You will probably agree that when thinking about a roof, the first thing that comes to mind is a wooden rafter system on which tiles, corrugated sheets or other roofing covering is laid. If there is an attic under the roof, then insulation is inserted between the rafters. And if the attic is cold and not habitable, then the insulation is not in the roofing pie, but in the attic floor. We intuitively understand that the roof covering protects the roof elements and the house as a whole from atmospheric moisture and destruction.

However, when imagining the design of a future roof or ceiling, rarely does anyone immediately think that they must be protected from moisture penetration not only from the outside, but also from the inside of the house. Moisture coming in the form of steam from residential premises is no less destructive than rain or snow. But protecting your home from this harmful phenomenon is much easier and cheaper than from precipitation - you just need to buy the right vapor barrier.

Why is roof vapor barrier needed in wooden houses, and how to protect the ceiling (floor) from vapor, we describe below.

Why do you need a roof vapor barrier?

In the interior of the house, a variety of economic and household activities are carried out, accompanied by the release of steam: we are engaged in cooking, wet cleaning, hygiene procedures, washing dishes, watering indoor plants. Even while at rest, we emit water vapor through breathing, not to mention intense physical activity.

Do you know how much moisture a person releases into the surrounding air? At 25 degrees Celsius per day, one person at rest throws 1.5 liters of moisture into the room, and with little activity up to 4.5 liters! Moisture evaporates through the skin and through breathing through the lungs

The vapor in the air is not visible to the naked eye. However, it is this that causes windows to fog up in cold weather, and after taking a shower we can see drops of condensed steam on the mirror in the bathroom. That is, steam is constantly in the air around us, and when it comes into contact with cold objects, it settles on them in the form of condensation. The more steam in the air and the colder the surrounding objects, the more condensation will fall.

During the cold season, the same water vapor settles in the form of small droplets in the structure of the insulated attic floor (ceiling) or in the roofing pie of an insulated roof. As a result, it causes dampness, the formation of fungus and the proliferation of pathogens. This happens if a vapor barrier was not created during construction, which is why fumes from the premises easily penetrate the layers of insulation and are absorbed into the wooden rafters and beams.

The lack of a vapor barrier in the attic floor resulted in steam leakage into the attic. During the cold season, steam condensed on the cold roof elements and turned into water and frost. Due to constant contact with water, the wooden elements of the roof have become infected with fungus and will soon become unusable. If you do not prevent steam from getting under the roof with a vapor barrier film, the roof will soon have to be replaced

During the cold season, the inside of the insulation and beams is warm, as it is heated by the internal air from the room. And their outer part is cold, because it is constantly exposed to the cold air of the street. Moving through the insulation and wood, water vapor at a certain moment cools to such a state that it can no longer be steam and turns into drops of water (dew point). This water wets the insulation and wood. The first loses its thermal insulation properties, and the wood begins to rot. Moreover, if the temperature drops further, the moisture accumulated in building structures will freeze. It is no secret that when water hardens, it greatly increases in size, and in our case this will lead to micro-tears and damage to the insulation and wooden elements.

In wooden houses, this problem is especially acute, since problems with excessive humidity directly affect the load-bearing capacity of structures and the sanitary condition of the house. Therefore, vapor barrier in a house with wooden floors or rafters is an urgent need, and not a marketing fiction.

Video about why vapor barrier of roofs and ceilings is needed

Where to put the insulation

This question is very important, because if you put the material in the wrong place, it will not work or it will work, but incorrectly. It is important to remember one rule: vapor barrier is always installed on the warm air side, and waterproofing on the cold air side . Typically, these materials work together, providing reliable protection for the floors in the house from all types of moisture.

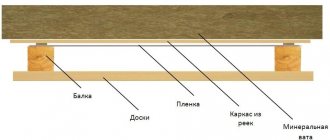

Vapor barrier film is laid on top of the floor insulation

Thus, it turns out that the vapor barrier of the wooden floor of the first floor should be carried out after installing the thermal insulation material, and protection from moisture in the air for interfloor ceilings or the attic should be laid from below.

The vapor barrier film of interfloor and attic floors is laid underneath the insulation

If you lay the material correctly, you don’t have to worry about the safety of the structures.

Why did they do without vapor barrier before?

