Ecology of consumption. Estate: Today we will talk about the invention of an innovative engineer who did the unprecedented: he built a stove that works for up to 7 days on one load.

Today we will talk about the invention of an innovative engineer who did the unprecedented: he built a furnace that works for up to 7 days on one load. Meet Lachinyan's pyrolysis furnace. The drawings of this miracle stove are freely available and we will provide them to you. We will tell you what makes such a long and efficient combustion, or more precisely, smoldering of fuel, possible. We will also reveal the secret of the developer Sergei Surenovich Lachinyan regarding the products of the pyrolysis process.

Stages of making the Lachinyanki stove with your own hands

Marking the holes in the furnace body.

The Lachinyanka stove is made in a certain sequence:

- a housing with a lid is made, as well as a reservoir for ash;

- all necessary holes are made;

- grooves are prepared into which river sand will then be poured;

- gas outlets and grates are made;

- two taps are installed that serve to supply oxygen;

- then you can start making the air intake;

- the entire structure is installed on the frame and a lever for the pallet is mounted;

- a chimney with a tank for collecting condensate is installed.

Finally, all the fittings (fasteners, handles, clamps) are hung on the Lachinyanka stove. If required, ribs are welded onto the housing to increase the heat exchange area and, accordingly, the power of the unit. The pan lever is needed only if the diagram does not provide for a hinged connection between the ash pan and the housing. In the latter case, installation will be much more difficult.

For a body with a tray and a lid, a pipe with the same diameter is used. You should not take a thin-walled pipe, since to work at high temperatures you need metal that is somewhat stronger. The drawing of the Lachinyanka stove is made for a pipe with a wall thickness of 5 to 8 mm. When making edges (grooves) for sand from two plates welded in a circle, the inner part should be welded first. This must be done so that the seam lies in the groove itself.

When making grate bars for the Lachinyan furnace, steel rods should be used and cast iron should be avoided. When choosing air supply valves, you should take into account that they will have to work in conditions of elevated temperatures, therefore, they must be completely metal, without plastic elements. A one and a half inch water tap with rubber seals will do. Rubber is quite functional in these conditions. For the body with a tray and a lid, a pipe with the same diameter is used.

Schematic markings for installing gas vents

You should not take a thin-walled pipe, since to work at high temperatures you need metal that is somewhat stronger. The drawing of the Lachinyanka stove is made for a pipe with a wall thickness of 5 to 8 mm. When making edges (grooves) for sand from two plates welded in a circle, the inner part should be welded first. This must be done so that the seam lies in the groove itself.

To avoid the formation of condensation, the chimney should be insulated or, if possible, located in a warm room. The chimney pipe should not be horizontal. It is necessary to give a slight tilt towards the heater so that the condensate flows first into the condensate collector and then into the Lachinyan furnace.

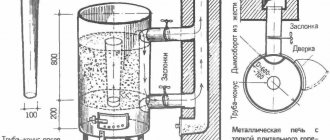

Design of the Lachinyan pyrolysis furnace

To make a Lachinyanka stove with your own hands, you will need instructions that will describe all the design elements and assembly steps. This information is already freely available on the Internet. We will briefly dwell on the key points. So, the design of the Lachinyan furnace (drawings):

- air supply valves;

- frame;

- case cover;

- firebox and grates;

- pipes for gas circulation;

- condensate collection tank;

- chimney;

- installation frame;

- pallet lever;

- locks of lid and tray latches.

The lid is equipped with handles for convenience to make it easier to remove. All the ash is collected in the pan, and it is also used to fire up the furnace. The design has two valves for supplying air: one for the pyrolysis reaction, and the second for combustion.

Some models of Lachinyanka stoves, made by yourself, have fins on the body and chimney. Additionally, the housing can be wrapped with thermal insulation. There are several models of stoves, the main difference between them is the power, which depends on the dimensions. Naturally, the larger the structure, the more thermal energy it releases during operation. So, there are small units of 50 sq. m., and there are also 300 sq. m.

