A pleasant stay in an apartment or private house is determined, first of all, by the fact that the room should be cozy and comfortable. And this is only possible if the living space is warm. Many people ask the question: what is needed for a heated floor? How to do it yourself, without resorting to the help of specialists? The answers are given in the article.

What you need for a heated floor

Water heated floor in the apartment

Design and principle of operation

Before you start studying information about what materials you may need to install a heated floor yourself, you should understand what the operating principle of this system is. So, a warm floor is a system of small diameter pipes assembled and laid in a certain way, inside which a coolant supplied by a pump is located and circulates. The heat carrier is ordinary water, heated in a special device. During installation, the pipes are laid under the floor covering or directly into the screed, depending on the installation method.

Operating principle of water heated floor

Expert opinion

Afanasyev E.V.

Chief editor of the pol-exp.com project Engineer.

To make it pleasant to walk on the floor barefoot, the temperature of the coolant should not be high - no more than +40-45 degrees. In this case, the floor covering itself will warm up to only +25-28 degrees. However, heating equipment usually warms up the water more strongly - up to +60-65 degrees.

Connection diagram for a water heated floor boiler

That is why it is necessary to regulate the temperature of the coolant. In the cottage, a condensing gas boiler will help ensure the ability to adjust, which is highly efficient even at low temperatures. Here the water will be immediately supplied to the heating system. For some other types of boilers, it is necessary to use a specially designed mixing unit, thanks to which cooled water will be supplied to the heated water.

Traditional radiator heating

Traditional radiator heating

Next, the water begins to be distributed along the heating circuit using a distribution comb - a pipe branching system. It is also called a collector. It consists of two pipes - supply and return - which supply and collect water from the branches of the system.

On a note! The distribution manifold may be absent if the heated floor is installed in a room with small dimensions.

Warm floor collector

Tools and consumables

To lay the pie you will need:

- Stationery knife;

- Roulette;

- Pliers.

To install fasteners under pipes (depending on the type of fasteners):

- Hammer;

- Drill;

- Screwdriver;

- Crosshead screwdriver.

Installation of metal pipes will require:

- Pipe bender;

- Pipe cutter;

- Low power welding machine;

- Solder;

- Flux;

- Crimping tool;

- Flaring kit (possibly).

To lay plastic pipes you need:

- Pipe cutter;

- Tool for crimping pipes;

- Pipe soldering apparatus (depending on the type of pipe);

- Glue and activator (depending on the type of pipes).

For installation and assembly of the manifold, connection of pressure gauges, controller. Thermostat and pump required:

- Set of wrenches;

- Set of flat and Phillips screwdrivers;

- Fum tape;

- Sealant.

Disadvantages of heated floors

Unfortunately, in multi-storey buildings built decades ago, it will be quite difficult to install warm water half-water - such apartments (or rather, the heating system in them) are simply not suitable for this technological solution. If such a floor is installed, then in winter the neighbors will complain about the cold in the apartment. And the homeowner is unlikely to be satisfied with the temperature readings at home. The management company will also most likely not give permission to install heated floors. In this case, it is best to install electric floor heating - it does not require a permit.

Electric heated floor

On a note! In new buildings now, as a rule, a special heating system is installed, which allows you to connect heated floors to it. In such buildings you don’t even have to ask permission from housing and communal services for installation.

Materials for heated floors

The diagram of such a floor in the picture always looks quite complex - a mass of communications connected to each other, through which water also flows. However, in reality the system does not include such an extensive list of elements.

Materials for water heated floors

Accessories for water heated floors:

- if it is not possible to connect to the centralized heating system, use a heating boiler ;

- pump , which is either built into the boiler or purchased separately. It will pump water into the system;

- directly the pipes through which the coolant will move;

- collector , which will be responsible for distributing water through pipes (not always necessary);

- the collectors will need a special cabinet, splitters that distribute cold and hot water, as well as valves, an emergency drain system , and devices for removing air from the system ;

- fittings, ball valves , etc.

One of the options for a heating scheme in a private house with heated floors on the ground floor

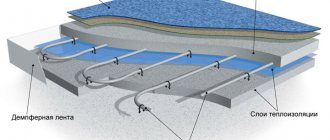

Also, to install a heated floor, you will need thermal insulation material, fasteners, reinforcing mesh, and damper tape. If the raw installation method is performed, then also the concrete mixture from which the screed will be made.

Fastenings for water heated floor pipes

Mounting strip for heated floors

The choice of materials and tools for the floor heating system will often depend on the installation method. There are two types of equipment laying - dry and wet.

