Specifications

| Parameter | Meaning |

| Relay supply voltage | 110…250V, 50…60Hz |

| Power consumption, no more | 1W |

| Duration of switching on relay contacts | 0sec…365days |

| Repeat period for switching on relay contacts | 2sec…365days |

| Time delay error at t=20С, typical | 1.7 sex days |

| Relay contact life at maximum switching current, active load, at temperature t=20C. | 50,000 on-off cycles |

| Maximum switching voltage | 250V alternating voltage frequency 50…60Hz |

| Maximum switching current | 16A board 1.02 (8A board 1.01) |

| Rated switching current when switching active load | 10A board 1.02 (5A board 1.01) |

| Maximum switching power | 3500VA board 1.02 (2000VA board 1.01) |

| Relay contact group | One, switch |

| Height above sea level, no more | 2000m |

| Degree of protection | IP20 |

| Working temperature | -25С…+50С |

| Storage temperature | -40С… +60С |

| Connection | Screw terminals, max. wire cross-section 2.5mm2 |

| Torque | 0.5Nm |

| Installation method | On a 35mm Din-rail or on a dielectric plane with two 3.5x35 screws |

Starting the load with a button for a specified time

At the request of reader Sergei, we are publishing a diagram, which, when implemented, will make it possible to launch an actuator for a specified time by pressing a button. For example, an engine. The RVO-P2-15 delay device was chosen at random; any other with similar parameters will do.

The diagram is simple and given without explanation:

For proper operation of RVO-P2-15, it is necessary to configure it according to the passport:

- In order for the delay device to turn on simultaneously with the power supply, DIP switch 4 must be set to position 2.

- Use DIP switches 1–3 to select the time range.

- Set the specified dwell time.

Easy adjustment of electric heating power

The closed or open position of the contacts depends on whether voltage is applied or removed from its control coil. It turns out that in order to assemble the automation, we must supply control signals (voltage) to the terminals of these same coils through some other elements.

The coil has two contacts A1, A2.

When purchasing, pay attention that starters can come with 380V and 220V coils. It's better to take the last option

In this case, you directly connect the neutral conductor to one of the contacts, and install microswitch buttons into the gap of the second.

What are they needed for? Thanks to them, you have the opportunity to turn on 1,2 or 3 heating elements alternately, thereby increasing or decreasing the heating power.

For example, the temperature outside the window is -5C. You press one button and start up just one heating element with a power of 2 kW. The frost hit -25C, press all three buttons and increase the power three times.

In this case, the number of heating stages will depend on the rated power of each heating element. If they are all 2 kW, that’s only three steps.

But if one is 2 kW, the second is 3 kW, and the third is 4 kW, then the number of stages automatically increases to seven!

Everything will depend on which phases (heating elements) are connected and in what sequence.

individually 2kW – 3kW – 4kW

together 2kw+3kw+4kw

separately 2kW+3kW

separately 2kW+4kW

separately 3kW+4kW

The current in the coil control circuits is very small (several milliamps). Accordingly, there is no need to install full-fledged switches here.

All these three microswitches must be supplied with one phase. Let's say phase C. Take it from the lower contacts of the input circuit breaker.

It is from this point that the entire further automation scheme begins.

Units, functionality, assembly

Now we will look step by step at how the automation for an electric boiler works and how to assemble it into a single unit responsible for the safety and control of the unit. Such a system will cost you much less than a factory-assembled one, and besides, you will know it thoroughly and can easily carry out maintenance.

Launch unit

Source principal.ua

Any electrical circuit begins with a device for breaking the circuit, and in our case, this is an input three-phase three-pole circuit breaker ≈380 V. Only at this point a mistake is very often made - instead of K3, three separate single-pole circuit breakers are installed. This is unacceptable, since individually each device is responsible for a separate phase, but K3, if the heating element is damaged in any of the three phases, de-energizes them all at the same time. In practice, this means that you won’t even have time to get an electric shock if a short circuit occurs.

Source domikelectrica.ru

After installing a three-pole circuit breaker, all phases must be separated and for this purpose electromagnetic contactors such as starters are used. They will be responsible for controlling electric boilers, and to be more precise, for automatic switching of the electrical network. Why is this needed: if the machine is turned on and off manually, using flags on the body, then the starter does this itself, without your intervention, when it receives an impulse from the corresponding sensor.

Source electrosam.ru

Single-pole contactors should not be in the form of a triple block, but separately, just do not buy or install old starters such as KMI, PML or PMA from your stash, and the point here is not the volume of clicks when switching, but more on that below. You will have the opportunity to simplify the power adjustment of the electric boiler - this is the main advantage of this option. Next, the heating elements or heater electrodes are connected according to the diagram - everything is simple here.

Boiler power adjustment

Voltage from the circuit breakers is supplied to the starters, and from them to the heating elements, and it is in this circuit node that the power control of the electric boiler should be installed. Whether voltage is supplied to the heating element of the boiler or not depends on the contactor (starter) coil, so in this section we will install the ability to change the heating mode. To do this, you need to connect zero to the contact marked on the body as A2, and to the terminal marked as A1 - a microswitch to break the circuit. However, A1 and A2 can be swapped in the circuit - this does not matter. All three starters must be connected from only one phase - it can be taken from the bottom terminal of any of the three machines.

These three buttons will allow the boiler to operate in seven modes. Let's say you have a heating element boiler with three heating elements of different power - let's call them No. 1, No. 2 and No. 3 - then it becomes possible to combine the outlet water temperature. Here's what the modes will look like:

- No. 1, No. 2 and No. 3 – included (maximum power).

- No. 1 – enabled, No. 2 and No. 3 disabled.

- No. 2 – enabled, No. 1 and No. 3 – disabled.

- No. 3 – enabled, No. 1 No. 2 – disabled.

- No. 1 and No. 2 are enabled, No. 3 is disabled.