Sergey Surenovich decided to use river sand as a sealant. It turns out that it does not allow air to pass through and after the edge of the lid is lowered into the sand, the connection becomes airtight. As we have already said, tightness is a necessary condition for the unit to operate in the specified mode for many days.

Types of pyrolysis furnaces

A high-quality long-burning stove must meet several conditions:

• to maintain maximum combustion temperature and long-term operation, have a sufficiently large loading chamber

;

• in order to prevent parasitic draft and excessive air intake, the boiler must be as tight as possible

; the doors on it should be adjacent to the body as tightly as possible;

• since the combustion of gases occurs partially in the chimney, to increase the efficiency of the stove, it is better to lengthen its horizontal section at the junction with the boiler to 1 m

and additionally insulate with mineral wool;

• in order to reduce the number of fuel deposits, it should be placed as densely as possible, without gaps - this way it will smolder much longer; It is advisable to cover large logs with wood chips or sawdust; in some models (for example, such as “Stropuva” or “Bubofanya”, which we will talk about below) the fuel is additionally compressed

;

• the presence of a minimum number of heat exchangers

(pipes with water to remove heat into the room) - since when heat is released into the pipes, the temperature in the furnace will drop sharply, and the gases, without burning, will simply evaporate into the pipe; In this case, the efficiency of the furnace will naturally drop sharply;

• to avoid smoke in the premises, humidity

the raw materials used should be as low as possible (up to 20%);

• since such boilers require frequent cleaning, the chimney connection must be dismountable

;

, water condensation often forms

; to drain it, a drain valve should be provided at the bottom of the chimney.

Important! The productivity of such furnaces directly depends on the volume of its working chamber. The shape of the boiler itself can be any

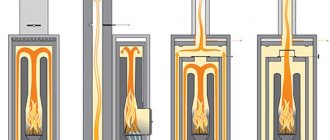

According to the method of fuel combustion, pyrolysis boilers are divided into:

• mine type

.

air is supplied to the chamber with solid fuel

from below, through the ash pan (a hole in the lower part of the firebox), and, naturally, the fuel also begins to burn from below;

Pyrolysis boiler of shaft type

• with top combustion of fuel

. air enters the first chamber from above through a special pipe.

Stropuva furnace with bottom combustion of fuel

According to the methods of air supply, all pyrolysis boilers are divided into:

• working on natural draft

(oxygen enters them naturally through special holes);

• forced draft: air dosage is carried out using a deflector (smoke)

.

located on the chimney, this mechanical device has several inclined planes; when air bends around such obstacles, a pressure difference is formed in the channel, and the thrust increases; Thrust can be significantly increased using electrical devices with a turbine operating principle

.

Deflector for a stove

Based on the type of fuel, long-burning stoves can be divided into:

• powered by waste oil; • wood; • coal.

Operating principle

When the amount of oxygen is reduced to 10%, the fuel does not burn, but slowly smolders, releasing pyrolysis gases

(gases formed during the decomposition of fuel under the influence of high temperatures). This is the basis of the operating principle of all long-burning boilers. The fuel in them is not coal or wood, but pyrolysis gases formed during its decomposition.

Such ovens consist of two chambers

.

In the first

, with a minimum amount of oxygen, the fuel smolderes.

The hot pyrolysis gas released in this case passes into the second chamber

, into which a sufficient amount of oxygen is supplied.

When it is mixed with gas, the fuel burns completely. To regulate the air supply into the chamber, an adjustable valve

.

The principle of operation of a pyrolysis boiler operating on sawdust

To make the simplest long-burning stove from a barrel, you can use the following scheme

Advantages and disadvantages of a pyrolysis oven

We should start with the fact that the mini gas generator, which is located in all devices of this type from a gas cylinder, has a very advantageous position. thanks to its operating principle. Its efficiency exceeds 80 percent! Due to this factor, the operation of the stove is very economical (which cannot be said about fireplaces): it is rational to use fuel without extra costs and adjust the process, as well as the degree of combustion, independently; The second advantage of pyrolysis stoves made from a gas cylinder is that the stove will operate on any fuel. A variety of waste from the wood processing industry can be used for fuel. This could be firewood, wood chips, sawdust, small branches, etc.

