The atmosphere of the steam room should be pleasant to breathe. But if you have to heat the stove right inside the bathhouse, the air can become filled with various harmful combustion products. This problem can be solved by installing a stove in a bathhouse with an external firebox in the dressing room. It will be useful for those interested to learn how to implement a firebox outlet through a wall made of different materials.

Removing the firebox to the rest room Source stove-86.rf

Advantages of a design with an external firebox

A classic Russian bath involves the use of a real wood-burning stove, and not its imitation. And in order to create the necessary atmosphere in the steam room, a means of heating the room is installed directly in it. This is the only way to achieve the desired temperature for steaming the entire body.

It’s good when the stove is heated with selected wood. The room is saturated with an indescribable pleasant aroma. True, there is always a possibility that harmful gases generated during combustion will fill the steam room, despite the fact that the stove should work as an exhaust ventilation. And this happens anyway when the firebox door opens.

The second unpleasant moment is the garbage in the steam room, which cannot be avoided when bringing firewood into it. And manipulating the stove in a cramped room, when they are already taking thermal procedures and trying to relax, is completely inappropriate. Therefore, the option when the stove is heated from another room looks very attractive.

Firebox in the rest room Source cstor.nn2.ru

In addition, a stove in a bathhouse with a firebox in the dressing room has a lot of advantages:

- Not only the steam room is heated, but also the adjacent room.

- There is nothing stopping you from regularly adding firewood to the stove. This means crowded conditions and people in the steam room.

- It becomes possible to protect a hot oven with a safety screen. And this will avoid accidental burns.

- The steam room will be kept perfectly clean.

- In the room where the firebox is located, you can arrange a place for drying firewood. There are situations when such a problem is very relevant.

- The air in the steam room always remains clean and pleasant to breathe. After all, the steam in this case turns out to be light.

- The steam room will receive more usable space, since the space occupied by the open firebox door will be freed up.

- If desired, the firebox can be taken not only into the next room, but also outside.

The latter circumstance is especially relevant when you need to heat the bathhouse with coal instead of firewood. In this case, combustion products are more harmful and it is better that they do not even get into the dressing room. In addition, there is much more dirt from such fuel.

Taking the firebox outside Source oboiman.ru

The option has a significant disadvantage. In order to add fuel to the stove, you must interrupt the bathing procedures and leave the room. Therefore, this approach is justified in commercial organizations, when a special employee monitors the kindling. But since coal provides more heat than wood, some bathhouse owners deliberately accept certain inconveniences.

Having a certain skill, the stove in a bathhouse with a firebox from the dressing room is laid out independently from brick. This approach will support the traditional foundations of bath procedures, since the heater has always been considered an indispensable attribute of the Russian bath. But progress also brings its advantages, which are more practical.

For example, metal stoves heat up faster and therefore require less fuel. In addition, in steel structures, the outlet channel is already welded to the boiler and all that remains is to equip an opening in the wall for it. And some heavy cast iron stoves have a removable firebox. And this adds new possibilities when used.

Installation of a cast iron stove with a remote firebox Source oboiman.ru

Modern stoves are equipped with a firebox door with transparent protective glass. There are both disadvantages and advantages to this. Since such material does not heat up, in the closed position no heat enters the dressing room. To heat the room, you will either have to regularly open the door slightly or install an additional heater.

But if there are no problems with the temperature of the rest room, then such a design can serve as a fireplace. If you move chairs to the firebox, you can observe the fire through the transparent glass. This type of relaxation is especially pleasant after couples treatments.

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

Setting up a chimney

You need to understand how to build a chimney so that carbon monoxide does not enter the steam room.

The furnace pipeline gets very hot and can cause a fire, so the place is prepared especially carefully:

- make markings in the ceiling and cut a window measuring at least 50x50 cm;

- install a passage unit with mineralite into it with a hole equal to the diameter of the pipe + 3-5 mm;

- secure the polyurethane foam with special fasteners and attach it to the ceiling;

- insert a pipe into the protective box and cover it with kaolin wool to a depth of 5-7 cm, no more, so as not to create the opposite effect of overheating;

- After completing the work, use a stainless steel protective screen to increase fire safety, as well as for decorative purposes.

Advice: no matter how well the installation is done, you need to know how to properly ventilate the bathhouse, otherwise the balance of air exchange will be disrupted.

Below is a link to a video where you can learn more about this system:

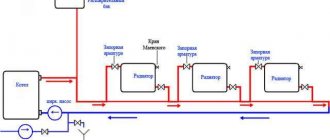

Mounting tank assembly

This mandatory element can be attached as follows:

- fixed on the side wall of the stove;

- placed on top of a single-wall chimney;

- at the end, the heat exchanger is connected to the tank for uniform circulation of liquid.

You can study the issue in more detail and visually examine the process in the video:

Safety requirements

Installing a sauna stove with an external firebox requires the introduction of additional protective measures. But we also shouldn’t forget about the basic ways to comply with fire safety in order to protect people visiting the steam room from injury, and yourself from penalties from supervision. And the implementation of all the recommendations prescribed in the sixth chapter of SNiP number 41-01-2003 will help in this.