- No. 1 and No. 3 are enabled, No. 2 is disabled.

- No. 2 and No. 3 are enabled, No. 1 is disabled.

Depending on the temperature outside the window, you can choose any of these modes, adding or decreasing the boiler power to heat the coolant.

Note: I hope it is now clear why we needed separate contactors - such adjustment will not work on a common unit.

Limit and control thermostats

Source astangas.ru

Such a device, as in the photo above, is now installed not only on electric, but also on gas, and sometimes on solid fuel boilers. It is necessary for emergency situations when something does not work in the electronics and heating of the coolant does not stop at the set temperature. This can happen when, for example, the circulation pump becomes clogged and liquid stagnates in the boiler or for some other reason. That is, by default the water will heat up to the limit on the thermostat, which is usually 95°C, after which the safety mechanism is triggered and the circuit breaks, but you can set the temperature limit yourself.

Since this device does not have a safety valve in an extreme situation, the control phase circuit is simply disconnected. Therefore, the device must be connected exactly as shown in the lower image so that it can break the control phase circuit.

Source domikelectrica.ru

In order to turn off and start the heating elements without your participation, you need to add one more device to the circuit - this is a control thermostat (just do not confuse it with a limit thermostat). The image shows that it is connected to the main phase in front of the limit device. This means that he will issue commands. That is, the working thermostat will operate at a certain temperature that you set for it - the process occurs automatically, without your participation.

In the case when you see that the circuit is open (the boiler does not heat) and the temperature is less than the one you set, this means that it is not the working thermostat that has worked, but the limit thermostat. This indicates that there is a problem somewhere and you need to find the problem, fix it and only then start the boiler again.

In addition to the working one, you can also connect a room thermostat, shown in diagram No. 3, to the control phase circuit. It will react to the temperature in the room, and the operation of device No. 2 will depend on it, since the working thermostat will not be able to break the circuit without the “consent” of the room sensor.

Room thermostat and energy saving

To get a more functional option, let’s add here a device for monitoring the air temperature in the room - a room thermostat.

It doesn’t matter to him what the temperature of the boiler water will be; he reacts precisely to the comfortable air temperature in your home. By analogy with the previous elements, mount it in the gap, in front of the working thermostat

The second simplest scheme is ready

By analogy with the previous elements, mount it in the gap, in front of the working thermostat. The second simplest scheme is ready.

But people always strive for more, and in addition to the comfort of electric heating, they always want to save money. Still, with rare exceptions, electric heating is not exactly a cheap thing in our realities.

How to do this by improving the above connection diagram? There is a night rate for this business.

To take full advantage of it, we need a time relay.

It will start electric heating only during a specified period of the day. Place it in the circuit in front of the room thermostat.

However, pay attention to one nuance. If there is such a device in the circuit, a minimum air temperature thermostat must be mounted parallel to it.

During the day, in your absence, the temperature outside can drop sharply. We left at -5C, arrived in the evening - minus 25C outside. Accordingly, your home will become significantly colder.

It will start heating as soon as the temperature in the house drops below the minimum threshold. As a result, it will prevent the house from cooling down and the system from defrosting.

To visually observe whether the sensors are turned on or off at the moment, you can connect a signal light to a common point in front of the microswitches and display it in a visible place.

This is especially useful when the control panel and the boiler itself are located in the basement of the house or in a neighboring outbuilding.

Most factory electric heating boilers are built precisely on such basic control schemes. There is one supply line (phase) that supplies a signal to the coil of the device with power elements, and all additional equipment, sensors and switches are “hung” on this very line, performing protective and monitoring functions.

As you can see, there is nothing complicated or intricate here.

https://youtube.com/watch?v=fw9BUOGXT4Y%3F

Maintenance

• When servicing the relay, it is necessary to comply with the “Rules for safety and technical operation of consumer electrical installations”. • Under normal operating conditions, it is sufficient to carry out an external inspection of the relay once every 6 months and check the set operating time (cycle). It is necessary to tighten the clamping screws, the pressure of which weakens due to cyclic changes in ambient temperature and the fluidity of the material of the clamped conductors. • The relay must be installed and serviced by qualified personnel. • When connecting the relay, you must follow the connection diagram.

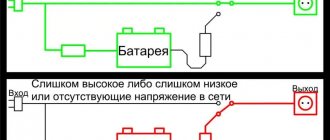

Let's move on to the principle of operation of the circuit

After power is applied, the R1–C3 chain generates a starting pulse with a duration of approximately 100 ms for the DD1 microcircuit, from which the OUT output of the microcircuit is set to log.1, thereby turning on the optosimistor VS1, the triac VS2 and connecting the load to the 220V network. From this moment the countdown begins.

The delay time of the timer is set by the chain R3–R6–C2. The charging time of capacitor C2 to the shutdown voltage, the output OUT of the DD1 microcircuit to logical 0 is determined by the formula:

t = 1.1*(R3+R6)*C2

Resistor R6 limits the minimum delay time to 3 seconds. Capacitor C1 is necessary to filter noise in the power supply of the DD1 chip and should be located as close to it as possible.

Resistor R4 sets the LED current of the optosimistor and when using MOC3043 analogues, for example MOC3042 or MOC3041, it should be reduced, since they require more current to operate.

This circuit can also be used for switching starters, but keep in mind that in cases of low current starters, false operation or their buzzing in off mode is possible, since they can be switched on through the R5–C5 chain. In this case, this chain requires correction according to denominations.

Such a device can be purchased immediately ready-made, or you can use an unnecessary one from any device: router, modem, phone or the like. In this case, the relay design will be significantly simplified.

Transformer T1 can be replaced with any other one with a rated input voltage of 220 Volts and an output voltage of 12 Volts.

If the turn-off delay relay circuit interests you and you would like to download a file with an image of the printed circuit board, leave your comments.

Timer connection diagram.