It is permissible to operate the unit on small household waste, in the form of plastic or small rubber products; The third positive feature is that pyrolysis gas is environmentally friendly, which means that no harm is done to nature; The “clean” operation of a stove from a gas cylinder is very important (which cannot be said about fireplaces). During operation of the device, no dirty substances such as soot or ash appear due to the operating principle of the gas generator

This factor greatly facilitates the use of the design: you will not need to spend a lot of time cleaning the stove and eliminating various dirt from its external and internal surfaces.

The advantages of a long-burning pyrolysis furnace from a gas cylinder do not end there; to better familiarize yourself with all the advantages, you can watch the necessary videos, but we will limit ourselves to this and begin listing the disadvantages of the device:

The first thing you need to pay attention to is the high cost of a pyrolysis stove for a bathhouse or home. Most often, this is what stops buyers

Unlike fireplaces, the cheapest model for a bath will cost at least 10,000 rubles. and if you want a more modern and improved model, you will have to pay approximately 17,000 rubles. On the other hand, the high prices for pyrolysis stoves for baths are fully compensated by their good quality and versatility: nothing will warm up your home as well as a pyrolysis stove will; The second disadvantage of devices made from gas cylinders of this type is the need for constant power supply. This is necessary to maintain the operation of the furnace. The costs of constant use of electricity are also very high, which cannot be said about fireplaces. Today, there are some models of pyrolysis stoves made from gas cylinders that do not require a constant supply of electricity. however, due to some circumstances they are not very popular.

If you don’t want to spend a lot of money on buying a pyrolysis stove or fireplace, there is an excellent solution - you can make it yourself using the drawings and videos given on the Internet. In order to make such a design with your own hands, you do not need to fully know the operating principle of the boiler and gas generator - it is enough to understand the basics that were listed above.

Unit design

The standard design of a pyrolysis stove is the following design (for a better understanding, it is recommended to look at various drawings):

- A fuel compartment with a combustion section is built into the common housing (it contains all the parts), the latter contains firewood, chips, sawdust, branches, paper or other fuel.

- The operating principle of the firebox and its design (sealed, with a tight door and a well-functioning damper, equipped with a supply and exhaust fan) ensures low air flow. Fuel is first placed in the fuel compartment, then it is ignited using special devices (burners) or with your own hands. After they flare up a little, the access to oxygen in the firebox is limited.

- The second chamber, where direct combustion occurs, can be combined with an air duct or chimney pipe (its beginning). It can be maintained using a special fan, which you can buy in a store or install yourself (as a rule, they use a supply and exhaust design).

It is permissible to use dampers that have the property of tightness using natural draft. However, this option is only permitted with a well-planned chimney system . It is also necessary to install a device with your own hands, the role of which in handicraft or industrial furnaces is usually performed by a rotary “retort”. Lachinyan’s design differs from standard pyrolysis furnaces in that it can have a water boiler , and the fuel burns in it in two stages, being divided into gas and solid residues. The solid residues are then also burned, the heat from them being used to maintain a constant desired temperature in the primary firebox. Firewood is almost completely burned, leaving very little ash behind - this is another feature of pyrolysis furnaces. Typically, such furnaces and boilers require ash removal every few days, or even once a week.

If you want to know more information about the Lachinyan furnace, you can watch the necessary videos, diagrams or drawings.

Do-it-yourself Lachinyanka stove

This boiler is a rather controversial (and little tested) model that runs on coal, wood, peat or pellets

. At its core, it is a smaller copy of the industrial furnace “Energy TT”. According to the author, his “Lachinyanka” is also capable of working without a break for quite a long time - a whole week. At the same time, the fuel loading rate is only 20 kg, and this boiler produces a minimal amount of soot. It can also be used as a regular potbelly stove.

Unlike other pyrolysis furnaces, “Lachinyanka” is equipped with a tank

.

installed on a chimney pipe in which condensate collects

. which is then fed into the combustion chamber. This is waste-free production. Even soot mixed with condensate burns to ashes.

Important! In order to obtain a sufficient amount of condensate, the temperature in such an oven should not be too high. Lachinyan S.S.

