The potbelly stove is very popular for heating small spaces. It is an excellent option for a summer residence, and is very economical and easy to use. The appearance of this stove is a small rectangular box on four legs; it has a door and a compartment for storing fuel, as well as an ash drawer, which must be cleaned regularly. Each stove has a pipe onto which an exhaust pipe is installed; its length must be at least 5 meters. The longer the pipe, the better the traction and, accordingly, the power of the stove. This type of heating device can be made of cast iron or steel.

Potbelly stoves were very popular in the second half of the 19th and first half of the 20th centuries; they appeared in Russia. At that time, this device was considered an excellent solution for heating small houses and even city apartments. The stove consumes wood as fuel, but produces enough heat to heat a room of up to 60-70 square meters. Now such stoves are used for secondary heating, for example, in a country house. potbelly stoves in our time . It allows you to warm the room at the right time, and does not require any financial costs. To operate such a stove, you only need firewood, a chimney and good ventilation in the room.

How to properly install a stove in a dacha?

Attention: installation and first firing of the furnace is carried out only with the participation of a specialist from the manufacturer or supplier!

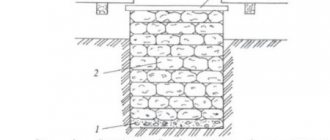

The stove can be installed on a foundation or directly on the floor. When installing the stove on a wooden floor, lay out a platform at least ¼ brick thick; its size should be such that the distance from the stove to the edges is at least 250 mm. A cement screed or metal sheet is laid on top of the brick. It is necessary to have a metal sheet under the combustion door. It is strictly forbidden to install fences around the stove that impede air exchange.

Distance to flammable materials:

- From the back and sides of the stove: at least 500 mm

- Door side: 1250 mm

- Top: 1200 mm.

The distance on one of the sides can be reduced provided that the flammable material is protected by brickwork ½ brick thick with a gap of at least 30 cm from the combustible surface. In this case, the distance from the other side of the stove to flammable materials should be 1 m or more. It is not permissible to reduce the safety distances behind, above or at the front of the oven!

Chimney. It is recommended to use thermally insulated sandwich modules in combination with single-wall pipes. The internal pipes of the sandwich are connected by inserting the upper element into the lower one, the external ones - vice versa: the upper segment is pushed onto the lower one. Remember: sandwich modules are under no circumstances installed at the base of the chimney, where it comes into contact with the stove; a single-wall pipe is installed in this place.

Where the chimney passes through the ceilings, a steel ceiling trim must be installed. The cutting thickness should be 70 mm greater than the thickness of the overlap. The gaps between the grooves and the floor structures are insulated with stone wool, expanded clay or other non-combustible materials. A special roofing passage unit is installed in the roof. When venting a chimney onto a roof made of flammable materials, it is necessary to install a spark arrester on the pipe.

The height of the chimney from the grate is at least 5 m.

The distance to flammable structures from the inner surface of the pipe is at least 500 mm. It is allowed to reduce the distance to 380 mm, provided that combustible structures are protected with a metal sheet on asbestos cardboard (8 mm) or plaster (25 mm) on a metal mesh.

The height of the chimney depends on its location and roof configuration.

- At a distance of less than 1.5 m from the ridge or parapet - at least 500 mm from the top point of the ridge or parapet.

- At a distance of 1.5 - 3 m from the ridge or parapet - not lower than the ridge or parapet.

- At a distance of more than 3 m from the ridge or parapet - not lower than a line drawn from the ridge downwards at an angle of 10° to the horizon.

- Above a flat roof - 500 mm.

We will allow the chimney to exit not through the roof, but through a wall made of non-combustible materials, subject to all installation rules. In this case, for normal removal of combustion products, the chimney pipe must be installed at an angle of at least 45° upward; horizontal placement of the chimney is unacceptable.

It is possible to heat the second floor by using heat from the chimney pipe. To do this, sandwich modules are installed only in places where they pass through the ceilings, and a single-wall pipe is installed in the heated room.

Potbelly stove in a country house

Content

Despite all the popularity of natural gas in the modern world, there are still places where its use is still unavailable. In this situation, a person will be helped by a stove in a wooden house, which is heated with wood fuel or coal. You can purchase this fuel at any time of the year.

Classic stove design

In appearance, the potbelly stove resembles an ordinary rectangle on legs. It is equipped with a door and a compartment for fuel, and an ash drawer for combustion waste. In addition, any potbelly stove is equipped with a branch pipe where an exhaust pipe with a length of 5 meters or more is installed. The length of the pipe directly affects the thrust and power of the device. The furnace body is made of steel or cast iron. We also recommend reading about the chimney for a potbelly stove in the garage on our portal.

Potbelly stoves are classified into two types:

- Metal devices.

