Warm floors are used to heat rooms for a long time. Modern projects for finishing and insulating residential buildings suggest using combined heating options, fixing the heating system not only to the floor, but also to the walls. Such heating can be used both in combination and separately, it all depends on the financial capabilities and preferences of the home owner.

Photo of the heating design “warm walls”

Can underfloor heating be mounted on a wall?

You can install a heated floor on any plane, including on a wall or ceiling, but to do this, the structure must be securely fastened and a channel for the power cable must be laid. At the same time, the heat transfer efficiency does not decrease depending on its location.

This placement option is suitable if it is not possible to install heating radiators, and installation of a heating electric or water floor is not possible. An example of such a room is a flight of stairs.

In addition, heating installed in this way will cut off cold air, which is especially important if the wall is outdoor. But it is worth noting that some of the heat will still be wasted, heating the street. Therefore, it is necessary to make a good thermal insulation layer to reduce heat loss.

Air-heated fireplace design

Traditionally, an air fireplace consists of the following elements:

- Fireplace insert.

- Portal.

- Air pipes that increase the thermal efficiency of the unit.

- A fireplace mantle that distributes heat.

- Fan.

- Filter.

- Ventilation grates.

- Firebox stand.

- Distributor and air tees.

The advantage of such heating is that it can be implemented in areas remote from the benefits of civilization. Where electricity is not provided. And at the same time, one fireplace can heat a fairly large house with several rooms.

Air hood for fireplace

The presence of two floors will require adding a special pump to the standard arrangement of an air fireplace, which will perform forced circulation of warm air.

Air heat exchange occurs in a closed cycle.

Advantages of this type of heating

Insulating walls with “warm electric floors,” like any heating, has its pros and cons.

Disadvantages of electric heating:

- It is not possible to place furniture near heating walls. It will prevent the spread of heat, in addition, hot air will have a negative effect on the products, which will ultimately shorten the service life.

- You cannot hang a picture or TV on such a surface, as this could damage the heating elements.

- Large heat losses occur. After all, the wall is heated, on the other side of which there is a street, resulting in unnecessary consumption of thermal energy.

- Shifting the dew point deeper into the wall. In winter, condensation will accumulate, which will lead to freezing, and this will accelerate the process of destruction of the walls.

- Increased electricity consumption.

- Destruction of the finishing - the service life of wall coverings will be significantly less than on walls without heating.

As you can see, there are many disadvantages, although one cannot help but mention the positive aspects of such heating:

- located vertically, so dust will not spread throughout the room;

- will free up space in the room that is occupied by standard radiators;

- cost-effectiveness in terms of installation - installation is inexpensive compared to installing another heating device;

- creates an excellent thermal effect;

- fights fungus and mold;

- does not dry out the air, since there are no open elements that burn oxygen;

- heating of the room occurs more evenly;

- does not spoil the interior of the room.

Since, with electric wall heating, the heating method is radiant, you can save money by setting the temperature level in the room 2 degrees lower, which will not affect the level of comfort.

Another important point is that if a wall separates two rooms in an apartment, then if there is heating on it, both rooms will be heated.

Pros of use

The advantages of wall heating are as follows. Thus, heat exchange is carried out due to radiation transmission - both people and animals feel comfortable when the temperature in the room becomes several degrees lower. Due to optimal fuel consumption for heating, it will be possible to save about 10% of energy resources in one season.

In addition, “warm walls” significantly reduce convective air flows in the room

Due to this, dust does not disperse into the air, and living conditions for those living in the house are improved - this is especially important for people with chronic respiratory diseases. Finally, for the effective operation of a “warm wall” system, it will be necessary to install circulation pumps of lower power than in conventional heating systems

Types of wall-mounted systems

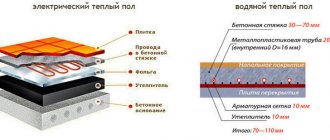

Electric heating floors come in cable and infrared types. In them, temperature regulation and control is carried out using a thermostat.