This question can be found quite often and there are answers to it:

- First, let's compare how many sources of steam in residential premises there were before and how many there are now? Previously, toilets were on the street, washing and washing were done in the bathhouse, irons were without steam, there was no running water in the houses, food was cooked in a stove, the chimney of which served as an exhaust hood. Now all of the above is located in our home and is actively floating;

- Secondly, until the middle of the last century, heating in most houses was stove. What is a stove? This is not only a heating device, but also a very powerful hood. For combustion, air is constantly needed, which is taken from the living room. Along with the air, the steam contained in it is also removed into the chimney;

- Thirdly, again about wooden and plastic windows. The old wooden windows really provided a serious influx of fresh air from the street, making ventilation easier. And in the cold season, when the effect of steam on the elements of the house is most harmful, the air outside has very low humidity, that is, it contains almost no steam. Once entering the room, such air constantly displaces warmer and more humid air into the chimney or ventilation. Modern plastic windows have stopped this flow of dry air, and few people install fresh air ventilation systems;

- Fourthly, look at the design of the previous roofs. The currently fashionable mansard roofs were practically never seen in our country, so there was no problem with their vapor barrier as such;

- Fifthly, compare the old and modern design of floors in private houses. Previously, earth, clay and straw, or, at best, furnace slag or its mixture with earth were used as insulation. Insulation materials made from the listed materials do not collapse under the influence of moisture, and most importantly, they have a very low vapor resistance, due to which the steam that gets into them easily comes out. The disadvantage of such insulation is the huge weight and large heat loss.

If we compare multi-storey buildings built in the second half of the 20th century with modern ones, then in most cases they have reinforced concrete floors insulated with loose expanded clay or slag. Reinforced concrete does not allow steam to pass through, but even that part of the fumes that managed to pass through the joints and leaks of the slabs freely escapes through the layer of loose insulation.

If high humidity is detrimental to floor and roof structures, then for normal human life and health the humidity level should always be around 50%. How to ensure this value, read our article “How to use a humidifier: basics of operation”

As you can see, modern buildings are radically different from their predecessors, and therefore the question of the advisability of using a vapor barrier for the ceiling and roof in a wooden house cannot be questioned.

Photo gallery (20 photos)

Vapor barrier device

Vapor barrier diagram with a reflex layer

Polyethylene foil film Reinforced film

Glassine

Polypropylene film

Breathable membrane

It is best to install vapor barriers together

Ceiling vapor barrier diagram It is best to glue the vapor barrier seams with special metallized tape

All seams of the vapor barrier film must be sealed

Tools for installing ceiling vapor barrier.

Attaching a vapor barrier using a stapler

Attaching the vapor barrier

Ceiling cladding with vapor barrier

- Soundproofing a stretch ceiling in an apartment

- How to drill without dust

- How to soundproof a ceiling

How does a vapor barrier for a ceiling in a wooden house differ from waterproofing?

The benefit of waterproofing is that it repels water. Waterproofing layers are used where it is necessary to protect materials from direct contact with water. In roof construction, for example, waterproofing is placed between the insulation and the metal roofing material. This is done so that drops of water, which sometimes condense on the inside of the metal, falling down, do not fall into the insulation, but onto the waterproofing film, and evaporate from it or flow down to the eaves.

At the same time, modern waterproofing materials, while holding back water, can allow steam to pass through them. Such properties allow better ventilation of the under-roof space. However, in no case should such waterproofing be used for vapor barrier, since steam will pass through them unhindered into the insulation and wood. Windproof materials that have come into use have similar characteristics to waterproofing. They should also absolutely not be used as a vapor barrier.

The figure on the left shows that the vapor barrier prevents steam from entering the insulation and rafter system from the room. Waterproofing protects the same roof elements, but not from steam, but from moisture from the street or condensation from metal tiles

Now about vapor barrier - its main task is not to allow water vapor to pass through, or to allow it to pass through in very measured doses. A vapor barrier is installed between the warm room and the structural elements of the roof and ceiling. Conventional vapor barrier 100% protects the insulation and beams from moisture from the premises, ensuring their dryness.