- Brick buildings.

Brick models fit perfectly into a small country house and can heat several rooms at once. The stove heats the rooms evenly and allows you to retain heat for a long time. The only drawback of a brick potbelly stove is the long heating process. But the brick adds more functionality to the device; for example, during masonry, you can build a place for cooking. Craftsmen can arrange a recess for the oven.

Models of cast iron stoves are compact and easy to install, because they can be placed in any suitable place. The main thing is to fold the chimney correctly so that it can be easily moved thanks to the corrugated pipes.

Difficult climatic conditions are a factor that everyone living in the vast Russian territory has to take into account. With the onset of cold weather, houses, apartments, and industrial buildings are connected to centralized heating systems that supply heat and create comfortable conditions for us throughout the heating season.

How to make a Loginov potbelly stove with your own hands?

Making a Loginov potbelly stove does not require special tools or materials. The master must be able to weld, cut and rivet metal, and strictly adhere to the diagram.

Tools

When working with metal you will need the following tools:

- Grinder for cutting metal.

- Welding machine and accompanying protective equipment.

- Gun for riveting metal.

- Tool for cutting threads of different diameters.

- Drill and drill bit for metal.

Materials

Materials for making a Loginov potbelly stove:

- Sheets of metal with a thickness of at least 3 mm, with a total area of 1.35 m2.

- Iron rods 45cm long – 6 pcs.

- 100mm pipe for chimney. The length depends on the height of the room.

- Pipe 80mm and 30mm for blower and outlet.

- 200mm pipe about 10cm long for the firebox door.

- Plug 220mm.

- The metal angle for the legs is about 1.2 meters, depending on the intended height of the structure.

- Rivets 6 pcs.

Step-by-step instruction

- Cut the metal into the required pieces in the form of a rectangle according to the diagram (above, in paragraph Diagram and drawing).

Prepare the leaf pieces

- Cut holes for the firebox door and ash pan in the pipes and sheet metal for the front of the stove, and also make a hole for the chimney pipe in the top sheet.

- Cut threads on the ends of the 200mm and 30mm pipes, inside the firebox door and the vent plug.

Carve pipes

- In the 30mm pipe in the thread area, drill holes in a circle in a checkerboard pattern. There should be no holes outside the thread.

- Weld a blower from 80mm and 30mm pipes according to the diagram, weld the edge of the 80mm pipe. Make a plug for the blower.

The blower can also be upgraded as in this photo

- Weld the sheets of metal together, weld the chimney outlet, fuel door and ash pan to the holes.

Weld the body

Weld the remaining parts to this body

- Weld iron rods onto the walls of the stove.

- Place the stove on its feet by welding a metal corner. Cut the corner legs and bend them as in the diagram.

- Weld the screen. Using a special gun, rivet the sheets together as in the drawing, bending the sheet of metal at the back of the screen.

- Weld the chimney pipe at the smoke exhaust point.

Weld the chimney

- Check for defects, assemble and remove the chimney to the street.

- Perform a test fire. If the stove does not smoke and has good draft, then the work is finished. The oven is ready for use.

Possible difficulties during construction

The gas cylinder valve is screwed on very tightly. It's not easy to remove. Unscrewing will require a good adjustable wrench and a lot of physical effort. To make the process go faster, it is recommended to fix the cylinder.

Attention! Do not start cutting the cylinder without first filling it with water, as residual propane can lead to an explosion. Cutting metal, cutting sheet steel with a grinder is a labor-intensive process

The work will be speeded up by a plasma cutter, which can be rented from specialized companies.

Cutting metal and cutting sheet steel with a grinder is a labor-intensive process. The work will be speeded up by a plasma cutter, which can be rented from specialized companies.

A finished potbelly stove placed on a base may wobble. This happens if the heater legs are of different lengths. Trim them using a grinder.

Types of potbelly stoves

The furnace body can be made of several types of metal:

- become;

- cast iron

When the stove is made of cast iron and heated with wood, we can talk about a very large weight. Warming up such a mass requires time much longer than heating the steel structure.

However, this inertia quickly becomes a positive quality when the oven begins to cool. Steel walls remain hot only in the presence of a combustion process. As soon as it stops, they instantly cool down.

Cast iron cannot cool down so quickly; it will give off heat for quite a long time after the combustion stops and is completely extinguished.

The service life of a cast iron stove is much longer than its metal counterpart. Burnout of the walls occurs very slowly. But unfortunately, there is one significant drawback. If the stove is hit with a heavy object, it may crack and become unsuitable for further use.

The “stove stove” models are available in several types:

- without legs;

- with legs;

- rectangular;

- barrel-shaped.

