Effective floor insulation in a frame house is carried out according to a scheme proven over the years. It provides the following sequence of layers: a strong and level base, vapor-permeable waterproofing, insulation, vapor barrier, subfloor. The scheme is quite variable, as it depends on the type of foundation being built, financial capabilities, the laying of certain communications and the required level of thermal insulation.

Foundation type and floor insulation

Depending on the quality of the soil at the construction site, a frame house is erected on a columnar, pile, monolithic or strip foundation.

Columnar and pile foundations imply the construction of a so-called suspended, raised floor . In this case, a significant distance remains between it and the ground, ensuring ventilation of the structure. The most important thing when installing such a structure is its reliable protection from moisture from the outside.

Note! The floor covering, which serves as the basis for laying insulation, on a pile or columnar foundation is carried out not from the inside, but from the outside. To do this, use boards with special crossbars, which are fixed to the load-bearing beams.

The situation is similar when constructing a strip foundation. The floor is also raised above the ground, but, as a rule, not to a great height. For its ventilation, holes are left in the foundation walls - vents.

A different situation arises with a monolithic foundation. In this case, we are talking about insulating the floor on the ground. Here it is important to ensure high levelness and waterproofing of the base. To install such a floor, a concrete screed is poured.

Preparatory work

This step is recommended to be performed before installing the frame of the house. For heaving (clay) soil with a high level of groundwater, you need to create a drainage system.

Advice

It consists of special pipes (drains) with holes that drain water beyond the foundation to a place of storage or processing.

Inside the foundation, a layer of soil of 40-50 cm is removed and drains are installed on the sand bedding.

Then they are covered with a sand and gravel cushion. It should not come into contact with the support beams. After this, you can begin installing the frame.

If it is already installed, and the soil inside the foundation is not prepared, you can use expanded clay. First you need to level the surface, and then evenly fill in the expanded clay. It is desirable that it contains different fractions - from 10 to 40 mm. Having completed this work, you can begin arranging the floor.

Selection of thermal insulation material

Materials for floor insulation in a frame house are presented in a wide range. The choice of one or another of them depends on the characteristics of the house being built and its heating system, and the climatic conditions of the region.

- Expanded clay - rounded elements made of baked clay. Despite the porous structure, it has high strength, is resistant to temperature changes and aggressive substances. The heat saving indicator is average, but expanded clay is perfect for insulating floors on the ground.

- Mineral wool is thin fibers pressed into mats from molten glass waste, quartz sand, and certain rocks. Available in the form of rolled mats or slabs. Lightweight, inexpensive and heat-intensive material. It loses its properties when wet and is absolutely not suitable for laying under a concrete screed.

- Extruded polystyrene foam is a fairly dense material with gas-filled cells. It surpasses traditional foam plastic not only in terms of thermal conductivity, but also in rigidity and fire safety. The main disadvantage is that when exposed to high temperatures, it releases toxic substances into the air.

- Polyurethane foam is a sprayed insulating material with a low thermal conductivity coefficient. Perfectly fills all voids, eliminating the formation of cold bridges, is resistant to ultraviolet radiation and fire, and does not emit toxic substances. The disadvantage is the use of special equipment and the high price.

Useful: Ground floor for a frame house

In each case, they individually determine not only what and how to insulate the floor in a frame house, but also how thick the thermal insulation layer will be. To do this, careful calculations are carried out at the design stage of the structure.

On the territory of the Russian Federation

Articles of the Criminal Code of the Russian Federation define an official as a person vested with the functions of a representative of power and exercising them in the administrative, organizational, economic or administrative areas of state bodies, as well as in local government, municipal or state institutions or corporations, in the Armed Forces of the Russian Federation and other military formations.

Public positions are only those that are established by the Constitution of the Russian Federation and federal laws to exercise the powers of the state. organs. An official holding public positions in the constituent entities of the Russian Federation is a person who occupies a position established by the constitutions or charters of these constituent entities. That is, these people directly exercise all the powers of government bodies.

Raised floor insulation scheme

When insulating the floors of frame houses, regardless of the type of foundation and design features, you should be guided by the provisions of the current GOSTs and SP 29.13330.2011 .

