One of the latest technologies that has become widely used is liquid foam plastic (penoizol). Due to its high thermal conductivity and durability, it is used for insulating buildings or producing cladding materials such as sandwich panels. First of all, the ability of this substance to fill even minor cracks is noted, although other advantages are no less significant, which makes it quite in demand when performing construction work.

Features of expanded polystyrene

The use of polymer resin is the basis for the manufacture of the substance.

There are many types of material. Purpose: technical and for residential buildings. Technical foam is harmful to the environment, as it contains toxic elements. The one that is used for residential premises has high cleaning performance and is also completely harmless. If we consider the technology by which the material is manufactured, it is safer in a frozen state. When working with liquid penoplex, there is a risk that harmful elements will be released when it hardens.

The ideal option is foam plastic in a liquid state, based on urea-formaldehyde resins.

From this video you will learn the features of penoizol equipment:

All foam insulation materials are obtained when the material hardens. The adhesion of the surface increases significantly if foam is applied to it, in contrast to the option when a polystyrene foam plate is simply installed on the surface.

Liquid polystyrene foam for wall insulation is prepared by mixing a hardener with resin. This is done by a special machine in which the ingredients are turned into foam. Then, through a hose with sediment, it is supplied to the item that requires insulation.

There are units for sale for such a process, but you can also make the device yourself. The purchased ones are quite expensive - around $3,000.

Liquid foam. Insulation. How it works:

Advantages and disadvantages

If you choose high-quality material, then its harmlessness to humans and environmental friendliness is guaranteed. In addition, the cost, despite the consumption, is lower than that of mineral wool. And also the foam is resistant to fungi, mold and various microorganisms.

And these are not all the advantages of the material:

- High adhesive ability.

- The surface does not require special preparation before applying the material.

- A perfectly even seam is formed that does not allow heat to pass through.

- The material is vapor-permeable, thereby maintaining an optimal microclimate in the building.

- Liquid foam insulation can be used on any surface (wood, brick, concrete).

- Fills the smallest cracks.

- Leaves virtually no smudges. If there are any, they can be easily removed.

- Polystyrene foam is functional at different temperature conditions.

Do not be embarrassed by the unpleasant odor when working with such material. soon he will be gone

While the material has many advantages, it also has some disadvantages.

Among which:

- There is a possibility of the material shrinking if it is used without the required pressure.

- An unpleasant odor that disappears after a while.

- Polystyrene foam absorbs moisture, so it should be protected on both sides from external factors.

- The composition contains formaldehyde, so it is recommended to use it as an intermediate or outer layer.

Scope of application

For internal insulation, liquid foam is used to a limited extent. It is widely used for horizontal planes, for example, between panels in the attic, as well as for insulating slopes and building gaps.

Urea liquid foam plastic - penoizol appearance and mechanical properties:

The liquid consistency makes it possible to perfectly insulate the area between closely adjacent walls. Foam plastic is also used for wooden floors, false walls and formwork. It is able to evenly fill all remote areas between the walls.

The unit is the basis for the manufacture of various foam products - plates, baseboards, baguettes and other elements. They are used to fix the slabs that are used to insulate the surface.

Expanded polystyrene in cylinders is used as glue. And it is somewhat reminiscent of polyurethane foam, but differs from it in better vapor permeability and the ability to conduct heat.

Liquid foam, instructions for use:

It is not difficult to do the work using liquid foam with your own hands. Before application, the surface must be cleaned of dirt and moistened with water for better adhesion to the foam. It is recommended to carry out work at +20 degrees; if the temperature is lower, the mixture must be heated with warm water. If it is very hot outside, then cool it in the same way.

Specifications

The main technical parameters of polystyrene foam are characterized by the following indicators:

- density - up to 25 kg/m3;

- operating temperature range - from -50 to +1200С;

- thermal conductivity coefficient - in the range of 0.012-0.047 W/m·K;

- water absorption by volume - up to 20%;

- flammability group - G2 (materials that do not support combustion and self-extinguish);

- vapor permeability - 0.23 mg/(m/h/Pa);

- technological shrinkage (depending on density) - up to 5%;

- service life up to 50 years.