The most suitable fuel for such a design, according to its manufacturers, is rectangular firewood. There are many more of them in the firebox.

cb678e447e48d3d55624aaee2a5bf068.jpe 575569543b630d3d5e4d27e16a8bd004.jpe ab80d2e71c5bd0767f7505f6bbb68c3e.jpe

When a “potbelly stove” is made with your own hands, it is most often given a barrel-shaped shape.

Safety Recommendations

dry firewood and logs

What must be observed for safe operation of the potbelly stove:

- The stove must be installed on a non-combustible base;

- All objects and flammable surfaces must be no closer than 70-80 cm from the stove;

- You should not put more than three kilograms of fuel into the potbelly stove at one time;

- The firebox door should always be closed, except when loading firewood;

- It is prohibited to operate the stove if there is a problem with the exhaust pipe;

- Do not leave the oven running unattended for a long time or in the presence of small children;

- It is forbidden to touch the oven body while it is running or immediately after the flame in it has gone out; the entire surface heats up to a very high temperature;

- Do not leave or keep flammable objects or materials near a working stove.

If all the rules are followed, the potbelly stove will heat the room for a long time.

Wood processing

The most common protective agents include special impregnations (fire retardants) and transparent mastics. They usually process the following elements of wooden structures:

- ceiling beams;

- floorboards in the stove installation area;

- walls adjacent to it.

Additional Information! When choosing products, it should be taken into account that putty has a higher fire protection rating than colorless impregnation.

Fire retardant treatment of wooden elements can be carried out not only by representatives of the Ministry of Emergency Situations, but also by the owners of the house. In the second case, they will need to obtain a special certificate confirming the correct installation of the oven.

Installation of a potbelly stove

It should be remembered that the installation and operation of a potbelly stove, as a temporary heating device, is almost always a struggle for the presence of draft in the furnace of the stove. When installing the stove, you should not abuse the length, as well as the number of elbows and bends of the chimney, since each of them increases the resistance to the gas flow, and accordingly, reduces the draft. But it is still desirable to have a horizontal section of the chimney leading from the stove to the exit from the room, the so-called hog. Since the hog significantly (up to 25%) increases heat transfer and, accordingly, the efficiency of the potbelly stove. The hog can be quite hot and therefore must be equipped above the average height of the people in the room. The outlet of the potbelly stove chimney from the room is equipped, as a rule, through a window (in light structures such as huts, tents - and through the ceiling), using a cutting - a metal sheet with a hole for the chimney, which isolates the hot chimney pipe from the wooden frame of the window and the awning of the tent.

Stove installation

The installation rules are based on protecting surrounding objects and walls from the hot walls of the potbelly stove:

- Base. It must be non-flammable. Of course, a concrete slab is ideal, but few people can afford such a high-quality foundation at their dacha. A section of ceramic tiles and a brick base are suitable. Models with legs are not so demanding on the base, since the legs, although they heat up, are to a lesser extent. Here you can use a sheet of tin.

- Distance to walls. If the walls are wooden or lined with flammable materials, the distance to them should be at least 70 cm, if plastic, even more. The same principle applies to furniture.

- Chimney. Pipe diameter from 85 to 150 mm. If possible, you should avoid joining pipes, especially in a residential area, but if you have to join, the joint must be completely airtight. The joints should not coincide with the place where the pipe passes through the floors and roof. In these areas, a fireproof barrier is made of brick, ceramics or concrete, which will protect the floor materials from fire. Often the stove pipe is placed out the window, and the stove itself is placed in the middle of the room. In this case, the section of pipe extending from the furnace (horizontal or inclined) will act as an afterburning chamber and transfer heat to the room.

- Ventilation. The potbelly stove burns with an open principle. This means that it will take the necessary oxygen from the room in which it is located. Therefore, according to the standards, it needs to provide a sufficient amount of fresh air: for 1 kW - 10 m3 per hour. Few country houses can boast of good supply and exhaust ventilation, so the problem is usually solved by ventilation. Otherwise, people will experience unpleasant symptoms of oxygen starvation.

Stove after installation

To make the potbelly stove mobile, that is, to be able to move it from place to place, part of the chimney can be made from fireproof corrugation. You just have to pay more attention to cleaning, because the corrugated area will become a place where soot accumulates.

Useful tips

A potbelly stove will be easy to use if you listen to the recommendations of experts:

- To check the quality of welded joints, the first ignition is carried out outdoors.

- To ensure tightness, the chimney running inside the garage is made from an all-welded pipe without horizontal sections.

- There should be a box of sand and a fire extinguisher next to the stove.

- The places where the chimney pipe passes through the wall or ceiling are insulated with fireproof material.

- A brick screen lined on 3 sides of the stove will protect against accidental burns and retain heat after the fuel burns out. The distance from it to the walls of the potbelly stove should be 5 - 7 cm.