Today, a huge number of different types of timers are sold, which will have their own connection features. I will look at the connection diagram for the popular model of a two-channel timer from the Russian manufacturer IEK.

On top, contacts numbered 1 and 2 are supplied with 220 Volts from the home electrical network. As a rule, in all models, power is supplied from the top, and switching (on and off control) is carried out using the bottom contacts. In this case, only the phase conductor is broken, and the zero goes directly to the electric lamps. On the middle contact 4, a phase from the electrical panel is connected, which will be separately switched with side connections 5 and 3. If you need to switch only one circuit, then contact No. 5 will remain free.

I recommend looking at ours on the topic. containing visual instructions for selecting, connecting and setting up the electronic timer menu!

Good afternoon! This is the question. The house is heated by a 12 kW electric boiler. No one lives in the house now. I want to install a relay so that the boiler turns on at night, the night tariff is cheaper. What is better to install, a single-phase relay and starter or a three-phase relay. If it's not difficult, a diagram by hand. I'm not an electrician myself, but I have the idea.

Anatoly, hello. I won’t draw the diagram, it’s on the Internet

It is better to use such a scheme. If you have 380 volts in your house, then it is better to use a three-phase starter (if this picture is talking about, then you apply voltage, three phases to contacts 1,3 and 5, that is, from above, and from contacts 2,4 and 6 remove and attach to the electric boiler. It is better to take an electronic timer, not a mechanical one, it can be in the form of a socket (this is cheaper) or in the form of a module on a DIN rail (this is several times more expensive, as a rule). Contactor (starter, which is both more convenient and call it) you need to take it with an operating current of 20 amperes or more. It is not necessary to install a thermal relay, it is usually installed on engines, but it is better to install a circuit breaker on the boiler with a nominal value of 20 amperes (this is the nominal value for about 13-13.5 kW).

There is a working diagram for connecting heaters through a magnetic starter with a block of 2 buttons. there is an IEK timer (exactly the same as yours in the picture). how to connect a timer to turn shadows on and off according to time, but so that the button can also be turned on and off? thank you in advance.

Alexey, hello. You need to supply power to pins 1 and 2, this will be the power supply for the timer itself. Next, as per the diagram, instead of light bulbs, you need to turn on your two heating elements, or more precisely, the control coils of the starters. One coil is turned on instead of the left two lamps, and the second coil is turned on instead of the right three lamps. The essence of the timer is that contact four is the control one (changeover), and contacts 3 and 5 are receiving (in one position, for example “on”, again, for example, contact 3 works, and in the other position “off” - contact 5) . Therefore, by setting equal intervals (or the intervals you need), when the timer is turned on, one heating element will work, and when the second one is turned off. Parallel to the timer, install a two-key pass-through switch in exactly the same way. Use the first key to switch power either to the second key or to the timer, and with the second key you control the first or second starter, bypassing the timer.

The black arrow is the incoming power, it goes to the first pass-through switch (you will use it to select control, either with the key of the second switch, or with the timer), the second key directly controls the heating elements, if power is supplied to it, and then comes the timer.

https://jelektro.ru

Operating principle of a time relay

The general principle of operation of a time relay is to form a time delay for turning on, off or switching control groups of contacts. The implementation of the delay depends on the design features of the device. The general differences in different types of relays lie in the switching of the executive part. Based on this feature, two groups of relay devices are distinguished:

- with shutdown delay;

- with switch-on delay.

Many relays allow you to change the type of switching or have both options.

The principle of timing and contact control depends on the design of the relay, but the general operating algorithm is as follows:

- upon startup, a contact group is activated, organized in accordance with the type of switching (for a time relay with a turn-off delay, the contacts close);

- at the same time, the time delay mechanism is cocked (the clock generator in electronic devices is started);

- after a specified interval, the contact group changes its state to the opposite.

A three-position relay has a more complex operating algorithm. The sequence of work is as follows:

- The circuit is open.

- Start. The circuit closes and the countdown begins.

- The countdown is over. The circuit is closed.

In cyclic devices, the above sequence is repeated many times.

The countdown is started manually or automatically by directly closing the power supply contacts or through an electromagnet acting on the mechanism.

A time relay with a switch-on delay works similarly.

Time relay for turning on the pump as an integral element of the automation system

Time relayBuy from 1875 rub.

A time relay is a special electrical device that can be used to control the operation of a pump and other electrical equipment. The device is capable of closing/opening electrical circuits. circuit and form time intervals for turning on/off electrical devices. Due to this, a certain sequence (algorithm) of the operation of electrical elements is ensured. scheme. Thus, the relay creates a time delay and automatically controls such technological processes as: irrigation, heating, water supply, air conditioning, etc.

For example, in a heating system with pump circulation, using a relay, it is possible to organize the operation of the pump so that it turns on with a certain time delay, and the heating elements of the electric heating boiler have time to warm up. Thus, the stability and uninterrupted operation of important production and technological processes depends on the reliability of the time relay.

We present to your attention professional devices for automating the operation of an electric pump from the Russian manufacturer NPO Elektroavtomatika - time relays. Electromechanical devices contain several algorithms for working with wide time intervals and supply voltage tolerances, due to which they demonstrate high quality characteristics in each case of operation.

We produce 2 types of relays:

- time relay for shutdown RV-OO for electrical control. circuits after removing the supply voltage;

- time relay for turning on RV-OV for electrical control. circuits after supply voltage is applied.

Let's tell you why a relay is an excellent choice for a water supply system. Using our devices, you can simultaneously control 2 independent electrical circuits - 2 switching groups of contacts. That is, you can connect 2 different devices and supply different power to them. The principle of operation of the functional device is that the relay does not turn on the pump immediately after the supply voltage is applied, but after a certain time.

Types of time relays

Time relay with shutdown delay - RV-OV is widely used to control a pump or pumping station. The device allows you to fill the hydraulic tank automatically, regulating the switching on and off of the pump. Contains two operation diagrams and five time delay ranges: 0.1 s; 1 s; 0.1 m; 1m; 0.1 hour. So, for each operation diagram you can specify one of three time intervals and set a time delay for the relay to operate after power is applied.

