Elaborate 19th century church

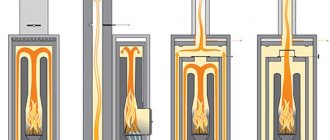

Heating stove, the diagram of which is shown in the figure

| Rice. 17. Diagram of one of the most technically sophisticated furnaces of the 19th century | |

| A. General draft valve B. First lifting well C. Parallel wells D. Cleaning door E. Direct draft suction E. Furnace door G. Grates K. Blower door L. Under fireboxes M. Afterburner chamber |

>This stove can be easily converted into a cooking and heating stove if the firebox is moved to the side of the stove, appropriately equipped with a stove, and the bottom of the smoke channels is lowered to the floor level.

A feature of this stove, apparently developed by V. A. Stroganov, is the presence of:

a) afterburning chambers; b) technically competent distribution of the direction and location of the channels, allowing for uniform heating of the entire area of the furnace smoke wells; c) calibrated direct draft suction hole; d) just one cleaning door, allowing you to easily and easily clean all wells; if necessary, through it you can get rid of the overturning of the draft in the furnace; e) grates and furnace hearth, which are arranged at thoughtful slopes, facilitating more efficient combustion of residual fuel than in stoves that have a strictly horizontal arrangement of the grate and furnace hearth. With this arrangement of chimneys, the stove will heat up evenly over its entire heat-releasing area. The draft in such furnaces is always good.

4. A heating stove with horizontal smoke wells (Fig. 18) is good because it does not require strict and clear fixed markings at the chimney outlet. In pre-revolutionary times, such markings could only be made by a senior furnace master. Marking the foundation and laying the first row was never trusted to apprentices. And not at all because it was a “matter of honor.” The reason for such strict subordination was not formality, but the possibility of making a fatal mistake.

Dimensions for firewood

Given the high flame trunk, experts recommend making a firebox for wood with a height of 80 cm to 1 m. If these parameters are not observed, the combustion of volatile substances will not occur, as a result of which these particles will settle in the chimney system.

Over time, a significant layer of soot will accumulate, which will lead to a decrease in the efficiency of the entire furnace. In order for the coals to roll, it is necessary to slightly bevel the corner parts of the firebox, which are in direct contact with the grate.

Self-laying a brick chimney: what you need to know

In the last decade, there has been a sharp increase in the construction of dachas and country houses, for which fireplaces and stoves are used for heating. But such devices cannot work without a chimney. Previously, stoves and, accordingly, chimneys were laid by experienced stove makers, whose knowledge was passed on from generation to generation. Today, the experience of the old masters is almost completely forgotten, but thanks to the use of the latest materials and developments, the construction of a chimney does not pose any special problems, especially since a high-quality sandwich pipe can be purchased in a store. Nevertheless, many continue to build brick chimneys for fireplaces, considering them the most authentic and durable. How to build a correct and high-quality chimney for your heating equipment will be discussed in this publication.

Delivery of materials

There was still a problem - how to bring the stove, it weighs 100 kg? After much doubt, the Predatory Mouse decided to do everything alone. At the store, upon purchase, they helped load it into the Chevrolet Niva. And at the dacha he unloaded it himself, carried it without outside help and installed it in the house.

He went to pick up the stove and pipes twice. First I bought a stove and all the necessary components for the chimney. And then he had to buy a stove stand, glass for the stove. For the chimney I bought: pipes, adapters, a tee, a wall outlet, thermal insulating filler - cotton wool, fasteners to the wall and a cap. Everything metal he bought was stainless steel.

Learning the Basics

Before you start laying a brick chimney, you should study SNiP 41-01-2003, which regulates the creation of heating systems in private houses. You should especially carefully read section 6.6 of this set of rules, which indicates all the parameters of chimneys.

Further, to build the correct chimney, you should know what this structure is, what types exist and what elements they consist of.

There are three main types of chimneys:

- Indigenous. Pipes of this type are laid on their own foundation. This is an independent structure combined with a fireplace or stove.

- Mounted. Such chimneys are mounted on the ceiling of the furnace and are its integral part.

- Wall. This type of pipe is made in the walls.

Let's look at the elements of the most common mounted chimney. It consists of:

- A mounted pipe, which is located on the ceiling of the furnace. The laying of this section of the chimney is done by tying each brick in a row with bricks of the next row. The laying of this section is done almost up to the ceiling, 5 rows short of it.