Despite its simple design, a potbelly stove is considered the most reliable and cheapest way to heat a garage. Even garbage can be burned in such a stove. When choosing, it should be taken into account that horizontal structures last longer than vertical ones.

How does a potbelly stove work?

The firebox consists of a combustion chamber, where wood is burned, and a chamber for the ash pan, separated from the combustion chamber by a grate. In the upper part of the firebox there is a flue channel and a hole for connecting the chimney.

The ash pan box is designed to collect ash that pours into it from the firebox. In modern stove models, the ash pan door is equipped with a seal and plays the role of a combustion mode regulator.

The oven door is a box with a window made of heat-resistant glass, a seal and a latch. The simplest models may not have a window.

The chimney consists of steel pipes, single-walled or double-walled (so-called sandwich). In the space between the pipes of the sandwich chimney there is a heat-insulating material (for example, expanded vermiculite). This technology increases the fire safety of the chimney by reducing the temperature in the places where it comes into contact with the structure of the house. The inner pipe of sandwich modules is made of stainless high-alloy steel, the outer pipe is made of mirror stainless or galvanized steel. The chimney is equipped with a special rotary damper - a damper for manual draft adjustment.

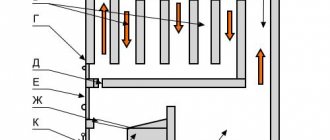

The furnace body is assembled from heat-resistant steel and covered with heat-resistant silicone enamel or other decorative materials that can withstand high temperatures. Modern stove models may have a special convector casing: cold air, entering it from below, is warmed by the walls of the stove and exits from above through special openings. This simple technology can significantly increase the efficiency of the furnace.

Optional equipment. A hob for cooking can be mounted on the top cover of the oven. There are models with a built-in electric heat gun, as well as with the ability to install heat sinks to supply warm air to adjacent rooms.

Stove for a summer residence (potbelly stove): device

Ceiling passage

To allow the sandwich to pass through the ceiling, a rectangular hole was cut to the size of the stainless ceiling cutout. An SML slab 8 mm thick and 60x60 cm in size was laid for cutting. This entire structure was screwed with self-tapping screws to the bars in the ceiling between the floors. In the ceiling around the pipe, insulation with foil two layers thick was laid, the foil was laid towards the sandwich. I taped all the seams with aluminum self-adhesive tape and covered the top with the same LSU sheet measuring 60x60 cm. The roof passage has not yet been laid in any way, because it is planned to redo the roof next year. Masterflash was placed on top and sealed with sealant.

| Produced in Russia, it is distinguished by its aesthetic qualities, the ability to cook, the presence of a transparent door, and quick cooling. Long-burning potbelly stove. | 14,000 rubles | |

| MBS Vesta | Efficiency: 85% | |

| Fireplace stove, made in Serbia, type – long burning. Decorative potbelly stove with high technical characteristics. Features a stylish design and is available in different colors | 32,000 rubles | |

| Termofor 5 | Efficiency: 85% | |

| Manufacturer Russia. Capacious firebox, convenient design, thoughtful design. The series represents several models that differ in size, capacity, heat transfer, and power. | 15,000 rubles | |

| Canada 85 | Efficiency: 85% | |

| Regulation of the intensity of air flow and heat release by the ash box. Compact size, weight 34 kg. The service life declared by the manufacturer is 10 years. The brand's cheap potbelly stoves come in several models. | 5,500 rubles | |

| Duval EYC 303 | Efficiency: 70% | |

| Brand Erendemir (Türkiye). A simple, inexpensive potbelly stove for a wood-burning cottage, the price of which is minimal. | 2,300 rubles | |

| Dream 15 | Efficiency: up to 85% | |

| Wood-burning potbelly stoves from the Mechta brand are offered for different areas. Model “15” is the simplest and least expensive. There is a hob. The height is small. | 6,000 rubles | |

| Buran Heater | ||

| Efficiency: up to 75% | Quickly heats the air, connects to the chimney in two ways, has a cooking surface (high heating rate), high efficiency, no smoke, no smog. Production: Ukraine. | 6,000 rubles |

| Met-Spos dwarf | Efficiency: up to 65% | |

| Convenient shape, high legs, ease of loading firewood, original design, ability to measure indicators. | 5,300 rubles | |

| Army POV 57 | Efficiency: up to 80% | |

| Cheap potbelly stove with hob. Due to its all-cast iron construction, it weighs 50 kg, is easy to install, and is easy to load fuel. The model is old, produced since Soviet times. | 5,500 rubles |

Main functions

Today, such models have a variety of styles. When installing them for heating, they also serve as room decoration.