Advantages of NPO Elektroavtomatika time relay:

- Reliable technical characteristics.

- Switching heavy loads: with active load - 5 A AC.

- Efficiency. Control of two independent electrical circuits - two switching groups of contacts.

- Easy installation. Installation on a 35 mm wide DIN rail.

The second type of shutdown time relay - RV-OO turns on immediately when the supply voltage is applied, and turns off after a certain time delay after the power is turned off. The device contains four operating diagrams and three time delay ranges: 0.1s; 1s; 0.1 min. In practice, the RV-OO relay allows you to organize an effective automated process control system both in production and in the home.

If you were looking for a reliable device to automate the operation of equipment such as a motor or a pump, and also want to organize a system for turning on and off electrical appliances, then the NPO Elektroavtomatika time relay is suitable for you. For more than 10 years, our devices have remained in demand in automation systems. When ordering, you can specify the required operating diagram, exposure time range, supply voltage and other characteristics.

Buy a time relay to turn on the pump

On our website you can order a functional time relay to turn on the pump. In addition, in our catalog you will find a comprehensive range of electrical products adapted to your requirements: from basic solutions to manufacturing according to the customer’s project and the embodiment of your ideas in the finished product.

We invite you to cooperate with our production company and offer to order reliable electrical products at attractive prices. In NPO Elektroavtomatika you will find a direct supplier and will be able to order the necessary electrical devices and components with delivery to any region of Russia.

Using a push-button station in conjunction with a time relay

You can realize the possibility of starting the engine not only from a time relay, but also from a push-button station by adding a second starter and assembling a special “pick-up” circuit.

Appearance of a push-button post with two buttons

Let's look at the circuit diagram below. When you press the “START” button, Starter 1 is activated and the corresponding contact K1.1, connected in parallel to the “START” button, is closed. When this button is released, the supply voltage continues to maintain Starter 1 in the on state and, accordingly, the parallel contact K1.1 in the closed state.

Simultaneously with contact K1.1, contact K1.2 closes, which directly turns on Starter 2, which controls the load. At the moment the time relay is triggered, the “time relay contact” is triggered and Starter 2 is turned on.

When you press the “STOP” button (it is closed by default), the circuit opens and Starter 1 is turned off. The state of Starter 2 will depend only on the state of the time relay.

The starter can control, for example, a motor or something else. If the number of its contacts is not enough, then their number can be increased with special attachments.

Timer for pump control Meander entertaining electronics

The device, the circuit of which is shown in the figure, periodically generates pulses of positive polarity at the output (at pin 11 of the DD1 microcircuit). It contains two IC generators operating alternately (on elements DD1.1 and DD1.2), a switch on element DD1.3, a serial circuit of four counters of microcircuits DD2, DDЗ, an inverter on element DD1.4 and an electronic relay on transistor VT1 and electromagnetic relay K2, which controls the operation of magnetic starter K1. The duration of the pulses (Ton) and pauses between them (Toff) depends on the frequency of the pulses generated by the pulse generators and the counter outputs used and can be adjusted within wide limits.

When the device is connected to the network, a constant supply voltage appears at the output of rectifier VD1 and, thanks to circuit R3C3, the counters of microcircuits DD2, DD3 are set to zero. In this case, a log level appears at the output of inverter DD1.4. 1 and the generator on element DD1.2 is switched on. At the same time, transistor VT1 opens, relay K2 is triggered and with its contacts K2.1 it connects the winding of the magnetic starter K1 to the network, as a result of which it also triggers and with contacts K1.1, K1.2 it connects the load to the network. From the output of element DD1.3, pulses with the repetition rate of this generator are supplied to the CN input (pin 2) of the first counter of the DD2 microcircuit. The countdown begins.

With the advent of log. 1 at the counter output (pin 14 DD3) logic level. 1 at the output of element DD1.4 is replaced by a log level. 0, transistor VT1 closes, de-energizing relay K2, it releases and breaks the power circuit of the magnetic starter K1, which, in turn, turns off the load. At the same time, the generator on element DD1.1 is turned on, pulses with the frequency of this generator begin to arrive at the CN input of the first counter of the DD2 microcircuit - the countdown of the Toff time begins, after which everything is repeated from the beginning.

In practice, the device has been used for four years to control, according to a given cycle, a water pump with a capacity of 2500 l/h, pumping water from a well with a flow rate of 300 l/h. For the ratings of the elements R1, R2, C1 and C2 indicated in the diagram, the pump is turned on for a time Ton = 151 s = 2 min 31 s, pumps out about 130 liters of water into the storage tank, and then turns off for a time Toff = 27 min, during which water accumulates in the well. The need to control a pump with such a cycle is due to the fact that without washing with water, the pump fails. The device is powered from an unstabilized source containing a step-down transformer T1 with a secondary winding of 9 V and a rectifier bridge KTs405A. To control the K1 starter, relay K2 is used with a winding resistance of about 700 Ohms and a rated voltage of 12 V.

Specifications

| Parameter | Meaning |

| Rated operating voltage | 220V |

| Mains frequency | 50/60Hz |

| Remains operational when the supply voltage is within | 180V-250V |

| Relay power consumption | no more than 2VA |

| Permissible switching contact current, with active load | 16A |

| Permissible switching contact current, with reactive load | 8A |

| Minimum programming step | 1 minute |

| Maximum programming step | 168 hours |

| Number of on/off programs | 16 cycles |

| Mechanical wear resistance, on/off cycles | 10⁷ |

| Electrical durability, on/off cycles | 10⁵ |

| Programming data storage time when power is turned off | up to 150 hours |

| Accuracy of the watch during the day, at a temperature of +25°C | ≤1 second |

| Overall dimensions (HxWxD), mm | 86.5x36x65.5 |

| Operating temperature range, °C | -10°С~+40°С |

| Relative humidity | 35~85% |

DIN rail mounting (occupies two S-type modules), the size of a two-phase automatic machine. Operate indoors with artificial ventilation and heating control.

