Here you will learn:

- Design and operating principle

- Models with water circuit

- The operating principle of Buleryan furnaces with a water circuit

- Disadvantages of Buleryan stoves with water circuits

- Popular models of Buleryan stoves

Wood heating units are not famous for their highest efficiency. Developers are putting a lot of effort into making stoves more efficient and capable of heating multiple rooms at once. This is how the Buleryan stove with a water circuit was born.

It is a modernized version of the air furnace of the same name, repeating its design. Only instead of air, it heats the coolant circulating through the system.

Who is the manufacturer

The patent for the manufacture of a long-burning wood stove belongs to the German organization “Bullerjan”. The company was the first to mass produce the product.

In the Russian Federation, the Laotherm organization manufactures stoves. Thanks to its design, the product quickly gained worldwide popularity.

Warming up of the air mass of the room is carried out in the shortest possible time. The furnace does not require the use of additional equipment, is easy to operate and repairable.

Efficiency compared to gas heating

Today, gas heating is undoubtedly the best in terms of cost of operation and ease of use. However, in some ways it still loses to Buleryan:

- A gas boiler cannot be connected without the approval of the gas utility.

- The operation of a gas boiler depends on the operation of the gas supply system, while Buleryan is completely autonomous.

Gas fuel is poisonous and explosive. Moreover, due to its volatility, it can easily spread throughout the room. Buleryan in this regard does not pose any danger.

Operating principle of the Buleryan stove

The product is economical and highly efficient. The principle of operation of the furnace is the heating of an air mass. For this purpose, metal pipes are built into the side walls of the firebox.

During operation, cold air passing through them quickly heats up. This allows you to warm up rooms of various sizes at high speed.

The principle of heating the stove is very simple and can be seen in the photo. Photo source: fb.ru

Buleryan is a long-burning wood-burning stove. Depending on the power of the product, one bookmark lasts from 6 to 12 hours. During the combustion of wood, gases are formed that burn out in the afterburner. Thanks to this design, Buleryan has a high efficiency. Firewood is inserted through a special Buleryan door located in the front part of the stove. The hatch for loading firewood with glass and the chimney are equipped with dampers.

They are necessary to regulate the amount of air mass supplied and the removal of combustion products. A specialized window is cut into the damper installed in the chimney. It prevents carbon monoxide from entering the room even when the damper is completely closed. The oven is equipped with a convector made of metal pipes. Their large surface area is the side walls of the firebox. This allows the air inside the convector to be heated at high speed.

Pros and cons of the boiler

Buleryan’s device allows it to be used to quickly warm up and maintain temperature in various types of rooms.

The stove has become widespread due to a number of advantages:

- High rate of room heating. The presence of a convector made of metal pipes allows you to quickly warm up the air masses. Heat is transferred to the surface of the collector directly in the firebox.

- Long burning time. The Buleryan boiler can operate for up to 12 hours without additional fuel. This allows you to save wood and does not require the constant presence of a person near the stove during operation.

- Easy to install. No specialized education is required to install the product. If necessary, you can quickly dismantle the stove and transport it to another location.

- Safety. With the constant movement of air mass through the pipes, their surface is partially cooled. This eliminates the risk of burns when touching Buleryan surfaces.

- Easy to use. To understand how to drown Buleryan, no special knowledge or skills are required.

- Possibility of modernization. If necessary, you can make Buleryan with a water circuit.

The list of advantages does not end there. The high efficiency of Buleryan allows it to be used effectively for heating both residential and non-residential premises.

In addition to the above advantages, the oven also has a number of disadvantages:

- Requirements for the quality and type of fuel. The device allows for the use of wood or shavings as fuel. It is strictly forbidden to lay coal. The high temperature of its combustion will lead to rapid failure of the furnace surfaces.

- Formation of condensation. Firewood contains a large amount of moisture. When the stove operates, it evaporates and settles on the internal surfaces of the chimney in the form of condensation.

- Large product sizes. The Buleryan long-burning stove has a three-dimensional design. This requires free space in the room.