More advanced are smart polymer membranes, consisting of several special layers that can allow a little steam to pass through. But the amount of passing steam is very small and is exactly as much as the insulation can safely pass through itself into the atmosphere. The use of such films allows you to maintain a more comfortable microclimate and somewhat simplifies the operation of ventilation.

There are also vapor barrier materials that can absorb excess moisture in the inner layer and then evaporate it during dry periods. At the same time, the outer layer of such films does not allow steam to pass through the roof and ceiling structures.

By the way, regarding this vapor barrier property, you can often come across a misconception that by absorbing evaporation, the film completely eliminates moisture. In fact, this is not the case: the membrane only temporarily captures water during periods of maximum humidity so that it does not bead up and destroy the finish. But subsequently, the collected moisture must evaporate, for example, when ventilating the room

When choosing a vapor barrier, you should be extremely careful not to buy waterproofing or wind protection instead of a vapor barrier. To do this, you need to carefully read the information indicated on the product packaging.

Moreover, some materials can actually be used for both hydro- and vapor barrier. The simplest such example is reinforced three-layer polyethylene or polypropylene films (greenhouse films). The material from which they are made does not allow water or steam to pass through.

The video talks about the differences in the purpose and properties of vapor barrier and hydro-wind protection. Despite the fact that the video example discusses the construction of a frame wall, everything described is completely suitable for installing a vapor barrier for the ceiling and roof

Installation of floor heating systems

The design of underfloor heating involves the installation of heating mats or infrared roll-out floor heating systems under:

- finishing coating laid using a floating method (parquet boards, laminate);

- floor tiles or porcelain stoneware laid in wet areas.

Laying tiles on an infrared floor heating system.

Manufacturers recommend installing a heat-steam-hydrobarrier with the reflective side facing the heating element. However, here you can successfully use ordinary foil-coated isolon or EPS, the cost of which is 2-5 times less than its membrane competitor.

The final scheme of work is as follows:

- Rough base

- Reflective vapor-waterproofing;

- Floor heating system, taking into account the characteristics of the type used (for example, infrared mats cannot be installed under heavy furniture);

- Finish floor covering

To summarize, we note that there is no complete replacement for vapor barrier membranes with selective permeability. Cheap analogues serve rather as waterproofing agents, excluding any diffusion of gases, steam or water.

Advice! If you need repairmen, there is a very convenient service for selecting them. Just send in the form below a detailed description of the work that needs to be performed and you will receive proposals with prices from construction teams and companies by email. You can see reviews about each of them and photographs with examples of work. It's FREE and there's no obligation.

Most read

Which vapor barrier is best to choose for the ceiling of a wooden house?

Warm air, saturated with water vapor, always moves upward and towards the cold. The cold space of the attic is exactly where steam from the interior rushes. Therefore, the first structure that needs strong vapor protection is the ceiling. In a wooden house, the effect of moisture on it is most critical, and this matter needs to be given the most serious attention.

The choice of vapor barrier for the ceiling in a wooden house today is huge. The range of available materials is approximately as follows:

- Aluminum foil is the simplest and most environmentally friendly material with zero vapor permeability. At the same time, foil is quite expensive and has low strength, so it is difficult to install. Because of these qualities, pure aluminum foil has not become widespread when working in ordinary rooms. But thanks to its environmental friendliness, high heat resistance and reflective properties, it is perfectly used in baths and saunas.

Advantages and disadvantages of foil for vapor barrier:

Environmentally friendly, heat resistant, reflects IR heat into the room

Low strength

- Vapor barrier based on kraft paper is thick, durable paper covered with a layer of aluminum foil, which provides heat-reflecting properties. It is inferior in strength to its polymer counterparts, but is more environmentally friendly;

Advantages and disadvantages of metallized kraft paper:

Eco-friendly, heat resistant, reflective

Strength is lower than that of films

- Polyethylene. Conventional polyethylene film is not used due to mechanical shortcomings, but reinforced multilayer modifications are characterized by strength sufficient to not deform due to temperature and not tear. Foil options are good because they reflect heat in the desired direction, reducing heat loss;

Advantages and disadvantages of polyethylene films:

High strength, complete vapor tightness

They are afraid of ultraviolet radiation, so you should not delay installation of roofing material on top of polyethylene

- Polypropylene. It is characterized by resistance to ultraviolet radiation and mechanical stress, and has a long service life. Multi-layer polypropylene membranes not only contain steam, but also temporarily store excess moisture and then evaporate it during drier periods. The most modern polypropylene membranes can remove fumes in a dosed manner.