Functions and characteristics of lighting control timers.

The main thing you should pay attention to when purchasing is the maximum permissible switched load.

Which is easy to calculate by simply adding up the power that you plan to connect to the timer. To convert to Amperes, divide the Watts by the operating voltage of 220 Volts. When purchasing, it is very important to pay attention to the type of fastening. which can be placed under the Din rail of the electrical panel, and the timer can also be designed for built-in installation inside a wall or overhead. Third is the operating temperature range

which is important when installing in unheated places.

According to the type of control, they are divided into: mechanical (Figure 1) and more accurate and functional electronic (Figure 2 and 3). There are models of switches with a built-in timer for entrances (Figure 4), which, after pressing, turn on and off after a specified number of seconds. Timers are available to control one channel or two, as well as multi-channel (Figure 3). Two-channel allows you to separately configure and control the main and auxiliary lighting. When purchasing, please note that the timer can only have a weekly or annual program. More expensive models almost always have all kinds of programs, including weekends. Pay attention to the astronomical timer. which allows, after setting the location coordinates, to automatically adjust the time of sunset and dawn taking into account changes in the length of the day during the year.

There are other unimportant characteristics. Such as, for example, time accuracy, minimum time setting (usually up to a minute), etc.

The simplest 12V timer at home

The simplest solution is a 12 volt time relay. Such a relay can be powered from a standard 12v power supply, of which there are many sold in various stores.

The figure below shows a diagram of a device for turning on and automatically turning off a lighting network, assembled on one integrated counter of the K561IE16 type.

Drawing. A variant of a 12v relay circuit that turns on the load for 3 minutes when power is applied.

This circuit is interesting in that the flashing LED VD1 acts as a clock pulse generator. Its flicker frequency is 1.4 Hz. If you cannot find an LED of this particular brand, you can use a similar one.

Let's consider the initial state of operation, at the moment of supplying 12v power. At the initial moment of time, capacitor C1 is fully charged through resistor R2. Log.1 appears at pin No. 11, making this element zeroed.

The transistor connected to the output of the integrated meter opens and supplies 12V voltage to the relay coil, through the power contacts of which the load switching circuit is closed.

The further principle of operation of the circuit, operating at a voltage of 12V, is to read the pulses coming from the VD1 indicator with a frequency of 1.4 Hz to pin No. 10 of the DD1 counter. With each decrease in the level of the incoming signal, there is, so to speak, an increment in the value of the counting element.

When the 256th pulse arrives (this equals 183 seconds or 3 minutes), a log appears on pin No. 12. 1. This signal is a command to close transistor VT1 and interrupt the load connection circuit through the relay contact system.

At the same time, logic 1 from pin No. 12 is supplied through diode VD2 to clock leg C of element DD1. This signal blocks the possibility of receiving clock pulses in the future; the timer will no longer operate, until the 12V power supply is reset.

The initial parameters for the operation timer are set in different ways by connecting the transistor VT1 and the diode VD3 indicated in the diagram.

By slightly transforming such a device, you can make a circuit that has the opposite principle of operation. The KT814A transistor should be changed to another type - KT815A, the emitter should be connected to the common wire, the collector to the first contact of the relay. The second relay contact should be connected to a 12V supply voltage.

Drawing. A variant of a 12v relay circuit that turns on the load 3 minutes after power is applied.

Now, after power is applied, the relay will be turned off, and the control pulse that opens the relay in the form of logic 1 output 12 of element DD1 will open the transistor and supply 12V voltage to the coil. After which, the load will be connected to the electrical network through the power contacts.

This version of the timer, operating from a voltage of 12V, will keep the load disconnected for a period of 3 minutes, and then connect it.

When making the circuit, do not forget to place a capacitor with a capacity of 0.1 μF, designated C3 in the circuit and a voltage of 50V, as close as possible to the supply terminals of the microcircuit, otherwise the counter will often fail and the relay dwell time will sometimes be less than it should be.

In particular, this is programming the exposure time. By using, for example, a DIP switch as shown in the figure, you can connect some contacts of the switches to the outputs of the counter DD1, and combine the second contacts together and connect them to the connection point of the elements VD2 and R3.

Thus, using microswitches you can program the relay delay time.

Connecting the connection point of elements VD2 and R3 to different outputs of DD1 will change the dwell time as follows:

| Counter leg number | Counter digit number | Exposure time |

| 7 | 3 | 6 sec |

| 5 | 4 | 11 sec |

| 4 | 5 | 23 sec |

| 6 | 6 | 45 sec |

| 13 | 7 | 1.5 min |

| 12 | 8 | 3 min |

| 14 | 9 | 6 min 6 sec |

| 15 | 10 | 12 min 11 sec |

| 1 | 11 | 24 min 22 sec |

| 2 | 12 | 48 min 46 sec |

| 3 | 13 | 1 hour 37 min 32 sec |

Digital timer for pump CAVR.ru

Share in:

The process is fully automated, and there is no need to constantly monitor the water level in the tank - the device controls and maintains the specified water level in the tank. The use of a microcontroller made it possible to increase its reliability, as well as to build a small-sized and easily repeatable design.