Reviews about cleaning features

After reading the reviews and disadvantages of the Buleryan stove, you can decide whether you should purchase such equipment for your garden or home. But if you have already made your choice, then you need to learn more about how cleaning is carried out. No matter how high-quality heating equipment is, it requires preventive maintenance from time to time. "Buleryan" will begin to show signs of contamination over time. According to consumers, they are expressed as follows:

- lack of traction;

- deterioration of melting;

- Difficulty closing the gate.

For cleaning, you can use one of several technologies. The main thing is that it is safe. Reviews and disadvantages of the Buleryan stove indicate that such equipment can become a source of increased danger. Consumers do not recommend using the so popular burning cleaning method. This method is dangerous, although effective. Some daredevils decide to take this extreme move.

Its essence is to heat the pipe to a temperature where the metal turns red. Under such conditions, the resin simply burns out, and the chimney is cleaned. Cleaning, according to stove buyers, can also be done mechanically. To do this, a special rod is used, with which you need to get into the pipe from the roof.

The length of the chimney above the surface should be approximately 3 m, so this approach is no less dangerous without the use of insurance. In winter, such manipulations should not be carried out. After reading the owner reviews about the Buleryan stove, you will choose another method for yourself - through a glass. If the smoker is thoroughly clogged, and it is impossible to clean it from above, then you can knock on the pipe. However, some of the resin will still remain in place.

The smoker is sometimes cleaned from the inside, although this option is quite complicated. From scrap materials you should make something like a folding meter with a ruff at the end. You can use an aluminum angle or pipe. The design should be quite light. The height of the pipe is decent, and if the device is heavy, then cleaning, according to the owners of Buleryan, will be quite difficult.

It is more economical and easier to use a rigid but flexible wire or cable. Its end must be rolled into a ring along the diameter of the pipe and the chimney must be cleaned through the condensate glass. According to homeowners where Buleryan is installed, this procedure has one drawback. It is expressed in the fact that a lot of dirt is formed in the process, but you have to spend no more than an hour on cleaning.

Construction of the Buleryan furnace

The oven is made of metal. Buleryan’s device includes a convector made of large-diameter pipes, a hatch for loading fuel, injection pipes and dampers.

The convector is made of metal pipes bent in the form of arcs. They are installed vertically and connected to each other at the intersection. Thus, a firebox is formed between the inner surfaces of the pipes. The air mass comes from the bottom of the convector. When heated, the air moves upward.

This is how the oven works

There is a partition inside the firebox. It is necessary to form a secondary chamber into which air enters through the injection tubes.

The products formed as a result of pyrolysis are burned in it. This design of the firebox increases the efficiency of the furnace. The hatch for loading firewood is equipped with heat-resistant glass. This makes it possible to monitor the combustion process. There is a blower at the bottom of the door.

The boiler itself can be placed in a casing. Photo source: ecoteplo.pro

It is equipped with a damper to regulate the flow of air supplied to the firebox. The tight fit of the hatch to the Buleryan body is ensured by a locking mechanism. The back of the stove is equipped with a chimney. It is necessary to remove combustion products into the atmosphere. The chimney is equipped with a damper that regulates draft.

Dimensions

The overall mass parameters of the Buleryan potbelly stove differ depending on its power. The market offers compact products for heating small spaces. More powerful models have increased dimensions and weight.

Differences from the Breneran stove

The Russian-made boiler is manufactured under license from a German company. The operating principle of Buleryan and Breneran stoves is no different. On some domestically produced models, the fuel loading hatch is made without an inspection window. The Buleryan solid fuel boiler can be equipped with a protective screen. It eliminates the risk of burns when touching the stove.

Water bullers

Buleryan water boiler

Is it possible to adapt such a really good stove for water heating? It is possible, and water buleryans are produced by industry. But, looking at this (see figure), one inevitably recalls the statement of an outstanding Soviet submarine builder about the project of a giant nuclear-powered missile submarine of the Akula type, also known as the Typhoon: “This is a vivid example of the victory of technology over common sense.”

The authors of “water bullers” forget, or ignore, based on market demands, that buleryan was originally created as an air furnace. And the heat capacity of water is 800 times greater than that of air. In order for the exhaust gases to transfer their heat to it, they need to be entangled in the labyrinth of the water heating register. But in a buleryan with its side-heated heat exchanger, this is basically impossible, otherwise you will have to create a completely different furnace.