Heating mat on the wall

Cable

Cable systems are ordinary wire, which can be single-core or double-core. When laying a cable floor on a wall, the wire is laid in a “snail” or “snake” pattern.

One of the types of cable heating is mats, this is the same single- or two-core heating cable, which is fixed on a special sheet. Therefore, the mats are easier to install; they can simply be rolled out on the surface.

The service life of cable-type heating devices is quite long. In terms of electricity consumption, they are comparable to conventional electrical appliances. But cable heating has a significant drawback - electromagnetic radiation .

Infrared

In infrared systems, heating is carried out due to long-wave infrared radiation that comes from carbon elements. This heating is environmentally friendly, as it does not emit electromagnetic waves.

The infrared heating method is:

- Film. Carbon plates sealed in polyester. The film is light and has a small thickness, so installing this system is quite easy.

- Rod. Carbon rods fixed on a special mesh. Rod systems are also called intelligent, so they have a high cost.

It is important to note the following point: foil insulation cannot be installed with electric infrared floors.

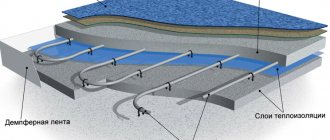

Laying technology

The installation technology for each type of heating system is different, but there are general requirements that apply to any of them:

- Carrying out wall insulation with foamed polyethylene or other insulation, with laying a foil base. This will reduce the consumption of thermal energy, preventing it from escaping outside.

- Creation of a two-layer plaster layer. Layers are applied in stages. The second - only after the first has dried.

- It is recommended to apply elastic similar paper or Strobe mesh to the finishing layer of plaster. Compliance with this requirement will prevent cracking of the last leveling layer.

- When laying water heating, the cement-lime mortar layer above the pipe should be 20–30 mm.

- Before starting installation, it is necessary to pre-install installation and distribution boxes for electrical and low-current wiring. The electrical wiring itself is stretched after finishing plastering, in the last layer of plaster.

Installation of the junction box

- When using water heating, the coolant is supplied to the pipes after the plaster layers have completely dried.

- When laying cable electric heating, the installation of the mesh can be done using dowels or mounting tape.

- Electrical equipment can be turned on after four weeks of settling. This is how long it takes for the plaster layers to dry completely.

- To install the film heater, it is necessary to make a frame for finishing.

- When installing an electrical circuit, you need to take care of fire safety; for this, appropriate finishing mixtures are selected.

The heating system can be laid on any surface. When installing a heating element on a wall, it is recommended to follow certain requirements that will ensure long-term and safe operation.

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...

What to choose?

When choosing a wall-mounted electric heating system, you should take into account its power, operating conditions and installation features. The height of the walls and the weight of the structure are also important. It is necessary to calculate the costs not only of purchasing the device, but also of its installation and further operation.

This have not happened before!!! Warm floor in the wall.

The most suitable for installation on walls is infrared film. It is lightweight and thin, so it does not thicken the walls and does not take up useful space. And with proper installation, it heats the surface efficiently and evenly.

In addition, it is not difficult to install a film infrared heated floor on a wall with your own hands, and it will only take a few hours. It is enough to roll it out over the surface and fix it to the insulation with special glue or clamps.

The environmental safety of infrared models is also important, since they do not emit electromagnetic waves like cable models.

Varieties of single-circuit circuits

With vertical wiring system

In this case, the coolant heated by the boiler rises through a vertically installed riser to the highest point of the heating network (into the attic or under the ceiling of the top floor), from where it then flows down, simultaneously heating the radiators located on each floor of the house.

Features of the design and operation of vertical heating circuits are as follows:

- the coolant can be moved naturally, without the use of electrical equipment;

- all sections of pipes should be laid with a slight slope towards the boiler in order to increase the intensity of water circulation and avoid the formation of air pockets;

- it is difficult to hide pipes in walls, since in this case you are unlikely to be able to maintain the slope;

- The system operates completely autonomously, so even in the event of an emergency power outage, you will not be left without heat.