The fuel for such a system is firewood, the length of which does not exceed 25 cm. You can also use other solid fuels. The main purpose of the potbelly stove:

- heating the building;

- cooking;

- interior detail or decorative decoration.

"Burzhuyka" successfully competes with brick and fireplace systems. However, it has one very important advantage: its dimensions are not large. This stove is easy to transport and connect. It is often used outdoors for cooking on a picnic.

When you constantly have to transport the stove to different places, a collapsible design may be the optimal solution. The top cover, which acts as a hob, is removed. The legs are very easy to disassemble and the chimney to be removed. If desired, you can divide the entire stove into several separate sections.

As a result, you don’t need a lot of space to store the stove; it becomes mobile and easy to transport.

Using such a heating device, you don’t have to worry about carbon monoxide getting into the upper respiratory tract. All harmful gas is removed through the chimney

To achieve this effect, it is very important to carry out the correct installation. The stove's power will reach its maximum if you create good draft

Water heating in a wooden house

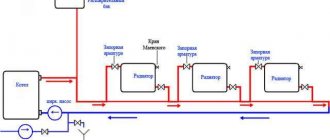

This is the most common type of heating. The coolant (water) is heated by a heating boiler and, circulating through a system of pipes and radiators, heats the house. Natural gas, diesel fuel, solid fuel - coal, firewood, pellets, peat, etc. can be used as fuel for the boiler. Electricity can also be used to heat water in the boiler.

The most economical option for water heating of a wooden house is gas heating. Therefore, if it is possible to connect to a gas main, it makes sense to take advantage of it. Heating with an electric boiler is quite expensive; it can be recommended in well-insulated houses, where energy consumption for heating will be minimal. Diesel fuel boilers are quite economical, but require the construction of a separate building.

The above heating systems are energy-dependent, i.e. If there is a power outage, the heating will not work. The good thing about these types of heating is that they are carried out automatically, with minimal human participation in this process. This cannot be said about solid fuel boilers, which require constant maintenance - fuel needs to be added to them every 3-4 hours. But this fuel has a relatively low cost, and heating with a solid fuel boiler is non-volatile, it will work even if there is a power outage.

When installing water heating for a wooden house, it is necessary to take into account that wooden houses shrink significantly over time, and also tend to dry out from exposure to high temperatures and deteriorate from dampness, which can be caused by condensation falling on cold pipes. Therefore, when laying heating and water pipes in wooden houses, the following conditions must be met:

- Compensators and sliding-type fastenings must be provided on vertical sections of pipes.

- All pipes must be protected with thermal insulation. Heating - to avoid heating the walls, and plumbing - to prevent dampness.

- When laying horizontal pipes hidden, drilling technological holes in the floor and ceiling beams is inevitable. In order not to harm their load-bearing capacity, this issue must be agreed upon with the designers.

User manual

The most important condition for operation is good welding quality. Using chalk coating and kerosene, check for fistulas and defects. Be especially careful with the chimney seams. Load firewood into the combustion chamber, light the fire, close the door and regulate the process using the blower. To reduce the intensity of combustion, you need to screw on the blower; to put out the fire, just screw it on completely.

Heat emanating from metal at a temperature higher than that from brick or stone

To adjust the blower, always use a thick potholder, do it carefully and quickly. Clean the oven after it has cooled completely

If there are welding defects, operation is stopped and the defects are corrected. Carbon monoxide can cause death.

According to some reviews, this stove can smoke when the firebox door is opened. This occurs due to decreased cravings. The defect can be eliminated if you increase the diameter of the chimney pipe to 150mm and reduce its length

Slow burning stoves are popular among fishermen and tourists. By replacing a thick sheet of metal with light and thin stainless steel chimney pipes, they successfully use the Loginov scheme for winter fishing and tourism

Welding is rarely used for such furnaces.

General rules

The art of properly heating a Russian bathhouse is not available to every steam room owner. Everything matters here: temperature, burning time of raw materials. You also need to be able to light wood in the stove. However, it all starts with careful preparation of the premises. All objects that are not directly related to the process of steaming and washing are removed from its space.

First, dry and then wet cleaning of the room is carried out. The shelves, walls, and ceiling are washed with a brush and an antiseptic solution. Upon completion of this procedure, doors and windows are opened and thorough ventilation is performed. This is necessary so that when the temperature rises in the bathhouse space, a favorable environment does not arise for the spread of pathogenic microflora.

Once the rooms have been properly ventilated, it’s time for kindling. Here are general recommendations that are relevant for all types of ovens. In general, the procedure includes several traditional points.

Preparing the oven. The grate and ash pan are cleaned using a special metal scoop with a long handle. You need to unload unburnt coals into any convenient container. Then the ash is used for its intended purpose as fertilizer or disposed of in any convenient way.