The only way to heat water for heating with a boiler is to intensify the combustion in the firebox. But at the same time, as discussed above, the efficiency will inevitably drop.

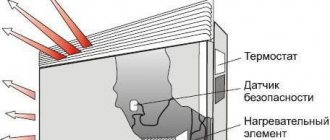

However, it is very simple to adapt any Buleryan for hot water supply. Let's say we have 2 batteries with 4 pipes each, and the whole furnace is 10 kW. As can be seen in the thermal image (see the figure on the left below), even with intensive heating for rapid heating, the air temperature in the battery nozzles is not higher than 160 degrees.

Thermal image of the Buleryan stove

Now let’s put the most ordinary metal hoses on two pipes and connect them to the pipes passing through the DHW boiler. Horizontally, vertically – it doesn’t matter. 2.5 kW will go into the water. If an 80-100 liter tank is insulated with 40-50 mm thick EPS, then in half an hour the water in it will heat up to 60-70 degrees, and then this temperature will be maintained. For comparison: 3.5-5 kW heating elements are installed in household 100-liter electric boilers.

This system is also good because without any automation, boiling of water is absolutely excluded. Let's remember the school physics problem for the especially (without quotes) gifted and savvy: how to heat water exactly to 100 degrees without letting it boil?

The answer is: take a pan and put wooden blocks in it for thermal insulation. Place another, smaller pan on them. Pour water into both pans and put on fire. The water in the outer pan will boil, but its temperature will not rise above 100 degrees, because... the heat of the fire will be used to transfer the latent heat of evaporation of water to the water.

The water in the inner pan will also heat up to 100 degrees, but there will be no temperature difference between it and the outside, and the heat required to evaporate the water will not be able to transfer to the inner pan. The water in it will heat up to exactly 100 degrees without any signs of boiling.

In the case of a “water buller”, in air with a temperature of 140 degrees there is no reserve of heat to ensure boiling of water. When its temperature approaches 100 degrees, the air in the heat exchanger will rapidly cool, the temperature gradient will approach 0, and the water will never boil.

What to look for when choosing

Before purchasing a stove, it is necessary to determine the volume of the room for heating which it will be used. It is better to purchase a product whose power exceeds the minimum required.

When choosing, there are a number of factors to consider:

- type of hatch for loading fuel. The oven door can be made in 3 options - all-metal, cast iron, with built-in glass. From an aesthetic point of view, it is better to choose a product whose hatch is equipped with an observation window. Manufacturers use heat-resistant glass. Thanks to this, the window does not collapse even with strong heat;

- type of draft control damper lever. Some manufacturers equip the damper control handle with an extension. In such models, adjustments do not require going to the back wall of the oven;

- presence of a hob. The stove can be manufactured in 2 versions - classic or with a built-in cooking surface. The Buleryan cooker does not differ in its characteristics from the classic model. If the stove will be used not only for heating the room, but also for cooking, you can choose a model with a built-in surface;

- a method of adjusting the amount of air supplied to the firebox. The blower hatch can be made of a damper or a latch located on the door body in the form of a butterfly. The choice is made based on the person’s personal preferences;

- protective screen. Some models have a casing on the side surfaces. It is used to protect against burns when touching Buleryan. If the stove will be used in a residential area, it is better to choose a model with a protective screen.

Installation of the Buleryan stove

The oven is mobile. Installation and dismantling of the product is not difficult. Installation does not require specialized education.

A person with minimal technical knowledge can perform the work.

Indoor boiler connection diagram. Radiator connection. Photo source: svoimi-rykami.ru

Fire safety standards for installation

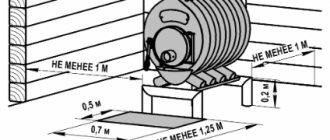

Buleryan is a furnace, some surfaces of which can heat up to high temperatures. This should be taken into account and fire safety standards must be observed during installation.