In order to popularize his brainchild, he also provides a detailed diagram of its manufacture (the diagram is both freely available on the Internet and on the author’s official website). Therefore, if you wish, you can easily try to design such a stove yourself. But there are still not enough reviews about her work, both positive and negative.

Lachinyan S.S. In order to popularize his brainchild, he also provides a detailed diagram of its manufacture (the diagram is both freely available on the Internet and on the author’s official website). Therefore, if you wish, you can easily try to design such a stove yourself. But there are still not enough reviews about her work, both positive and negative.

Appearance of the Lachinyanka stove

Operating principle of "Lachinyanka"

Condensate drain device

Lachinyanka stove without external casing

"Lachinyanka", view from the inside

Video: DIY pyrolysis oven

Operating principle of the Lachinyan furnace

Furnace named after Sergei Surenovich Lachinyan

The pyrolysis furnace of Sergei Surenovich Lachinyan operates by the method of complete combustion of fuel and its pyrolysis products. In other stoves, pyrolysis involves the release of gas from solid fuel, but this design has some differences. In addition to gas, during the pyrolysis process a special liquid is also released from the fuel. In ordinary stoves it evaporates and goes into the chimney along with combustion products.

What is special about the Lachinyan pyrolysis furnace? Product drawings include a cooling tank in which condensation is collected. The tank is installed on the chimney pipe itself. After condensation has collected in the tank, it is fed into the combustion chamber. This contributes to:

- increasing the efficiency of the device;

- reducing the amount of condensate in the chimney.

After the fuel has been loaded and ignited, the furnace is hermetically sealed. Tightness is a prerequisite for the low-temperature reaction necessary for the pyrolysis process to occur. In this mode, the device will work for up to seven days and can be left unattended. In addition, there is a high-temperature regime in which the Lachinyan pyrolysis furnace operates. The drawings remain the same. High-temperature conditions are achieved with the pan open when the device is not sealed. In this case, the unit is no different from a conventional stove. In such conditions, the heat source constantly requires supervision.

To ignite Lachinyanka, you can use either wood or a gas burner. The main thing is that the coals flare up and the oven enters pyrolysis mode.

During operation, the housing lid heats up to 85 degrees, which allows it to be used as a surface for heating food or water. Unfortunately, it cannot be used as a hob, since the temperature is not so high.

Scheme of assembly and installation of a stove for a bathhouse or home

If you nevertheless decide to create a pyrolysis furnace for heating a house, bathhouse or sauna, as well as any other premises, then you will need the following tools and materials:

Note to Samodelkin

- A steel sheet measuring 6 by 1.5 m. Its thickness must be at least 4 mm.

- Ceramic and fireclay bricks.

- Fan with a power of at least 300 W.

- 2 doors for the blower and furnace.

- Cast iron grates - about 3 pcs.

- Lever thermostat.

- Electric drill.

- Welding machine.

- Grinders with 2 different circles – small and medium.

- Pipes with a diameter of 3.2/5.7/15.9 mm.

- Profiled pipes with a diameter of 80x40.

- Temperature sensor.

- Electrodes for welding.

Depending on the purpose of the stove - for a bath, for a special heater, for the home, etc. – sizes and quantities of materials may vary, but the average parameters remain the same.

To make a pyrolysis stove for a bath, you need to be able to use, first of all, construction tools, in particular, a welding machine, and be sure to have an assembly drawing, where:

- A – boiler circuit controller;

- B – door for loading;

- C – ash pit door;

- D – smoke exhauster;

- E – coupling for temperature sensor;

- F – emergency line pipe;

- G – supply line;

- H – cold water connection;

- K – hot water heat exchanger;

- L – boiler circuit return;

- M – expansion tank.

The sequence of work is as follows:

- First of all, you need to draw up a diagram of the future design of the stove for a bathhouse or any other room.

- Next, the perimeter of the furnace needs to be laid out from ceramic bricks.

- Fireclay bricks are used for finishing and construction of external partitions.

- It is necessary to weld special pipes that will increase the tightness.

- Install a partition between the gas and secondary combustion chambers.