Rice. 1

The timer circuit is shown in Fig. 1. The clock frequency of the ATtiny2313 (DD1) microcontroller is set by an external quartz resonator ZQ1. The duration of continuous operation of the pump and the duration of the pause from turning it off to turning it on again are set using two buttons (SB1 and SB2)

These values are stored in the microcontroller's non-volatile memory, so there is no need to reset them after each power cycle, which is especially important in rural areas. When the power is restored, the timer begins its work with a pause, which protects the pump from failure as a result of repeated switching on and off in a short period of time

During the timer operation, two three-digit seven-element LED indicators with common cathodes (HG1, HG2) display the time remaining until the pump turns on (when pausing) or until it turns off (during water supply). Indication is dynamic. The DD2 decoder with outputs made according to the “open collector” circuit converts the three-digit binary code of the familiarity number generated by the microcontroller into signals supplied to the cathodes of the indicators for their turn-on. The pump also stops when the maximum level sensor SF1 is triggered. This is accompanied by the display of the inscription FULL on the indicator. The sensor can be any microswitch equipped with a lever with a float. For greater reliability, you can install another microswitch that breaks the power supply circuit of the timer if the SF1 sensor does not work for any reason.

Rice. 2

All parts of the device, except for the SF1 sensor, are mounted on a printed circuit board made of fiberglass foil on both sides, shown in Fig. 2. In its original version, unused sections of foil on both sides of the board are connected to the -(9...12) V circuit and serve as an additional common wire. The board is designed for surface-mount parts (except for the quartz resonator ZQ1, stabilizer DA1, indicators HG1, HG2, buttons SB1, SB2 and relay K1). Relay type - JRC-23F. Its coil resistance is 167 Ohms, operating voltage is 5 V. The contacts are designed for switching alternating voltage up to 125 V with a load power of no more than 62.5 VA. A pump or other actuator whose power exceeds the capabilities of this relay can be turned on using another relay or contactor rated for the appropriate current and voltage. Relay K1 in this case will serve as an intermediate one.

Rice. 3

The board also has an XP1 pin connector, the contacts of which are connected to the pins of the microcontroller according to the diagram in Fig. 3. It is designed to connect the programmer to a microcontroller already installed on the board. The table shows how the microcontroller configuration bits should be programmed. They specify its operation with a quartz resonator with a frequency of more than 8 MHz and a program start delay of 16,000 cycles. To protect information in the EEPROM of the microcontroller from accidental damage during the rise of the supply voltage, the response threshold of the internal voltage detector (BODLEVEL) is set to 1.8 V.

When loading codes from the Pump-Control.hex file available in the application into the microcontroller's program memory, the pump operating time and pause duration can be independently changed from 0 to 60 minutes in 1-second increments. The timer consumes a current of no more than 500 mA from a voltage source of 9...12 V.

The timer microcontroller program can be downloaded here

Leave your comment or question:

Liquid crystal display

LCD display data

At the top of the display: days of the week MO - Monday; TU - Tuesday; WE—environment; TH - Thursday; FR - Friday; SA - Saturday; SU - Sunday. The day of the week is set using the D+ button

In the middle part of the display: current and programmable time. Time is set using the , H+ and M+ buttons

In the lower left part of the display: numbers of on and off cycles ON - on; OFF - disabled; numbers from 1 to 16 — cycle number. Cycles are configured using the button

In the lower right part of the display: control mode ON - always on; AUTO - automatic mode; OFF - permanently disabled. The control mode is set using the MANUAL button

Schemes of various time relays

There are different versions of time relays, each type of circuit has its own characteristics. You can make timers yourself. Before you make a time relay with your own hands, you need to study its structure. Schemes of simple time relays:

- on transistors;

- on microcircuits;

- for output power 220 V.

Let's describe each of them in more detail.

Transistor circuit

Required radio components:

- Transistor KT 3102 (or KT 315) - 2 pcs.

- Capacitor.

- Resistor rated 100 kOhm (R1). You will also need 2 more resistors (R2 and R3), the resistance of which will be selected along with the capacitance depending on the timing of the timer.

- Button.

When the circuit is connected to a power source, the capacitor will begin to charge through resistors R2 and R3 and the emitter of the transistor. The latter will open, so the voltage will drop across the resistance. As a result, the second transistor will open, which will trigger the electromagnetic relay.

As the capacitance is charged, the current will decrease. This will cause the emitter current to decrease and the voltage drop across the resistance to a level that will cause the transistors to close and the relay to release. To restart the timer, you will need to briefly press the button, which will cause the tank to completely discharge.

To increase the time delay, a field-effect transistor circuit with an insulated gate is used.

Chip-based

The use of microcircuits will eliminate the need to discharge the capacitor and select the ratings of radio components to set the required response time.

Required electronic components for a 12 volt time relay:

- resistors with a nominal value of 100 Ohm, 100 kOhm, 510 kOhm;

- diode 1N4148;

- capacity 4700 uF and 16 V;

- button;

- TL 431 chip.

The positive pole of the power supply must be connected to the button, to which one relay contact is connected in parallel. The latter is also connected to a 100 Ohm resistor. On the other side, the resistor is connected to resistances of 510 and 100 kOhm. One of the terminals of the latter goes to the microcircuit. The second pin of the microcircuit is connected to a 510 kOhm resistor, and the third to a diode. A second relay contact is connected to the semiconductor device, which is connected to the actuator. The negative terminal of the power supply is connected to a 510 kΩ resistor.

For power supply 220 V

The two circuits described above are designed for a voltage of 12 V, i.e., they are not suitable for powerful loads. This drawback can be eliminated using a magnetic starter installed at the output.

If the load is a low-power device (household lighting, fan, tubular electric heater), then you can do without a magnetic starter. The role of a voltage converter will be performed by a diode bridge and a thyristor. Required parts:

- Diodes designed for current more than 1 A and reverse voltage not higher than 400 V - 4 pcs.

- Thyristor VT 151 - 1 pc.

- Capacitance 470 nF - 1 pc.

- Resistors: 4300 kOhm - 1 pc., 200 Ohm - 1 pc., adjustable at 1500 Ohm - 1 pc.

- Switch.

The 220 V power supply is connected to the diode bridge contact and switch. The second contact of the bridge is connected to the switch. A thyristor is connected in parallel to the diode bridge. The thyristor is connected to a diode and resistances of 200, 1500 Ohms. The second terminals of the diode and resistor (200 Ohms) go to the capacitor. A resistance of 4300 kOhm is connected in parallel to the latter. But it must be remembered that this device is not used for powerful loads.