The stove is installed:

- on a non-combustible base. If the floor in a room is susceptible to fire when exposed to high temperatures, it is necessary to arrange a specialized area on which the product will be installed;

- distance to walls. Before installing Buleryan, you need to choose the right installation location. The stove heats the room by heating air masses. When choosing a location, you need to take into account the distance from the stove surfaces to the walls.

This parameter depends on the material from which the vertical surfaces are made. For wooden, unplastered walls, a minimum distance of 1 m is required. for concrete surfaces this figure is reduced.

Is a foundation needed for Buleryan

The location and method of installing the boiler differs depending on the preferences of the owner of the room and the materials from which the surfaces are made.

At the installation site, it is necessary to equip a specialized platform made of non-combustible material. Typically, a sheet of metal is used or a foundation is fabricated.

Some experts mount the stove on a stand made of a profile pipe.

The foundation is made with a height of 10–30 cm. The material for arranging the site can be brick, cinder block, concrete, etc.

Furnace installation option. Photo source: willow-bag.ru

The overall dimensions of the foundation must exceed the dimensions of the boiler. The protrusion located under the fuel loading hatch should protect the floor covering from sparks and heat.

Possible mistakes

When installing the Buleryan stove with your own hands, it is important to maintain all the necessary distances to vertical surfaces. This will ensure fire safety and free access to the boiler for maintenance.

Operating principle

General operating principle of the furnace:

- a manifold is placed on the convection pipes to connect the return and supply;

- during heating, pressure is created, the liquid can rise to a height of up to eight meters without using a pump;

- when pressure is created, the coolant flows to the radiators of individual rooms (a slight slope of the pipes is used for natural circulation);

- From the radiators, cooled water flows to the boiler for heating.

The principle of operation of a buleryan with a water circuit

Kindling technology

To use the stove, no specialized knowledge or skills are required. The boiler is easy to heat and maintain.

You can melt Buleryan as follows:

- Fuel is loaded into the firebox. First, firewood of small thickness is used. The fuel should be dry, this will minimize the amount of condensation that forms and allow the fire to start quickly.

- The wood is set on fire. The dampers that regulate the draft and the amount of air supplied are fully open.

- After hot coals have formed in the firebox, thicker firewood is loaded through the door. The dampers are installed in the desired position to ensure long-lasting combustion.

After all the above steps, Buleryan will work as normal. The frequency of laying firewood depends on the intensity of fuel combustion.

Operating rules for Buleryan

• Perform ignition only after checking the draft and opening the dampers.

• The ash is removed from the cooled furnace. It is recommended to leave a 5 cm layer in the combustion chamber to facilitate the next ignition.

• Periodically clean the chimney of ash through the tee.

• Use the regulator to set the combustion mode.

• Fuel is added only when the smoke damper is open.

• If there is no traction, set fire to the paper in the firebox.

• In case of any malfunction, call a stove technician to repair the breakdown.

How to make a Buleryan stove yourself

Some experts make the boiler with their own hands. This will require certain tools and equipment.

A drawing according to which you can make a boiler with your own hands. Photo source: ogodom.ru

First of all, a drawing is made according to which the furnace will be assembled. All details are made in strict accordance with the drawing. Metal parts are connected to each other using electric or gas welding. If the assembly rules are followed, it will be possible to produce a stove whose performance is not inferior to the original model.

Making a chimney

The smoke exhaust channel is made of a large diameter steel pipe. A specialized outlet is installed in close proximity to the stove. It is necessary to collect and drain condensate from the chimney. The chimney can be removed from the room either through the roof or through the wall. To avoid fire, an insert made of non-combustible material must be made where the pipe passes through the surfaces of the building. The Buleryan stove is highly efficient and easy to operate. It quickly warms up the room and saves fuel. You can choose either a finished product or make a boiler yourself.

Reviews about installation features

The Buleryan 100 stove, reviews of which you could read above, according to consumers, should be installed at some distance from flammable objects and materials. The distance should be 1 m. If the surfaces are covered with plaster, then this parameter can be reduced to 75 cm.

“Buleryan” is usually installed on a pedestal, which acts as decoration and serves as a functional element. Inside, consumers advise making a niche for firewood. Usually the base is made of piles.