In terms of sound and thermal insulation properties, liquid polystyrene foam is superior to insulation materials made from polystyrene foam and mineral wool.

Penoizol adheres well to almost all building materials and perfectly fills voids. It usually hardens within 20 minutes after application, and the next stage of work can be carried out after 2 hours.

RAW MATERIALS FOR PENOIZOL

The components that make up PENOIZOL are not in short supply and are produced by many chemical enterprises in Russia and the CIS.

Resin for penoizol.

The actual polystyrene foam bearing the name PENOIZOL is made only from VPS-G resin. But any other polymer resin can be used, but the foam cannot be called PENOIZOL. We use KFMT-15 resin, which is produced in all regions of Russia.

Below is a list of factories and cities where KFMT-15 resin is produced, which is preferable for the production of penoizol:

- Yaroslavl OJSC "Lakokraska", Yaroslavl. For purchasing questions, please contact the sales department, 06/27/12, 06/27/57 Larisa Aleksandrovna Batagova.

- Donetsk SGPP "Association Azot" Tel. (06452) 92141, sales department. Contact person: Sergey Anatolyevich Sokolov Telephone FaxKrasnoyarsk Address: 660004, Krasnoyarsk, st. 26 Baku Commissioners, 1 E-mail General Director: Goncharov Viktor Sergeevich Chief Engineer: Vinokurov Anatoly Alexandrovich

- Moscow E-mail Address: 109202, Moscow, st. 1st Karacharovskaya, building 8 (DOK-3). Orekhovo-Zuevo, Moscow region.

- Nizhny Tagil, Sverdlovsk region. Russia, Sverdlovsk region, 622012, Nizhny Tagil, Northern highway, 21

It is most convenient to transport and store resin in steel barrels with a capacity of 200 liters.

Foaming agent for the production of penoizol (PO).

In the production of PENOIZOL, ABSPA, an alkyl benzene sulfonic acid produced in Voskresensk and Kirishi, is usually used as a software.

When preparing a foaming solution, ABSPC must be dissolved in warm or hot water, and then added to the solution. At the same time, the amount of ABSPC required to produce 10 cubic meters of polystyrene foam must be vigorously kneaded with hands in water for 20 minutes, since when it gets into water, this product turns into a jelly-like mass.

We offer software for penoizol that does not require prior dissolution in warm water. It can be added directly to the solution. Storage and transportation in polyethylene containers...... Curing catalyst. (CO) The curing catalyst for penoizol is orthophosphoric acid. Available for sale everywhere. Approximate price - 30 rubles. per kg. If necessary, it can also be supplied by us. Storage and transportation in polyethylene containers.

To produce 1 cubic meter of polystyrene foam you need:

| Resin | 20kg |

| Foaming agent | 0.5 kg |

| Curing catalyst | 0.6 kg |

| Water | 45 l |

Based on current prices, the cost of 1 cubic meter of polystyrene foam components made from KFMT-15 resin is approximately 135 rubles, and from VPS-G resin - 195 rubles.

Necessary equipment

Foam insulation installation To insulate a floor that does not yet exist, no special equipment is needed, of course, except for a foam insulation installation.

After the material has hardened, any splashes will need to be removed from the logs. A spatula, knife or chisel can easily handle this task. If the finished floor was insulated, then the following will be useful in your work:

- tape measure and pencil for marking holes;

- electric drill or hammer drill with drills with a diameter of 25 mm to create holes in the floor;

- knife, chisel, spatula to remove splashes of penoizol and some of the material that has appeared in the cracks;

- spatula and mortar for sealing holes in the floor.

Insulation with liquid foam plastic

Penoizol is widely used when insulation measures are required for houses and other objects. They can be used to treat walls, roofs, and floors.

Walls in houses are insulated in three ways:

- during the process of building a house, they fill the gaps between the walls layer by layer;

- in a finished house, they heat-insulate walls that have at least a 3-5-centimeter space behind them: drill holes in a checkerboard pattern at a meter distance, then pour penoizol into them;

- when there is no space behind the wall, a false wall made of plasterboard or plastic is used.