- The supply is mounted in the upper part, and the return is mounted in the lower part.

- Doors are manufactured and installed from heat-resistant steel. Doors are needed to clean the oven and regulate the air supply. For a bath they are reinforced with a metal corner. Further, the doors are equipped with locking handles.

- Attach a pipe to release smoke.

- Connect a fan that will force air into the gas-oxygen mixing chamber.

Advice from the master!

However, before starting work, you need to sensibly assess your strengths. If you are not sure, then it is better not to take risks and use the services of professional companies and firms involved in the assembly and installation of such systems.

Self-assembly options

Pyrolysis furnace made from a metal barrel

Homemade structures can be made from various materials, such as a gas cylinder, tin cans, barrels, bricks and much more.

Depending on the material of production, all furnaces are divided into:

- stone;

- metal.

Stone or brick ovens are used extremely rarely. This is due to the fact that its construction will require a lot of investment and time.

Of course, recently such designs have undergone some modifications, which has significantly increased their efficiency. As for metal stoves, they are especially popular. The fact is that they can be made even from an old gas cylinder or barrel.

Pyrolysis furnace Lachinyanka

Depending on the principle of operation, the fuel and material used, all furnaces are divided into the following types:

- furnace operating on treated oil;

- Kuznetsov furnace;

- Lachinyanka;

- Buleryan stove;

- Bubafonya.

The principle of operation of all these structures is the same - afterburning the gas that is released from the fuel. But, when choosing a design, it is worth considering some features of each type.

Thus, it is undesirable to use stoves that run on waste oil in bathhouses and other residential premises. They are ideal for heating garages and other non-residential premises.

Of course, it is worth considering that small furnaces running on waste oil are highly productive. You only need a cup of oil to get the job done.

You might be interested in an article on how to make a pyrolysis boiler with your own hands.

Read a review of modern models of pyrolysis boilers for heating here.

Made of brick

To build a brick stove you will need:

Drawing of a pyrolysis furnace. (Click to enlarge)

ceramic and fireclay bricks; steel sheets; cast iron grates; 300 W fan; door to the furnace room and for the blower; welding machine; drill; Bulgarian and others.

Having such materials and tools at hand, you can build a stove with your own hands. Of course, we should not forget about some nuances on which the strength and efficiency of the heating structure will depend.

If you have chosen a brick kiln, the construction process will look like this:

- Clearing the site and installing the foundation. The best option would be a strip foundation. It must have high strength.

- After the foundation has hardened, you can begin laying bricks. For this purpose, high-quality refractory bricks are used, which are highly durable.

- The inside of the oven is lined with fireclay bricks, which can withstand high temperatures.

- Chimney installation. It is best to use metal inserts or ceramic structures here.

Keep in mind: the installation of a chimney must be approached with great responsibility and it is better to consult with a stove professional in advance.

All work is carried out according to a pre-drawn plan, which is best agreed upon with a specialist.

If necessary, you can decorate the structure. For this, facing bricks, stone and other materials that can withstand high temperatures are often used.

From a gas cylinder

The peculiarity of the Bubafonya stove is that it can be used with different fuels.

To make such a design with your own hands, you will need the following tools:

- hammer;

- Bulgarian;

- welding machine and electrodes;

- pliers.

The manufacturing process of the Bubafonya stove is carried out in the following sequence:

- Cut off the top convex part of the cylinder.

Be careful: cut off the top of the cylinder below or above the welding seam, since the connecting seam is reinforced from the inside with a metal plate, which can complicate cutting.

There is a hole in the center for the air duct. At the top of the cylinder body, a hole is made for the chimney. Make a gas divider with a pipe through which oxygen will be supplied to the second chamber. Weld the chimney.

As you can see, you can easily make a stove from a gas cylinder with your own hands

But you should pay special attention to cutting the cylinder. Before you start working with an angle grinder, you need to make sure that there are no gas residues in the cylinder; to do this, fill the cylinder completely with water

DIY ovens

The most versatile and widely used shaft-type

with a fairly high efficiency (up to 75%) is “Buleryan”. There are 6-8 pipes on the sides of such a boiler. Their lower ends “suck” cold air from below. Pipes tightly surrounding the stove quickly receive heat and throw it upward into the room. On our website there is a very detailed description of the principle of action of “Buleryan”.