Advantages and disadvantages of polypropylene membranes:

High strength, UV resistance

There are breathable and foil modifications

Films with outstanding characteristics are quite expensive

Each of these materials has its own disadvantages and advantages, but in terms of overall indicators for residential premises, polyethylene and polypropylene materials are the most popular.

Old method (folk)

In the old days, the northern peoples inhabiting the territory of what is now Finland, as well as the inhabitants of Siberia, used a natural “breathing” birch bark membrane to protect the ceiling in a bathhouse or sauna. Layed in several layers and covered with two layers of turf (the first grass down, the second up), it worked on the principle of two in one. It completely protected the wooden roof of the building from rain and at the same time allowed the room to breathe, making it a pleasure to be in the bathhouse. The birch bark should be laid correctly with the inside down and the bark facing up. This is explained by the fact that humic acids contained in the soil (turf), which have a detrimental effect on the sheathing, are better retained by the inside of the birch bark.

How to make a vapor barrier for a ceiling in a wooden house?

The ceiling in any house is the floor (floor) of the next floor. The attic space in wooden houses is most often not used. Therefore, in order to protect the roof from moisture, it is enough to vaporize the ceiling of the last heated floor, above which the cold attic begins.

Please note that when using stone wool in the form of slabs, a continuous rough ceiling (6), as in the figure, is not necessary. This solution is more justified for interfloor ceilings to reduce audibility. In practice, for attic floors, a scheme with vapor barrier fastening directly to the beams is more often used. Then insulation is laid on the insulation, and the counter-battens are attached not along the beams, as in the figure, but across them. This way they provide additional support for vapor barriers and insulation.

The work is carried out according to the following scheme:

- The ceiling is cleared of dust, cobwebs and debris;

- The wooden ceiling is treated with fire protection and dried;

- The vapor barrier is attached to the ceiling on the room side. To do this, the polymer film is cut to the required length and pressed against the ceiling so that its smooth side faces the ceiling, and the fleecy side with the manufacturer’s logo or foil layer faces the room;

- Each film sheet is fixed to a wooden ceiling with a stapler. You can also use special double-sided adhesive tapes for installation;

- The individual panels are laid with an overlap of 15 cm. The edges of the film are glued with adhesive tapes suitable for the material used;

- The ceiling vapor barrier is applied to the walls and sealed at the overlap;

- The final fastening of the vapor barrier is carried out with wooden slats 3-5 cm thick or metal profiles for gypsum boards, depending on the selected finishing material.

After the vapor barrier of the ceiling in a house with wooden floors is completed, it can be covered with wooden lining or other finishing material. Installation of sheet and roll materials on the ceiling is not fundamentally different.

Video about installing vapor barrier film

Production

In recent years, many methods have been tried for making concrete supports for sleepers. There are 4 methods of technology used in the world for the production of reinforced concrete products. They provide reliable and proven products that meet the requirements of international standardization.

Carousel type with delayed release of molds

The finished solution is poured into cassette molds, in which the product is compacted. The technology involves the use of cassette forms consisting of 6 elements. The prepared mixture is poured into cassettes, where it is then compacted. To obtain the required adhesion and provide prestress, a reinforcement cage is installed in the solution. The finished product is removed from the fixtures after reaching the highest strength indicators. After completion of the production cycle, the molds freed from the structures are sent for the next batch of products.

Linear type

For this type, a conveyor is used, on which forms for pouring concrete are installed in turn, their length is 100 meters. The side parts of the devices are covered with special devices that transmit mechanical stress to the metal frame. As the mixture matures, stress is distributed over the entire concrete surface.

Mold dismantling method with the following voltage

This technology involves the use of special shapes and embedded templates that mark the location of the reinforcement cage. The forms are filled with concrete mortar, which is compacted. When the mixture sets, steel rods are fixed into it. After the concrete has matured, the finished sleeper is removed from the mold and template. The production of products occurs continuously.

