boiler equipped with a loading chamber, a heat exchanger, the chambers are separated by a fire-resistant ceiling.

Shakhtny

Devices operating on the principle of conventional fuel combustion are simpler than pyrolysis ones. The design includes:

- Firebox. This zone occupies 50% of the equipment volume and often has a rectangular shape. Its height is slightly less than the length of the entire structure.

- Fuel loading hatch. It is installed on top or side relative to the firebox.

- Ash pit. A chamber where ash and coal residues naturally fall. It is equipped under the firebox.

- Grate. Performs the function of a dividing grid between the internal sections of the boiler.

- Door. The dimensions are selected taking into account the possibility of simultaneous access to both the ash and the lower part of the combustion chamber. To regulate the air volume, a damper is installed on the door.

- Section with heat exchanger. In mine boiler projects, water or fire tube type designs are used. A hole is made in the heat exchanger chamber for the entry of carbon monoxide.

- Chimney pipe made of metal or brick with a damper.

Once loaded and ignited, the fuel emits flammable gases. Through the hole they enter the chamber with the heat exchanger, heating the latter. The smoke releases energy and exits through the pipe, and hot water enters the heating network.

Photo 3. Long-burning shaft-type boiler with a heat exchanger in which the fuel emits flammable gases after ignition.

Is it worth heating with wood?

The following solutions are suitable for the dacha: heating with electricity, fuel oil or used motor oil, bottled gas, and the use of solar heating. However, wood heating remains one of the leaders.

Advantages:

- Cheap available fuel.

- Simplicity and low cost of equipment.

- A huge range of technical solutions for any task.

- Aesthetic component: some types of boilers have a transparent door for viewing the living flame.

Flaws:

- The need for labor-intensive fuel procurement, storage and drying.

- Heating with solid combustible material requires at least one stack of firewood per day; if the owners are temporarily away, the house will be cold.

These shortcomings can be solved by installing alternative heaters and purchasing ready-made fuel.

Recommendations for selection

The first and main recommendation is to choose a solid fuel boiler based on the benefits of the type of fuel used, but with a long-term perspective.

If you have a constant source of cheap firewood, then we recommend purchasing a classic wood-burning boiler, despite all its shortcomings.

If you select the right heating unit in terms of power, install the piping and install a heat storage tank, then the direct combustion boiler will reliably serve you for many years.

When choosing, you need to consider the following points:

Take the power of the TT boiler according to the heating needs of a private house, only with a safety factor of 1.2. If you need to additionally heat water for domestic hot water, then take a unit with a power reserve of 1.5. The more powerful the boiler, the longer the firebox and the longer the combustion duration. The less often you will have to visit the boiler room. Do not rely on a double-circuit boiler if you constantly need hot water in large quantities. It will not provide the required flow; it is better to install a solid fuel boiler with an indirect heating boiler. Choose a model with a maximum operating pressure of 3 bar. Cheap heaters made of thin metal can withstand only 1-2 Bar. Try to choose a boiler with a large firebox volume. The standard size of a firebox designed for 6 hours of operation at a power of 20 kW is 60-65 liters; for long-burning units this figure will be 80 or more liters at the same 20 kW. A heat generator equipped with a fan works better than a simple one with air supplied through an open door. Such a unit is worth buying only if there are frequent power outages. Make sure that the ash door is controlled by the mechanical draft regulator. The fan will last longer on a solid fuel boiler when it is on top

On models where the blower is built into the door, the impeller pulls dust and dirt from the floor. Pay attention to the origin of the electronic control unit. Avoid Chinese controllers; when choosing budget models, you can find an inexpensive heater with a more reliable Polish unit. Do not get carried away with top-burning boilers; they have a number of significant disadvantages. Low operating pressure, wood waste hanging on the walls of the firebox and the inability to add firewood “on the go” are included in this list. If you plan to heat your home with coal, pay special attention to the thickness of the walls of the firebox of the model you like

After all, the combustion temperature of coal reaches 1000–1100 °C; in order to withstand it for a long time, you need a steel thickness of at least 3 mm, and better yet, 5 mm. Otherwise, your new boiler will not last long.