- Wet technology involves the use of insulation, fastening systems, pipes, and concrete screed. After all the elements have been filled with screed, the floor covering itself is laid on top. A damper tape must be laid around the perimeter of the room. It is advisable to place a waterproofing layer under the insulation in case of water leakage - it will protect neighbors from a possible flood.

Water heated floors. Water floor diagram

- Dry technology. In this case, the heating system is placed on wooden plates or polystyrene mats in specially made channels. Sheets of plywood or gypsum fiber board are laid on top of the system. The flooring is installed on top. By the way, you should not lay chipboard or OSB on top of the system, since they contain substances that, under the influence of elevated temperatures, begin to evaporate and negatively affect the human body.

Warm floor without screed

Neither the first nor the second methods are ideal - each has its own advantages and disadvantages. However, most often the wet method is used, when the underfloor heating system is laid in a screed. The reason is simple - low cost, although this type is quite difficult to maintain. For example, repairing pipes in a screed will not be easy.

Screed for heated floors

Boiler and circulation pump

A boiler is needed when heated floors are installed in a private house. In ordinary apartments this is prohibited, but new buildings, where water-heated floors are provided in advance, require their connection to a separate circuit. A circular pump is necessary in any case, as it ensures the movement of water.

The boiler capacity, pump power, as well as the possibility of connecting an additional one depend on the planned capabilities of the system and are calculated in advance. If desired, you can even purchase a ready-made pumping and mixing group.

Distribution manifold and cabinet for it

It makes sense to install the distribution comb or manifold inside a cabinet specially designed for this purpose, so that the mass of pipes is not noticeable and does not spoil the appearance of the room. The width of such a structure should be about 12-15 cm, but other parameters will largely depend on the dimensions of the entire communication system - the larger it is, the larger the cabinet. When arranging it, the need for space for bending pipes supplied to the collector system must also be taken into account.

Collector in a niche

Important! If the underfloor heating system is divided into two rooms, then the box with the collector should be located in the middle between them. In this case, it is better to install equipment that allows you to regulate the heating temperature.

manifold for underfloor heating

Nuances of choosing a finishing coating

The best floor covering for a “warm floor” system is ceramic tiles (or porcelain stoneware). It has sufficient strength and does not emit harmful substances when heated.

The only disadvantage of ceramics – the coldness to the touch – disappears, so the combination of warm floors/tiles is ideal for the kitchen, bathroom or balcony.

The tiles will be laid on a pre-prepared base - a leveled concrete screed, so a thin layer of tile adhesive is sufficient for fixing

If you plan to decorate the interior with practical linoleum or beautiful carpet, then when choosing coatings, be sure to pay attention to the markings: products intended for heated floors are marked with the appropriate sign.

Pipes

Pipes in a heated floor system are the most important element. After all, it is along them that the heated water will move. They need to be chosen correctly.

Choosing pipes for heated floors

Table. Types of pipes for heated floors.

| View | Description |

| Copper | Very good, but also very expensive looking. It is ideal for installing a heated floor, but the pipes themselves and the components for them are very expensive. The heated floor system is reliable, capable of withstanding almost any load and very high heating temperatures, and does not burst when overcooled. |

| RE-X or cross-linked polyethylene | Often found pipes are quite durable and can withstand heating up to +125 degrees. When water flows through them, it is practically inaudible due to the high sound absorption rate of the material. Elastic and pleasant material. |

| Metal-plastic | Consists of 3-5 layers, which are connected to each other with special glue. The center of the pipe is foil-coated, thereby increasing the thermal conductivity of the material. The pipes bend well. |

Polypropylene | A cheap option, which is almost never used for installing heated floors, as it bends poorly. It will not be possible to lay it with the required step, and its thermal conductivity is poor. |

Aluminum pipes for heated floors - another possible option

Copper pipes have many advantages

Advice! It is best to purchase pipes made of cross-linked polyethylene - this is the optimal price-quality ratio.

pipes for heated floors

The recommended diameter of pipes for heated floors is 16-20 mm. In this case, the material must withstand heating up to +95 degrees and pressure up to 10 Bar.

KAN-therm pipes for heated floors

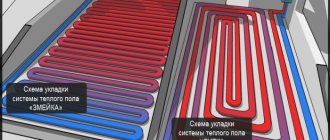

There are different pipe laying schemes, but the most commonly used are snake, double snake and snail-spiral. The first is simple to implement, but as the coolant passes through the circuit, it has time to cool significantly. In this case, installation is carried out from a cold zone to a warm one - for example, from a window to a wall. Spiral and double snake are more difficult to install, but more effective in terms of heating.