The insulation is applied vertically, so it is advisable to clean the surface before doing this and then wet it so that the substance adheres more firmly to the surface. When you have to work in cold weather, there is no need to wet the wall. Then it’s better to warm up the foam cylinders. A bucket of warm water is suitable for this. They should not be heated too much, as the container may explode if overheated.

Before use, you need to shake the container, after which you can use it. The supply of the substance is regulated by a special dosing screw. When attaching the cylinder to the mounting gun, keep the container upside down. If breaks are required between work, there is no need to detach the cylinder. You just need to clean the gun nozzle.

The ability of penoizol to penetrate into all cracks and voids allows you to save time and efficiently insulate the facade of a house or cottage at minimal cost. For example, to process a building of 100 square meters. m can be spent only 3-4 hours - significantly less than when working with other insulation materials.

However, penoizol is used not only for thermal insulation of walls. It also does an excellent job as an adhesive for slabs intended for insulation.

The work is performed in the following sequence. First, the surface is cleaned, and the slab is also inspected for errors (defects, contaminants) and, if necessary, they must be eliminated. Then you need to moisten the area where the adhesive will be applied with water. And this is done in two ways:

- distribution of foam mass over the surface;

- applying liquid foam around the perimeter and diagonal of the slab.

Both options are used. True, the second one does not provide such high-quality grip; it makes it possible to save on foam insulation.

Next, the prepared slab must be immediately pressed well against the wall. As you continue your work, you must not forget about the need to apply foam to the joints between the slabs. This technique will allow them to be firmly fixed.

Wall insulation work is best done when there is no frost.

Penoizol is considered a fast, high-quality and inexpensive roof insulator. This is one of the most popular insulation methods used for pitched and flat roofs. Foam is also used to insulate attic floors. Its best advantages are revealed on the roof: it does not weigh down the structure, does not rot and is not destroyed by microorganisms. Moreover, it is durable and easy to use. Even inexperienced builders can build a roof of 150 square meters. m insulated with penoizol in three hours.

Penoizol, informally called liquid foam, is also indispensable for floor insulation. Work can be carried out in two versions:

- when a plank floor is installed;

- if it is impossible to free the room for insulation work.

When a house is just being built, usually the entire surface area that the floor will occupy is covered between the joists with foam insulation. After it hardens, the boards are laid.

For a building in which people already live, foam insulation is used to insulate not only a wooden floor, but also any other floor that has voids. For this purpose, 25 mm holes are drilled in a checkerboard pattern over the entire area occupied by the floor, placing them at a two-meter distance. Next, insulation foam is introduced into these holes, which then spreads throughout the underground space, filling it and possible cracks. After the liquid foam has hardened, the holes are closed using appropriate materials (wood plugs, cement, etc.).

Thermal insulation of houses with liquid foam in cylinders is gaining popularity. And this is understandable. After all, the composition makes it possible to insulate a room most effectively due to the ability to fill even small cracks.

Review article about liquid insulation materials. Types, characteristics, pros and cons of liquid insulation

An important step in almost any construction is thermal insulation. This is especially true for residential buildings. In the modern world, there are a lot of different materials for home insulation on the construction market. They all have different properties and characteristics and have their pros and cons. But today we will talk about a relatively new technology for insulating houses. The topic of our review today is liquid insulation , its types, characteristics, advantages and disadvantages. We will tell you everything you need to know about liquid insulation for your home, and also help you choose the best one.

So, what is liquid insulation? Let's start by conditionally dividing all liquid thermal insulation materials into two main, fundamentally different types. The first type is warm paints , and the second is foamy substances. How these types differ, in what cases it is better to use them and which brands are better to use, we will talk about all this further. To make it easier for you to navigate, we note that foam mixtures include: penoizol, polyurethane foam, polystyrene foam and other similar materials, which are often called liquid foam. But thermal paints have a more accessible application from the point of view of everyday issues, and in many external features they are similar to facade mixtures. Let us remind you that we examined most types of solid insulation in the last article, solving the question of which insulation is better, so we recommend that you familiarize yourself with this material.