Installation of an iron stove with the firebox removed to the dressing room Source oboiman.ru

And in a few words, all the basic requirements boil down to the following:

- A reliable foundation is erected under the main structure of the furnace, which should be adjacent to the wall of the room where the firebox will be installed.

- The remote fuel duct made of iron should only pass through a stone wall. Therefore, if the latter is made of wood, it is necessary to equip a niche in it, which is lined with brick.

- The distance between the metal parts of the stove and the wooden wall must be at least 40 cm.

- This parameter can be reduced if the fuel channel is laid with a reliable insulator. For example, basalt wool or cement-fiber material. If the insulation thickness is at least 5 cm, then the distance can be reduced to 25 cm. When an even thicker gasket is used, then even to 12.5 cm.

- Before the firebox, a steel sheet with dimensions of at least 40x80 cm must be laid on the floor. It will not only prevent fire from coals falling out of the stove, but will also help in removing debris from the fuel.

Steel sheet in front of the firebox Source remontnik.ru

- The distance from the stove to the ceiling of the steam room must be at least 120 cm.

- The edge of the combustion door should be 125 centimeters from the nearest door.

- A homemade iron stove must be lined with bricks.

This last measure will help to avoid a fire in the room if, through negligence, wooden objects, of which there are plenty in the sauna room, interact with the stove body. Factory-made products are usually protected by double walls.

Useful tips

When heating the stove, the smoke must go freely into the chimney, since if carbon monoxide is not removed through the hood, it can cause serious harm to the human body. If a problem exists, you must immediately find the cause of the weak draft and eliminate it.

Several ways to determine the absence or interruption of furnace draft:

- The easiest way is a regular sheet of paper or a lit match, brought to the open door while the stove is firing. If the sheet or flame of a match deviates inward, then there is a draft. If there is no deviation or it occurs outward, then there may be a so-called backdraft, which can be very dangerous.

- One of the reasons for weakening draft may be a depressurized chimney, crack, break, pipe shift, or other defects.

- Another danger is an accidental spark falling into a crack in the chimney onto flammable material, which leads to a fire.

- The small size of the blower through which the exhaust is made can lead not only to the occurrence of reverse draft, but also to an insufficient supply of oxygen to the fuel combustion process.

- Blockages in the chimney can also interfere with the process of normal draft. In this case, regular chimney cleaning will help restore normal air movement. It should be noted that the presence of even one elbow in the pipe, where the bulk of soot accumulates as a result of aerodynamic processes, will greatly complicate the work of the “chimney sweep”.

- If for some reason the stove cannot be heated for a long period of time, an air plug consisting of dense air layers may form in the chimney. As a rule, it resolves immediately after regular heating begins on its own.

- Insufficient firebox volume.

- A wide and long chimney does not work with a small firebox.

Construction of a brick kiln

Having the skill of bricklaying, you can install the stove in a bathhouse with a firebox from the dressing room yourself. To do this, you need to stock up on the necessary materials and tools. You will need clay, sand and fire bricks. You will also need grates and doors for the firebox. You can’t do without a steel corner.

The work cannot be completed without a construction trowel and levels of different lengths. And initially you need to decide on the layout of the furnace. If your work experience is minimal, then it is better to abandon sophisticated projects and stick to the simplest ones.

Laying a stove for a bath Source remontik.org

Putting the stove into operation

During the first kindling, the stove is heated for 1.5 hours, then proceed to a full-fledged firebox.

The brickwork is dried at a temperature of +5 - +30°C. At this time, doors and valves are opened around the clock. The first kindling takes place without the use of flammable liquids and flammable materials. Use dry newspapers and small wood chips. After obtaining a stable fire, you can add logs in small portions.

The ashpit is kept open, the intensity of combustion is controlled by closing or opening the door. Check the draft and heating rate. The heating process lasts 1 - 1.5 hours, then you can proceed to normal heating of the stove.

Installation of a metal structure

Today, manufacturers produce a large number of designs of iron stoves for baths. And options with the removal of the firebox to an adjacent room are especially popular among buyers. In addition, the remote channel is often equipped with a door with panoramic glass. And this helps to monitor the kindling process without opening the stove.

The installation of a metal stove in a bathhouse takes place on a foundation located near the partition. In the latter, an opening is cut for the fuel channel. Before installation, all surfaces are carefully insulated to protect them from excessive heating.

For the same purposes, metal stoves are often lined with brick. But this measure is more common for home-made structures. Because factory-made ovens have very reliable protection and do not need additional protection. Therefore, their lining is purely decorative.

How to install a heating device

Many home craftsmen ask how to properly install a sauna stove on an already poured foundation.

There is no need to attach the heater to the foundation, but sometimes experts advise attaching the legs to anchor bolts.

If you are installing a model with a protruding channel, then it is important to well insulate the portal from fire - this can be done using polyurethane foam or other material that does not ignite.