Preparing firewood. They need to be brought into the bathhouse and placed at a sufficient distance from the firebox to avoid accidental sparks.

Preparing the stones. With a closed type of heater, only rinsing the surface from settled soot is possible. When open, the stones are washed before each new use. You should take warm water.

Checking the water tank (if equipped)

It is important to make sure there is enough liquid inside. If the boiler is empty, the metal will simply burst under intense heating

For washing and rinsing in bathhouses without a plumbing system, a supply of water is prepared in a separate clean container.

Preparing for kindling. The steam room is closed, the valves, the doors of the smoke window, the blower and the firebox are pulled out and swung open. Next, using a lit match, you need to check the presence of draft - the flame should follow the air flow. If this does not happen, the chimney is clogged and needs cleaning. You need to use a special wire brush to remove carbon deposits.

Start of kindling. 2 thin logs are placed in the firebox on top of the grates, between them - crumpled newsprint, on top of it - thinly planed birch bark, wood chips or shavings. To secure it, a few more logs are added on top diagonally to the resulting structure, with a small gap. You should get a kind of “well” with dry and light filler inside.

Lighting the fire. If you lack experience, you should use long fireplace matches. They are lit and brought to the paper inside the firebox. It is strictly forbidden to use any chemical liquids for ignition in sauna stoves. If the firewood is damp, it is permissible to put a tablet of dry alcohol inside the kindling “well”. After the paper ignites, you need to wait a little and then close the firebox door.

If everything is done correctly, after a few minutes the fire will engulf the wood. Combustion will be accompanied by a characteristic measured hum. If the flame goes out, the steps will have to be repeated. After the flame flares up, the firebox door should be half-open, providing air flow. Then, if the structure has a water tank, its view opens and closes in the flood pipe - this is necessary so that the contents of the tank are heated.

5-10 minutes after kindling, the ignited firewood and coals are leveled, firewood is laid on top, filling no more than 2/3 of the firebox.

When the fuel burns completely, the coals become red, covered with gray ash, there are no blue tongues left in the flame (signs of the presence of carbon monoxide in the chamber), you can complete the procedure. It is worth making sure that the desired temperature has been reached in the steam room and that the stones in the oven are hot. After this, you can open the valves, simultaneously blocking the access of air through the blower. The firebox remains closed.

Upon completion of all combustion processes, you need to thoroughly ventilate the bathhouse from dampness by opening the doors and windows. The stones are rinsed with water from a ladle. This is necessary to remove traces of soot. Then the windows and doors are closed, except for the window in the steam room. After 1-2 hours you can start using the bath.

Operating a potbelly stove

Using a potbelly stove involves alternating cycles of its kindling, which include:

- fuel loading;

- ignition of loaded fuel in the stove;

- heating the stove (its beneficial use for heating people and premises);

- cleaning ash from the ash pit and combustion chamber.

The most important stage is the loading of fuel, which must be placed in an order that facilitates its ignition. First, paper and thin dry branches are laid, with larger dry chopped logs on top of them. Coal is loaded, as a rule, from above onto already well-lit firewood. To restore draft, quite often you will have to disassemble the chimney and clean its pipes and elbows of accumulated soot. Also, the draft in the stove must be regulated by a damper damper, or by changing the length and position of the chimney pipes. Thus, powered by solid fuel, which can be found almost everywhere, a hand-made mobile potbelly stove made of metal will become a reliable help to the zealous owner in many difficult life situations.

Criterias of choice

To choose the appropriate option, use the following recommendations:

- Select the maximum possible cost limit for the potbelly stove;

- Firebox volume (check the maximum load rate);

- Chimney diameter;

- Efficiency indicator;

- The presence of additional layers to improve efficiency;

- Composition of the material (metal or cast iron);

- Quality of finish, if any;

- Size and weight of the structure.

You can find a potbelly stove with a hob on sale. This will help reduce resource costs and save space - you can cook on the equipped surface of the oven.

Simple designs of potbelly stoves

There are several options for potbelly stoves, each of which has a set of both positive and negative properties.

Potbelly stove from a gasoline barrel

As already noted, this version of a homemade metal stove is not durable, but is captivating with its low cost and ease of manufacture. As a rule, it involves placing the barrel in a horizontal position, but you can equip the potbelly stove in the form of a vertically located metal barrel. In the front wall of the barrel, rectangular windows of the firebox and blower are carefully cut out with a grinder; doors are made from the cut out parts (awnings, a handle, a latch lock, and dimensional strips around the perimeter are welded on), which are hung on the corresponding windows of the front wall of the barrel. There is no need to cut through the blower window; instead, at the very bottom of the front wall, it is enough to drill a series of air supply holes with a diameter of about 20 mm. In the rear part of the upper wall of the barrel, several radial cuts are carefully made from the center marked with a core or punch to the size of the future chimney opening. After which the resulting metal petals are bent upward, forming at the same time the opening of the chimney and the semblance of its pipe.