In this article, we will look at examples of specific brands of liquid insulation that a group of experts have identified so that you can choose the best liquid insulation for your needs. If you know any other brands or options for insulating houses, be sure to share your opinion in the comments.

KFP installation technology

Houses are insulated with foam insulation using a foam generator. It is also used for filling and foaming. Really good equipment is equipped with an electronic system with which the product is produced and controlled. Also, most devices have pumps, the characteristic feature of which is a volumetric manifold drive.

What fills are used?

Wall insulation with foam insulation can be done in combination with a variety of materials. Typical reviews are about insulating houses with foam insulation, in which consumers place one of the first places on the technology of working with the material.

The point is that it can be used comfortably almost anywhere. Filling between slate and internal fencing, filling between drywall and the main wall, filling the cavities of the outer and inner walls, pouring under siding - this is not the entire list of possible uses of the material.

Holes in the wall

Insulating walls with foam insulation involves making special holes. They need to be done in different places on the wall. For ease of use, they should be slightly thicker than the supply hose. Since the density of the pumped material is very low, it can also be used in rather frail and dilapidated buildings.

When it hardens, it does not expand, so you don’t have to worry about the CFP breaking apart the structure. This is another fact about which reviews about insulating walls with foam insulation are everywhere. For example, polyurethane foam does not have such qualities.

Drilling and filling

Holes are drilled in the wall in a checkerboard pattern, through which the penoizol is then poured. An important point: this must be done from the bottom up.

Thus, the material begins to evenly fill the cavity, flowing out through adjacent holes. At this time, you need to quickly seal them with wooden plugs.

You need to continue until the mixture is completely dry. There are no joints or seams in the mass poured in this way. This fact guarantees the density of thermal insulation.

Reviews about insulating houses with foam insulation are positive, not least because the virtually unlimited service life of the material means you no longer have to worry about insulating external walls.

Warm paints

Unlike foaming polymers, thermal paints contain ready-made additives that provide thermal insulation. The most common are ceramic microspheres, fiberglass particles, perlite fillers or foam glass. Acrylic dispersion is used as a binder; water-based mixtures are also common.

Corundum

Multicomponent heat insulator on a polyacrylic base. Ceramic microspheres of different densities are used as a filler in its composition, which allows you to create a thin porous coating.

This is a white suspension, similar in consistency to regular facade paint. Once hardened, corundum forms a durable coating that is resistant to cracking due to its ductility. This allows the mixture to be used as insulation in a fairly wide range:

- Thermal insulation of walls, window and door openings;

- Insulation of floor coverings and roofs;

- Pipelines for any purpose, as well as steam pipelines and air ducts in air conditioning systems;

- Refrigeration systems (thermal insulation of refrigerators, thermal boxes and trailers).

One common application is the insulation of cold water supply lines. A layer of thermal paint prevents the appearance of condensation and corrosion on metal pipes.

Depending on the surface being treated and the required degree of insulation, several types of insulation are available:

- Classic . A universal mixture to protect almost any surface. Retains all performance qualities over a wide temperature range (from -60° to + 200°C) for at least 15 years. A twenty-liter bucket costs about 8,000 rubles . This is enough to cover up to 40 m2 of surface with a layer of 2-3 mm.

- Antikor . As the name implies, this composition can be used to protect metal elements from corrosion, including those elements that already have rust (the main thing is to remove loose fragments). The mixture has high thermal insulation properties, and its cost does not exceed 450 rubles per liter.

- Winter . Unlike conventional mixtures, when applied, the ambient temperature should not be lower than +5°C, Corundum Winter insulation can be used even in cold weather (down to -10°). This is the most expensive product in the line (the cost exceeds 500 rubles).

- Facade . The priority use of this mixture is insulation of external surfaces made of brick, cinder block or concrete. The material is weather-resistant and quite vapor-permeable. Cost - about 400 rubles / liter.