The economical furnace has also proven itself well during testing. Its design is as simple as possible, and making such a boiler yourself does not present any particular problems.

Furnace in production

A very original (and, most importantly), quite effective design with top combustion of fuel

and high efficiency is the Bubofanya stove. It was based on the widely advertised Stropuva model. But, unlike the industrial model, the design of “Bubofani” is extremely simple, and any novice welder can do it. You can get acquainted with the principle of its operation and the stages of its creation by following this link.

Design features of a long-burning heating unit

If you want to make a long-burning installation with your own hands, you must first of all understand how its design and operating principle differ from traditional heat generators.

In a conventional stove, with strong draft and a large amount of oxygen, dry wood burns very quickly. But by fully loading fuel and limiting air access to the combustion zone, intense combustion can be turned into smoldering. The intensity of air intake is regulated using a damper.

Fuel combustion in such an installation, unlike units of traditional design, occurs from top to bottom. When the fuel burns, the hearth lowers. This is achieved using a special lid that presses on the hearth from above.

Oxygen for fuel combustion in the upper zone of the furnace enters through a pipe, which is mounted on top of the lid.

https://youtube.com/watch?v=R—IcJX-uX4

Job requirements

The operating principle described above is the basis. However, in addition to all this, there are also additional requirements that are necessary for the full and high-quality operation of pyrolysis. If assembled correctly, such a boiler can be used for heating and for supplying hot water to the bathhouse. In order for the process to proceed smoothly, without sudden changes in temperature and pressure, certain conditions must be observed. Here are some of them:

Homemade heater from an aluminum bucket

- To make your own boiler, you only need high-quality materials.

- First of all, the metal from which the frame and casing of the boiler is made must be of high quality. Alloy steel is perfect for this, as it meets all the required parameters and building codes.

- You need to know how to use a welding machine, without which it will be impossible to assemble the entire system. In addition, you need to be able to understand the drawings of units and their structural parts.

- Electronics are required to monitor the operation of the boiler, which can be expensive.

Operation of the Lachinyanki stove

Once you already have a Lachinyanka pyrolysis oven, you need to know how to handle it. We will divide the operating manual into several sections:

- installation rules;

- how to light a stove correctly;

- application features;

- preventive maintenance.

The Lachinyan pyrolysis furnace should be placed on a flat surface; it should not wobble. Since the design has many movable elements (pallet, fasteners, etc.), there should be enough space around the unit. In addition, the furnace body can heat up to high temperatures, so you need to make indentations from the walls. It is better, of course, for the latter to be covered with some kind of heat-insulating material, or equipped with a heat shield.

The design of a Lachinyan stove is impossible without a chimney. It is subject to the same requirements as for chimneys of other gas or solid fuel heating appliances

It is also extremely important to correctly calculate the diameter of the chimney. It must be no less than the cross-section of the pipe in the furnace, and there should be no narrowing in any places, otherwise the draft will be lost

To light the Lachinyan stove, coarse coal, without dust, is poured into the firebox. A fire is built in the tray. It is necessary to open both air supply valves and close the pan loosely. After the coal has flared up, the tray can be hermetically closed, and more coal can be poured into the firebox. After an hour, the stove can be switched to pyrolysis mode. To do this, the lower valve is completely closed and the upper valve is almost completely closed.

During operation, it is necessary to remove ash and periodically clean the boiler and chimney. The frequency of cleaning depends on the quality of the coal. The higher it is, the less often you need to carry out the cleaning procedure. In addition, you need to periodically change the sand in the grooves for sealing. It is necessary to use clean, dry river sand, not too fine. You can add fuel by simply opening the top cover; you do not need to stop the combustion process to do this. published econet.ru

SUBSCRIBE to OUR YouTube channel Ekonet.ru, which allows you to watch online, download free videos from YouTube about human health and rejuvenation. Love for others and for yourself, as a feeling of high vibrations, is an important factor in healing - econet.ru.