Potbelly stove for a summer residence from a gas cylinder

As a rule, it is equipped with a horizontally located cylinder, the thick-walled metal body of which forms the combustion chamber of the future stove. The end part of the cylinder with the tap is carefully cut off with a grinder, and a firebox door is made from it (canopies, a handle, a lock - latch are welded), which is hung back on the cylinder - the firebox. In one of the side walls of the cylinder, which will become the lower wall of the combustion chamber, a series of holes are drilled in a checkerboard pattern (with a diameter of about 20 - 30 mm, and in increments of about 20 mm). The drilled holes will serve as a kind of permanent grate for the future stove. From below to the cylinder, completely covering the grate, a separately made iron ash box with doors hung on its window is attached (tacked by welding), and the support legs are welded.

Rectangular stove - potbelly stove

The stove body is made in the form of a rectangular welded metal box with a thickness of 3 mm or more, inside of which a horizontal partition made of a sheet of metal of the same thickness is equipped (welded), dividing the internal space into two chambers: the upper, larger part, the firebox, and the lower part, the ash pan. . A grate window is cut into the horizontal partition, which can be equipped in both removable and non-removable versions. In a simpler, non-removable version, the grate is formed by metal rods, laid parallel with some clearance and welded across this window. The removable grate is made in the form of a metal frame according to the size of the grate window, to which the grate bars are welded in parallel with the gap (the gap to the size of the thickness of the rod used). In the front wall of the box, rectangular windows of the combustion chamber and the blower are cut, onto which the corresponding metal doors are hung. The rectangular shape of this stove is convenient in that its upper wall can be additionally equipped with a cooking hole with a burner, and a metal box with sand can be installed on it, which will significantly increase the heat capacity of the stove and smooth out its heat transfer.

Oil fired metal stove

The designs of metal portable stoves, which use waste motor oil as fuel, stand somewhat apart. Their scope of application is quite narrow, and it is determined both by the specific fumes emitted, which are unacceptable in rooms where people stay for a long time, and by the corresponding fuel, which can only be found in quantities sufficient for heating in car garages, car repair shops and industrial enterprises. The design of this stove is relatively simple. It consists of a “pan” - a container for oil with a filler hole, closed with a plug with a throttle to allow air to pass through.

A little history

Potbelly stove Mr. Heath Where did this design come from, and why does its popularity continue unabated these days?

The history of the appearance of the potbelly stove begins at the end of the 18th century. Essentially, it is a cheap alternative to expensive fireplaces and stoves. The device gained particular popularity during the October Revolution, when all the norms and foundations of life were turned upside down. Heating residential and non-residential premises became problematic, so this simple unit quickly spread throughout the country. After all, everything solid that could burn was used as fuel here. And this is firewood, coal, peat, furniture, wooden windows and doors. Potbelly stoves gained a second round of popularity during the Great Patriotic War. In many cities, centralized heating networks did not work, and the country saved energy by sending it to the front. The population had no choice but to use the old proven method - install potbelly stoves in their own apartments.

This stove saved a large number of people from freezing. It worked flawlessly, although it consumed a lot of fuel. And this is its big disadvantage. But this is the simplest and cheapest device that you can make with your own hands, and it is easy to operate.

Currently, potbelly stoves have found their application in country houses, garages, bathhouses and other outbuildings. In modern apartments they were practically not used, if only as a decorative element, creating an antique style. But recently the fashion for them has returned.

True, consumers began to impose more stringent requirements on potbelly stoves:

- Reducing fire danger.

- Presentable appearance.

- Economical fuel consumption.

Let's look at these requirements separately and reveal the secrets of new popularity.

What types of stoves are there?

To make the case, one of two metals is used:

- Cast iron.

- Steel.

Wood-burning cast iron stoves for a summer residence will have an impressive mass. Its heating takes a little longer than steel.

But inertia pays off when decay occurs. The steel walls are hot while the combustion process is going on, and then they cool down just as quickly. Cast iron retains heat for some time after extinguishing.

In addition, cast iron has a longer service life; such a stove will not burn out for a long time. But at the same time, it can be damaged, for example, by dropping it or hitting it with a heavy object - there is a possibility of cracks appearing and the device will become unusable.

Other differences in models. Potbelly stoves can be:

- With legs.

- Without legs, on a flat base.

The former look more elegant and are safer to use.

- rectangular;

- barrel-shaped.

Barrel-shaped potbelly stove

The latter are most often made with your own hands, for example, from a piece of pipe.