Low operating pressure, wood waste hanging on the walls of the firebox and the inability to add firewood “on the go” are included in this list. If you plan to heat your home with coal, pay special attention to the thickness of the walls of the firebox of the model you like. After all, the combustion temperature of coal reaches 1000–1100 °C; in order to withstand it for a long time, you need a steel thickness of at least 3 mm, or better yet, 5 mm

Otherwise, your new boiler will not last long.

Unscrupulous manufacturers often use this trick: the parts of the firebox that face outwards are made of 3 or 4 mm steel, and the remaining elements are made of thinner metal. By pointing to the ends of the parts, the user is convinced that the entire boiler is welded from thick “boiler” steel, although in reality this is not the case.

We can recommend purchasing a pyrolysis heat generator only if you plan to burn dry wood, fuel briquettes or anthracite. Then it will give the expected result. When using fresh firewood, very little combustible gas is released, and therefore the pyrolysis boiler does not work efficiently.

It also does not always make sense to buy a solid fuel boiler with a cast iron heat exchanger, which is much more expensive. Under normal operating conditions, steel will quietly serve for at least 10 years.

Heating a country house with gas

The choice of heating system for a country house, as a rule, depends on a number of factors, and often one of the key criteria is the presence or absence of a gas main near the building. If access to this inexpensive and efficient fuel is free, then the most correct solution would be to install a gas heating system. Accordingly, one of the main questions that arises for those owners who decide to connect gas heating to a country house is how to choose a heating boiler.

This element is the main source of heating, and its selection can be based on different criteria:

Based on how the heating equipment will be operated, boilers can be single-circuit or double-circuit. The first sample is suitable if the only purpose of the boiler is to heat the home. But if you need to not only heat the room, but also heat water for domestic needs, only a dual-circuit unit would be a suitable option. Despite its functionality, using a boiler with two circuits will be extremely unprofitable in those buildings whose area does not exceed 300 m², since the cost of heating a country house will be too high; depending on the method of fixation, a distinction is also made between floor-standing gas boilers and boilers fixed to the surface of the walls (the second option will be relevant for houses with an area of no more than 200 m², since their sizes are small). In a large building, it is advisable to use floor-standing boilers, which are characterized by their large size, but at the same time significant power; When considering methods of heating a country house using gas equipment, it should be noted that boilers may also differ in the type of heat exchange element installed. The most popular samples today are made of copper, steel or cast iron. It is worth saying here that copper heat exchangers can only be installed in wall-mounted boilers; accordingly, in most private houses they are used extremely rarely. Cast iron and steel models have the highest levels of strength and reliability, so the choice should be directed in their direction; heating a country house, where the fuel source is gas, involves installing a chimney pipe, with which you can safely and quickly remove all combustion products outside

But many experts today advise paying attention to the so-called turbocharged boilers, for which installation of a chimney is not necessary. Their design includes two circuits: through one, oxygen enters the combustion chamber (but it is not taken from the room), and through the other, exhaust gases are discharged to the surface

The draft in these devices is provided by the presence of a fan, due to which its installation does not involve any difficulties.

When assembling such a communication as a heating system for a country house, the device diagram requires special attention to be paid to the heating circuit pipes, so how to select these structural elements of the system should be considered in more detail

The best pyrolysis solid fuel boilers

The original system of a solid fuel boiler of this type has a two-chamber design. In the first chamber, when there is a lack of air, the fuel burns, releasing pyrolysis gas. Pyrolysis gas burns in the second chamber; this process can be regulated, which saves fuel. Two-stage combustion allows the solid fuel to burn out completely, which increases efficiency. The equipment is more comfortable to use, but requires the use of dry firewood and depends on electricity. The VyborExpert.ru team analyzed 9 models and selected 3 pyrolysis boilers, which are highly efficient, reliable and do not require complex maintenance.

Vesuvius Elbrus-10

A simple and reliable design, designed for heating a small house or cottage with an area of up to 100 sq.m. It runs on wood and coal, it is possible to install a heating element with a power of 6 kW. The recommended pressure in the system is up to 3 atmospheres. The design of the heat exchanger simplifies access for cleaning. The efficiency reaches 80%, approaching the performance of diesel fuel boilers.