All work is carried out in a certain sequence:

- The bottom frame is framed along the foundation and powerful wooden logs are installed in increments of 400 or 600 mm.

- Support boards (25x100 mm) or skull blocks (50x50 mm) for rough flooring are attached to the logs.

- Lay the flooring - OSB sheets or boards with a section of 25x100 mm. Installing the board is cheaper.

- The subfloor is covered with a wind- and moisture-proof membrane and fixed with a construction stapler. At the junctions of individual panels, an overlap of at least 15 cm must be made. This helps prevent the formation of cold bridges in the structure.

- Insulation is placed in the cells formed by the joists. It should fit snugly against the boards. If gaps remain, they are filled with foam.

- Lay a layer of vapor barrier - a film that protects the insulation from vapors penetrating into the structure from the premises.

- The logs are sheathed with boards or wood boards, forming a finishing coating or a flat base for further finishing.

It is important! All wood materials must be pre-treated with antiseptics and fire retardants.

Do-it-yourself floors in a frame house: list of tools

When performing the work yourself, you need to have a building construction project in hand. It contains a complete list of work and the required consumption of materials. Tools for installation you will need:

- Circular Saw;

- drill with a set of drills;

- plane;

- hammer;

- level and plumb;

- chisel;

- screwdrivers;

- brushes

A ladder and a construction pencil for markings will also come in handy. During installation, it is necessary to maintain the clarity of horizontal and vertical lines and surfaces. It is necessary to maintain right angles between intersecting structures

Particular attention should be paid to the strength of the floor, because it will serve as the basis for the frame of the house

Scheme of floor insulation on the ground

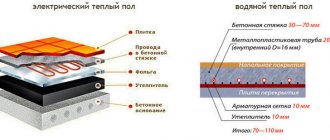

The “pie” of a heated floor on the ground is laid according to the same principle - a base is formed, the insulation is protected from moisture and a finishing coating is installed. The fundamental difference lies only in the materials used. Work technology :

- level the soil at the construction site;

- pour a “cushion” of coarse crushed stone and compact it;

- fill the base with a leveling layer of cement screed;

- lay a layer of waterproofing;

- lay insulation;

- lay a vapor barrier film;

- pour a concrete screed with a thickness of at least 50 mm;

- lay finishing material.

This option for floor insulation in a frame house is quite labor-intensive, but reliable and durable.

Useful: Basic and auxiliary components of a frame house

If you have a carefully designed project, in both cases you can do the floor insulation yourself, with the help of a few friends. Only to work with the screed will you need special equipment, for example, a tamping machine.

What is the need

The absence of one, first of all, will lead not only to inconvenience during the operation of the building, but also to greatly increased heating costs in the winter. The reason is that without proper insulation, the floor simply will not retain heat inside the structure.

It is important to know: a correctly laid thermal insulation cake makes it possible to avoid the occurrence of such negative situations, as well as significantly increase the service life of both the building itself as a whole and its individual elements.

It is also possible that certain problems may arise in the form of:

- Formation of condensate on the surface of many floors;

- Rotting of wood due to the formation of mold on it, which is preceded by increased moisture;

- Significant reduction in the energy efficiency of such a house.

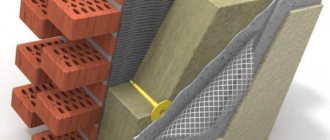

Waterproofing device

Material for waterproofing can be rolled, in the form of paints, deep penetration compounds and plaster. We install it on top of the insulation.

- After laying the thermal insulation and vapor barrier, we lay a cement-bonded or glass-magnesite board in two layers along the load-bearing joists.

- We make a cement-sand screed.

- After drying, prime the surface with a primer.

- We lay waterproofing (preferably rolled) in 1-2 layers.

- Fill with mortar 8 mm thick.

- We install the tile covering with glue.

The waterproofing process depends on the material from which the floor is made. Wooden products require the creation of a complex and reliable structure.