Please LIKE and share with your FRIENDS!

https://www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -

What is needed to make a stove?

In order to make a Lachinyan pyrolysis oven, you will need:

Tools:

Materials:

1. Pipe with a diameter of 355 mm (wall 4-7 mm) and a length of 1000 mm (taking into account the width of processing and cuts).

2. For grate bars - reinforcement with a diameter of 10 mm or a rod with a diameter of 8÷10mm - 5 m (or in sections of 20-40 cm) or steel wire - stainless steel Ø 8-10mm - 4 m. (For high-temperature conditions and for a bath it is better to take stainless steel).

3. A steel pipe with a diameter of 80 mm (external diameter 88.5) for the pipe outlet (1-2 m) and a bend that is bent at an angle of 90 degrees (depending on where you will lead the pipe, the angle of the pipe may be completely different, and the chimney pipe can be welded directly into the furnace firebox).

4. Stopcocks 2 pcs. One - water tap - 1 pc. by 1 ½” (outer diameter 48) (Or, another large faucet, only without plastic parts). The second is a ball valve – 1 pc. by 2” (d.60mm.) for hot water.

6. Thick-walled pipes with a diameter of 1 ½” (forty), for gas outlets 1.2 m.

7. Any pipes, with an outer diameter of 27-42, with a total length of 5 m. For frame and racks.

8. Sheet metal (2.7-3.5 mm thick) for the lids - half a standard steel sheet 1250*1250.

9. Steel strip with a width of 50-60mm and a thickness of 2.7-3.5 mm and, for sand gates - 6m. (Can be cut from a sheet).

10. A thick steel strip with a width of 45-60 millimeters and a thickness of 5-7 millimeters, for locking levers, can also be cut into pieces of 250 mm (2 m in total). You can also cut it from a sheet of metal (thick), or take a ready-made profile (for example, a corner or a rectangular pipe).

11. Wire (rod) dia. 8 millimeters - 6 meters (or in sections of 1.25 m.)

12. Wire with a diameter of 4-5mm - 5 meters. (or in 1.2 m sections)

13. A thick-walled rectangular pipe or a corner - necessary for the radiator fins. Pipe with dimensions 40*25 or 60*30 or more, or corner 30*3-50*4, etc. only 5-8 meters. (sections of 200-550 mm.). Finning is also possible with a metal strip 40-60*3.5 mm wide or with any round thick pipe. Note: if an air intake is used, then you will also need a casing and corrugation specifically for the air duct, materials/length according to location.

14. Bolts M10x70-100mm, 4 pieces. Bolts with countersunk heads M8x35-45mm, 4 pcs. All with washers and nuts, 2 pieces per bolt.

15. Asbestos thread (200 grams). For sealing threaded holes.

Note. The list of materials indicates the internal standard diameters (sections) of chimney pipes. But their external diameter size will depend on the thickness of the walls, so the holes are cut using existing pipes that are already available - see the table.

Pyrolysis process

First of all, you need to understand what pyrolysis is and what the principle of its operation is. The combustion process takes place with a lack of oxygen. Only after combustion does oxygen begin to react. If we talk about this process in more detail, it happens like this:

- In the presence of high temperature, combustion of fuel is accompanied by the release of gas from it.

- Gas is released, as already described, when there is a lack of oxygen inside the furnace.

- Combustion temperatures for each fuel are different: for example, for petroleum products the combustion temperature should be at 800-900°C, and for wood 400-500°C will be sufficient.

- When wood is burned, additional products appear: charcoal, resin, methyl alcohol, acetic acid, acetone, etc. Some of these products are used in the secondary and tertiary combustion process.

Device Specifications

- The power range does not exceed 7 kW.

- The maximum fuel weight when fully loaded is 24 kg.

- The burning time of one load can last a week, this is determined by the room temperature. If it is high, less fuel will be consumed, if low, correspondingly more.

- The weight of the oven can be very different: from 30 kg to 80 kg . The weight of the unit depends on the material from which it is made.

If you want to know more information, you can view the necessary drawings.