Tips and tricks

In order to reduce the costs associated with the thermal insulation of a structure, you can not purchase ready-made equipment, but install it yourself at home. Such a device must have:

- gas-liquid unit;

- hoses for supplying reagents and foam;

- plastic containers;

- compressor;

- taps.

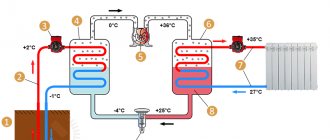

A diagram of self-installation of the installation is shown in Fig. 1.

Installers advise working with penoizol according to this scheme:

- assembling the installation in accordance with the instructions;

- mixing all the necessary components in a barrel;

- preparing the surface to be treated by dismantling old facing materials (the base does not need leveling: a layer of liquid foam can hide all bumps, protrusions and other flaws);

- installation of metal or wooden sheathing (wooden structures must be treated with antiseptic compounds);

- installation of logs from wooden beams;

- applying a uniform layer of penoizol or foaming voids;

- cutting off excess material with a construction knife after it has hardened;

- installation of reinforcing mesh after polymerization of insulation;

- facing works.

Craftsmen are able to quickly insulate any structure and provide a guarantee for the work done.

Where to use spray insulation

Due to compliance with safety standards, sprayed insulation can be used in public and residential buildings. The range of its application is quite universal:

- Roofing and attic structures

- Insulation of floors

- Insulation of wall surfaces

Objects can be classified as follows:

- Industrial buildings

- Outbuildings

- Refrigeration equipment

- Pipeline communications

- Vessels for technological purposes

Important to consider! Although spray-on insulation is considered environmentally friendly, thoughtful precautions must be taken when installing insulation in residential buildings. At the moment of application of the material, a polymerization reaction occurs, accompanied by a high degree of toxicity. And only after final hardening the risk of poisoning disappears completely.

And only after final hardening the risk of poisoning disappears completely.

As for the type of materials that can be used for insulation, there are no restrictions in this regard.

DIY spray insulation

Many owners of private houses, and even apartments, try to do all the work around the house with their own hands. But in this case, doing this without theoretical training and the necessary equipment is not easy.

In any case, for self-insulation with polyurethane foam you will need a balloon installation and the components necessary for this procedure, namely:

- Polyol, which must be mixed in a container with freon

- Isocyanate, also combined with Freon 134

Both cylinders must be inflated until the pressure in them reaches at least 8 atmospheres.

Next, spraying is carried out on the treated and prepared surface - just press the spray gun and direct a stream of insulation to the desired area.

Attention! When working independently with sprayed insulation, it is imperative to use personal protective equipment!

Sprayed insulation in cylinders

Since the independent process is not as complicated as its preparation, it will be easier to immediately resort to ready-made insulation kits in cylinders. In addition, there will be no noticeable difference in cost.

Sprayed insulation in cylinders is more practical, as it has been professionally prepared at the factory, including optimal pressure conditions.

Price for sprayed insulation

The cost of this insulation may seem slightly higher than materials in other categories. However, the economic efficiency of this thermal insulator is obvious when calculating, of course, the cost of other materials with the inclusion of additional equipment - profiles, sealants, fasteners and payment for the cost of professional work.

In the long term, the cost of insulation with sprayed insulation pays off by reducing energy costs.

Sprayed polyurethane insulation Polynor

An example of a successful choice of such insulation is Polynor insulation. Its advantages are evidenced by reviews of Polynor sprayed polyurethane insulation and instructions provided by the manufacturer in video format. The price for sprayed polyurethane insulation Polynor is identical to similar sprayed insulation in this category.

Thus, this type of thermal insulators is a priority in the choice of material for a number of technological indicators and for reasons of practical and budgetary value.

Flaws

- In severe frosts, slopes in a panel house completely freeze if applied incorrectly or if the manufacturer's recommendations are not followed.

- When using TSM Ceramics, cracks may appear on the facade of buildings, since this manufacturer simply moves the dew point and does not protect the house from heat loss at all.

- Liquid thermal insulation Izollat, Asstratek is prohibited from being applied to the facade, but can only be used for waterproofing metal structures.

- When water is diluted above the specified standards, the thermal insulation simply flows off the walls.