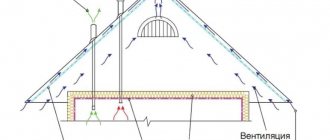

Roof vapor barrier in a wooden house

If the attic in a wooden house remains cold, then only the ceiling of the upper heated floor needs to be protected from steam, as described above. In this case, no additional vapor barrier of the roof is required. But if the attic (attic) space is heated and the roof is equipped with insulation, it is necessary to vapor barrier the roof, and not the attic floor.

Please note that when constructing a roof, it is imperative to provide ventilation gaps between the vapor barrier and the finishing of the ceiling, as well as between the waterproofing and the roofing material. To create gaps, you need to use bars 30-50 mm thick.

There is no fundamental difference when working with vapor barrier material from the technique described above, with the only difference being:

- This vapor barrier runs along the inside of the rafters, behind it is a layer of insulation, then waterproofing, sheathing and the roofing itself (tiles, slate, corrugated sheets, etc.);

- The geometry of the roof makes its own adjustments. The joints of vapor barrier panels with chimneys, dormer windows and ventilation ducts are sealed using special glue, or special passage units are used.

Do not use regular tape to seal vapor barrier joints! After a short time it will come off and the tightness of the vapor barrier will be broken. Use only special adhesive tapes

In addition to protecting roof elements from the penetration of steam and getting wet, a vapor barrier also protects against the penetration of small particles of insulation into the room. As is known, insulation materials based on mineral wool actively generate dust and also contain harmful phenol. Therefore, the use of films helps preserve health.

Installation of roof vapor barrier on the attic floor

Insulation materials

What is the best way to insulate a cold ceiling? The main thermal insulation materials used for insulating ceilings can be divided into the following categories:

- Solid. Such materials consist of foamed plastics, are little susceptible to moisture, and are easy to install.

- Fibrous. Mats or rolls are formed from compressed fibers. Inexpensive, have good thermal insulation. Sensitive to moisture, when wet they lose their thermal insulation properties.

- Bulk. Traditional bulk materials - sawdust, expanded clay, etc. The cheapest ones have the weakest thermal insulation. Ecowool stands out separately - an expensive, but extremely effective material.

- Sprayable. Modern coatings made of foamed plastics. They are sprayed locally and do not form joints or seams. The best thermal insulation, very expensive equipment.

How to insulate the ceiling, everyone decides for themselves, based on their needs and capabilities.

Mineral wool

Rolled mineral wool The most popular type of fibrous materials. Produced from several types of raw materials:

- Basalt wool from volcanic rocks. High strength and density, short hard fibers. High moisture resistance.

- Glass wool from recycled glass. Low strength, light and elastic, long elastic fibers.

- Slag from blast furnace waste. Low thermal insulation properties, low cost. Not applicable for residential buildings.

To insulate with mineral wool, no special equipment is required; the installation process is simple and quite fast. It is produced both in rolls and in slabs with insulation thickness up to 150 mm.

Mineral wool is harmful to health; during installation you must use a respirator, protective gloves and goggles.

An important feature of mineral wool that must be taken into account when designing and installing is the large number of joints and junctions. They need to be done so that the gap is minimal, the slabs are laid against the guides and apart from each other

Half-centimeter gaps between slabs can reduce the effectiveness of the coating by a third.

Correct and incorrect installation of insulation

The thermal insulation properties of mineral wool are reduced until they are lost when the material gets wet. Therefore, it is necessary to ensure the removal of vapors and condensate.

Monolithic

The most suitable and popular material for thermal insulation of ceilings is polystyrene foam. It is produced in the form of 1200*600mm panels equipped with tongue and groove. This allows you to make high-quality joints during installation. In addition, cracks and gaps are sealed with polyurethane foam. The material is resistant to moisture and temperature fluctuations. Works great when insulating ceilings both outside and inside

We suggest you familiarize yourself with: Table of copper wire cross-section by power

Its disadvantage is low fire resistance. When burned, it releases substances harmful to health.

Insulation with polyurethane foam

Review of offers from vapor barrier manufacturers

Izospan

Trusted manufacturer

A domestic manufacturer offering a wide selection of hydro, wind and vapor barrier films. The vapor barrier segment is represented by the following materials: Izospan RS, Izospan FS, Izospan B, Izospan B fix. Izospan materials are of excellent quality.