Park or Rockwool

Many developers are trying to determine which thermal insulation - Parok or Rockwool - has the best technical characteristics. If many user reviews on the Internet point to Parok, then in our article we will provide a comparison of these two products.

| Characteristic | Park | Rockwool |

| Coefficient of thermal conductivity | 0.036 W/μ | 0.036 W/μ |

| Vapor permeability indicator | 0.55 mg/mchpa | 0.3 mg/mchpa |

| Maximum Density | 35 kg/m³: | 35 kg/m³: |

| Fire resistance | Incombustible | Incombustible |

| Overall dimensions of products | 1.2*0.6 m | 1*0.6m |

| Total area of slabs in one package | 10.08m2 | 6m2 |

| Packaging cost for a product thickness of 5 centimeters | 800 rubles | 550 rubles |

| Price m3 of thermal insulation | 1600 rub. | 1800 rub. |

Note! Despite similar technical characteristics, Parok mineral wool does not tend to shrink, which cannot be said about Rockwool thermal insulation. In addition, such material has a lower cost.

Dismantling the old block

2.Old socket block with switches in disassembled condition

What do we see? Everything is loose and rickety, the two upper switches are in a completely dead state, the third is not connected, and according to the owner, it never worked. The socket is more or less compared to them, considering that in such a place it is almost never used.

At this stage, we understand the wires, check where the phase is, and turn off the power. In this case, you must have a headlamp; you can’t do without it.

We take out the insides. The main thing is not to break the wires and notice where everything goes.

3. We take out all the insides - the old socket, switches, metal box

The bad ends that went to the switches had to be cut off - they were still short.

The two bottom wires go to the socket. On the left is zero, on the right is the phase, which in the old days electricians designated with black rag tape (there was no other tape, no markers).

4.No one will ever need this again. Thanks for your service!

Expanded clay

Expanded clay

Expanded clay is a popular thermal insulation material used in wooden floors and floors with dry screed based on gypsum fiber board. In the latter case, in addition to thermal insulation, it is also a leveling material.

Expanded clay is one of the cheapest materials for thermal insulation; it does not burn, is safe for health and is lightweight. At the same time, it easily absorbs water, which reduces its thermal insulation properties and significantly increases its weight. Therefore, the use of expanded clay requires reliable waterproofing. Another disadvantage of expanded clay is that when working with it, a large amount of dust rises into the air.

Expanded clay as thermal insulation

In terms of thermal insulation properties, expanded clay is inferior to most synthetic materials, so it requires backfilling with a thicker layer, which reduces the height of the ceilings in the room.

Using expanded clay for insulation. The photo shows expanded clay being poured with lean concrete

For effective thermal insulation of the first floors of buildings from the ground, the expanded clay layer must be at least 400 mm when using wooden floors and 300 mm when using concrete floors.

Between the floors of private houses, at least 200 mm of expanded clay should be poured into the floors for wooden floors and 150 mm for concrete floors. In apartment buildings, a layer of expanded clay of 50-80 mm is sufficient.

| Indicators | 10-20 mm | 5-10 mm | 0-5 mm |

| Bulk density, kg/m3 | 280-370 | 300-400 | 500-700 |

| Crushing strength, N/mm2 (MPa) | 1-1,8 | 1,2-2 | 3-4 |

| Grading, % | 4 | 8 | 0 |

| Frost resistance 20 cycles, gravel weight loss, % | 0,4-2 | 0,2-1,2 | not regulated |

| Percentage of crushed particles, % | 3-10 | 3-10 | No |

| Thermal conductivity, W/m*K | 0,0912 | 0,0912 | 0,1099 |

| Water absorption, mm | 250 | 250 | 290 |

| Specific effective activity of natural radionuclides, Bq/kg | 270 | 270 | 290 |

What to choose

All the described materials have their advantages and disadvantages, however, when choosing, it is also necessary to take into account the characteristics of the insulated room. Complexity of installation, availability of appropriate qualified workers. Under no circumstances should you violate the technology for laying this or that material, as this can lead to a lack of heat in your home, and identifying and eliminating such defects may require much greater resources.

If your choice is between basalt blocks and ecowool, take into account the availability of qualified installers with special equipment; if you don’t find them, it’s better to use a simpler material - basalt blocks.