Scheme of single-circuit heating with vertical wiring

With horizontal wiring system

The vertical riser is not mounted here. The main pipeline is laid along the floor or under it. If you decide to disguise pipes in a concrete screed, take care of their thermal insulation, otherwise quite significant heat losses cannot be avoided.

In addition, it is advisable to observe the slope in this case:

- firstly, the heating network will be able to operate (albeit less efficiently) during a power outage;

- secondly, when filling pipes with liquid, you will avoid the formation of air locks.

Single-circuit connection diagram with horizontal wiring

Application area

Warm electric walls can be used not only in houses and apartments, but also in garages, offices and warehouses. Their installation is allowed even in wooden houses, but a “dry” installation method is recommended.

In the garage, installing a wall heating system becomes especially important. This is due to the impossibility of installation on the floor, due to the entry and further placement of the machine on the structure, which will lead to failure of sections of the cable or film.

In addition, if you plan electric heating at the stage of building a private house, you can save on heating. For example, if you install heating in a wall that is a partition between two rooms, you can provide heating for both rooms at once.

And if we compare the electrical system with the water one, then to equip the second one, additional costs will be required for installation work and the purchase of additional components and products, such as a heating boiler, pump, pipes, etc.

Wall heating is suitable for small rooms (bedroom, bathroom), where it is quite difficult to install a warm floor due to clutter with furniture or plumbing fixtures. Warm walls will be more effective than underfloor heating in rooms with high humidity (bathtub or swimming pool), since there is no energy consumption for water evaporation.

Warm floor on walls and ceiling

In addition, electric cable or infrared heated floors in the bathtub on the wall can be laid directly on the tiles.

An infrared system is ideal for heating a loggia or balcony decorated with clapboard or plasterboard sheets.

Features of installation of a rod-based IR heating system

Rod heating elements are installed similarly to film ones. Due to higher surface temperatures, the distance between adjacent rods should not be less than 100-150 mm. The difference in the installation of rod and film heating elements is that the sheet with rod heaters is more rigid. However, the rods themselves make it possible to increase the electrical power passed through them, so such systems are suitable for installation in large rooms. Their use is limited by the power of thermal safety automatics installed in the house. Rod IR elements do not need to be turned on for a long time, so it is advisable to install thermostats for them.

Installing heated floors on the wall

Let's look at the installation of heating devices using infrared film as an example, since this is the most suitable and easy-to-install model of electric heating for walls.

Heating warm wall DIY infrared heater

It should be taken into account that when installing the film on the wall, the strips are attached not horizontally, but vertically. In addition, the wires are connected from above.

You need to start building a heating system by preparing all the components and tools that will be needed for the job.

Then you should develop a layout diagram for the heater. According to technology and standard standards, you need to make an indent of 1 - 4 cm from the edge of the wall. One strip should not be allowed to overlap another.

Work on installing wall-mounted infrared heating is carried out in the following sequence:

- The wall surface is cleaned and leveled. It should be smooth, without deep depressions or cracks. If the wall has large differences, then it is better to putty it, applying a thin layer of mortar.

- A heat-reflecting coating is installed. For this, you can use any heat-reflecting material, but it should not have a foil layer. A heat-reflecting layer is necessary to direct heat flows inside the room and prevent them from escaping outside.

- A frame is being constructed to install the finishing touches. A sheathing is made on which sheets of plasterboard or chipboard will be attached to the wall.

- The film is laid. It is fixed to the wall with dowels. For this purpose, there are special places on the film where conductive elements do not pass. There should be gaps of no more than 5 cm between the rows of strips, this will ensure uniform heating of the room, without the formation of cold zones. If you need to cut a film of a certain size, then this must be done along special lines that are on the canvas.

Another way to fix the film is to glue it to the insulation using special glue.

- A temperature sensor and thermostat are installed. The regulator should be placed in a convenient place, preferably close to the power source. The temperature sensor is installed between the heating elements and connected to the thermostat.