Izospan B and Izospan B fix (with adhesive tapes) – a two-layer polypropylene sheet that is smooth on one side and rough on the other. During installation, the smooth side is located towards the insulation, the rough side - inside the room. Temperature range from – 60 to + 80 °C. The width of the rolls is 1.6 m. Price is 18 rubles/m2.

Izospan RS is made of polypropylene and additionally reinforced with reinforcing mesh. Application temperature from – 60 to + 80 °C. Can also be used as waterproofing. Width 1.6 m. Cost – 56 rubles/m2.

Izospan FS differs from Izospan B by having a metallized layer applied on one side, which reflects heat (infrared radiation) into the room. Suitable for use in ordinary rooms at temperatures from – 60 to + 80 °C. Cost 37 rub/m2.

Vapor barrier for wooden houses Tyvek (DuPont)

Premium segment

Tyvek AirGuard® SD5 is a two-layer polyolefin membrane with the highest price in the selection at RUB 113/m2. The material is intended for internal use at temperatures from – 40 to + 80 ° C. During installation, the material is placed with an inscription inside the room. Material width 1.5 m.

The manufacturer’s line also includes the AirGuard® Reflective product, which consists of four layers and has increased vapor resistance.

Isover

High quality material

Two-layer vapor barrier from a well-known manufacturer of insulating materials. Temperature range from – 60 to + 80 °C. Width 1.5 m. Cost 26 rubles/m2.

TechnoNIKOL vapor barrier film

Proven quality

Another well-known domestic manufacturer that produces high-quality roofing and facade materials. Its vapor protection is represented by three films.

TechnoNIKOL Alfabarrier 2.0 is a two-layer film for use in insulated pitched roofs, attics and walls. Limits steam from entering the insulation. Able to accumulate excess moisture and then remove it. Film width 1.5 m.

TechnoNIKOL Alfabarrier 3.0 is a three-layer translucent material reinforced with reinforcing mesh. Has increased vapor permeability. Material width 1.5 m.

TechnoNIKOL Alphabarrier 4.0 - consists of four layers, including a layer of foil to reflect IR radiation back into the room. Absolutely no steam leaks. Roll width 1.5 m.

Vapor barrier for roofing Yutafol

Vapor barrier films Yutafol N 110 Standard and Yutafol N 110 Special consist of three layers: external polyethylene, internal - polyethylene reinforcing mesh. In the production of Special film, a self-extinguishing reagent is used. The film is sold in rolls 1.5 m wide.

Yutafol Thermo reflective film is produced for baths and saunas.

Vapor barrier membrane Ondutis (Ondutis)

Professional polypropylene vapor barrier films for the protection of insulated walls, ceilings and roofs. The material is mounted with the smooth side to the insulation. The width of the rolls is 1.5 m.

Ondutis B passes less than 10 g of steam per m2 per day. Operates at temperatures from -40 to + 80 °C. Price 17 rub/m2.

Ondutis Smart B is distinguished by the presence of adhesive strips applied to it to seal the joints, which simplifies installation. Cost 19 rub/m2.

Polinet

Polinet Lux 2x50 is a three-layer reinforced transparent film made of high-pressure polyethylene. Application temperature from -40 to + 80 °C. The roll width is 2 m to speed up installation. Price 21 rub/m2.

Vapor barrier Izobond

The vapor barrier from this manufacturer is similar in markings and technical characteristics to Izospan. For ordinary rooms, you can use material with the index “B”.

For the bathhouse, Izobond FB 1x12 is offered - this is a vapor barrier based on kraft paper with aluminum foil. Temperature from -10 to + 140 °C. Cost 41 rub/m2.

Vapor barrier for bath Isobox (Isobox)

Isobox Thermo 70 is also more suitable for use in steam rooms, due to its high heat resistance from -40 to + 130 ° C. However, thanks to the standard roll width of 1.5 m, it can be conveniently used in any room. The material consists of three layers with a polypropylene base and reflective foil. Cost 26 rub/m2.

TDStels (TDStels)

Reinforced three-layer high-pressure polyethylene film 2 m wide with a temperature range of use -40 to + 80 °C. Cost 28 rub/m2.