The body is made of structural steel, the sealed doors are made of cast iron. The thermostat, heating element and heating system can be connected from either side of the housing. The equipment is designed to work in systems with natural and forced circulation.

Advantages:

- Precise power control helps create a comfortable microclimate;

- Effective basalt thermal insulation;

- Compact design;

- One stack of wood burns for 8 hours;

- Easy maintenance.

Flaws:

Small volume of the chamber, which is designed for firewood 38 cm.

The model has a simple design, which allows you to do without installing a smoke exhauster powered by electricity. A non-volatile pyrolysis boiler is an economical solution for a country house and cottage in a village remote from civilization.

Burzhuy-K Standard-20

High power and efficiency of 85% allow the equipment to be used for the heating system of a house with an area of 200-220 sq.m. The heat exchanger is made of heat-resistant steel. The volumetric chamber allows the use of firewood up to 55 cm long. Works on all types of solid fuel. The maximum coolant temperature is 95 degrees, the pressure in the system can reach 4.5 atmospheres.

The model is equipped with a thermostat, a pipe for connecting a chimney with a damper. Mechanical control makes the system energy independent. Built-in thermometer and pressure gauge make it easy to control key operating parameters.

Advantages:

- Burning time on one stack of firewood is up to 12 hours;

- Low percentage of harmful emissions into the atmosphere;

- Maximum fuel burn;

- High rate of room heating;

- Manufacturer's warranty 30 months.

Flaws:

There is no provision for connecting a heating element.

Atmos DC 32S

A powerful model designed to heat a building with an area of 250-350 sq.m. When creating, heat-resistant steel with a thickness of 3 to 8 mm is used. To increase heat transfer, ceramic blocks are used in the chamber. The power is automatically adjusted using an electromechanical damper. The regulator performs the function of overheating protection. The control thermostat controls the fan, which blows air and maintains the set temperature. It can work with the fan turned off, but the power drops to 70%.

The model can be equipped with a proprietary electronic control system that takes into account the air temperature indoors and outdoors. The microcontroller controls fans and other equipment, allowing you to save fuel and increase the burning time on one tab.

Advantages:

- Efficiency up to 90%;

- Spacious camera;

- Maximum log length 53 cm;

- Dust-free ash collection;

- The cooling circuit protects against overheating;

- Automatic shutdown when fuel burns out.

Flaws:

High price.

Heating the house with wood

Wood-burning boilers use the appropriate fuel. Having prepared the material, it is dried and then processed into small logs. The product is stored in a room with low air humidity. A kilogram of firewood with a moisture content of less than 20% can produce 4 kW of heat

It is important to keep the fuel dry, otherwise consumption will increase.

How much do you need to prepare?

To generate 1 kW of energy from firewood you will need 360 kg of fuel. A standard 150 kW oven will require approximately 2.7 cubic meters. m. forest.

This number is enough to heat a house of 150 square meters. m. for a month. Converting to kilograms, you get about 1.3 tons of wood with a moisture content of 20% or less.

Thus, about 4 tons of wood will be needed for the winter.

Combustion process

The logs are set on fire and added as they burn. The firewood is kept in a special room where low humidity is maintained, but some of it is located near the boiler. In this way, fuel is obtained, dried by the heat of the device.

The boiler is cleaned every week. This will help maintain high furnace efficiency.

Attention! Once every 5-6 months, the chimney is cleaned, which improves the removal of harmful combustion products. The ash stand is cleaned as it accumulates

The ash stand is cleaned as it accumulates.

Types of boilers and their operating principles

All solid fuel boilers are divided into several types, which differ in many respects. But according to their main characteristics, they are divided into four types:

- Classic;

- Pyrolysis heating boilers;

- Long burning boilers;

- Automatic;

Classic boilers - the operating principle of a classic solid fuel boiler is that heat is provided by flaming combustion of fuel. It has two doors, through one of which fuel is loaded, through the other the boiler is cleaned of ash and other combustion products. They can operate on two types of fuel - wood and coal.

They differ in the material used to make the heat exchanger; they can be made of cast iron or steel. Cast iron is a higher priority in terms of durability, its service life is more than 20 years. Among the disadvantages, one can note the fact that it is afraid of mechanical shocks and is very sensitive to temperature changes, which can lead to destruction. A steel heat exchanger is more resistant to temperature changes and damage, but its service life is much lower - a little more than 6 years.