- Next comes the expansion of the masonry, without increasing the internal dimensions of the channel. This area is called "fluff". The fluff (cut) is placed with expansion from row to row until it passes through the ceiling.

- A straight chimney – a “riser” – is placed on the fluff (already in the attic). This part of the chimney reaches the roof.

- To pass through the roof, an extension of the “riser” masonry is made, which is called an “otter”. It prevents moisture from entering the attic through the roof.

- A straight section of the chimney is laid, which is called the “neck” of the chimney.

- It, again, ends with expansion. An umbrella or deflector is mounted on the head to prevent debris, precipitation, etc. from entering the channel.

The figure below shows a standard type of chimney indicating all its elements.

Snake - an effective solution

This is how chimneys appeared, built on the “snake” principle, or, more simply, multi-turn chimneys, the length of which is many times greater than the length of a straight pipe.

Movement of gases in a horizontal chimney.

There are multi-turn chimneys, vertical and horizontal. In vertical multi-turn chimneys, the location of the main channels is directed strictly vertically. The main disadvantage of such a chimney is uneven heating.

In contrast, a horizontal multi-turn chimney heats up much more efficiently. Since hot gases tend to rise upward, and the upper area of a horizontal chimney is much larger than that of a vertical chimney, accordingly, heating is carried out much better using the same volume of fuel.

The hottest areas.

Three basic rules

It is much more difficult to assemble a multi-pass chimney for a stove than to assemble a modular gas exhaust system for a gas boiler. When performing work, you must follow strict rules:

- The cross-section of the chimney must be strictly the same size throughout the entire chimney.

- It is necessary to minimize sharp corners inside the chimney.

- Keep the inner surface smooth.

At first glance, these are very simple rules, but how can you follow them in practice?

Brick and chimney - dimensions matter

When faced with laying a horizontal chimney for the first time (see Do-it-yourself chimney), even an experienced craftsman can be stumped when following these rules.

But let's look at everything in order.

- A standard brick has a size of 250×120×65 mm . What do we have in this case?

- It is clear that half a brick will have a size of 1 25 × 120 × 65 mm . Since we are covering the horizontal section of the chimney with brick, we decided on a size of 125 mm.

- Since the height of the brick is 65 mm , it becomes clear that to create one channel you will need to lay out two rows, 65 + 65 = 130 , add to this two layers of mortar.

Our chimney will have a cross-section of 125×125×140 mm . This is very important to remember, since when laying chimneys of this kind, many make a grave mistake.

If the horizontal part of the chimney has a size of 125 × 125 × 140 mm , then the maximum length of the vertical section of the smoke circulation is arranged completely arbitrarily, i.e. as it turns out.

This should not be allowed if, when laying the last brick of the floor, the size of the vertical transition does not correspond to the above parameters, cut the brick to maintain the size. Again, this is very important.

Swirls - methods for solving the problem

The next question is minimizing sharp corners. If you imagine the movement of combustion products inside the chimney as a water flow, it becomes clear that turbulence will appear at the sharp corners of the brickwork, preventing the normal movement of gases and, as a result, deterioration of draft.

Swirls inside the chimney.

The only correct solution in this case would be to smooth out the sharp corners inside the chimney.

Examining the transitions inside the chimney, it is clear that it is possible to smooth out sharp corners only at the very ceiling of the smoke channel. This is done by simply chipping off the sharp corners of the brick. This must be done very carefully and carefully.

Our advice: to smooth out the sharp edges of the brick, use an electric sander. This is much faster and the result will be much better.

Brick, mortar and necessary tools

To build a brick smoke exhaust system, you will need the required amount of bricks and a specially prepared mortar. The brick must be red, solid and fired, with a smooth surface and right angles. The use of bricks with cracks is not allowed.

Using high-quality brick with smooth edges will allow you to build a chimney with uniform and thin seams.

Mortars for laying chimneys can be simple, complex or mixed. The simple type of mortar contains a binder and an aggregate. Mixed and complex solutions contain several types of binders and fillers. The following are usually used as binding components of the solution:

- Clay.

- Lime mixture.

- Gypsum mixture.

- Cement.