Kolotek

Vapor barrier film at an extremely low price - only from 8 rubles/m2. Judging by the information on the packaging, the manufacturer’s films are similar in labeling and purpose to Izospan.

Unispun (Unispan)

For vapor barrier, the manufacturer offers polymer material Unispun B. The width of the rolls is 1.6 m. The cost starts from 10 rubles/m2.

Technohaut

The materials are mainly represented by three-layer reinforced vapor-waterproofing films: Technohaut B70, Technohaut C90, Technohaut D90, Technohaut H110. The price starts from 17 rubles/m2.

There is also a material with a reflective layer Technohaut FS150, which can also be used in a bathhouse.

At the end of the review, we note that when choosing vapor barrier films, it is better to give preference to trusted manufacturers, whose products have been used on the market for a long time and have proven themselves positively.

The use of films and membranes with a reflective metal layer will reduce heating costs, since such films will reflect part of the infrared radiation back into the room, reducing heat loss.

Costs (average for the Russian Federation) for materials and cost of work

Cost of materials for hydro- and vapor barrier:

- glassine – 200 r/sq m;

- polyethylene films - 1000 rubles/roll 1.5 meters wide (100 m);

- polypropylene films – 2000 rubles/roll 1.5 meters wide (100 m);

- waterproofing membrane, price depends on the manufacturer, range from 3,000 to 15,000 or more, per roll.

The cost of installing hydro- and vapor barriers depends on the category of performer; it is usually included in the price of installing floors, on average about 100 rubles per square meter for each layer.

Errors when installing vapor barrier films and membranes

Read this section carefully and do not make mistakes that will inevitably lead to the destruction of house structures and harm your health.

So, here are the Top 5 mistakes when installing vapor barriers:

- Wrap wood floor beams or rafters with a vapor barrier. Vapor barrier is designed to cut off steam-saturated air in the room from the ceiling or insulated roof. At the same time, free air circulation must be maintained inside the ceiling itself to ventilate the insulation and beams. If wooden beams are completely wrapped in a vapor barrier film, it will not allow the moisture contained in the wood to freely escape into the surrounding space. Since even chamber-dried wood has up to 15% moisture content, moisture trapped in the wood will inevitably cause rotting and destruction of the beams. The picture will be even worse if wet, fresh wood is used during construction;

- Install a vapor barrier on both sides of the insulation in the ceiling. This mistake is similar to the previous one, only the victim is not only wooden elements, but also insulation. Moisture trapped in the insulation will reduce its thermal insulation properties, and at subzero temperatures it will condense at the junction of the insulation and wooden beams, leading to their rotting. However, the insulation on the outside still needs to be protected from wind and moisture. Only for this you should not use a vapor barrier, but special moisture and windproof films;

- Refusal to use vapor barrier in the ceiling of a cold attic. Another common mistake based on the opinion that they previously lived without it. We discussed in detail above the differences between modern buildings and “earlier” ones. And absolutely neglecting the vapor barrier layer will lead to wetting and subsequent destruction of rafters, beams and insulation;

- There is no gap of 3-5 cm between the vapor barrier and the final finish. This gap is needed to ensure air circulation along the vapor barrier film. The fact is that it is the surface of the film that will be the place of maximum humidity and constant circulation is designed to remove excess moisture. Otherwise, the steam will be trapped in a thin layer of air between the film and the finish. High humidity will lead to the appearance of fungus and deterioration of materials;

- Lack of proper ventilation in the house. This error is more likely not of installation, but of operation, but it is very dangerous. It is not enough to make a good vapor barrier, protecting the ceiling and roof from moisture and trapping the vapor inside the room. If there is no ventilation in the house, then the trapped steam will have nowhere to escape and the result will be the effect of a greenhouse with high humidity. In this case, it will no longer be the roof and ceilings that will get wet, but internal objects and walls. The risk of mold and mildew increases, and the indoor microclimate worsens. The presence of working ventilation is a prerequisite for normal life in a wooden house with a vapor barrier.

We hope that this article helped you understand how important vapor barrier is in a wooden house and how vapor barrier differs from moisture and wind protection. Making the right choice of material is not difficult; to do this, you just need to carefully read the instructions for use. Installing a vapor barrier is also not difficult: modern materials are durable and equipped with special adhesive layers to simplify installation and sealing.