How to make a water heated floor - installation diagrams

Styling tips

- The contour should always start only from the coldest wall - from an external load-bearing one or one equipped with a window.

- If the room does not have a common wall with the street, then the system can be laid from the edges of the room to its center.

- The snake will provide gradual heating of the floor.

The pitch of laying the pipe system is usually about 10-30 cm: where heat losses are high, the pitch should be 15 cm, and where they are normal or minimal - 30 cm.

Installation sequence for a heated water floor

The number of pipes will have to be calculated individually for each room. This takes into account the dimensions of the room, the pitch between the pipes, the power of the boiler, the cross-section of the pipe and a host of other small nuances.

Pipe laying

Advice! The easiest, fastest and most accurate way to calculate the number of pipes is using special computer programs.

If an error is made in the calculations, various problems may subsequently arise:

- poor water circulation;

- “thermal zebra” effect - alternating warm and cold areas on the floor;

- heat leak.

Warm floor

Heated floor pipe circuit length calculator

Go to calculations

Collector-mixing group

This equipment may be indicated differently in different diagrams. Somewhere there is a separate mixing unit and collector. Somewhere they are united. Or is there only a collector. All of these are working options, they are just selected for different systems.

Various equipment and functions performed

Mixing unit: why and when you need it

As already mentioned, usually a warm water floor is part of the heating system. Moreover, an additional part. Radiators provide the main heat. Hot coolant is supplied to them. Up to 95°C. For heated floors, the maximum temperature is 50°C. To reduce almost boiling water to just hot water, you need a mixing unit.

The mixing group is an adjustable jumper between the supply and return pipelines. With its help, a certain amount of cold is supplied to the hot coolant from the boiler. This reduces the temperature to the set value.

Mixing and pumping unit. Essential item for most water heating systems

This unit usually includes a pump. Even if there is a pump in the boiler, a water heated floor needs its own. This is a system with high hydraulic resistance. And to ensure normal movement of the coolant, you need your own pump that can overcome this resistance.

Is a mixing unit always needed? Not always. It is not needed if coolant with the required temperature comes from the boiler or riser. For example, if there is a condensing gas boiler. Or there is a riser with coolant +40-50°C. In this case, simply place the pump on the supply or return pipeline. And it's all.

Collector and its equipment

The underfloor heating collector (also called a comb) performs several functions at once. The main one is the distribution of the coolant along the supply circuits and its collection at the reception. The most basic pipe with welded pipes can handle this. Or rather, two similar devices. Pipes are connected to the taps. To one is the supply, to the other is the return. Elementary device.

This is what underfloor heating collector groups look like

The necessary components of this unit also include two taps - on the supply and return combs. Through them, the system is filled with coolant and then pressurized (checked with high pressure using a special device). The coolant is drained through the same taps. It is also very advisable to have a pressure gauge here to control the pressure. This is something that is difficult to do without.

It seems clear with both nodes. But why can the group be called a collector-mixing group? Because in most cases both of these nodes are required. Placed separately, one after the other, these are additional fittings. And they are always the most expensive components of the system. And additional connections increase the risk of leakage. That’s why manufacturers make a mixer and a collector unit in one housing. And they call him accordingly.

Flow meters

This option - just a pipe with taps - works normally only if all connected circuits are the same length. This is what experts recommend doing. But in reality it is very rare to plan a system this way. And if the circuits are of different lengths, then they will heat up differently. The hottest will be the shortest. It will have the least hydraulic resistance, so that most of the coolant will flow through this circuit. The coldest, therefore, will be the longest.

Flow meters are part of the components that allow you to balance the hydraulic resistance of warm water floor circuits of different lengths

To avoid such a picture, flow meters are installed at the supply level, which equalize the hydraulic resistance of the circuits. They are placed on each of the circuits. All they do is, if necessary, reduce the clearance, which increases hydraulic resistance. In this way, the intensity of coolant movement along contours of different lengths is equalized.

Thermostats

There is another device that is placed on the taps of the heated floor collector. These are thermostats. Can be manual or servo driven. You will have to turn manual ones yourself, but servo drives require a thermostat with a temperature sensor from which the control wires are pulled. The system turns out to be more expensive and difficult to install, but also provides a higher level of comfort. With such a device, you can set the floor temperature in each room independently of the others.

The device of a warm water floor with the ability to automatically adjust its temperature

In this case, you can control either the floor temperature (the sensor is installed in the screed) or the air temperature. The latter option is used if a warm water floor is the main source of heat.