- The system is connected - this should be done according to the instructions that came with the device. The film strips are connected in parallel using clips, all contacts are insulated with bitumen tape. The power wires are connected to the thermostat.

- Functionality is checked. Each strip of film should heat evenly. If this does not happen, then you should check the quality of the contacts; sometimes it is necessary to replace a separate defective section of the film.

Only after you are sure that the heating device is functioning well can you proceed to installing the finishing material.

Rolled insulation materials for wallpaper

It is easier to work with rolled products; it is a dry process that does not require much effort. Even beginners can cope with the task. Previously, when the construction market was not so diverse, ordinary newspapers were used as insulation for walls inside an apartment under wallpaper. They were simply glued to the wall before installing the trellises.

Nowadays there is no need to do this. Modern heat insulators are many times more effective. Here is their list:

- Expanded polystyrene thermal insulation. The properties are almost identical to plaster with polystyrene foam. Only this insulation option is better, as it is sold in rolls. The backing is fixed to the walls under the wallpaper with a specially created glue. As an option, use glue for heavy canvases, supplementing it with a small part of gypsum-based finishing plaster.

- Foamed polyethylene foam, as insulation under wallpaper. It is also called polyph. One of the most popular options. Thanks to its cellular and airy structure, the wallpaper backing retains heat well and soundproofs the room. It is covered with paper on the front and back sides, so it somewhat resembles wallpaper. This makes it easier to fix the insulation to the wall. The same applies to subsequent wallpapering. The main thing is to remove all defects and irregularities from the walls.

- Balsa wood or roll insulation for walls under wallpaper. Environmentally friendly and excellent insulation in all aspects. Reduces noise from the yard. Externally attractive, not afraid of moisture and breathable. It will not absorb unpleasant odors. Cork roll material allows you to hide the imperfections of the walls and create a high-quality insulating layer. Hypoallergenic.

- Special insulating wallpaper. They are made of spandbond, fibers and aluminum foil. Thanks to this, heat will not leave the walls, and the gluing process is simplified. This is the best option if the room does not need enhanced thermal insulation.

Whatever insulating material you choose for wallpaper, roll or plaster, the main thing is to perform the installation correctly. Moreover, in such cases, savings can also be disastrous. It’s better to save up some money and buy a high-quality heat insulator. This is a guarantee that repair work will not need to be repeated for decades.

Cosmetic finishing

Undoubtedly, walls with a built-in heating system need finishing. When choosing a finish, you need to understand that placement on a heating surface reduces its service life. Therefore, when purchasing material, you should make sure that it is compatible with heating devices.

For example, wallpaper or laminate of the wrong type installed on such a surface may fall off after a few months. If ceramic tiles are used as finishing in the bathroom, then it is important to choose the right adhesive composition so that the tiles do not crumble.

If it is cable heating or rod mats, then after checking the heated floor is covered with two layers of concrete plaster. Only when it dries - after 4 weeks - can wallpaper or tiles be glued to the surface.

It is important to remember that tile adhesive cannot be applied to infrared film, so plasterboard finishing is recommended. In addition, this is practically the only type of finish that can withstand heat.

To summarize, we can say that the “warm walls” system can be mounted on any surface. But this will require serious investments, technical knowledge and skills. When installing such heating on the wall, the main thing is to follow the instructions, and then the device will serve you for a long time.

Maintenance

All heating systems require monitoring and maintenance. Warm water walls differ from conventional water heating due to their large volume of liquid content. As a rule, the water in standard radiators is rarely changed, but they are located only in a few places in the room. A system of warm wall channels penetrates large areas. Considering the latest discoveries of scientists in the field of energy, radiation from dirty water can depress biological organisms, weakening their immunity. Therefore, it is advisable to change the water in the system every season.

During operation, automatic ventilation devices must be checked periodically. They may leak. It is also necessary to monitor the pressure in the system and control the return temperature. If it does not warm up enough, turn on the highest speed on the circulation pump, expelling air pockets. It is advisable to do the same during prolonged power outages.