Clean sifted sand is most often used as aggregates. The solution, where clay is used as the main binding component, is used for laying stoves and fireplaces and sections of chimneys up to the roof. The simplest and “time-tested” clay mortar for laying chimneys consists of sand and clay in a ratio of 1:1 or 2:1. The mass fraction of sand in the solution depends on the fat content of the clay. The volume of water should be equal to a quarter of the volume of clay used.

Determining the “fat content” of clay is quite simple: you should form a ball of clay with a diameter of about 50 cm. After complete drying (about 3 days), look at the product. If there are cracks, then the clay is oily. If when a ball falls from a meter height it does not break, then such clay can be used to prepare a solution.

The quality of the prepared clay mixture can be determined as follows: lower a trowel soaked in water into the solution (without filler). If clay sticks to it, then the composition is “greasy” and sand should be added. If the mixture pushes out water, then it is “skinny” and you need to add clay.

It is better to start making the mortar for laying the chimney in a shallow and wide container. First, soak the required amount of clay. After some time, the clay must be shoveled, breaking up the lumps. If necessary, add a little water again. When the clay is wet, you should transfer the layer to the flooring and moisten it with water. Using the blade of a shovel, cut into plates and shovel again. This procedure should be repeated 3-5 times until all lumps are completely broken and the solution turns into a plastic and homogeneous mass. If necessary, sand should be added to the solution.

Now a few lines about the instrument. To build a brick chimney you must have the following tools:

To cut the material, it is best to use a grinder with a set of cutting discs.

Beginning of work

He had little space to install the pipe, so everything had to be calculated down to the millimeter. He needed to lead the chimney through the wall and install the pipe strictly vertically upward so as not to interfere with the two edges of the roofs. In addition, the pipe should be installed away from the window. Having calculated everything, he set to work.

The Predatory Mouse considered the main and crucial point to be the manufacture of a support bracket for the chimney, because the entire chimney with tees and other parts should rest on it. The Predatory Mouse made the support bracket for the chimney himself from a 30 mm and 50 mm angle, using a drill and grinder, using bolts of the appropriate length with a diameter of M10 and M8.

And before that, he had to dismantle the wall and strengthen the mounting spots for the bracket from inside the house. Then he assembled the outer bracket and attached two corners to it on top in the form of runners - so that the tee could be moved when adjusting, that is, move the entire chimney away from the roof. After assembling and installing this support bracket, he coated it with metal varnish and protected it from corrosion.

How does the power of a stove depend on the size of the firebox?

The power of the heating device depends on many factors. Let's look at some of them:

- Constructive. The heating device must be folded so that all its component elements are in the correct relationship to each other. Consequently, only the correct design provides the required furnace power depending on the size of the firebox, the height of the pipe and the cross-section of the chimney.

- Operational. The more moisture the fuel holds, the more heat and energy must be expended to evaporate it. The same applies to fuel temperature. Only coals brought from the street will take part of the heat for heating. The combustion temperature is reduced by a large amount of air, causing incomplete combustion of the fuel. Lack of air leads to underburning of the fuel, which reduces the combustion temperature and leads to soot deposition.

The power of the heating device depends on the parameters.

The larger the firebox capacity, the more powerful it is. For 1 kg of dry fuel it is usually considered 4 kW. If the heating device places 3 kg of fuel, then it will produce 12 kW of heat.

Typically, per 10 m2 of heated room area, 1 kW of heating device power is taken.

When laying stoves, only heat-resistant materials are used that do not deform from high temperatures. It is also necessary to take into account that materials have different expansion properties. Clay and bricks are the basis of any good stove. The type of brick should be the first, and all auxiliary materials should be heat-insulating.

A chimney of horizontal design brings heat into the house, not into the chimney

If for a gas boiler it is more profitable to install a metal chimney, then for a wood-burning stove the best option is a brick structure. If the brick pipe is strictly vertical, then most of the heat will go outside.

Many people have probably heard the name horizontal chimney? No, we do not mean a chimney for a “pipe-in-pipe” gas boiler, located horizontally and designed to remove combustion products from a forced-draft gas boiler. Such chimneys are called coaxial.

Verticality is not always justified

Today we will talk about the design of horizontal stove chimneys and the intricacies of their design.