About some important points

Typically, long-burning stoves are made of metal. The optimal metal thickness is 4 mm (more is possible). It is better to make the chimney consisting of several parts to make it easier to clean in the future. The chimney also needs a fairly thick metal - this will extend the service life of the element.

Making a stove with your own hands will not be very difficult for a person who has the necessary skills

For the body, you can use a piece of large pipe, a gas cylinder or an old 200-liter barrel; or, alternatively, it can be welded from pieces of metal. You need to make a hole on top of the body to install the chimney (its diameter should be about 15 cm); another hole (10 cm in diameter) will be required for air flow, without which the wood will not burn.

You will also need a load - it will put pressure on the fuel. This should be a heavy iron circle with a diameter slightly smaller (several millimeters) than the diameter of the body. The circle should have a small air duct through which oxygen will flow.

How and with what to heat a potbelly stove?

Fuel. Steel stoves are designed for wood heating. You can also use sawdust-based fuel briquettes, which are sold in construction shopping centers. Stoves designed to fire coal are made of cast iron.

Operating modes. Most stoves of this type can operate in one of two modes: intense combustion and temperature maintenance. For intense combustion, after adding firewood and closing the oven door, open the ash pan drawer to ensure that the maximum amount of oxygen enters the firebox. To switch the stove to slow burning mode (maintain temperature), add firewood again and close the ash pan drawer. The slow burning time depends on the design of the stove and can reach 8 hours for models equipped with afterburners.

The draft is adjusted using a damper: if there is excess draft, the damper is partially closed.

Remember: you can use the stove in high-burning mode for no more than 2 hours a day!

ADVICE To extend the service life of the stove, experts recommend heating the stove intensively for 15-20 minutes after the slow burning mode: this is necessary to remove soot formed during the slow combustion of fuel.

Design and principle of operation

What is the difference between the Loginov Potbelly stove and other metal stoves? The point is the L-shaped blower. The ash pan door is replaced with pipes welded perpendicularly. The edge of the horizontal pipe is tightly welded, and the edge of the vertical pipe has a thread for a plug. There are holes made on the thread - by screwing the plug you can reduce the air flow, thereby regulating the combustion process.

Loginov's original potbelly stove

It is important to make a plug with a slight play, so that expansion of the metal when heated will not cause problems. A screen is welded to the sides and back on the stiffeners to increase efficiency

Without such screens, it is extremely uncomfortable to be near the stove - the temperature is too high and can cause burns. The firebox door is also threaded. A 200mm pipe serves as the firebox opening, and a plug with a handle 220mm in diameter is screwed onto this pipe.

12918027525f238194e21c71fdf01c56.jpe

You can see more details about Loginov’s potbelly stove in this video:

Modification

N. Pyankov’s model is distinguished by the presence of an additional combustion chamber. Unlike more complex designs of slow combustion stoves, the Pyankov potbelly stove is manufactured even faster, the model proposed by Loginov. It is enough to weld steel sheets 140-160 mm long to the back and front walls of the furnace at different distances from the top. The distance between the sheets should be 80mm. The grate is installed 80mm from the bottom. Pyankov moved Loginov’s firebox door to the top of the stove and began using it as a hob.

It will not be difficult for a good master to evaluate all the advantages and disadvantages of the two drawings. If desired, you can make a new model of a potbelly stove using only these two developments, changing the rectangular shape to a round one.

An example of a homemade design (in this photo there is a modernized Pyankov stove), but there is practically no difference in the manufacturing process.

From rims

The materials to weld a potbelly stove, in addition to a couple of disks, will also require a piece of pipe 30 - 45 cm long with a similar diameter, a sheet of metal, and a pipe for removing smoke. This potbelly stove is easy to assemble:

- To adjust the diameter of the pipe to the size of the disks, the ribs are cut off at the joints. After welding, a vertical structure is obtained.

- An opening for the firebox is made on the side surface.

- A door is made from the cut piece.

- To allow air to enter the firebox, a square hole with a side of 10-12 cm is cut out in the lower disk.

- A hole is made on the back of the upper disk for the chimney pipe.

- To construct an ash pan, a metal circle is welded to the bottom.

- To heat food on a potbelly stove made with your own hands, install a hob made of metal 4 - 5 mm thick on the upper disk.

Design

The old models of “bourgeois” were not very diverse; designers did not pay any attention to them. Usually the owner of such a model himself came up with the appropriate design for it. He gave it a more attractive appearance and sought to improve its functionality.

Today you can use modern options that can decorate your interior. These include:

- art casting;

- colored glaze;

- overlays;

- heat-resistant paints.

Such models, in addition to their original external design, also differ in their shape. They can successfully replace a fireplace in the house. "Potbelly stove" will be able to repeat its classic form.