Read further:

What is a voltage divider and how to calculate it?

Basic types and principle of operation of time relays

How to determine the polarity of electrolytic capacitors, where is the plus and minus?

Operating principle and connection diagram of a thermal relay

How to connect a 3-phase electric motor to a 220 volt network through a capacitor

How to save on electric heating? Time relay.

Hello, dear readers. For a long time I went to implement a project for heating a country house, but somehow it didn’t work out - either other worries, or mother laziness. Last week I finally completed the installation (my wife got it) and I hasten to share my experience.

Since our “beloved” GAZPROM still has not supplied this same gas to the village, we had to solve the problem ourselves. Choosing between electricity, diesel fuel or wood/coal, I settled on the first option: I don’t want to deal with liquefied gas - I’m afraid that diesel fuel is getting more expensive these days and it’s becoming unprofitable to use it, and coal/firewood is eternal dust and soot, settled ash on things , and you constantly need to heat it, add fuel! I decided to install a heating system based on an electric boiler, because at night electricity tariffs are significantly lower.

But then another problem arose: how to regulate the operation of equipment at night? Constantly run to it turning it on and off? The solution was found after a little research on the Internet and turned out to be quite simple - use a digital timer.

My cottage is small (100 m2), an electric boiler with a power of 12 kW, operating at 380V, is enough for 100 m2.

The next step was to decide on specific equipment models and then I grunted…. Too large assortment of goods - it took a long time to sort. As a result, none of the Belarusian, Polish and French components fit - some were expensive, some were of poor quality. Completely desperate, I came across a Nizhny Novgorod company producing boilers and automation from the Czech Elko ep and now I’m happy as an elephant!

So, I settled on the equipment: Electric boiler - Evan standard for 12 kW Evan S1-12 380V; it also has a pump; Digital timer – Elko Ep SHT-1/230V; Contactor – VS440-40/230V for switching a 380 V load.

Below I will tell you about the connection diagram of the electrical component: we connect the power cable through the VS440-40/230V contactor to the boiler, and the contactor is controlled by a time relay. To save money, the relay will turn on the boiler from 23.00 to 7.00; at night, the cost of a kilowatt is 3 times cheaper. Of course, you could have chosen a more expensive boiler with external control, then you wouldn’t have had to use a contactor, but my combination turned out to be cheaper.

As a result, having spent time, effort and money, I finally equipped a heating system in my country house. The solutions used allowed us to save a lot of money on the family budget, my wife is happy, and I am happy. I hope my experience will be useful to those who are thinking about heating their home. Good luck to all!

Andrey Fedorov

Setting up a time relay

It is recommended to start with the RESET button (press gently with a thin screwdriver; no force is required). After pressing, the display goes blank and then all elements are displayed, all settings and the current time are reset. Setting up a time relay begins with setting the day of the week and the current time. We press (with our fingers) and hold the button (hereinafter referred to as the clock) and press the D+ button, select the current day of the week, continue to hold down the clock button, and use the H+ and M+ buttons to set the current time. After setting the current time and day of the week, we proceed to programming the time relay.

Electromagnetic starter

An electromagnetic starter is an electrical device that allows you to start, stop and protect three-phase asynchronous electric motors.

In addition, these devices allow you to start and turn off any type of load, for example, heating elements, lighting sources and others.

Electromagnetic starters are produced in single or dual versions. The latter have mechanical protection against simultaneous starting.

Open-type devices are used in panel installations; they are used inside closed specialized cabinets, as well as in other places that are reliably protected from small particles and mechanical damage.

In contrast, protected starters can be used indoors if the environment is not very dusty. There are also starters that have reliable protection from moisture and dust; they can be used in both indoor and outdoor installations.

Lighting timer type TO-2

Appearance of timer TO-2

The light switching timer of the TO-2 series is designed for constant automatic switching on of the lighting system (turning it off at night) according to an autonomous table of the movement of the Sun. Also used as a time relay, which turns on lighting networks at a selected period of time. The maximum lighting load for 1 device is no more than 1 kW.

Scheme TO-2

Application

- Security lighting of facility areas, emergency lighting of non-residential buildings. In this mode, the timer turns on the lamps after sunset and turns off at sunrise.

- Lighting of areas of garden association houses and local areas. Identical to the first mode. It is also possible to turn off the lighting load at a specified time interval.

- Billboard lighting. Operating mode – only during the designated time period.

Principle of operation

- The controller compares the readings of the built-in clock with an astronomical table and transmits signals to two relays.

- Relay No. 1 turns on the timer for the light only according to the readings of the built-in clock.

- Relay No. 2 works similarly, there is also an additional function to turn off the load for a certain period of time (set by settings).

Device settings

It consists of setting the date and time for the correct operation of the twilight relay. Settings are controlled using buttons located on the front panel of the device.

Advantages

- Availability of a six-digit indicator;

- Possibility of installation on DIN rail;

- Reducing financial costs for electricity;

- Equipment resistance to temperature changes;

- Ability to operate in 50…300 V networks;

- Fast reprogramming;

- Saving the specified settings when the external power is turned off;

- Electronic display that displays device parameters.

Preparatory work before turning on the device

- Select the electrical connection diagram (for large load values, use contactors);

- Install the device and switch in the lighting control panel;

- Connect the device with cables or wires to the power supply and lamps via a relay;

- Apply voltage to the device.

Models of the TO-2 series are programmed to be able to shift the relay response time (up to 127 minutes in both directions).

It is recommended to carry out technical inspection and routine diagnostics of the device at least once every six months. The terminal blocks and fastening of the timer, the connection points of the electrical circuit elements are subject to inspection.

Modes

- Indications. Normal operating mode, the display shows all timer operating parameters at the current time.