With respect to you and your home, the information portal ProfSovet.

Installation expert advice

When laying a vapor barrier layer, it is necessary to eliminate the presence of holes and gaps between the sheets.

This will protect the thermal insulation and structural elements of the building. If you use sheet vapor barrier, then installation is carried out from the roof side. The material is located under the insulation layer after it has been completely installed.

There should be another layer of vapor barrier on the outside. This will guarantee better protection for the insulation. Liquid vapor barrier for the ceiling is applied from the outside onto a previously prepared structure.

After the first layer has dried, you need to apply two more with an interval for complete drying. It is better to carry out such work in warm weather. It is important to wait until there is precipitation.

When building any house, a vapor barrier is necessary. You should ask which side to lay this material at the initial stage of the work.

For example, foil sheets are quite actively used today for the vapor barrier layer. They have one advantage, which is the ability to reduce heat loss. To do this, the foil side must be facing inside the room so that the heat goes back into the house.

Where to start and what you should be interested in

There are certain stages according to which such repair activities should be carried out. Before you begin, you need to prepare properly

Particular attention should be paid to the first stages of repair

The first stage is the careful and correct installation of the vapor barrier material. It should be fixed in the place where the side wall is shortest. This is the most convenient place, which is perfect for covering the top with blocks or boards of wood. If during installation the ceiling beam sags or bends, it must be reinforced with support.

Previously, such support bars were strengthened on both sides, as a result of which the load-bearing properties of the wall significantly increased. Today, such a reinforcing matrix is made from a treated wooden beam, which is installed long before the vapor barrier of the ceiling of the house is made. Before this, it is necessary to very carefully and carefully evaluate the technical condition of the support rods. They should not show any serious damage, signs of corrosion, or any other imperfections or defects that could lead to complete or partial collapse.

Types of material

When thinking about which vapor barrier to choose for the ceiling, you should take a closer look at various rolled materials. Mainly polyethylene films, which are considered universal and provide simultaneous vapor and water protection.

They are reinforced with mesh or a special mesh to increase strength. Manufacturers produce films with and without holes. Installation of such material is carried out with an overlap, and the joints are glued with special tapes.

The most popular are films made of polyethylene with a metallized layer on one side. They create a high-quality vapor barrier and also reflect the heat that goes down. Thanks to this effect, heat losses through the attic floor will be reduced to a minimum.

No less popular are films made of polypropylene, which have a moisture-absorbing layer. When vapors settle on viscose and cellulose fibers, they absorb moisture. This means that it will no longer be able to penetrate the thermal insulation layer. Vapors are removed due to ventilation between the vapor barrier layer and the insulation. This material is chosen for rooms with constant humidity.

https://youtube.com/watch?v=-EfnehD3Pi8

Special vapor-permeable membranes are an innovation in the list of vapor barrier materials. They are used not only in private construction, but also in industrial construction.

How to choose a material - some practical tips

There is an idea to build a wooden house, then you need to choose only modern materials as a vapor barrier. And under no circumstances should you save money at this stage. Wood is susceptible to rotting, and a vapor barrier will protect it from this process.

Experts recommend using the following materials:

- Isopane B is one of the most famous materials with a two-layer structure. It is attached to the inside of the thermal insulation.

- Alucraft is a material with three layers, ideal for bathrooms and kitchens. The film is often used when finishing public saunas.

- Penofol - combining hydro, heat and vapor barrier characteristics. Types of material with different structures are available. Advantages: ease of installation due to the presence of a self-adhesive layer.

Thanks to modern technologies, new materials have been created that are distinguished by high quality and better performance properties. Therefore, the age of roofing felt and glassine (the first vapor barrier materials) is becoming a thing of the past.

Before you buy film, you need to decide on the installation method. If the work will be carried out independently, then it is better to purchase all consumables from one manufacturer. Polymer diffuse or multilayer membranes are ideal for attic floors.

Advantages of film

The demand for vapor barrier films can easily be explained by the large number of advantages. Firstly, the material will maintain its integrity even if damage occurs in the roof itself. Secondly, film editing takes little time.

To choose the right material, just look at the vapor permeability coefficient. It shows the number of grams of steam that can penetrate the film in 4 hours.