If a solid fuel or gas boiler is designed to heat heating radiators, which, in turn, give off heat inside the room, with their chimneys everything is clear, the more vertical, the better.

More is not better

On what principle does a conventional brick oven work? Heated bricks give off their heat inside the room. Accordingly, the greater the maximum length of the heated brickwork, the more heat enters the room.

But this does not mean at all that it is imperative to build a large oven. You just need a furnace design that will maximize the use of heat obtained from fuel combustion.

Furnace appliances

Furnace appliances - doors, water tanks, grates, dampers, views and valves - are made mainly of heat-resistant cast iron. Cast iron appliances are stronger, more durable, do not burn out or rust. The same stove appliances come in different shapes and sizes, so their exact copy is not given here - the pictures simply show which stove appliance is installed in a certain place in the stove.

When purchasing a valve, pay attention to the engine. If the engine moves very freely along the frame (there is a high gap in it), then with strong traction it will begin to rattle. If there is a special hole on the “underside” of the valve, then this valve is good, and the hole, which should be at the bottom when installed, serves to allow soot to spill out, which accumulates behind the engine in the frame.

What should be the size of a brick stove for a bath?

Brick structures are more diverse in terms of volume and design. What needs to be remembered when laying such a stove is the standard size of the red brick, which has dimensions (250 x 120 x 65 mm). The base is usually laid out in 3.5 by 4 bricks (89 x 102 cm) or 4 x 5 bricks (102 x 129 cm). The height excluding the pipe is 168 or 210 cm.

Most often, the water tank is installed directly into the stove.

How much will it cost

It is difficult to say definitively how much it will cost to build a brick chimney. It all depends on various factors. If you turn to stove makers, in addition to the cost of consumables, you will have to pay well for their services. And this will double the cost of the chimney.

If you do the masonry yourself, then the cost of the structure will depend only on the purchased materials (brick, cement).

In conclusion, it is worth noting that laying a brick chimney on your own is a long, labor-intensive and responsible process. There is no point in experimenting here. Having absolutely no skills in construction, it is better to entrust this matter to specialists. Since the life and health of you and your loved ones depends on the proper operation of the chimney.

Source

The simplest kitchen stove made of bricks

| Rice. 24. The simplest kitchen oven. |

| A. Valve B. Spark arresting tooth C. Stove D. Firebox D. Stove E. Side section G. Front section |

Characteristics:

a) very low height of the firebox - only 21 cm (if someone doesn’t like this size, the height of the firebox can be raised, but in this case you will need two to three times more firewood for cooking).

For firewood in a stove with a similar firebox height, it is best to use an old picket fence and unnecessary leftover lumber. Two or three old pickets will be enough to prepare a full dinner in the summer for a family of six people. However, in our time, when most rural residents use gas or electricity for cooking, a stove of such height is unlikely to find its mass user;

b) the presence of a spark-extinguishing tooth and the absence of everything unnecessary.

Practical advice on how to select the size of a sauna stove

There are several key factors to take into account.

- The most important thing is that the dimensions of the heating unit correspond to the size of the room. For a small steam room, you should give preference to a compact model, this will protect you from contact with a hot surface and protect you from burns.

- The design must be thought out in advance to make it easier to work with heating elements and to be able to regulate the temperature.

- The power should be sufficient to heat the room well and generate steam.

- To exclude the possibility of spontaneous combustion, it is imperative to comply with all fire safety rules regulated by SNiP 41-01-01.

The dimensions of the sauna stove are an important aspect that you should pay attention to. Take a responsible approach to the manufacture of this element, and your bathhouse will become a place of better relaxation.

Subscribe to our Social networks

What is a Swedish stove and where is it used?

If you recall the life of an ordinary Swedish family in the 18th-19th centuries, it will immediately become clear what interests the stove served in each home. The hostess was engaged in cooking and household chores, the owner - mainly fishing or hunting. The harsh northern climate and capricious changeable winds made it necessary not only to heat the living space, but also to often dry shoes and clothes. Food can wait a long time for the hunter to return from hunting. In case of hypothermia, you need to quickly warm up and restore your health. The design of the Swedish stove meets all these needs.

Today, the requirements for stoves are no different from medieval ones. People still need warmth, the ability to cook food, a comfortable temperature while relaxing and minimal effort to maintain all this.