- Settings. Set the current date and time.

- Checks. Test mode to check the functionality of the device.

- Settings. Correction of previously set operating values of the device.

Important! Calibration and repairs of timers must be performed at specialized service centers or at manufacturing plants.

Tags: , automatic, ampere, sconce, type, switch, generator, engine, house, , capacity, clamp, sign, like, kW, capacitor, contactor, , magnet, magnetic, installation, power, load, voltage, setting, nominal , lighting, heating, connection, polarity, principle, wire, start, , work, size, reverb, resistor, relay, repair, row, garden, light, lamp, LED, network, resistance, circuit, type, current, transistor, , installation, phase, filter, shield, electric motor

How to connect an electric boiler

An electric boiler is the best in terms of comfort - it does not require maintenance, it is the most reliable, and replacing a burnt-out heater costs pennies. It is programmable, almost silent, compact, and can be installed anywhere. Let's look at how to connect and operate it...

- In terms of comfort, the electric boiler has no equal - “press the button and forget it”, no need to approach it at all. It is because of this that electric boilers are increasingly being installed as the main heat generator.

- An electric boiler is considered the best backup because of its reliability. Its experts recommend installing it with any other - gas, solid fuel, liquid fuel...

But the price of electricity plays a key role. In most cases, the electric boiler remains a backup or temporarily switched on. Its heat will cost 5 times more than from gas or coal. True, it is possible to reduce the price quite significantly under certain circumstances, which we will consider below. But first of all - how to connect an electric boiler...

What cable for the boiler, what cross-section of conductors

The power of a two-phase electric boiler (designed for 220 V) is up to 7 kW, more often 3 – 6 kW. The power of three-phase 380 V is usually from 6 to 20 kW. When connecting, you must strictly comply with the requirements of the regulations.

The electric boiler is connected directly to the switchboard with a separate cable. The required cross-section of the cores for the boiler will be indicated in its instructions. You can use general recommendations if you know the maximum power of the device. A fragment of a table from the PUE for choosing the cross-section of copper conductors...

For a 5 kW boiler at 220 V, connection with a 2.5 mm2 conductor, maximum current up to 25 A and power up to 5.5 kW is allowed. For a 6 kW boiler at 220 V, it is recommended to connect it with a conductor with 4 mm2 copper conductors.

At 380 V, a 10 kW boiler requires a five-core cable with a copper core cross-section of at least 2.5 mm2, but for a 15 kW boiler it is recommended to use a cable with copper cores from 4.0 mm2. General recommendations are in the table.

Three-core cables of the PVV type or similar are used for 220 V, and five-core cables for 380 V, laid in accordance with the requirements of the regulations.

What protection is required - circuit breaker

For an electric boiler, maximum current protection is additionally installed on the panel - a circuit breaker. A machine with a small overload capacity, class B, is recommended, since there are no large starting currents characteristic of electric motors. The machine is selected based on current. Recommendations for selecting a circuit breaker according to current for 220 V and copper cable are given in the table.

For example, for a 5 - 6 kW 220 V boiler, a switch for a current of 32 A is recommended.

General circuits for switching on electric boilers at 220V and 380V.

Leak relay

Protection against current leakage to ground (protective shutdown) must be installed. Recommended differential operating current is 30 mA.

(The earth leakage relay evaluates the current difference between all connected phases. If an earth leakage occurs anywhere in the circuit, then a current difference occurs between the phases - a differential value. The device registers this and turns off the network, and the response time is short, such that when a person touches a conductor, a current of dangerous magnitude does not have time to develop through the body...)

- Differential circuit breakers can be installed - devices that combine maximum current protection and a protective relay in one housing. An example of selecting a difavtomat for boilers depending on their power for a voltage of 380 V is given in the table.

Connecting heating elements in an electric boiler

Each boiler is supplied by the manufacturer with a schematic electrical diagram, which includes, among other things, a rewiring diagram if the boiler will be used with a different supply voltage.

Boilers designed to operate on a 220 V network are also equipped with heaters with an operating voltage of 220 V, which are connected in parallel. An example of an electrical installation diagram for an electric boiler on a 220 V network with 3 heaters, each of which is turned on by a separate switch, is shown in the figure.

Boilers for 380 V can be equipped with heaters designed for 220 V. Then the heaters are connected according to a star circuit with a common zero.

If the heaters are designed for a voltage of 380 V, then they are connected in a triangle.

How to connect an electric boiler to heating. Hydraulic diagrams.

In the simplest version, the electric boiler is connected to the heating system just like any other. The safety group, circulation pump, and expansion tank may already be included in the boiler itself (expensive models).

If the electric boiler is used only as a reserve for any boiler, then it is much more advisable to provide manual activation through valves, without using check valves. A simple scheme for backing up any other electric boiler.

To use the boiler “on the fly,” it turns on when the main solid fuel burns out and the temperature of the air or coolant decreases, which is registered by the corresponding relay (thermostat). The circuit for turning it on together with the solid fuel must necessarily turn off the solid fuel pump as soon as there is no longer a flame present in it, so that it does not act as a cooler on the chimney.

Here the boilers are connected to hydraulics through check valves to ensure automatic switching on without human presence. But at the same time, you will have to put up with the disadvantages of such inclusion - clogged valves, increased hydraulic resistance...

How to heat cheaply with an electric boiler

The night tariff for electricity is usually comparable to the price of cheap fuel, for example 1.7 rubles. per kW, by comparison, - 1.1 rubles. per kW of energy from coal. But for an electric boiler the efficiency is close to 100%, and for a coal boiler it is 80%, therefore: 1.1/0.8 = 1.38 rubles/kW...

If you connect an electric boiler, powered through a two-tariff meter, to a buffer tank, and at night take maximum energy from the electrical network, then the stored energy will be enough for almost a day... Depends on the connection conditions - the power allocated by the energy supervision and the power of the equipment itself...