Fasteners for heated floors

If heated floors operating on the basis of electricity are quite simple to install - cable or roll heaters are simply attached with ordinary tape under the level of the floor covering - then the system for fastening a heated floor on water is more complicated.

Methods for attaching underfloor heating pipes

The coolant system can be secured:

- using a grid, to which the pipes are attached with wire or clamps. The step between the rods is 5 cm;

Fastening pipes using mounting mesh and plastic clamps

- using fasteners , which are used together with the thermal insulation layer. The clamps are attached to the subfloor according to a pre-designed pipe laying pattern;

- mounting tape, polymer or metal . In the first case there are special grips, in the second there are petals that bend and then wrap around the pipe;

- in expanded polystyrene slabs or heated floor mats in which the retainers are already formed. The most expensive fastening method. But this method allows you to combine the thermal insulation layer with the fastening system.

The cheapest option is reinforcing mesh, and the most expensive is polystyrene foam.

Installation of a pipe system for heated floors (without screed)

Rack type installation of water heated floor

Thermal insulation for heated floors

Thermal insulation is an important element when installing heated floors. It will avoid heat loss and increase the efficiency of the system. It is laid on the floor itself, and a damper tape is also installed along the walls, which will compensate for the thermal expansion of the screed and reduce heat loss.

Thermal insulation for underfloor heating pipes

Advice! It is advisable to lay a heat-reflecting layer - thanks to it, the heat directed downward will be reflected and returned upward.

The thickness of the thermal insulation layer will mainly depend on how well the subfloor is insulated. For example, if there is a heated room below the floor, then a layer thickness of only 1-2 cm is sufficient. If the housing is located on the ground floor or above an unheated room, then the thermal insulation layer should be at least 5-10 cm, especially in the northern regions of the country.

Screed device for heated floors

Insulating the floor with cork

Most often, manufacturers of heated floors recommend using natural sheet cork for thermal insulation. In many ways, the properties of cork allow it to be considered one of the best insulation materials. The advantages of cork as insulation include:

Energy and heat capacity of floors with a minimum amount of wasted insulation material. No serious deformation after pouring the floor with concrete screed. Environmentally friendly material. Does not change volume when temperature changes.

The main disadvantage of this material is its price category. Compared to other heat-insulating materials, sheet cork in place with aluminum foil (1 mm thick) will cost you 3 times more. Read: how to calculate the electrical consumption of a heated floor.

How to make a water heated floor

Making a simple water heated floor in a small room is quite simple even without the help of specialists. The technology for laying a water floor is as follows.

Step 1. The base is prepared - a thin layer of sand is poured onto the subfloor, compacted and leveled.

Preparing the base

Step 2. A layer of waterproofing material is laid - for example, polyethylene construction film.

Laying polyethylene film

Step 3. A thermal insulation layer is laid on top - polystyrene foam 5 cm thick. If necessary, the material is cut to the required size.

Laying polystyrene foam

Step 4. A damper tape is attached around the perimeter of the room.

Attaching the damper tape

Step 5. Reinforcing mesh is laid.

Laying reinforcing mesh

Step 6. According to the chosen scheme, a pipe is laid through which the coolant water will flow.

Laying a water heated floor pipe

All is ready

Step 7. The pipe is secured using plastic clamps.

Plastic clamps

Step 8. The supply and return are removed from the system.

Exiting supply and return from the system

Step 9. Next, work is carried out on laying the cement screed and leveling it.

Cement screed device

Attention! It is worth remembering that the concrete layer above the heated floor system must be at least 3 cm. In this case, the screed should be poured after filling the system with water.

A thermostatic column for underfloor heating is installed on the “return”, which will regulate the temperature of the water in it (“return”). The work is completed by connecting the system to the heating. It will be possible to use a heated floor after laying it using the wet method only after the concrete has dried thoroughly. The approximate period is 28-30 days.

Video - Laying a warm water floor

Main elements of the system

A warm water floor is a whole complex of equipment. It includes:

- Source of warm water or coolant;

- Circulation pump for pumping;

- Distribution manifold;

- Controller or thermostat;

- Emergency system for draining water and venting air from the heated floor;

- Pipes and fasteners;

- Thermal insulation (pie);

- Fittings (taps, valves, couplings, etc.).

Distribution manifold (comb) for a warm water floor.

The following can be used as a source of warm water:

- A gas boiler;

- Central heating system, central heating system;

- Electric water heater;

- Heat pump;

- Solid fuel boiler;

- Indirect heating boiler;

- Solar collectors.