Pyrolysis (gas generator) boilers—this type of boiler operates on the principle of pyrolysis, that is, the decomposition and gasification of solid fuel. This process occurs with a closed chimney and a closed combustion chamber. After the wood gas produced by the pyrolysis process is released, it is directed into the burner nozzle, where it is mixed with secondary air, which is pumped by a fan. After this, the gas mixture enters the combustion chamber, where it ignites. Combustion occurs at a temperature that sometimes reaches 1200°, and the process will continue until the solid fuel is completely burned.

Long-burning boilers—in this type of boiler, a long combustion process is ensured by special techniques. Currently, there are two long-burning systems (the Canadian Buleryan system and the Baltic Stropuva), but the second has not found widespread use due to its high cost, complexity of operation and many other technical parameters.

Long-burning boilers can be classified as pyrolysis boilers, but the operating principle will be slightly different. The first system (Burelyan) is a furnace consisting of two chambers, where smoldering and gas formation occur in the lower chamber. After the gas enters the second chamber, it mixes with air and then completely burns it (afterburning the fuel). The design of such a solid fuel boiler is a cylinder with pipes welded into it for half a circle. The arrangement of the pipes from bottom to top ensures good air circulation, thereby increasing heat transfer. They are installed mainly in non-residential premises, perfect for heating a garage or cottage. The price for such a boiler is adequate, it is possible to choose a standard size suitable for a particular area.

The boiler according to the Stropuva system has two cylinders, one of which is located inside the second, according to the matryoshka principle. The entire space between them is filled with water, which gradually heats up. The inner cylinder of the system plays the role of a firebox, into which air is supplied using a distributor. After loading fuel, it begins to burn from top to bottom, thereby heating the coolant. The price stated by the manufacturer, the long burning time, from 2 to 4 days, depending on the fuel, the required cooling of the boiler and further cleaning before re-ignition, double the task and cause inconvenience. Therefore, this type of boiler did not become widespread.

Automatic boilers - in this type of boiler, the process of loading fuel and removing ash is fully automated. The boiler is equipped with a screw or conveyor hopper for fuel supply and automatic ash removal. The automatic coal boiler option involves movement of the fuel combustion layer, which is necessary for complete combustion. To do this, the automatic boiler is equipped with movable grates, or chopping and moving mechanisms. The coolant heating and fuel combustion parameters are provided by forced charging.

The benefits and features of automatic boilers can include;

- Do not require labor-intensive maintenance and close attention to the combustion process;

- Equipped with a temperature regulator included in the kit;

- Many are equipped with a sensor that monitors the temperature in the boiler itself;

- The efficiency of an automatic boiler is up to 85% of the total;

- Long-term operation, limited only by the capacity of the hopper for automatic fuel supply.

It is worth considering that fuel consumption, in particular coal, is much less than in traditional solid fuel boilers.

Materials

When choosing a solid fuel boiler, you should also pay attention to the material of manufacture: they can be made of steel and cast iron. Cast iron solid fuel boilers are resistant to corrosion, have high efficiency and require almost no cleaning

A cast iron solid fuel boiler usually uses coal and wood as its main fuel. Domestic KChM and imported “Solida” from the manufacturer Sime are popular. But such household units have one drawback - they are very heavy and a foundation needs to be laid under them. Steel boilers are easier to install and transport due to their weight, but are also less reliable in long-term operation.

What is a heat accumulator and what function does it perform?

When the combustion is strong, the system overheats; when it is weak, it cools down. The amplitude can be reduced and the period of oscillations can be increased by using a large tank with a heat accumulator. The latter is a heat exchanger with a large container filled with heat transfer fluid. One part of the system takes excess energy from the boiler, the second gradually releases heat into the heating system, preventing the temperature from dropping sharply. This entire process occurs automatically through coils controlled by three-way valves.

Operating principle

A heat accumulator is a container within which a hot coolant fluid circulates. The temperature is maintained in the desired range thanks to the dosing of energy transferred to the circuit. The heated tank releases heat into the rooms gradually. As a result, there is no need to constantly maintain combustion in the boiler furnace.