Video description

The video will show what a stove looks like in a bathhouse with a firebox in the dressing room, metal, lined with brick:

Exiting the firebox through a stone wall

A window is cut out in a concrete or brick partition. Its location is precisely measured using the dimensions of the oven. Since the designs of stoves with remote fireboxes are varied, the height of the window can vary from 40 to 60 cm. And the width can be from 25 to 50 cm.

But to the exact dimensions of the external firebox you should always add 20 mm in each direction. This must be done because metal expands when heated. And all gaps are sealed with elastic, heat-resistant material. The most commonly used is asbestos cord.

In addition, it is necessary to install a metal fence. All free space between the fuel channel and the facing material is sewn with a steel sheet. Since most often all surfaces in the bathhouse are covered with clapboard, the distance from the wood to the firebox should be at least 25 cm. Taking into account that a fairly thick insulator is used.

Video description

For information on how to install an iron stove in a bathhouse with a firebox from the dressing room, watch this video:

Firebox outlet through a wooden wall

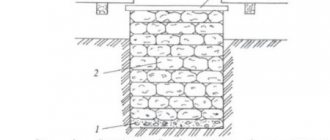

If the partition is wooden, then you can’t get away with a window. It will be necessary to create a full opening to the floor, which is then covered with bricks. And already in the masonry a window for the fuel channel is equipped.

To find the height and width of the opening, you need to mark exactly where on the wall the door to the firebox will be located. Having transferred its contours to the surface of the partition, you need to add 25 cm up and to each side. And already using these marks to cut out the opening.

When creating a window for the fuel channel, which is required by installing an iron stove in a bathhouse, you must follow the recommendations described above.

What to do when the wall thickness is significant

It happens that the stove design has a very short fuel channel. And if the wall thickness is significant, then the door does not extend beyond its surface. In this case, it is necessary to cut an opening in the wall and lay a stone niche made of decorative bricks in it.

And for reliability, a flat jumper is installed above the masonry. A metal sheet with a thickness of 8 to 10 mm is selected for it. As in previous cases, you must remember to seal all gaps with asbestos materials.

Additional wood processing

Fire safety standards require wood to be treated with special impregnations to reduce its flammability. But many people know that impregnations are not particularly useful, especially in a bathhouse, where high temperatures are deliberately planned, at which chemicals will begin to be released into the air and poison a person’s lungs. This is not the result you want to get from visiting a bathhouse.

However, not the entire bathhouse has a high temperature; as a rule, only the steam room. Therefore, in order to avoid fires in other parts of the room from sparks, for example, in the chimney area, experts advise treating the wood with fire retardants at least there.

Important! It will not be possible to treat wood once and forget it for the entire time it is used in the house. You can do a small check: if the wood chips ignite with a match, then it’s time to renew the impregnation

On average, the frequency is once every two years.

Step-by-step instructions for installing a metal stove are as follows:

- Having chosen a place to install the stove, we dismantle the old floor, taking 10 - 15 cm more than the bottom of the stove on each side;

- We dig a hole half a meter deep, compact the bottom and pour a thin layer of sand and crushed stone into it;

- We lay out plastic film to waterproof the slab (double layer);

- We cut out a frame from the road mesh, which is 5 cm smaller in width than the hole, and place it on stands made of pieces of reinforcement resting on the floor, tied to the mesh with wire;

- Fill the hole with concrete. Formwork from boards on top will make the edges smoother and raise the level of the slab. Horizontalness can be checked using a level;

- As soon as the slab hardens, we cover its surface with roofing felt, consisting of two layers, and then 1-2 layers of fireclay bricks so that the base level is equal to the floor level. It happens that the base rises above the floor by 5 - 10 cm;

- After the brick has cooled and hardened, we install the stove according to the design;

- We install an adapter in the wall with welded plates that protect the wall near the chimney;

- We weld the chimney pipe to the adapter;

- On the outside of the bathhouse, we weld another part of the pipe and cover it with a special nozzle to prevent the ingress of precipitation and debris;

- We also install a chimney there;

- We protect the slab from three walls with facing or fire-resistant bricks;

- We line the stove itself with bricks;

- We fill the tank with water, lay the stones;

- Making the first test firebox;

- We control that there are no smoke leaks in places of welding and connections, water leakage from the tank onto the stones or into the firebox, etc.

Briefly about the main thing

Exiting the furnace firebox to the dressing room is largely considered a practical solution. In this case, two rooms are heated at once. Therefore, the rest after taking paired procedures is more comfortable. It is also easier to maintain the required temperature in the steam room and restore order. Because there is much more freedom of movement in the waiting room.

The most difficult thing to implement is the classic version of a brick stove, since its construction requires some experience. But if you follow all the recommendations of experts, you can build a fully functional stove. And also take care of the fire safety of the premises.

It is much easier to use a ready-made factory-made oven. It is more reliable and even compact. Its installation in a steam room is not difficult. The only problem will be arranging a niche for the fuel channel. But following the instructions of specialists, covering the opening with bricks and insulating it will not be difficult even for a beginner in this matter.